Preparation methods of castor oil base carboxylate radical intercalated hydrotalcite for PVC (Polyvinyl Chloride) and compound heat stabilizer thereof

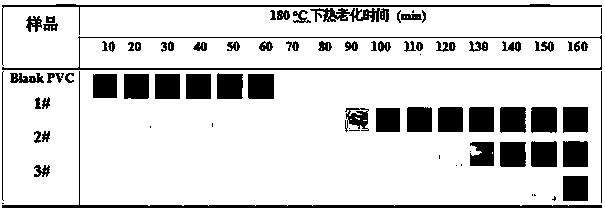

A composite heat stabilizer and oleyl carboxylic acid technology, which is applied in the field of preparation and application of plastic additives, can solve problems such as unsatisfactory initial effect, slow absorption of HCl, complex synthesis process, etc., and achieve excellent thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

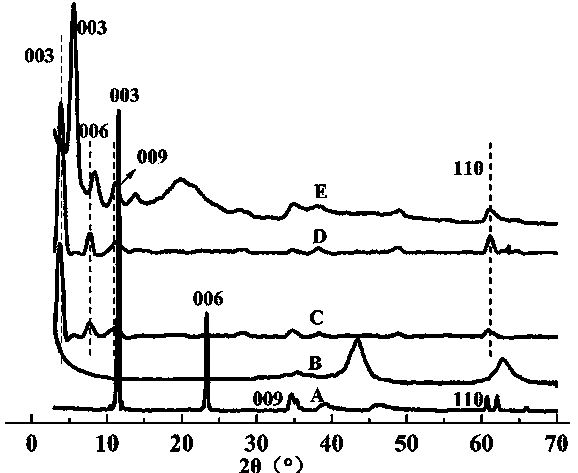

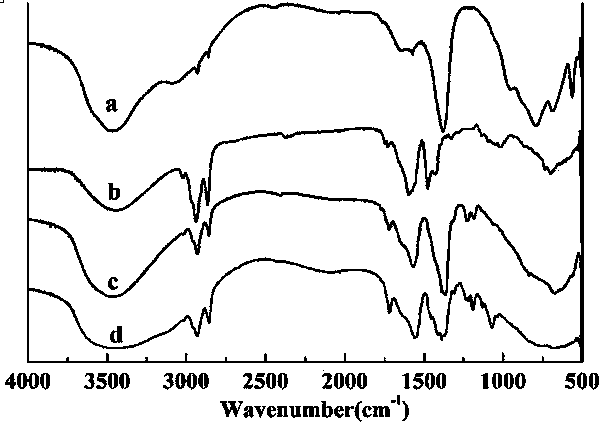

[0026] Preparation of Ricinoleic Acid Intercalated Hydrotalcite

[0027] (1) To 7.71g of ricinoleic acid, add 100mL to remove CO 2 deionized water, adjust the pH of the solution with dilute nitric acid to make the solution pH=4~6.

[0028] (2) The ordinary hydrotalcite is calcined, the calcining temperature is 450°C, the heating rate is 4°C / min, and the calcining time is 5h.

[0029] (3) Add 3.95g of calcined hydrotalcite to the above-mentioned ricinoleic acid solution, control the reaction temperature to 135°C, and the reaction time to 6h. After the reaction product is filtered, washed and dried, ricinoleic acid radical intercalation water is obtained. Talc, recorded as LDHs-RA.

Embodiment 2

[0031] Preparation of ricinoleyl maleate carboxylate intercalated hydrotalcite

[0032] (1) Add 68.62g of ricinoleic acid and 21.58g of maleic anhydride into a 250mL three-necked flask with a condenser and stir well. Raise the temperature to 90°C and react for 3.5 hours to obtain ricinoleyl maleate, which is denoted as RAM.

[0033] (2) To 4.51g of RAM, add 100mL to remove CO 2 deionized water, adjust the pH of the solution with dilute nitric acid to make the solution pH=4~6.

[0034] (3) The ordinary hydrotalcite is calcined, the calcining temperature is 450°C, the heating rate is 4°C / min, and the calcining time is 5h.

[0035] (4) Add 7.89g of calcined hydrotalcite to the above castoroleyl maleate solution, control the reaction temperature to 135°C, and the reaction time to 7h. The reaction product is filtered, washed and dried to obtain maleic acid Acid ricinoleyl carboxylate intercalated hydrotalcite, denoted as LDHs-RAM.

Embodiment 3

[0037] Preparation of Ricinol Hexahydrophthalate Carboxylate Intercalated Hydrotalcite

[0038] (1) Add 68.62g of ricinoleic acid and 33.92g of hexahydrophthalic anhydride into a 250mL three-necked flask with a condenser and stir well. Raise the temperature to 100°C and react for 3.5 hours to obtain ricinoleol hexahydrophthalate, which is denoted as RAH.

[0039] (2) To 3.47g of RAH, add 100mL to remove CO 2 deionized water, adjust the pH of the solution with dilute nitric acid to make the solution pH=4~6.

[0040] (3) The ordinary hydrotalcite is calcined, the calcining temperature is 450°C, the heating rate is 4°C / min, and the calcining time is 5h.

[0041] (4) Add 5.26g of calcined hydrotalcite to the above castoroleyl hexahydrophthalate solution, control the reaction temperature to 135°C, and the reaction time to 7h. The reaction product is filtered, washed and dried. The hydrotalcite intercalated with ricinoleyl hexahydrophthalate carboxylate is obtained, which is deno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com