Glass fiber

A glass fiber, total mass technology, applied in the field of glass fiber, can solve the problems of inability to meet the high modulus field, high crystallization temperature, and difficulty in fiber forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Select the raw material of glass fiber according to the ratio of each component shown in Table 1, transport the weighed raw material to the mixing tank, and transport the raw material to the pool kiln silo after being mixed uniformly in the mixing tank;

[0067] Then put the mixed material in the tank kiln into the tank kiln, melt the mixed material in the tank kiln at 1450~1600°C to obtain molten glass; clarify and homogenize the obtained molten glass to obtain stable and high The high-quality molten glass is transported to the wire drawing operation channel;

[0068] After the glass liquid in the wire drawing operation channel is cooled to 1330°C, it flows out through the platinum bushing, and is quickly drawn by the wire drawing machine to form glass filaments with a diameter of 3 μm to 25 μm;

[0069] The obtained glass filaments are subjected to spray cooling and sizing agent coating to obtain glass filament fibers.

[0070] In the present invention, the obtained ...

Embodiment 2~9

[0072] According to the preparation process described in Example 1, the raw materials of each example listed in Table 1 were prepared to obtain glass fibers. The difference is that in Examples 2 to 9, the cooling temperature of the molten glass in the working channel is controlled according to their respective molding temperatures.

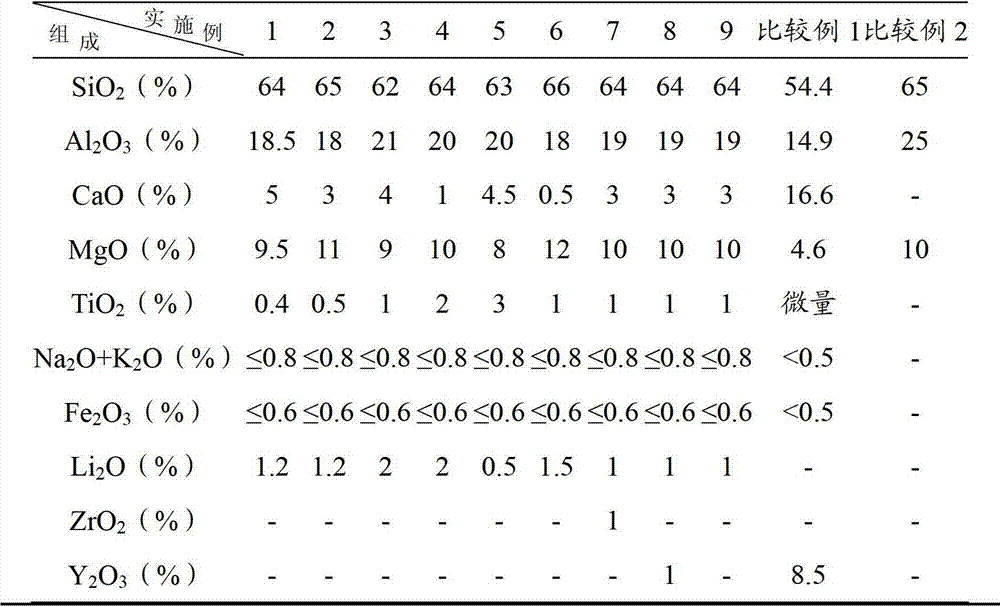

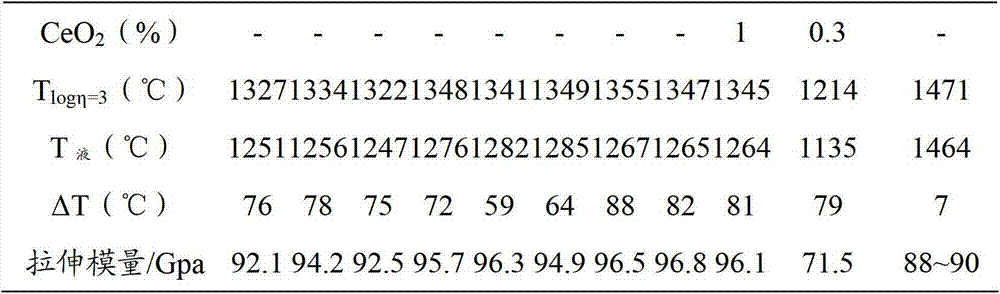

[0073] In the present invention, the obtained glass fibers are tested for performance, and the results are shown in Table 1. Table 1 shows the composition of the raw materials in the examples and comparative examples of the present invention and the performance test results of the obtained glass fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com