Preparation method of hot melt adhesive film for vehicle flexible flat cable (FFC) wire and hot melt adhesive film

A technology of hot-melt adhesive film and hot-melt adhesive, which is applied in the direction of film/sheet release coating, adhesive, film/sheet adhesive, etc., which can solve poor weather resistance, conductor fracture, conductor and connector insulation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

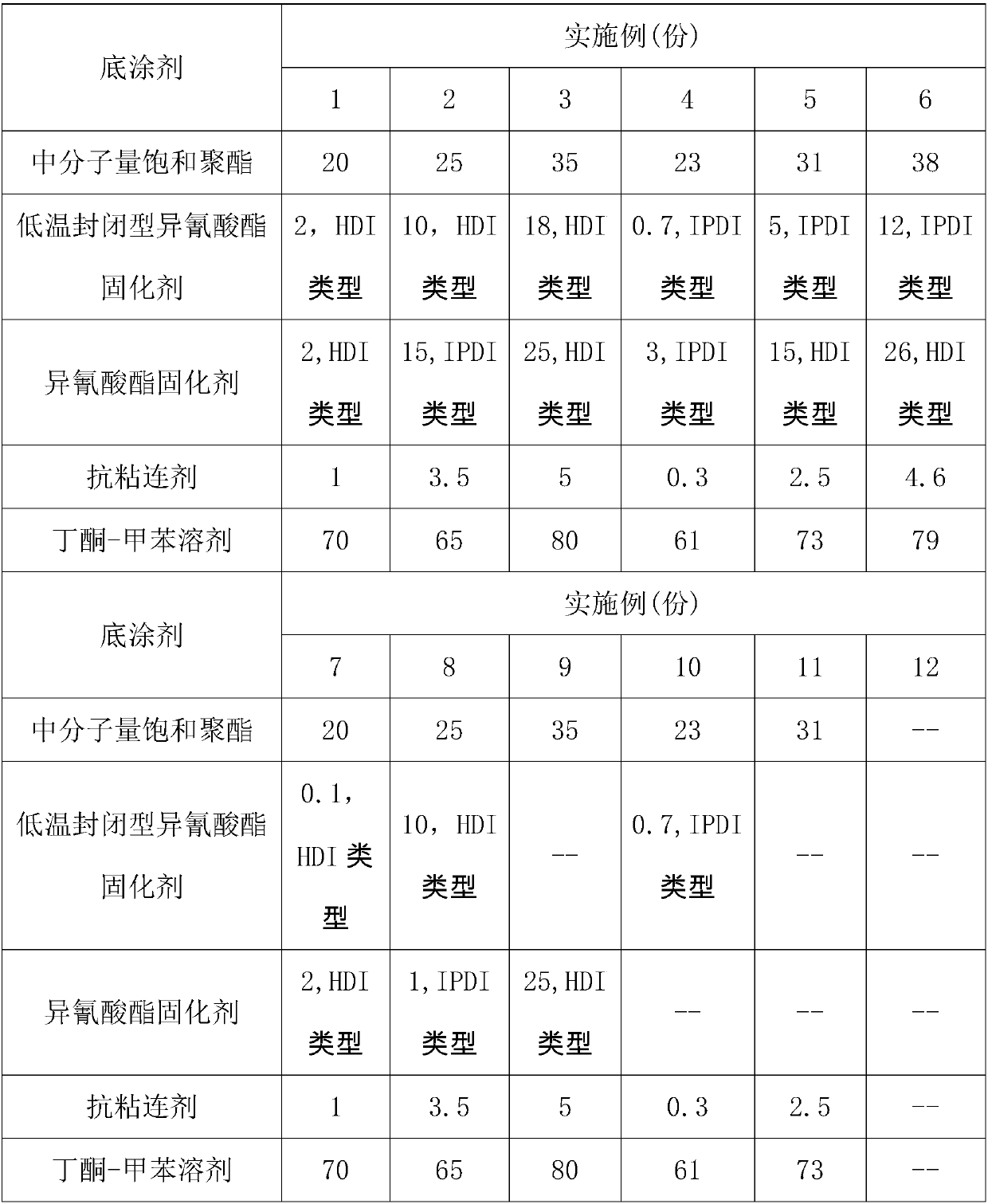

[0046]Embodiment 1~11 prepares primer according to the following steps:

[0047] Step A1, according to the mass parts in Table 1, add medium molecular weight saturated polyester and butanone-toluene solvent into the reaction kettle and stir to dissolve, the stirring speed is 500-1000r / min; the molecular weight of medium molecular weight saturated polyester is 4000, glass The melting temperature is -30°C;

[0048] In step A2, the reaction kettle in step A1 is stirred and dissolved evenly and then lowered to room temperature, and then according to the parts by mass in Table 1, add an anti-blocking agent and a low-temperature blocked isocyanate curing agent, and stir and disperse evenly;

[0049] In step A3, according to the mass parts in Table 1, add an isocyanate curing agent into the reaction kettle in step A2 before coating, and stir and disperse evenly to prepare a primer.

Embodiment 1~12

[0050] Embodiment 1~12 prepares hot-melt adhesive according to the following steps:

[0051] Step B1, according to the mass parts, add 35 parts of high molecular weight saturated polyester a, 10 parts of high molecular weight saturated polyester b and 50 parts of toluene solvent into another reaction kettle, heat up to 70 ° C, stir and dissolve, and the stirring speed is 800r / min; high molecular weight saturated polyester a has a molecular weight of 30,000 and a glass transition temperature of 10°C; high molecular weight saturated polyester b has a molecular weight of 20,000 and a glass transition temperature of 80°C;

[0052] Step B2, after stirring and dissolving the reactor in step B1, add 5 parts of epoxy resin according to the mass parts, and stir and dissolve evenly;

[0053] Step B3, according to the mass parts, add 30 parts of flame retardant, 2 parts of anti-blocking agent and 1 part of titanium dioxide to the reaction kettle in step B2, and then stir and disperse eve...

Embodiment 12

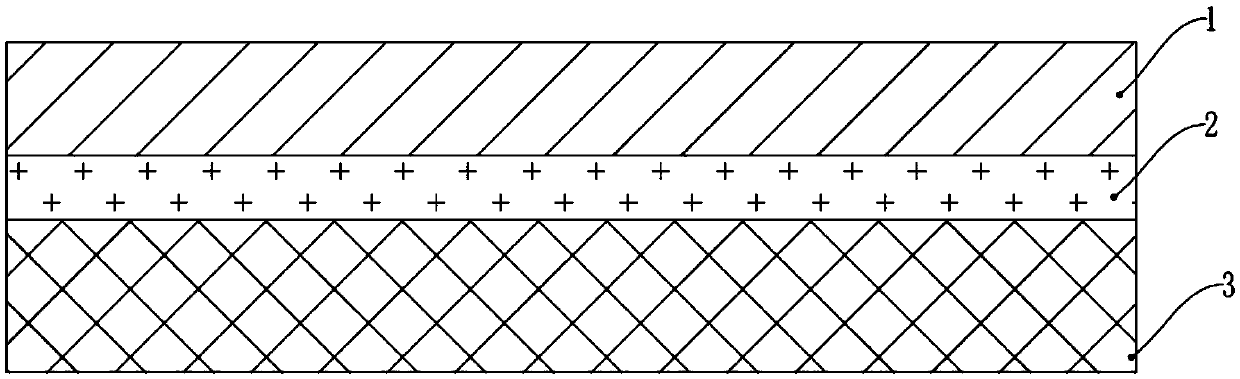

[0058] Embodiment 12 prepares a hot melt adhesive film according to the following steps:

[0059] On the PET polyester film 1 with a thickness of 25 μm, a hot melt adhesive with a thickness of 35 μm was coated to obtain a hot melt adhesive film. The width of the hot-melt adhesive film sample is 25.4mm, the hot-melt adhesive surface is heat-sealed with the adhesive surface, the heat-sealing pressure is 0.5Mpa, the time is 1 second, the temperature is 180°C, and after heat-sealing, it is 120°C and matured for 1 hour.

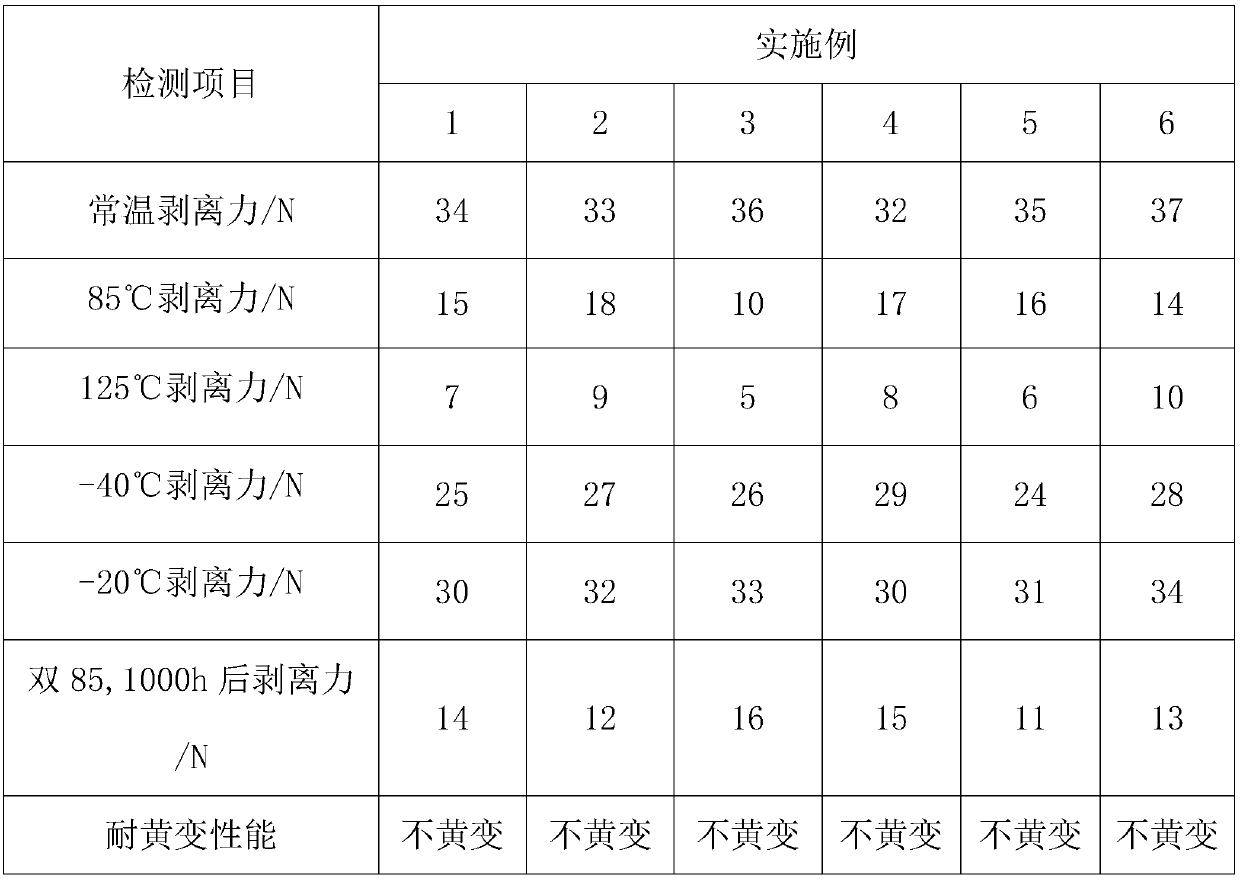

[0060] The hot-melt adhesive film sample that embodiment 1~12 makes tests the peeling strength of primer to hot-melt adhesive and PET polyester film 1 at different temperatures;

[0061] Place the hot-melt adhesive film samples prepared in Examples 1 to 12 for 1000 hours at a temperature of 85°C and a humidity of 85°C, and then test the peel strength;

[0062] The anti-yellowing properties of the hot melt adhesive film samples prepared in Examples 1-12 were teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com