Composite polyether, polyurethane rigid foam as well as raw material composition and usage thereof

A raw material composition and a technology for combining polyethers, which are used in the fields of polyurethane rigid foam foaming and polyurethane combined polyethers, can solve the problems of poor yellowing resistance and good dimensional stability, and achieve extended service life and good dimensional stability. Sex, smell little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

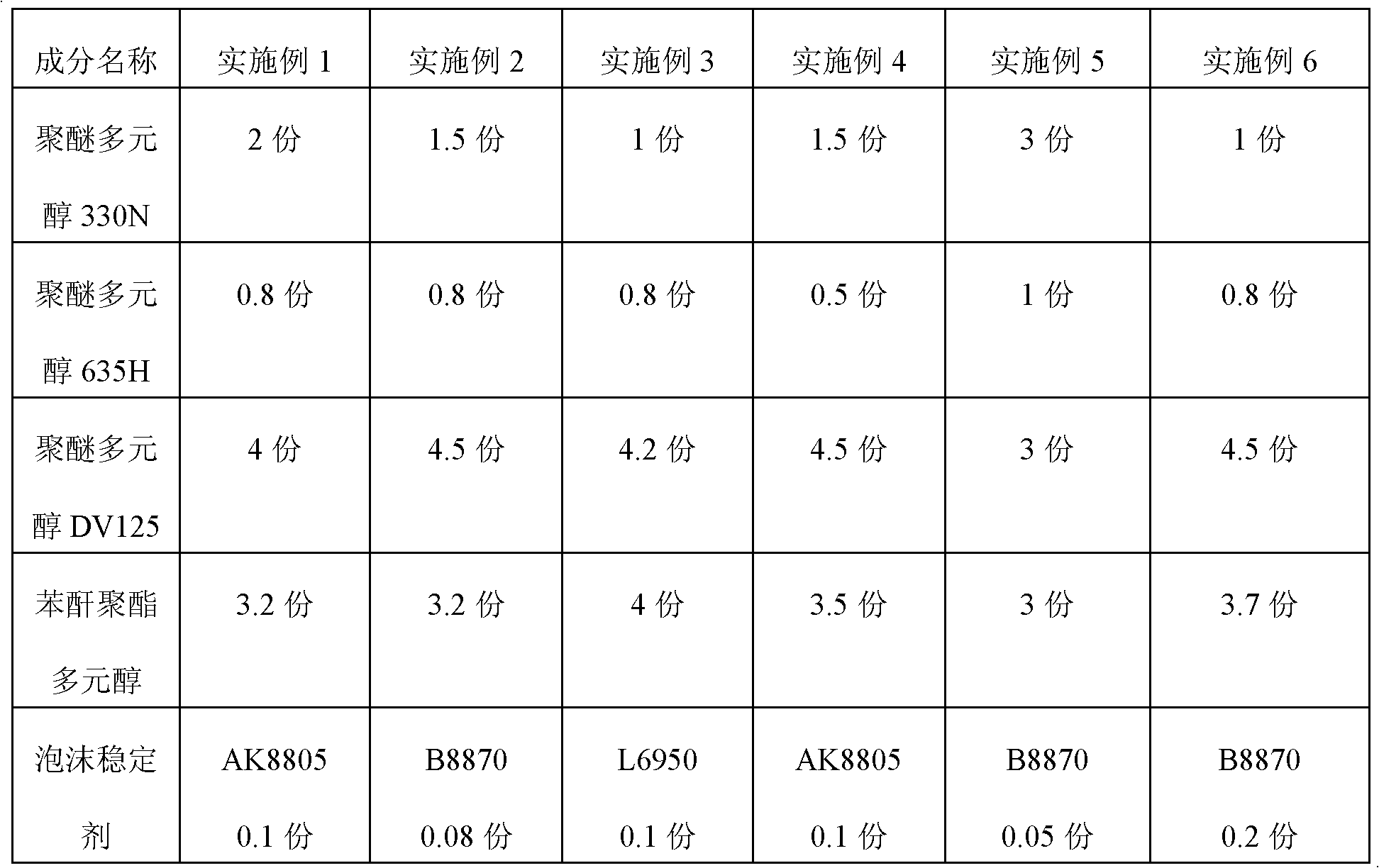

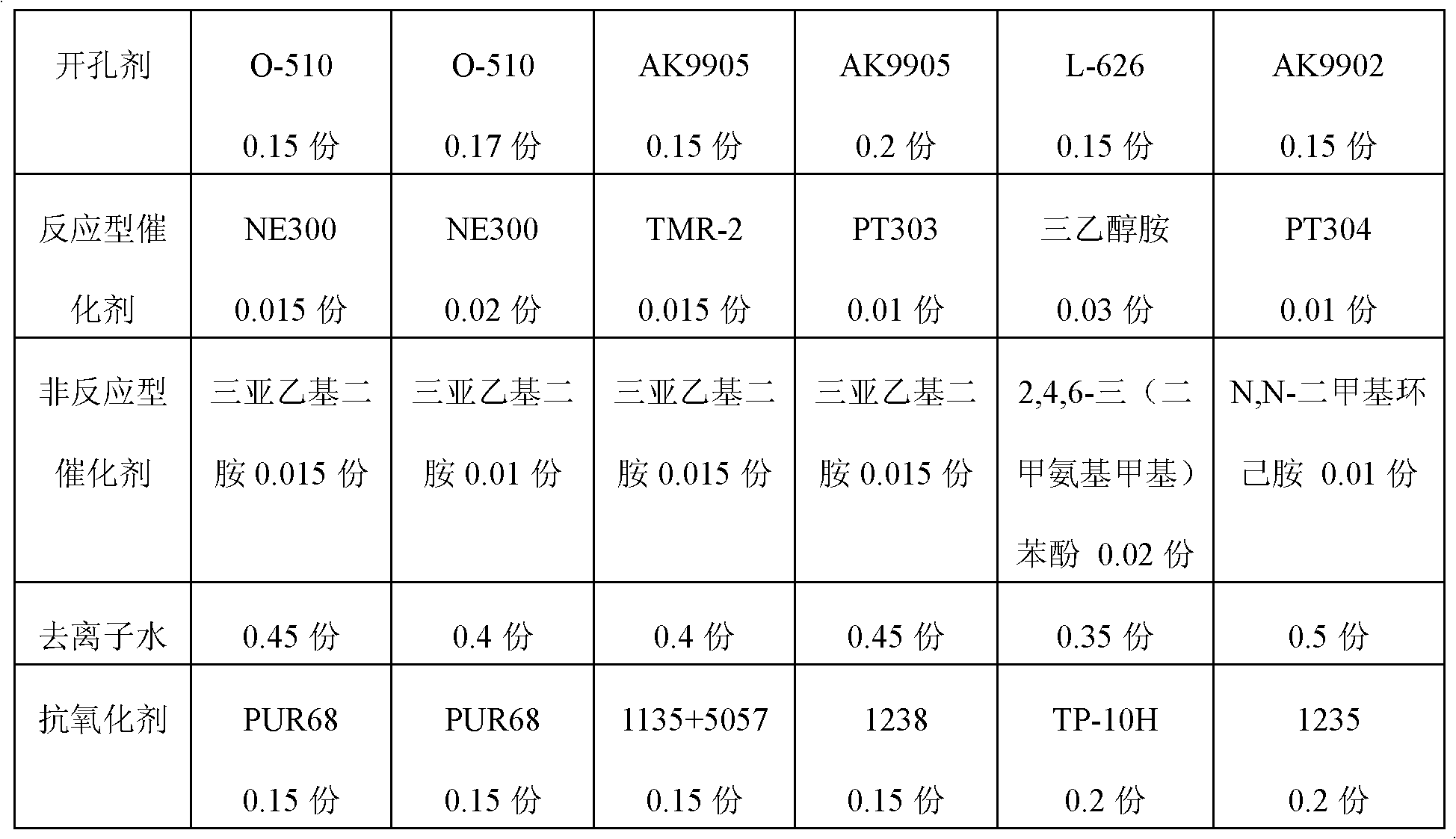

[0038] 1. Preparation of combined polyether:

[0039] Fully mix in the stainless steel mixing tank for 4 hours according to the formula and sequence listed in Table 1 to form the combined polyether of the present invention, which is a light yellow transparent liquid with a hydroxyl value of 280 mgKOH / g and a viscosity of 900 mPa.s (25°C).

[0040] Two, the preparation method of rigid polyurethane foam for automobile roof:

[0041] The prepared combined polyether and PAPI were mixed rapidly at a material temperature of 20° C. at a mass ratio of 1:1.4, and mechanically stirred evenly to obtain rigid polyurethane foam.

Embodiment 2

[0043] 1. Preparation of combined polyether:

[0044] Fully mix in a stainless steel mixing tank for 3 hours according to the formula and sequence listed in Table 1 to form the combined polyether of the present invention. The combined polyether is a colorless transparent liquid with a hydroxyl value of 300 mgKOH / g and a viscosity of 850 mPa.s (25°C).

[0045] Two, the preparation method of rigid polyurethane foam for automobile roof:

[0046] The prepared combined polyether and PAPI were mixed rapidly at a material temperature of 20° C. at a mass ratio of 1:1.5, and mechanically stirred evenly to obtain rigid polyurethane foam.

Embodiment 3

[0048] 1. Preparation of combined polyether:

[0049] Fully mix in a stainless steel mixing tank for 2 hours according to the formula and order listed in Table 1 to form the combined polyether of the present invention, which is a colorless and transparent liquid with a hydroxyl value of 298 mgKOH / g and a viscosity of 980 mPa.s (25°C).

[0050] Two, the preparation method of rigid polyurethane foam for automobile roof:

[0051] The prepared combined polyether and PAPI were mixed rapidly at a material temperature of 20° C. at a mass ratio of 1:1.3, and mechanically stirred evenly to obtain rigid polyurethane foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com