Adhesive film and flat cable using same

一种粘接膜、粘接层的技术,应用在粘接膜,扁平电缆领域,能够解决环境不良影响等问题,达到粘接性良好、耐热性和阻燃性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

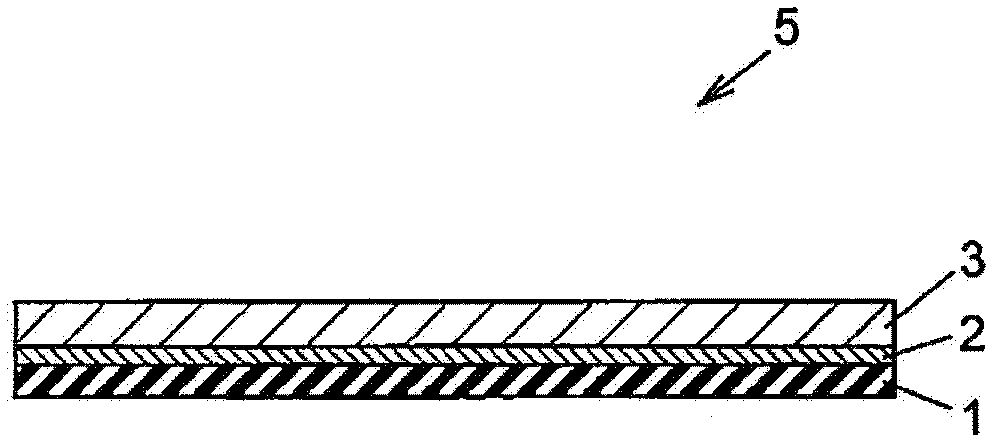

[0051] figure 1It is a cross-sectional view showing an example of the structure of the adhesive film according to the first embodiment of the present invention. Such as figure 1 As shown, this adhesive film 5 has an insulating film 1 , an adhesion-promoting coating 2 formed on one surface of the insulating film 1 , and an adhesive layer 3 formed on the adhesion-promoting coating 2 .

[0052] Engineering plastics are suitably used for the insulating film 1, and for example, polyester resin, aromatic polycarbonate resin, polyphenylene sulfide resin, polyimide resin, polyetherimide resin, and the like can be used. Examples of the polyester resin include polyethylene terephthalate resin, polybutylene terephthalate resin, polyethylene naphthalate resin, polybutylene naphthalate resin, Polytrimethylene terephthalate resin, polytrimethylene naphthalate resin, polycyclohexanedimethyl terephthalate resin, polycyclohexanedimethyl naphthalate resin, polyarylate resin, and the like. Am...

no. 2 Embodiment approach

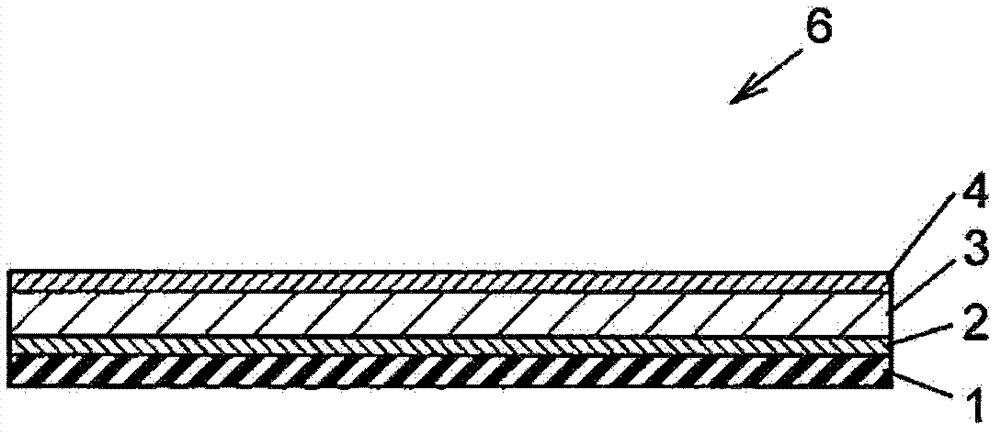

[0067] figure 2 It is a cross-sectional view showing an example of the adhesive film according to the second embodiment of the present invention. The adhesive film 6 in figure 1 On the adhesive layer 3 of the adhesive film 5 composed of the insulating film 1 , the adhesion-promoting coating 2 and the adhesive layer 3 shown, a conductor adhesive layer 4 capable of bonding metal conductors is further formed.

[0068] The adhesive layer 3 has the same configuration as that of the first embodiment, but regarding the amount of the flame retardant added to the adhesive layer 3, when the conductive adhesive layer 4 is provided on the adhesive layer 3, the 100 parts by weight of the resin is not less than 120 parts by weight and not more than 200 parts by weight.

[0069] As the base resin constituting the conductive bonding layer 4 , a resin soluble in a halogen-free solvent having a boiling point of 120° C. or lower can be used. This is because if the boiling point of the solven...

no. 3 Embodiment approach

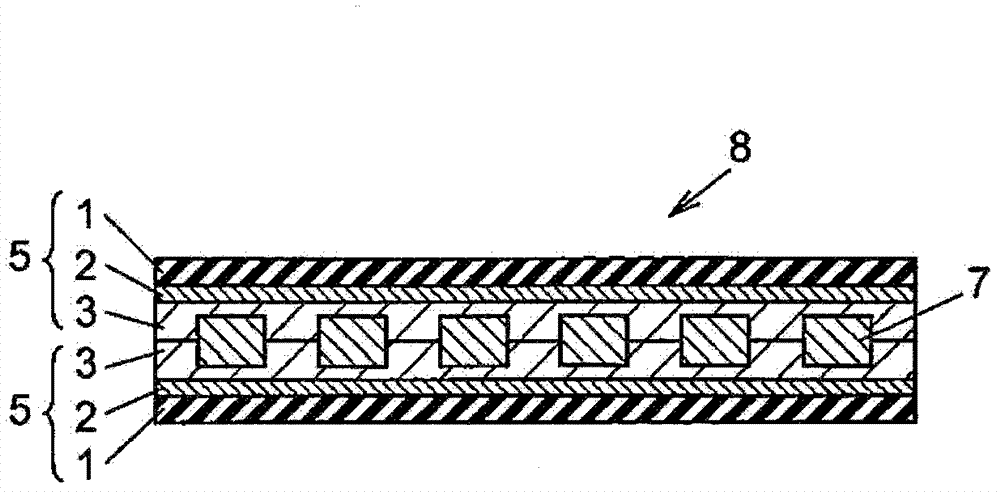

[0074] image 3 It is a sectional view showing an example of the structure of the flat cable according to the third embodiment of the present invention. The flat cable 8 is used figure 1 The adhesive film 5 shown is formed. That is, two adhesive films 5 are arranged so that the adhesive layers 3 face each other, and after a plurality of metal conductors 7 are arranged in parallel between the adhesive layers 3, the adhesive layers 3 are bonded to each other with a laminator, thereby A flat cable 8 is formed.

[0075] For the metal conductor 7 , conductive materials such as copper-based materials made of copper or copper alloys, iron-based materials made of iron or iron alloys, and aluminum-based materials made of aluminum or aluminum alloys can be used. Examples of the copper-based material include oxygen-free copper, tough copper, phosphor bronze, and the like. In addition, metal conductor 7 may be plated with metal such as Sn or Ni. image 3 The metal conductor 7 shown h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com