Secondary amine chain extension cross-linking agent and polyurethane elastic material

A technology of polyurethane elasticity and cross-linking agent, which is applied in the field of chain extension cross-linking agent and polyurethane, can solve the problems of decreased product strength and hardness, decreased intermolecular hydrogen bonding force, and extended operating window, etc. The effect of improving water resistance and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

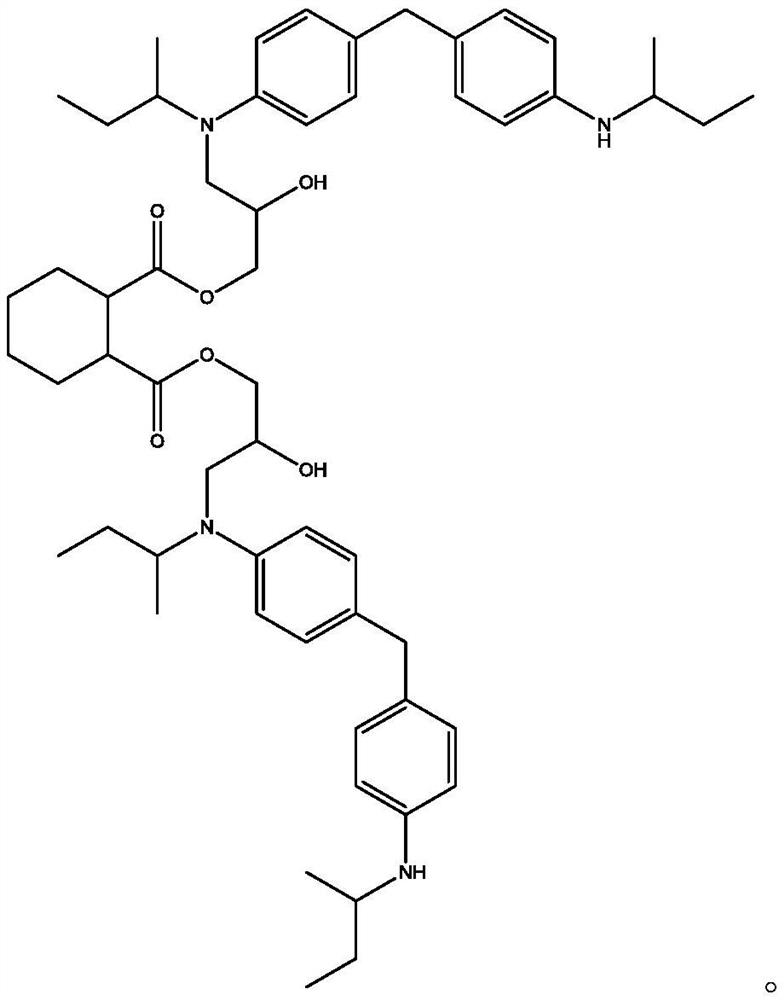

[0039] Embodiment 1 Preparation of chain extension crosslinking agent A

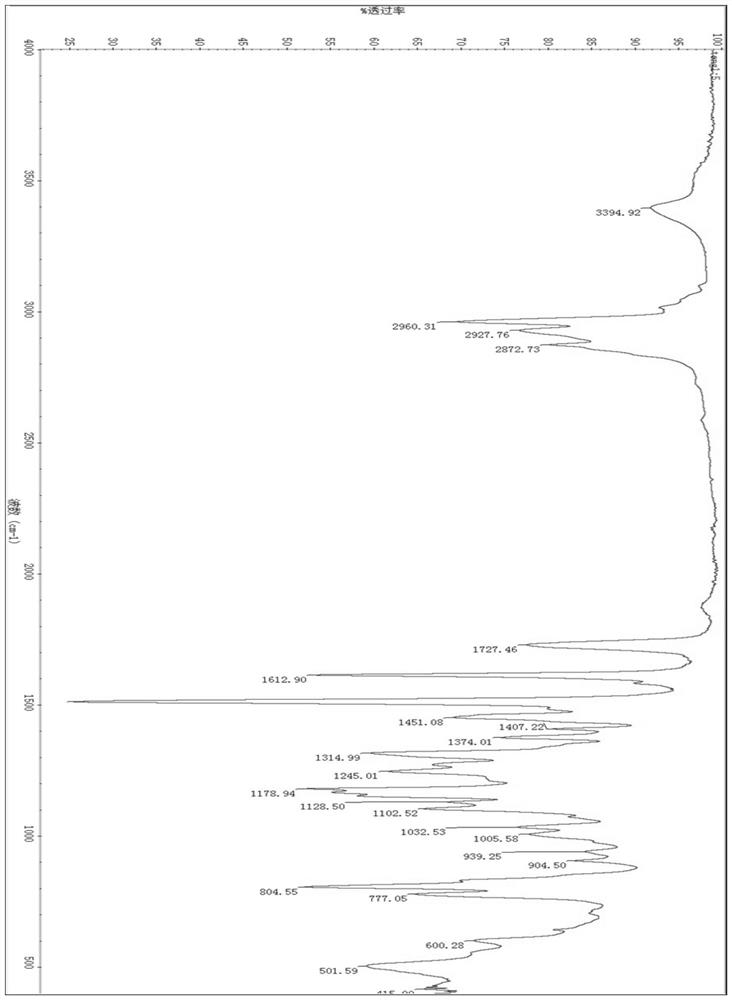

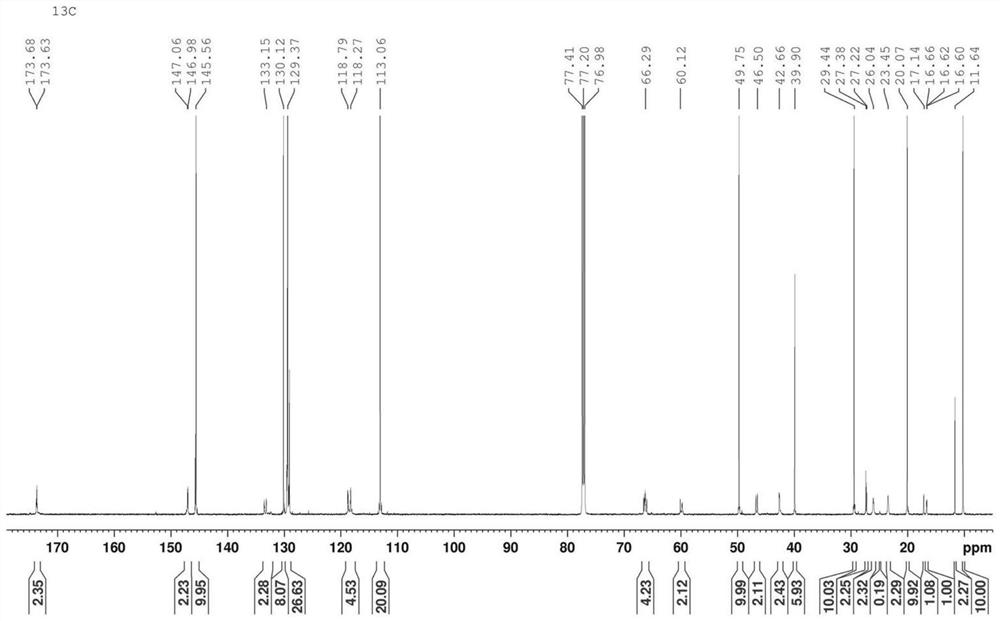

[0040] Add 150g of 4,4'-bis-sec-butylaminodiphenylmethane (Wanhua Chemical) and 30g of diglycidyl hexahydrophthalate (Yantai Donghua New Material) into a three-necked flask, heat to 80°C, After 30 minutes, 0.010 g of boron trifluoride monoethylamine (Aladdin's reagent) was added and reacted for 6 hours to obtain chain extension crosslinker A. Nitrogen protection was carried out during the reaction. Use NicoletiS5 Fourier Transform Infrared Spectrometer (U.S. Thermo fisher brand) to test the above product, and the infrared spectrogram is shown in figure 1 , through infrared spectrogram analysis, it can be seen that the epoxy group in the raw material has reacted completely, and the target group hydroxyl is formed. Adopt Bruker AVANCEⅢ400Hz nuclear magnetic resonance spectrometer to carry out carbon spectrum analysis to product, solvent is CDCl3, the result is as follows figure 2 shown.

Embodiment 2

[0041] Example 2 Preparation of chain extension cross-linking agent B

[0042] Add 160g of 4,4'-bis-sec-butylaminodiphenylmethane (Wanhua Chemical) and 25g of diglycidyl hexahydrophthalate (Yantai Donghua New Materials) into a three-necked flask, heat to 70°C, After 30 minutes, 0.015 g of boron trifluoride monoethylamine (Aladdin's reagent) was added and reacted for 5 hours to obtain chain extension cross-linking agent B. Nitrogen protection was carried out during the reaction.

Embodiment 3、4 and comparative example 1、2

[0043] Embodiment 3,4 and comparative example 1,2 TDI system polyurethane elastic material preparation

[0044] The formula of isocyanate prepolymer component (Group A) is as follows in Table 1:

[0045] Table 1 isocyanate prepolymer component formula

[0046] raw material Grade / Name parts by weight Polyether polyol C2020 60 Polyether polyol F3056D 20 plasticizer ATBC 15 polyisocyanate TDI-80 15 Total 110

[0047] Add polyether polyols C2020 and F3056D into the flask according to the formula in Table 2, vacuum dehydrate at 105°C for 2 hours, cool down to 70°C, add TDI-80, heat up to 90°C and react for 5 hours, add ATBC, cool down to 50°C and discharge to obtain Isocyanate prepolymer component.

[0048] The formula of the combined material components (group B) is shown in Table 2:

[0049] Table 2 Combination material composition formula

[0050]

[0051] Mix the raw materials according to the formula in Table 2, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com