Method for preparing calcium sulfate crystal whiskers by using natural gypsum

A technology of calcium sulfate whisker and natural gypsum, applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc., can solve the problem that raw materials cannot be fully utilized, environmental pollution, and poor quality of calcium sulfate whiskers and other problems, to achieve the effect of strengthening the promotion and application value, reducing production costs, and making the production process clean and environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

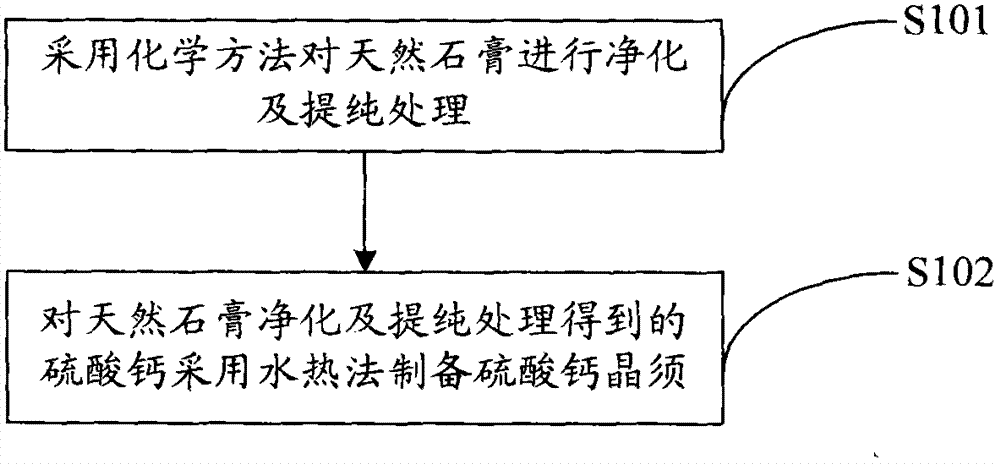

Method used

Image

Examples

example 1

[0026]Example 1: Rinse 86g of natural gypsum to remove some impurities, then add it to the reactor, add 130ml of circulating solution or water, start stirring and heat to 45°C, add 40g of ammonium bicarbonate and 35ml of ammonia water in batches, and stir for 60min After vacuum filtration, ammonium sulfate solution and crude calcium carbonate were obtained. Take 64g of calcium carbonate crude product, add 300ml of 2.5mol / L hydrochloric acid solution, stir and react at 20-30°C for 20-30min, recover the CO produced by the reaction 2 After the reaction is completed, filter to remove impurities to obtain a calcium chloride solution; mix and react the obtained ammonium sulfate and calcium chloride solution at a molar ratio of 1:1 at room temperature according to their concentrations, and separate by filtration to obtain calcium sulfate precipitate and chloride Ammonium solution: take 5g of purified calcium sulfate, add 95g of water, stir evenly, adjust the pH to 9-10, place it in a...

example 2

[0027] Example 2: Rinse 1000g of natural gypsum to remove some impurities, then add it to the reaction kettle, add 2000ml of circulating solution or water, start stirring and heat to 55°C, add 610g of ammonium bicarbonate and 550ml of ammonia water in batches, and stir for 1 hour , the temperature was raised to 60° C. and the stirring reaction was continued for 1 h. After the reaction was completed, vacuum filtration was performed to obtain ammonium sulfate solution and crude calcium carbonate. Take 110g of crude calcium carbonate, add 540ml of 2.5mol / L hydrochloric acid solution, stir and react at 20-30°C for 20-30min, recover the CO produced by the reaction 2 Gas, after the reaction is completed, filter to remove impurities to obtain a calcium chloride solution. The obtained ammonium sulfate and calcium chloride solution are mixed and reacted at room temperature according to the molar ratio of 1:1 according to their concentrations, and separated by filtration to obtain calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com