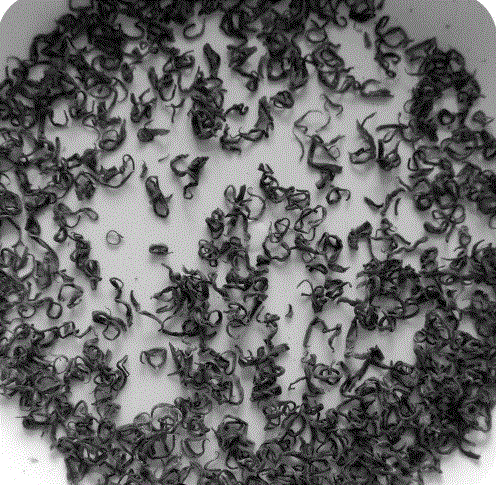

Making process of curly white leaf tea

A production process and technology of white leaf tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of high picking cost, unfavorable white tea green tree rate, and short time, so as to increase the rate of tree falling, reduce the cost of picking, and facilitate The effect of carrying and transporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A manufacturing process of curly white leaf tea, comprising the following steps:

[0028] A. Picking: Mix one bud with one leaf, one bud with two leaves and one bud with three leaves as tea raw materials;

[0029] B. Spreading green: the room temperature is below 25°C, put the tea raw materials in the greening tank, cool for 3-5 hours, turn it every hour, and wait until the leaves become soft and the water content of the tea leaves will reach 68-72%. Can;

[0030] C. Finishing: use metal heat conduction to finish, the time is 2 minutes, and the finishing temperature is 340-350°C;

[0031] D. Kneading: Use a kneading machine to knead, and knead according to the principle of "light weight and light" pressure, light pressure: fresh leaves are put into the kneading barrel at 5-10cm, and the fresh leaves are covered with the lid of the bucket to lightly press, time 8-12 Minutes; heavy pressure: Turn the handle, lower the lid to a distance of 15-20cm from the kneading bucke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com