Resource processing method and device for preparing industrial salt from high-concentration and high-salt chemical wastewater

A technology for chemical wastewater and high-salt wastewater is applied in the field of resource treatment of industrial salt extracted from high-salt and high-concentration chemical wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, a kind of high-concentration high-salt chemical industry waste water produces the resource treatment method of industrial salt, comprises the following steps as follows:

[0027] 1. Homogenization step: For each strand of high-concentration and high-salt wastewater in the chemical production process, first place it in a high-salt water buffer tank for homogenization;

[0028] 2. Neutralization step: transfer the high-concentration and high-salt wastewater to the neutralization tank in batches and use hydrochloric acid (lye) to adjust the pH to 4~5;

[0029] 3. Three-phase catalytic oxidation step: After the neutralization step, the high-concentration and high-salt wastewater continuously enters the catalytic oxidation tower, and the surface active catalyst is loaded in the catalytic oxidation tower. The organic matter, oxygen and oxidant molecules in the final high-concentration and high-salt wastewater are oxidized and decomposed after adsorption, strong ...

Embodiment 2

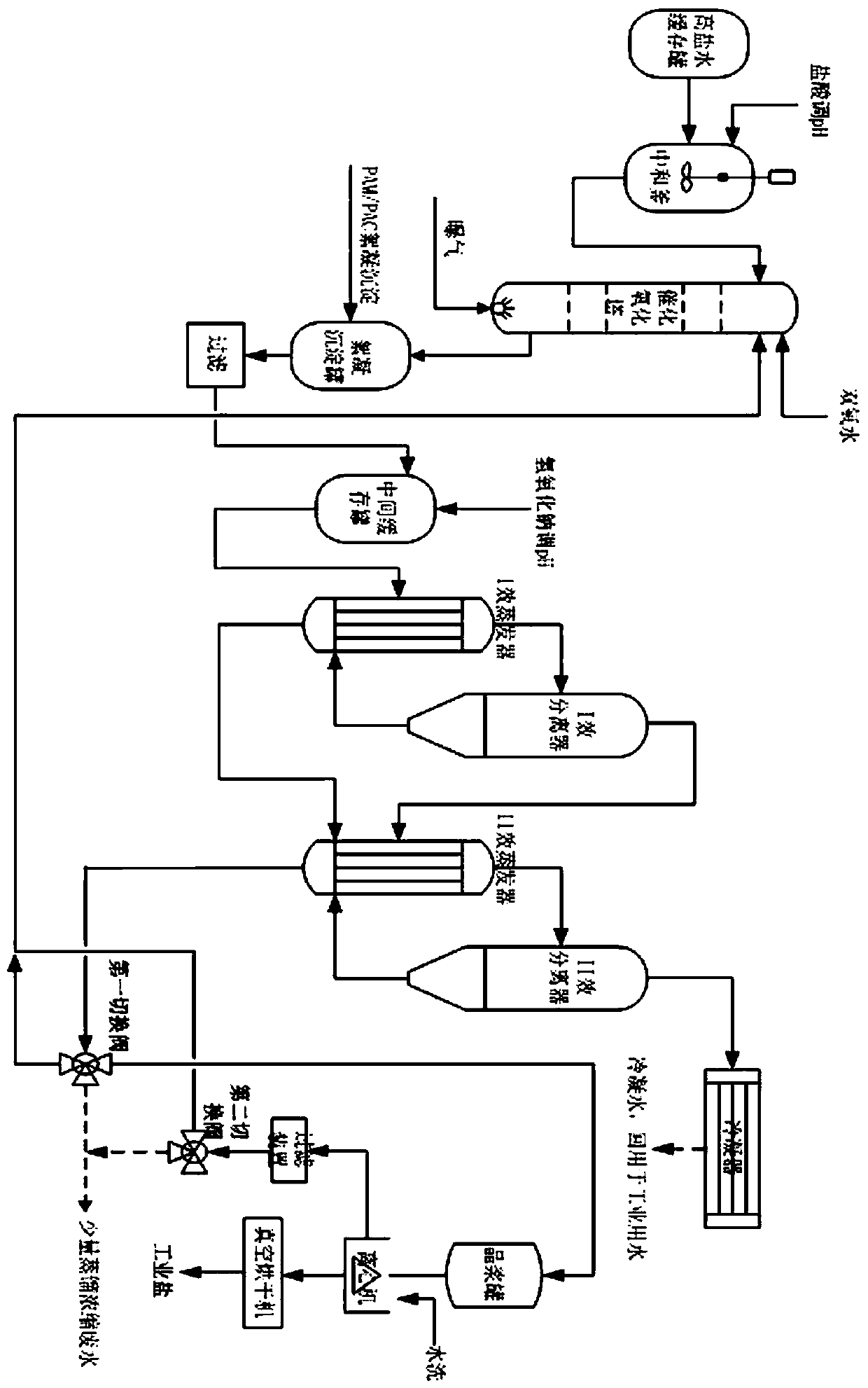

[0036] Example 2, a resource treatment device for preparing industrial salt from high-concentration and high-salt chemical wastewater, including a high-salt water buffer tank, a neutralization tank connected to the high-salt water buffer tank, a catalytic oxidation tower connected to the neutralization tank, and catalytic oxidation The tower has a material inlet and a material outlet. The bottom of the catalytic oxidation tower is provided with an air inlet, and the top of the catalytic oxidation tower is provided with a liquid inlet. The liquid outlet of the neutralization tank is connected to the catalytic oxidation tower with a material inlet. The material outlet of the tower is connected to a flocculation sedimentation tank, and the flocculation sedimentation tank is connected to an intermediate buffer tank through a filter device. The effect evaporator is connected with the I effect separator, the II effect evaporator is connected with the II effect separator, the II effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com