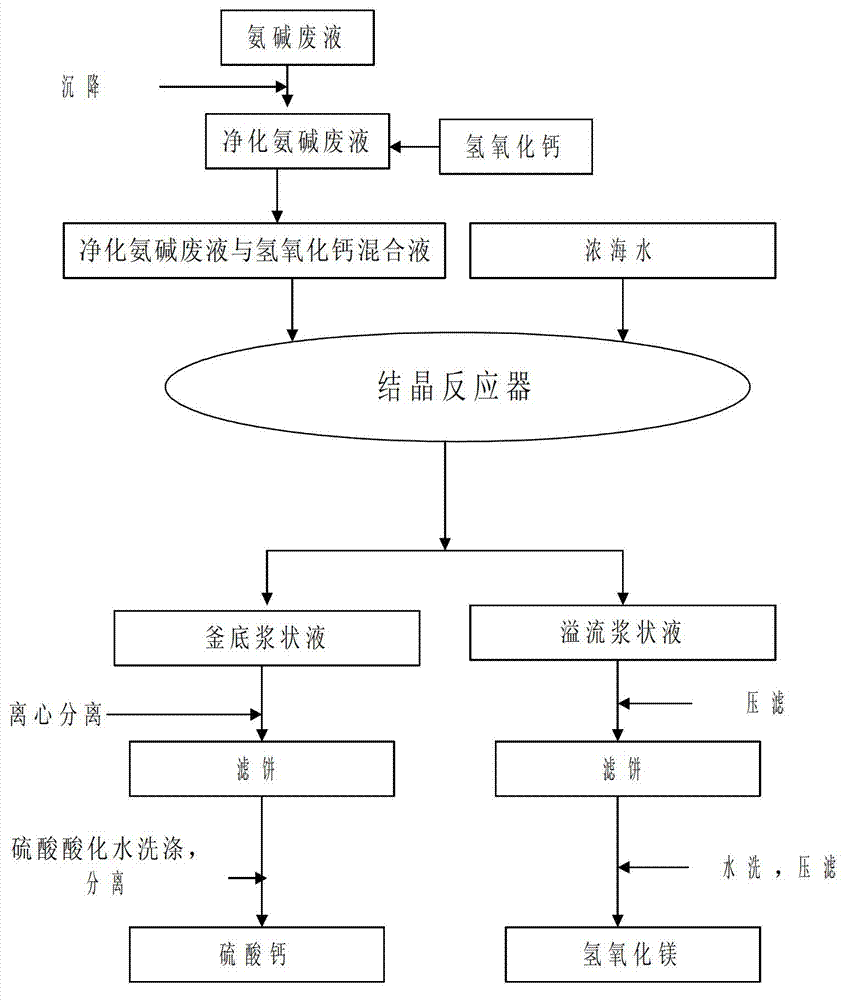

Method for co-producing calcium sulphate and magnesium hydrate by ammonia alkali waste liquid and concentrated seawater

A technology of magnesium hydroxide and concentrated seawater, applied in the direction of magnesium hydroxide, calcium/strontium/barium sulfate, etc., can solve problems such as salt pans occupying a large area, achieve comprehensive utilization, inhibit spontaneous nucleation, and high separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take ammonia-alkali waste liquid, place it in a settler for sedimentation, and purify and remove insoluble matter. Pump the supernatant of the settler into the filter for filtration, and analyze the composition of the filtrate: Ca 2+ 0.90mol / L, Na + 0.79mol / L, Cl - 2.59mol / L. Weigh 347g of calcium hydroxide, dissolve it in 8L of purified ammonia-alkali waste liquid, and stir to form a mixed solution. Take 24L concentrated seawater and analyze the composition of concentrated seawater: SO 4 2- 0.094mol / L, Ca 2+ 0.033mol / L, Mg 2+ 0.19mol / L, Cl - 1.68mol / L, K + 0.036mol / L, Na + 2.13mol / L.

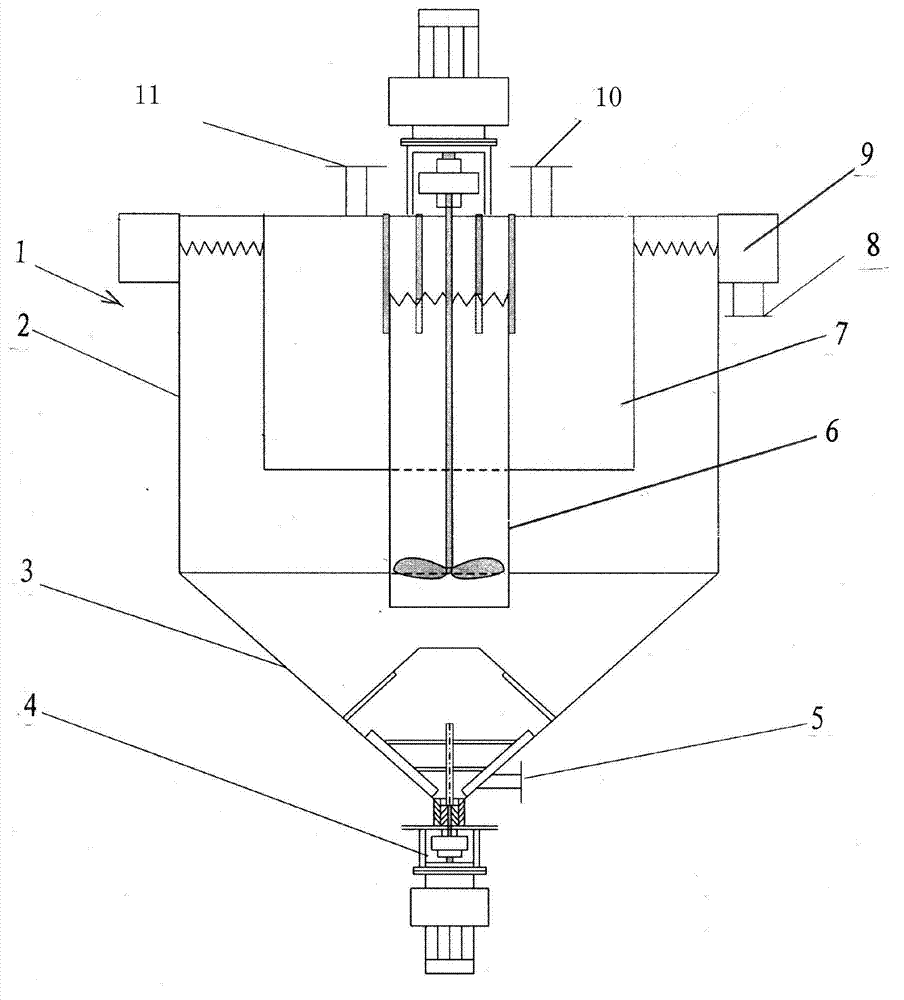

[0032] The above-mentioned mixed solution of purified ammonia-alkali waste liquid dissolved in calcium hydroxide and concentrated seawater are continuously added to the crystallization reactor at the same time from the mixed liquid inlet 10 and the concentrated seawater inlet 11 respectively, and the mixed solution of the purified ammonia-alkali waste liquid dissolved in calciu...

Embodiment 2

[0036] Take ammonia-alkali waste liquid, first place it in a settler to settle, and remove insoluble matter. Pump the supernatant of the settler into the filter for filtration, and analyze the composition of the filtrate: Ca 2+ 0.90mol / L, Na + 0.79mol / L, Cl - 2.59mol / L. Weigh 520 g of calcium hydroxide, dissolve it in 6 L of purified ammonia alkali waste liquid, and stir to form a mixed liquid. Take 24L concentrated seawater and analyze the composition of concentrated seawater: SO 4 2- 0.094mol / L, Ca 2+ 0.033mol / L, Mg2+ 0.19mol / L, Cl - 1.68mol / L, K + 0.036mol / L, Na + 2.13mol / L.

[0037] The above-mentioned mixed solution of purified ammonia-alkali waste liquid dissolved in calcium hydroxide and concentrated seawater are continuously added to the crystallization reactor at the same time from the mixed liquid inlet 10 and the concentrated seawater inlet 11 respectively, and the mixed solution of the purified ammonia-alkali waste liquid dissolved in calcium hydroxide is ...

Embodiment 3

[0041] Take ammonia-alkali waste liquid, first place it in a settler to settle, and remove insoluble matter. Pump the supernatant of the settler into the filter for filtration, and analyze the composition of the filtrate: Ca 2+ 0.90mol / L, Na + 0.79mol / L, Cl - 2.59mol / L. Weigh 832g of calcium hydroxide, dissolve it in 10L of purified ammonia alkali waste liquid, and stir to form a mixed solution. Analysis of concentrated seawater composition: SO 4 2- 0.13mol / L), Ca 2+ 0.05mol / L, Mg 2+ 0.3mol / L, Cl - 3.26mol / L, K + 0.064mol / L, Na + 2.78mol / L.

[0042] Take the above-mentioned purified ammonia-alkali waste liquid dissolved calcium hydroxide mixed solution and 30L concentrated seawater and add them continuously to the crystallization reactor at the same time through inlets 10 and 11 respectively, and adjust the inlet of the purified ammonia-alkali waste liquid dissolved calcium hydroxide mixed solution and concentrated seawater. The feed rate is 3.2L / h and 9.5L / h respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com