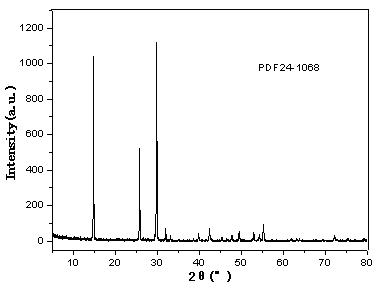

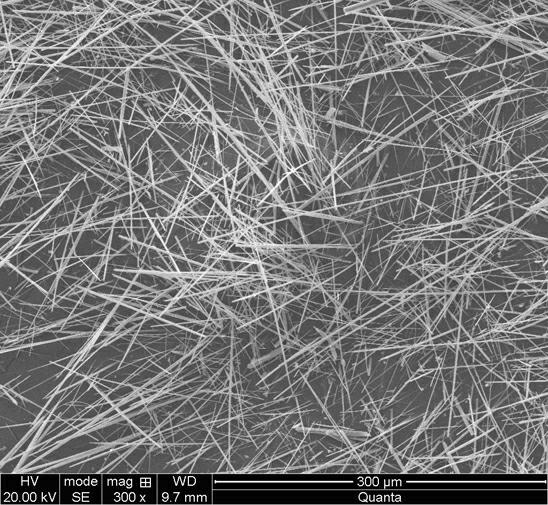

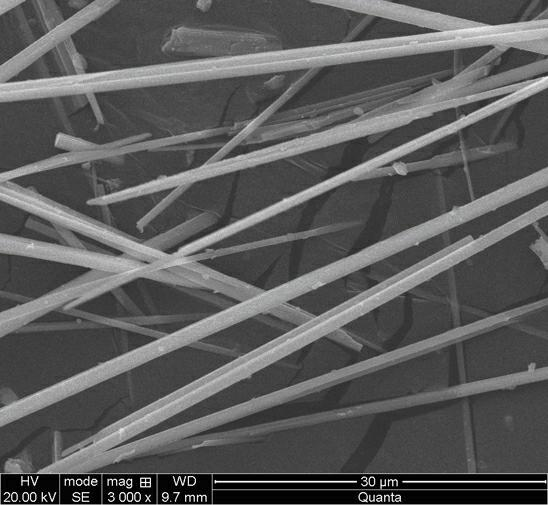

Process for preparing calcium sulfate crystal whisker by desulfurized gypsum as well as calcium sulfate crystal whisker

A technology of calcium sulfate whisker and desulfurization gypsum, applied in the direction of calcium/strontium/barium sulfate, single crystal growth, crystal growth, etc. High cost, affecting the quality and application of whiskers, etc., to achieve high social value and significance, good crystallization, and high cost solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of technique of preparing calcium sulfate whisker by desulfurization gypsum, its preparation technique comprises the steps:

[0032] Step 1, taking material: manual selection of desulfurized gypsum;

[0033] Step 2, ball milling: send the desulfurized gypsum selected in step 1 into a high-energy ball mill for ball milling, the medium of the ball mill is distilled water, control the mass ratio of desulfurized gypsum, balls, and water to 1:2:1, and the ball milling speed is 300r / min, Ball milling time 150min;

[0034] Step 3, preparing slurry: adjust the mass concentration of the slurry after ball milling in step 2 to 5% with water, adjust the pH value to 2, and then move it into the reaction kettle;

[0035] Step 4, add crystallization agent: directly add cupric chloride crystallization agent in the slurry in the reactor in step 3, the quality that adds is 1% of dry base desulfurization gypsum quality;

[0036] Step 5, hydrothermal reaction: heat the slurry in t...

Embodiment 2

[0049] A kind of technique of preparing calcium sulfate whisker by desulfurization gypsum, its preparation technique comprises the steps:

[0050]Step 1, taking material: manual selection of desulfurized gypsum;

[0051] Step 2, ball milling: send the desulfurized gypsum selected in step 1 into a high-energy ball mill for ball milling, the medium of the ball mill is distilled water, control the mass ratio of desulfurized gypsum, balls, and water to 1:2:1, and the ball milling speed is 200r / min, Ball milling time 300min;

[0052] Step 3, prepare slurry: adjust the mass concentration of the slurry after ball milling in step 2 to 3% with water, adjust the pH value to 3, and then move it into the reaction kettle;

[0053] Step 4, add crystallization agent: directly add cupric chloride crystallization agent in the slurry in the reactor in step 3, the quality that adds is 2% of dry base desulfurization gypsum quality;

[0054] Step 5, hydrothermal reaction: heat the slurry in the ...

Embodiment 3

[0067] A kind of technique of preparing calcium sulfate whisker by desulfurization gypsum, its preparation technique comprises the steps:

[0068] Step 1, taking material: manual selection of desulfurized gypsum;

[0069] Step 2, ball milling: Send the desulfurized gypsum selected in step 1 into a high-energy ball mill for ball milling, the medium of the ball mill is distilled water, control the mass ratio of desulfurized gypsum, balls, and water to 1:2:1, and the ball milling speed is 400r / min, Ball milling time 100min;

[0070] Step 3, prepare slurry: adjust the mass concentration of the slurry after ball milling in step 2 to 8% with water, adjust the pH value to 4, and then move it into the reaction kettle;

[0071] Step 4, add crystallization agent: directly add cupric chloride crystallization agent in the slurry in the reaction kettle in step 3, the quality that adds is 4% of dry base desulfurization gypsum quality;

[0072] Step 5, hydrothermal reaction: heat the slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com