Modified red mud and its preparation method and application

A red mud modification technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of small adsorption capacity and large amount of adsorbent dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

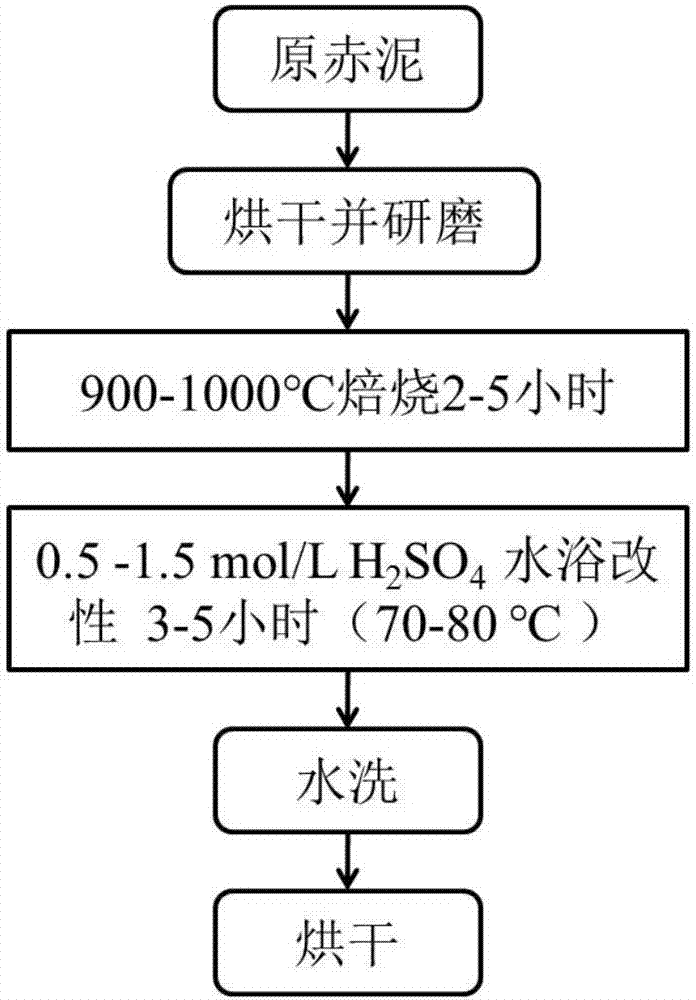

[0027] The invention provides a method for preparing modified red mud, comprising the following steps:

[0028] Roasting the waste residue red mud to obtain a roasted product;

[0029] The roasted product is acid-leached with sulfuric acid to obtain modified red mud.

[0030] The invention roasts the waste residue red mud to obtain a roasted product. The present invention does not have any special limitation on the source of the waste residue red mud, and the source of the waste residue red mud well-known to those skilled in the art can be used, specifically, the alkaline waste residue red mud produced by the aluminum smelting industry. In the present invention, the waste residue red mud is preferably crushed, and the particle size of the waste residue red mud after crushing is preferably 50-80 mesh, more preferably 60-70 mesh.

[0031] In the present invention, the calcination temperature is preferably 900-1000°C, more preferably 920-950°C; the calcination time is preferabl...

Embodiment 1

[0047] Weigh 10 g of alkaline waste residue red mud produced in the aluminum smelting industry and break it into 60 meshes, and roast it at 900°C for 5 hours to obtain a roasted product, and then use 0.5mol / L sulfuric acid in a water bath and stir the roasted product at 70°C acid leaching for 5 hours, wherein the liquid-solid ratio of roasted product to sulfuric acid was 10:1, and then centrifuged, washed and dried to obtain modified red mud.

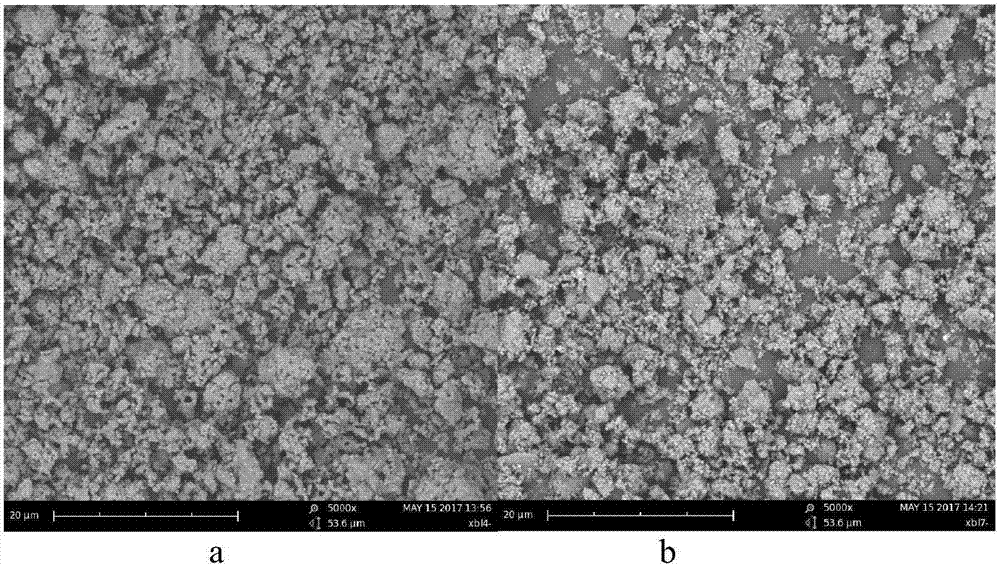

[0048] Scanning electron microscope analysis was carried out on the waste residue red mud before and after roasting, and the results were as follows: figure 2 As shown, where a is the scanning electron microscope spectrum of waste residue red mud after roasting, and b is the scanning electron microscope spectrum of waste residue red mud before roasting. figure 2 It can be seen that the surface of the roasted waste red mud presents a porous state.

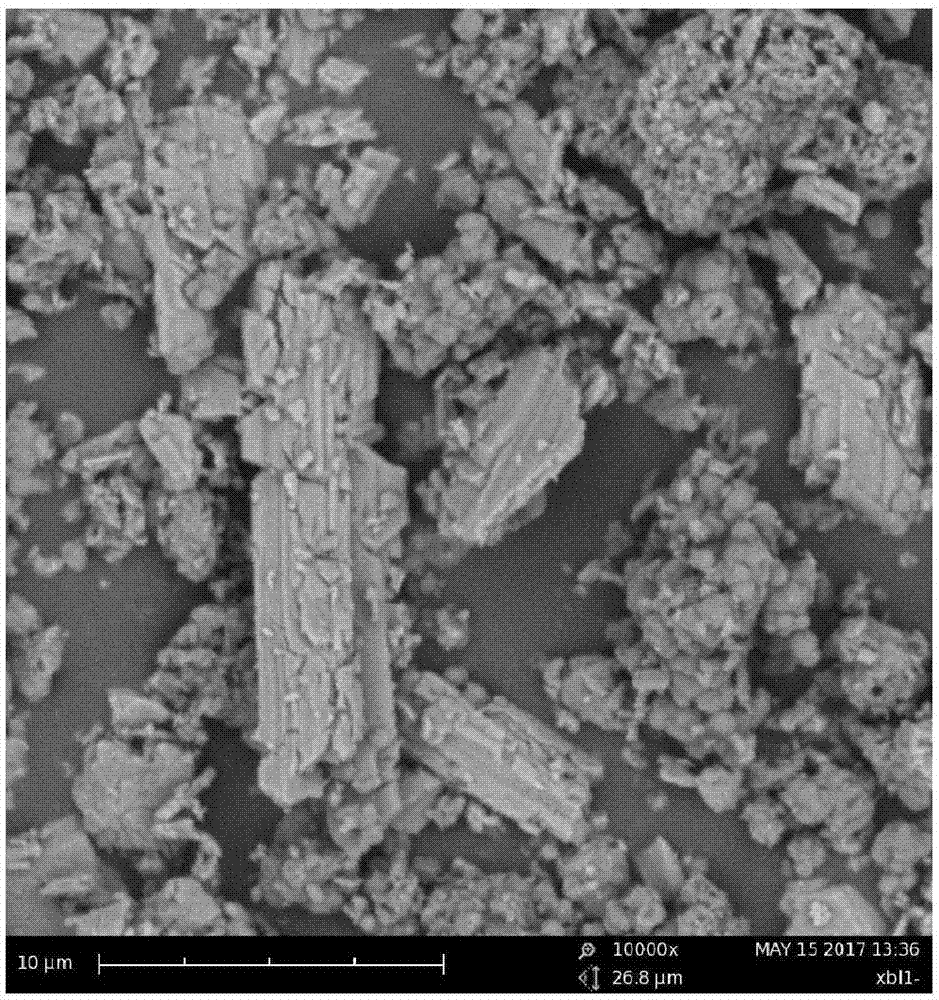

[0049] Scanning electron microscope analysis was carried out to the product after acid...

Embodiment 2

[0056] Weigh 10 g of alkaline waste red mud produced in the aluminum smelting industry and break it into 100 meshes, and roast it at 1000°C for 2 hours to obtain a roasted product, and then use 0.5mol / L sulfuric acid in a water bath under stirring conditions to heat the roasted product at 80°C Under acid leaching for 3 hours, the liquid-solid ratio of roasted product to sulfuric acid is 10:1, and then centrifuged, washed and dried to obtain modified red mud.

[0057] The modified red mud prepared in Example 2 is used to adsorb arsenic and fluorine of different concentrations in the water body, the amount of modified red mud=5g / L, the results are as follows Figure 6 shown by Figure 6 It can be seen that the removal rate of arsenic and fluorine at different initial concentrations can reach more than 99%. When treating drinking water with low concentration of arsenic and fluorine (arsenic concentration <5mg / L, fluorine concentration <30mg / L), the water quality after adsorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com