Halogen-free hot-melt adhesive film with high metal-bond force and good fire resistance and preparing method thereof

A kind of hot melt adhesive film, flame retardant technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

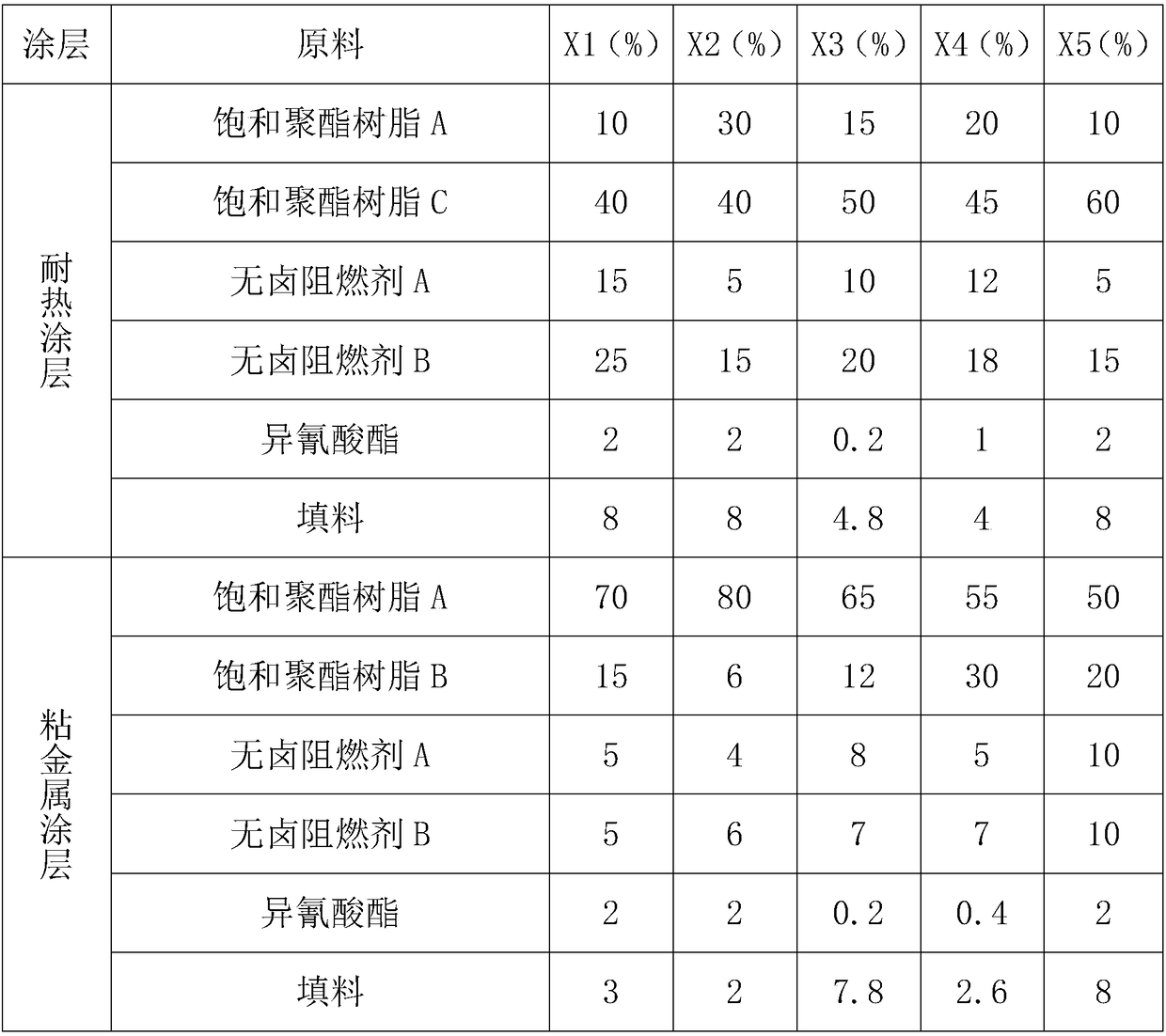

[0048] For the preparation of heat-resistant coating 2, according to the proportion shown in Table 1, the saturated polyester resin A, the saturated polyester resin C, the halogen-free flame retardant A, the halogen-free flame retardant B and the filler were dispersed at a speed of 2400r / min for 2 hours, and then the isocyanate was added to disperse at a speed of 1200r / min for 30 minutes. Finally, two grindings were performed, each grinding for 30 minutes, to obtain the heat-resistant coating 2.

[0049] Step 2, coating the heat-resistant coating 2 on the polyester film 1 with a thickness of 50 μm, controlling the coating thickness of the heat-resistant coating 2 to be 20 μm, and drying in an oven at a temperature of 160° C.

[0050] Step 3, coating the adhesive metal coating 3 on the heat-resistant coating 2 with a thickness of 20 μm, controlling the coating thickness of the adhesive metal coating 3 to be 15 μm, and drying at an oven temperature of 140° C. , and after drying,...

Embodiment Y1

[0064] Embodiment Y1 makes a halogen-free hot-melt adhesive film according to the following steps:

[0065] Step 1, the preparation of heat-resistant coating 2, according to the ratio shown in Table 2, the saturated polyester resin A, the saturated polyester resin C, the halogen-free flame retardant A, the halogen-free Flame retardant B and fillers were dispersed at a speed of 2400r / min for 2 hours, then put into isocyanate and dispersed at a speed of 1200r / min for 30 minutes, and finally grinded twice, each time for 30 minutes, to obtain the heat-resistant coating Layer 2.

[0066] Step 2, coating the heat-resistant coating 2 on the polyester film 1 with a thickness of 50 μm, controlling the coating thickness of the heat-resistant coating 2 to be 20 μm, and drying at an oven temperature of 160° C. After drying, the halogen-free hot-melt adhesive film is obtained.

[0067] The above-mentioned performance test was carried out on the prepared halogen-free hot-melt adhesive fil...

Embodiment Y7

[0069] Embodiment Y7 makes the halogen-free hot-melt adhesive film according to the following steps:

[0070] Step 1, the preparation of the adhesive metal coating 3, according to the proportion shown in Table 2, the saturated polyester resin A, the saturated polyester resin B, the halogen-free flame retardant A, the halogen-free Flame retardant B and filler were dispersed at a speed of 2400r / min for 2 hours, and then put into isocyanate to disperse at a speed of 1200r / min for 30 minutes, and finally grinded twice, each time for 30 minutes, to obtain the sticky metal coating Layer 3;

[0071] For the preparation of heat-resistant coating 2, according to the proportion shown in Table 1, the saturated polyester resin A, the saturated polyester resin C, the halogen-free flame retardant A, the halogen-free flame retardant B and the filler were dispersed at a speed of 2400r / min for 2 hours, and then the isocyanate was added to disperse at a speed of 1200r / min for 30 minutes. Final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com