Process for producing epoxidation hexahydrophthalic acid di-octyl

A technology of dioctyl dicarboxylate and epoxidized cyclohexane, which is applied in the production process of epoxidized cyclohexane dioctyl phthalate, and can solve the problems of long reaction cycle, high production cost, and large amount of waste water. , to achieve the effects of short production cycle, reduced production cost, and less wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

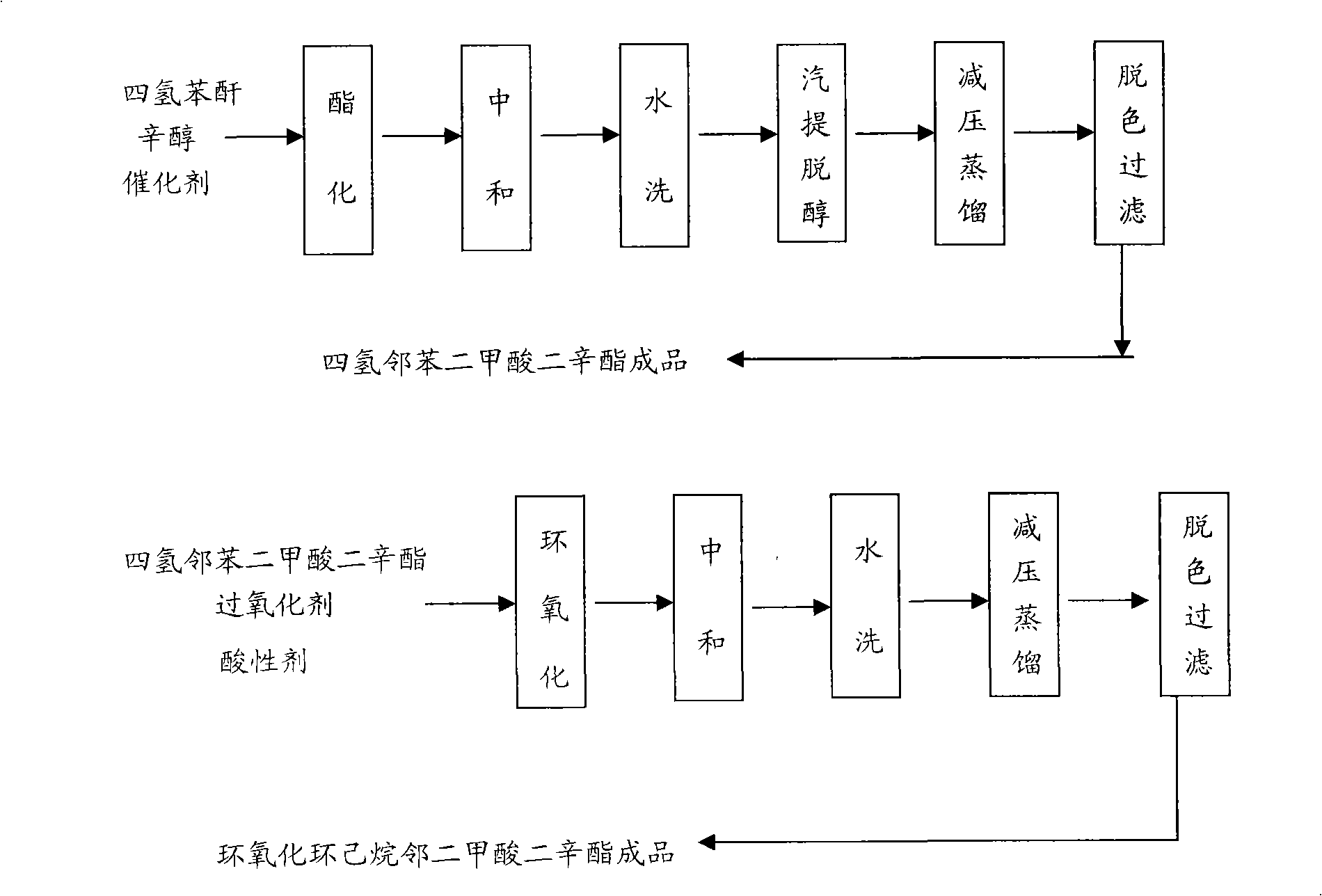

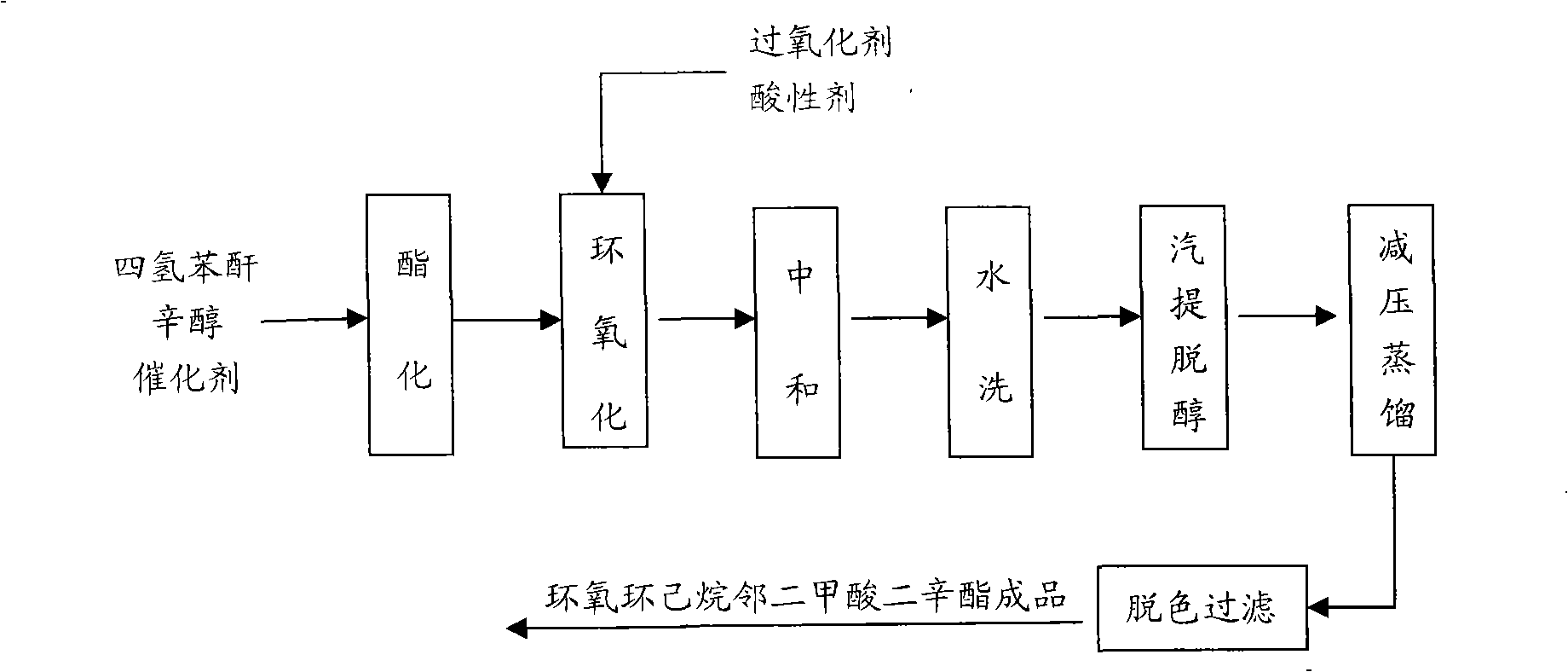

Method used

Image

Examples

Embodiment 1

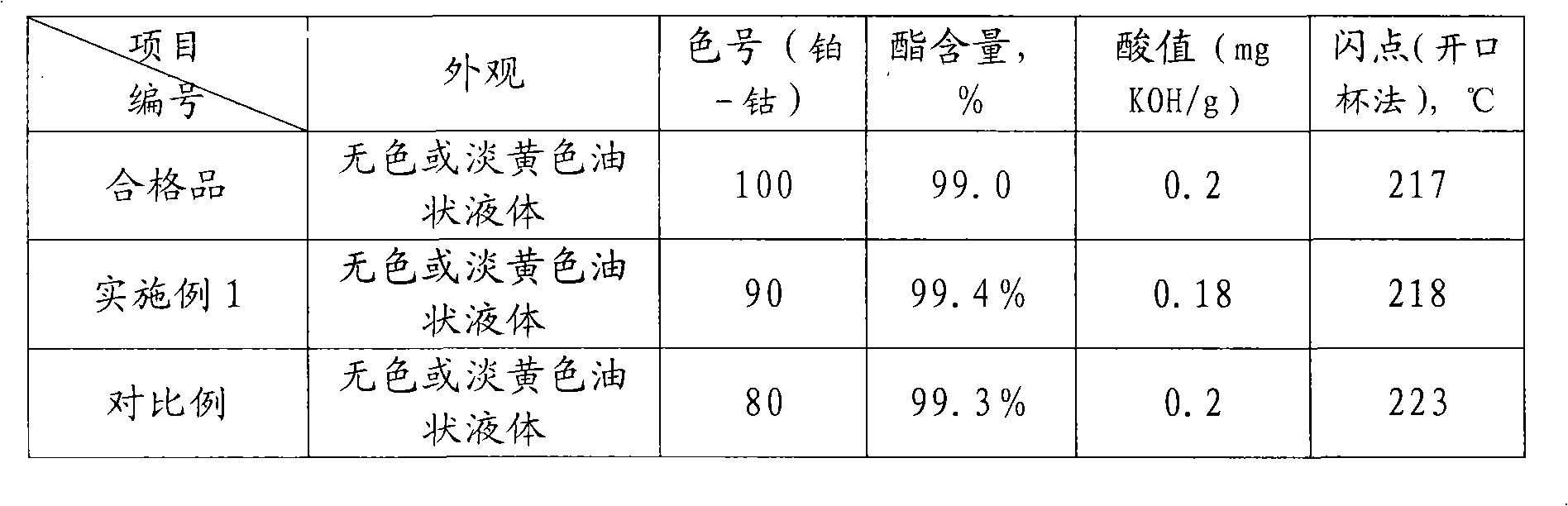

[0016] at 10m 3 Add 4143kg of tetrahydrophthalic anhydride, 7857kg of octanol and 124.29Kg of 20% sulfuric acid solution in the esterification reaction kettle, and reflux at 120-140°C for about 2 hours under a vacuum pressure of 0.075-0.095Mpa to measure the acid value of the crude product End esterification when it is below 2.5mgKOH / g; add 584kg of 30% hydrogen peroxide, 387kg of formic acid, 10Kg of 20% sulfuric acid solution, react at 75-85°C for 3.5h, then neutralize and wash with water, strip alcohol, vacuum distillation, decolorization and filtration to obtain the finished product of epoxidized cyclohexane dioctyl phthalate, and the product performance index is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com