Cold-resistant high-wear-resistant polyurethane resin for synthetic leather

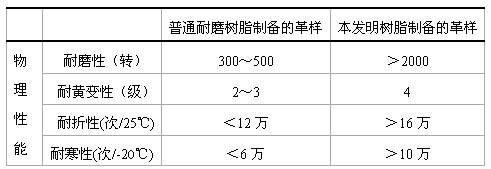

A polyurethane resin, high wear-resistant technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems that it is difficult to make greater progress, there is no satisfactory high wear-resistant product, and the comprehensive performance requirements are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Raw material name Weight (unit: kg)

[0011] Polytetramethylene ether glycol (molecular weight 2000) 80

[0012] Polycarbonate diol (molecular weight 2000) 120

[0013] Ethylene glycol 15.5

[0014] 4,4′-Diphenylmethane diisocyanate (MDI) 87

[0015] Antioxidant 245 0.5

[0016] UV absorber Tinuvin101 4

[0017] Anti-sticking agent 0.5

[0018] Light stabilizer 765 4

[0019] Abrasion Agent 10

[0020] Butanone (MEK) 212

[0021] N,N-Dimethylformamide (DMF) 494

[0022] The preparation steps are as follows: put 80 kg of polytetramethylene ether glycol, 120 kg of polycarbonate diol, 15.5 kg of ethylene glycol, 0.5 kg of antioxidant and 353 kg of DMF into the reaction kettle together, and stir evenly , then add MDI in batches, react at 70-80°C, continuously add DMF and MEK to control the viscosity, until the viscosity rises to 80-120MPa·S, add an appropriate amount of methanol to block, and finally add ultraviolet absorbers, anti-sticking agents, light Stabilize...

Embodiment 2

[0024] Raw material name Weight (unit: kg)

[0025] Polytetramethylene ether glycol (molecular weight 2000) 100

[0026] Polycarbonate diol (molecular weight 2000) 80

[0027] Hydroxy silicone oil (molecular weight 2000) 20

[0028] 1,4-Butanediol 22.5

[0029] MDI 87

[0030] Antioxidant 245 0.5

[0031] UV absorber Tinuvin101 4

[0032] Anti-sticking agent 0.5

[0033] Light stabilizer 765 4

[0034] Abrasion Agent 8

[0035] MEK 217

[0036] DMF 505

[0037] The preparation steps are as follows: 100 kg of the above-mentioned polytetramethylene ether glycol, 60 kg of polycarbonate diol, 20 kg of hydroxyl silicone oil, 22.5 kg of 1,4-butanediol, 0.5 kg of antioxidant and 361 kg of DMF Put them into the reaction kettle together, stir evenly, then add MDI in batches, react at 70-80°C, continuously add DMF and MEK to control the viscosity, until the viscosity rises to 80-120MPa·S, add an appropriate amount of methanol to block, and finally add Ultraviolet absorber, an...

Embodiment 3

[0039] Raw material name Weight (unit: kg)

[0040] Polytetramethylene ether glycol (molecular weight 3000) 90

[0041] Polycaprolactone diol (molecular weight 2000) 100

[0042] Hydroxy silicone oil (molecular weight 2000) 40

[0043] 1,4-Butanediol 24.8

[0044] MDI 93

[0045] Antioxidant 245 0.6

[0046] UV absorber Tinuvin101 3.6

[0047] Anti-sticking agent 0.6

[0048] Light stabilizer 765 4.8

[0049] Wear agent 9.6

[0050] MEK 255

[0051] DMF 596

[0052] The preparation steps are as follows: 90 kg of the above-mentioned polytetramethylene ether diol, 100 kg of polycaprolactone diol, 40 kg of hydroxyl silicone oil, 24.8 kg of 1,4-butanediol, 0.6 kg of antioxidant and DMF426 Put the kilograms into the reaction kettle together, stir evenly, then add MDI in batches, react at 70-80°C, continuously add DMF and MEK to control the viscosity, until the viscosity rises to 80-120MPa·S, add an appropriate amount of methanol to block, and finally Add ultraviolet abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com