Preparation method of niobium alloy long thin-walled pipe

A niobium alloy and thin-walled tube technology is applied in the field of preparation of niobium alloy long thin-walled tubes, which can solve the problems of high room temperature strength of tungsten alloys, long preparation cycle, and difficulty, and achieve short processing cycle, good plasticity, and production process. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

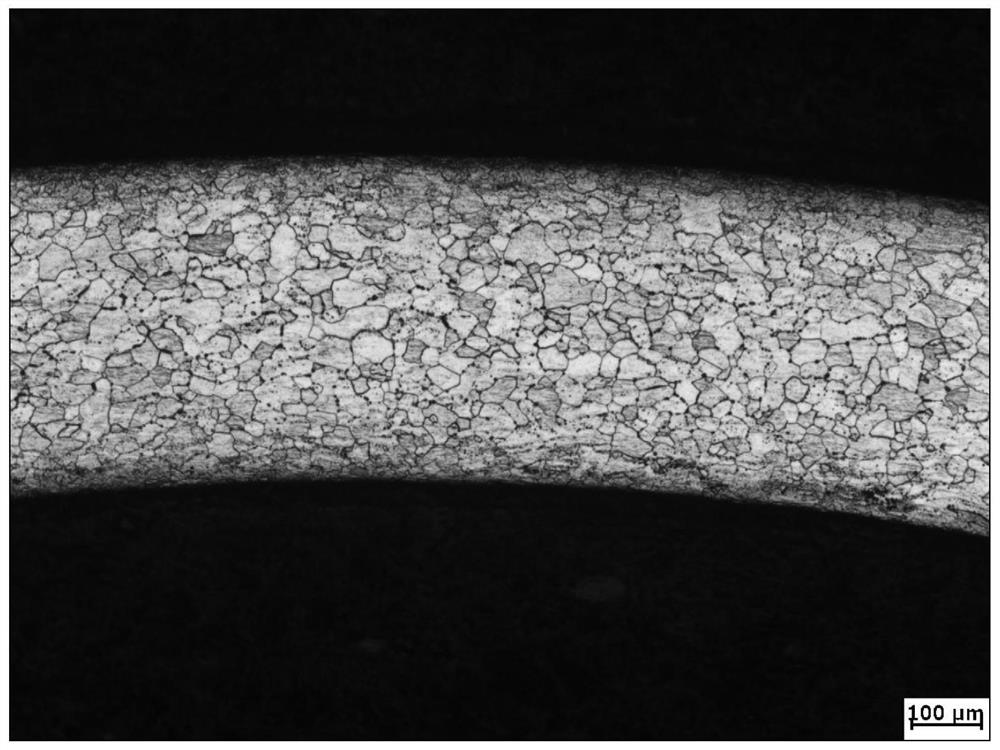

Image

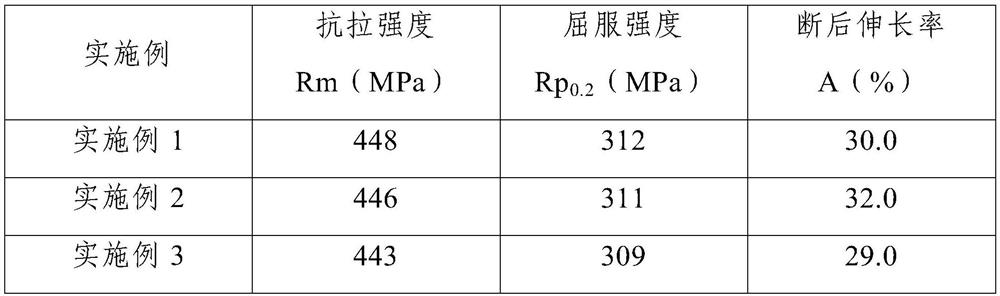

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

[0028] Step 1. Drilling and boring the completely recrystallized niobium alloy rod in sequence to obtain a niobium alloy tube blank; the diameter of the completely recrystallized niobium alloy rod is 36 mm, and the outer surface roughness is not greater than 6.3 μm; the completely The recrystallized niobium alloy bar refers to the niobium alloy bar that has been annealed after forging to a completely recrystallized state, and the composition of the niobium alloy bar is Nb-5W-2Mo-1Zr; the niobium alloy tube billet The diameter of the inner hole is 25mm;

[0029] Step 2. Honing the inner hole of the niobium alloy tube blank obtained in step 1 to obtain a honed niobium alloy tube blank; the surface roughness of the inner hole of the honed niobium alloy tube blank is not greater than 1.6 μm;

[0030] Step 3. The honed niobium alloy tube blank obtained in step 2 is sequentially acid-washed and washed with water, and then a two...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] Step 1. Drilling and boring the completely recrystallized niobium alloy rod in sequence to obtain a niobium alloy tube blank; the diameter of the completely recrystallized niobium alloy rod is 39 mm, and the outer surface roughness is not greater than 6.3 μm; the completely The recrystallized niobium alloy bar refers to the niobium alloy bar that has been annealed after forging to a completely recrystallized state, and the composition of the niobium alloy bar is Nb-5W-2Mo-1Zr; the niobium alloy tube billet The diameter of the inner hole is 25mm;

[0037] Step 2. Honing the inner hole of the niobium alloy tube blank obtained in step 1 to obtain a honed niobium alloy tube blank; the surface roughness of the inner hole of the honed niobium alloy tube blank is not greater than 1.6 μm;

[0038] Step 3. The honed niobium alloy tube blank obtained in step 2 is sequentially acid-washed and washed with water, and then a two...

Embodiment 3

[0042] This embodiment includes the following steps:

[0043] Step 1. Drilling and boring the completely recrystallized niobium alloy rod in sequence to obtain a niobium alloy tube blank; the diameter of the completely recrystallized niobium alloy rod is 46 mm, and the outer surface roughness is not greater than 6.3 μm; the completely The recrystallized niobium alloy bar refers to the niobium alloy bar that has been annealed after forging to a completely recrystallized state, and the composition of the niobium alloy bar is Nb-5W-2Mo-1Zr; the niobium alloy tube billet The diameter of the inner hole is 32mm;

[0044] Step 2. Honing the inner hole of the niobium alloy tube blank obtained in step 1 to obtain a honed niobium alloy tube blank; the surface roughness of the inner hole of the honed niobium alloy tube blank is not greater than 1.6 μm;

[0045] Step 3. The honed niobium alloy tube blank obtained in step 2 is sequentially acid-washed and washed with water, and then a two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com