High-weather-proof bulk molding compound

A technology of bulk molding compound and high weather resistance, which is applied in the field of materials and can solve problems such as cracking, brittleness, and easy yellowing, and achieve high weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

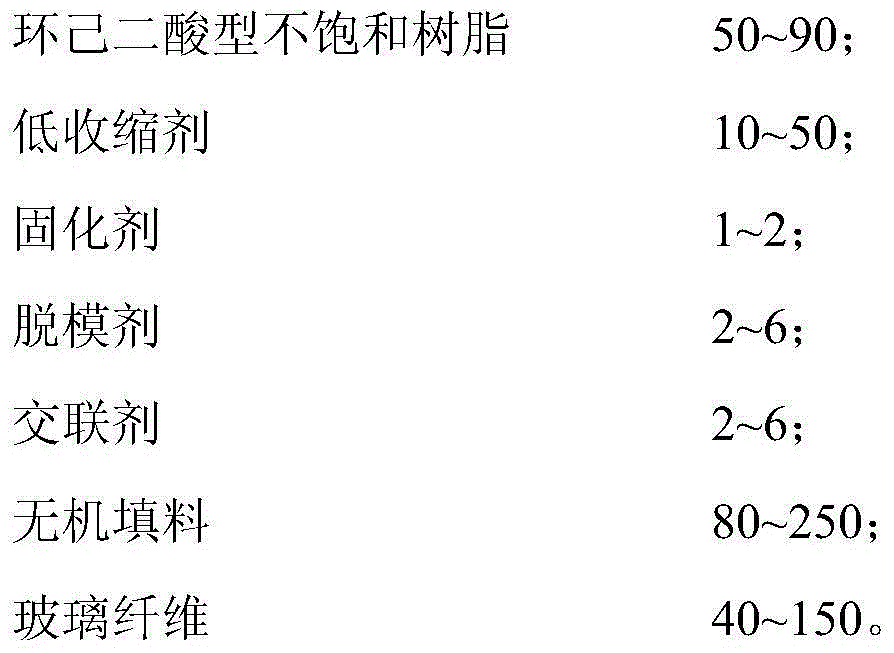

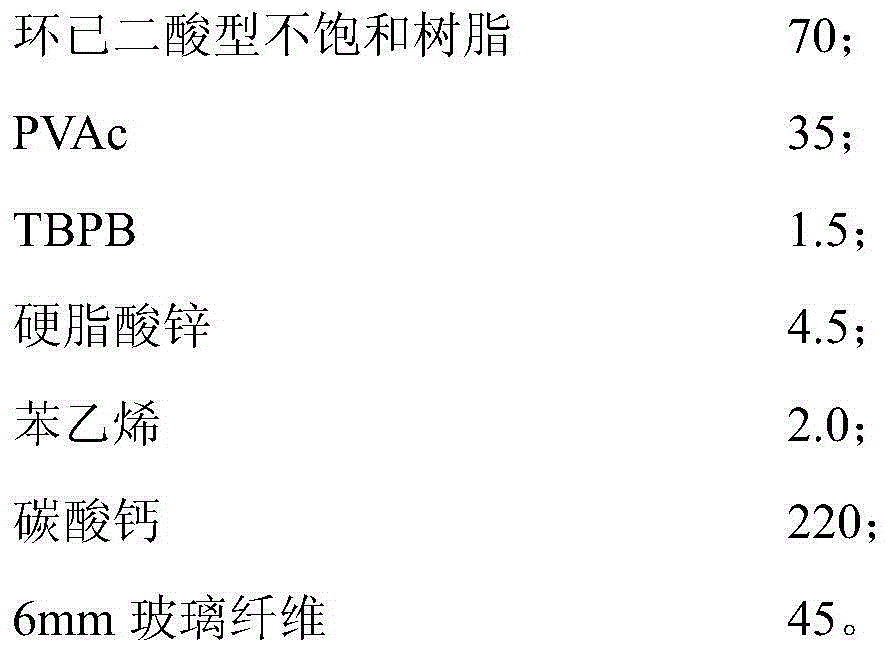

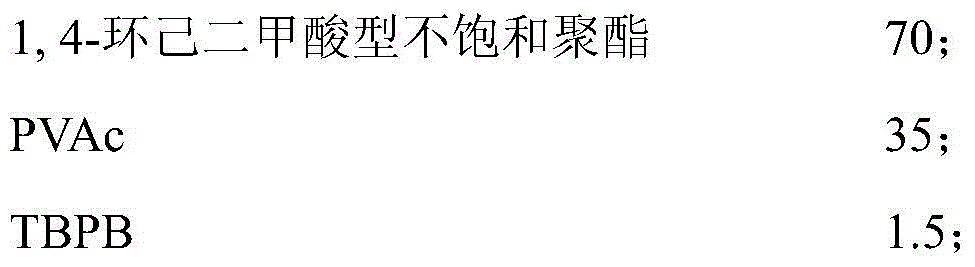

[0020] A high-weather-resistant bulk molding compound (BMC), which is obtained by polymerization of the following raw materials in parts by weight, wherein:

[0021]

[0022]

[0023] The preparation steps are as follows:

[0024] 1. Preparation of resin paste:

[0025] Pour 1,4-cyclohexanedicarboxylic acid-type unsaturated polyester and PVAc into stainless steel containers respectively, turn on the high-speed disperser and set the speed to 1200 rpm, and stir for 2 minutes; add TBPB, at 1200 rpm Speed to medium for 8 minutes.

[0026] 2. Kneading:

[0027] Add calcium carbonate and zinc stearate into the kneader, close the kneader cover, beat the kneading rollers at a fast speed, knead for 5 minutes, pour the resin paste mixed in step 2, knead for 6 minutes at a fast speed, and then add Glass fiber, kneader speed to slow, kneading for 9 minutes. Just pack it out.

[0028] 3. Press standard mechanical property test strips. Use the ultraviolet weathering accelerate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com