Recognizable cable, extrusion die and manufacture method thereof

An easy-to-identify and cable technology, applied in the direction of insulating cables, marking conductors/cables, insulating conductors/cables, etc., it can solve the problems of complex processing technology, poor adhesion of coating color strips, and inability to identify, and achieves high recognition. , The effect of firm attachment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

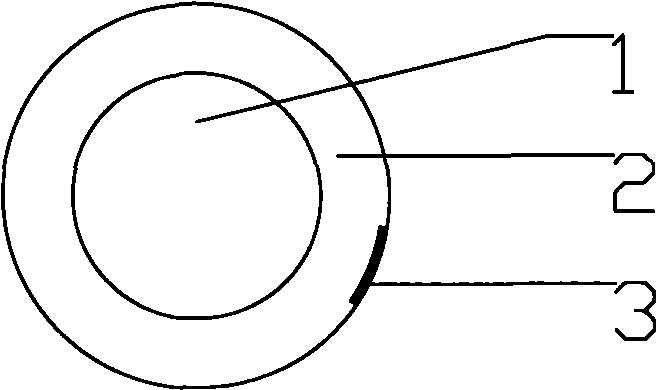

[0023] Embodiment 1: see figure 1 , the easy-to-identify cable of the present invention, the cable itself is a conventional structure, that is, a sheath and / or an insulating layer 2 are extruded outside the cable core and / or conductor 1, and the gist of the present invention is that the sheath and / or insulating layer The surface of 2 is also extruded with several longitudinal color stripes 3 of different colors from the body of the sheath and / or insulating layer 2 . There are three longitudinal color stripes, arranged at intervals of 120° on the surface of the sheath and / or insulating layer, the width of the color stripes is 2.5mm, and the thickness is 0.25mm.

Embodiment 2

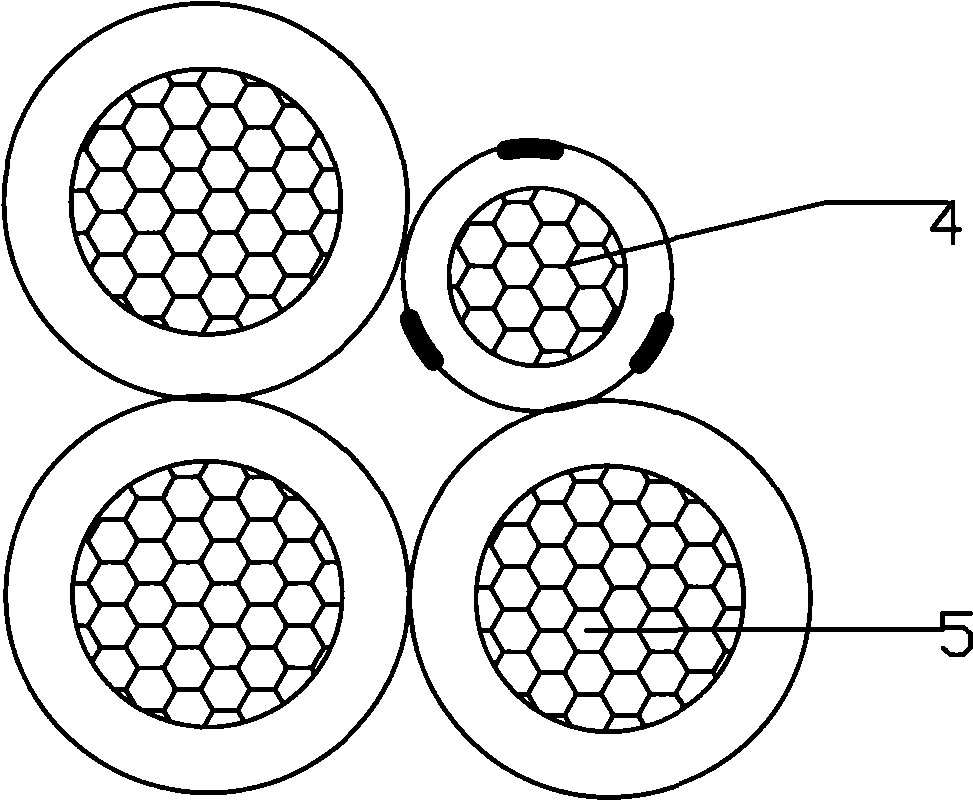

[0024] Example 2: see figure 2 , take the colored striped core of Example 1 as the neutral core 4, and twist with the other three cores 5 to form a four-core distribution cable.

Embodiment 3

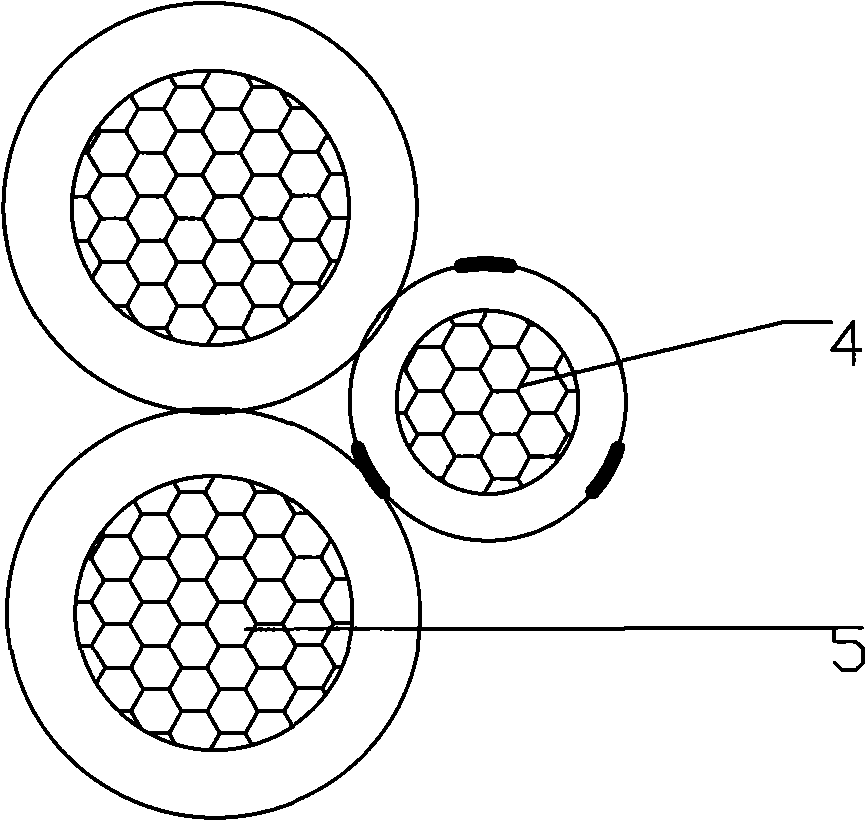

[0025] Embodiment 3: see image 3 , take the colored striped core of Example 1 as the neutral core 4, and twist with the other two cores 5 to form a three-core distribution cable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com