Reactive polyurethane hot melt adhesive for reflective fabric and preparation method thereof

A polyurethane hot-melt adhesive, reactive technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of curing bond strength, washing resistance, solvent resistance, temperature resistance and storage Unsatisfactory stability, poor strength, poor metal bonding performance, etc., to achieve good initial bond strength, improve heat resistance and oxidation resistance and yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

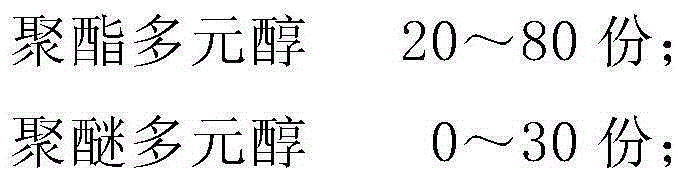

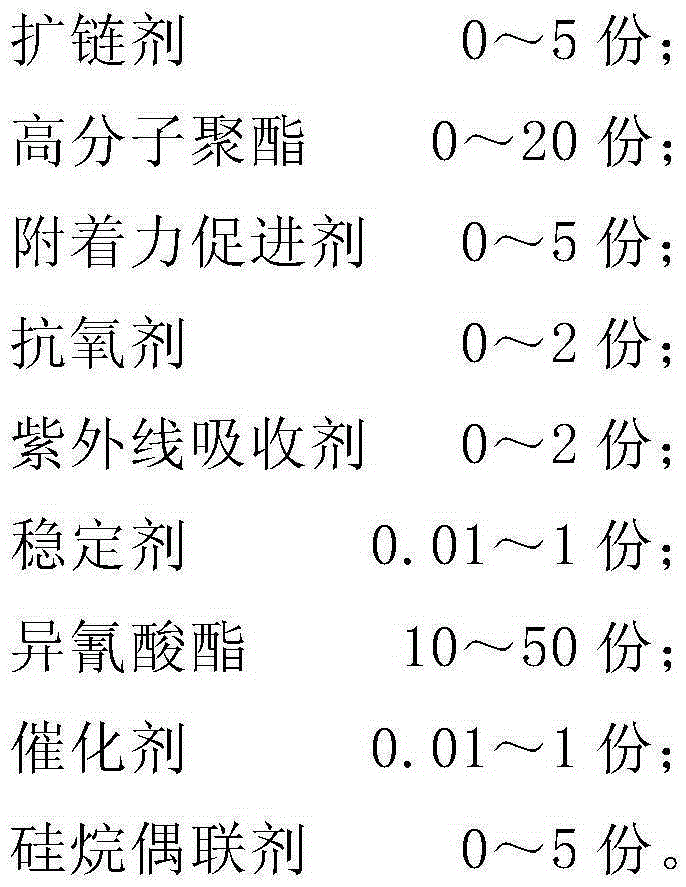

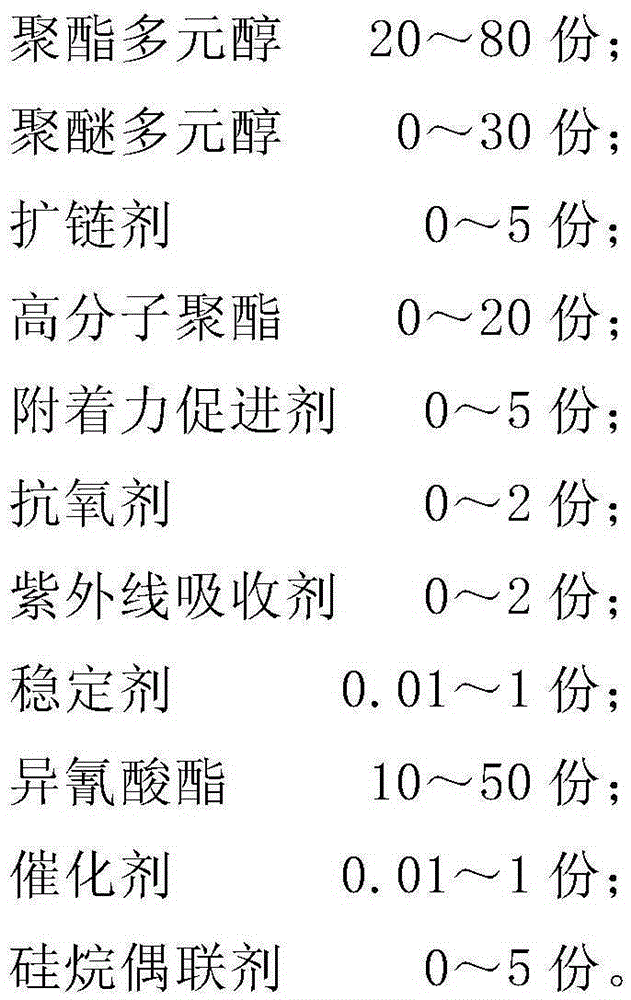

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of reactive polyurethane hot-melt adhesive for the reflective fabric of this embodiment, its steps are as follows:

[0054] 1) Get 40 parts by weight of amorphous polyester polyol, 25 parts by weight of crystalline polyester polyol, 10 parts by weight of polyether polyol, 3 parts by weight of polymer polyester, 2 parts by weight of adhesion promoter, 0.1 part by weight of anti- Add oxygen agent, 0.05 parts by weight of ultraviolet absorber, and 0.03 parts by weight of stabilizer into the reaction kettle, and vacuum dehydrate at 110-120 ° C for 60 minutes;

[0055] 2) Cool down to 80°C, and add 19 parts by weight of isocyanate while stirring;

[0056] 3) Slowly heat up to 100-120°C, vacuum defoaming reaction for 60 minutes;

[0057] 4) Cool down to 90°C, add 0.02 parts by weight of catalyst and 0.8 parts by weight of silane coupling agent, then heat up, vacuumize at 100-120°C until no bubbles appear, and test viscosity and NCO%;

[0058] 5) After...

Embodiment 2

[0086] The preparation method of reactive polyurethane hot-melt adhesive for the reflective fabric of this embodiment, its steps are as follows:

[0087] 1) Get 30 parts by weight of amorphous polyester polyol, 30 parts by weight of crystalline polyester polyol, 15 parts by weight of polyether polyol, 2 parts by weight of polymer polyester, 1 part by weight of adhesion promoter, 0.1 part by weight of anti- Add oxygen agent, 0.05 parts by weight of ultraviolet absorber, and 0.03 parts by weight of stabilizer into the reaction kettle, and vacuum dehydrate at 110-120 ° C for 60 minutes;

[0088] 2) Cool down to 80°C, and add 21 parts by weight of isocyanate while stirring;

[0089] 3) Slowly heat up to 100-120°C, vacuum defoaming reaction for 60 minutes;

[0090] 4) Cool down to 90°C, add 0.02 parts by weight of catalyst and 0.8 parts by weight of silane coupling agent, then heat up, vacuumize at 100-120°C until no bubbles appear, and test viscosity and NCO%;

[0091] 5) After ...

Embodiment 3

[0119] The preparation method of reactive polyurethane hot-melt adhesive for the reflective fabric of this embodiment, its steps are as follows:

[0120] 1) Get 25 parts by weight of amorphous polyester polyol, 25 parts by weight of crystalline polyester polyol, 15 parts by weight of polyether polyol, 3 parts by weight of chain extender, 2 parts by weight of polymer polyester, 1 part by weight of adhesion Accelerator, 0.1 weight part of antioxidant, 0.05 weight part of ultraviolet absorber, 0.03 weight part of stabilizer are added to the reaction kettle, and vacuum dehydration is carried out at 110-120 °C for 60 minutes;

[0121] 2) Cool down to 80°C, and add 27 parts of isocyanate while stirring;

[0122] 3) Slowly heat up to 100-120°C, vacuum defoaming reaction for 60 minutes;

[0123] 4) Cool down to 90°C, add 0.02 parts by weight of catalyst and 0.8 parts by weight of silane coupling agent, then heat up, vacuumize at 100-120°C until no bubbles appear, and test viscosity a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com