Five-finger end effector

An end-effector and five-finger technology, which is used in picking machines, manipulators, chucks, etc., can solve the problems of poor operation, low operation efficiency, and unfavorable long-term preservation of picking operations, and achieves reduction of picking costs, large movement space, and resistance to picking. Strong impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described:

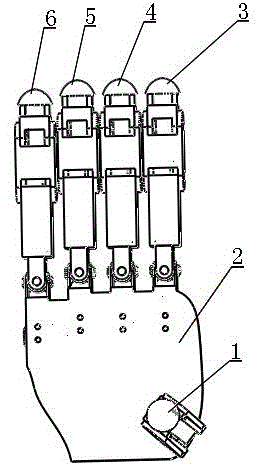

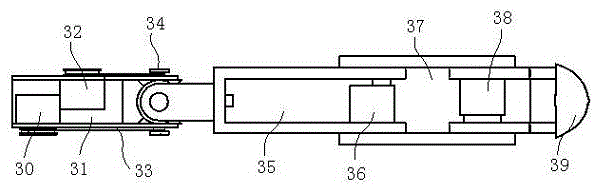

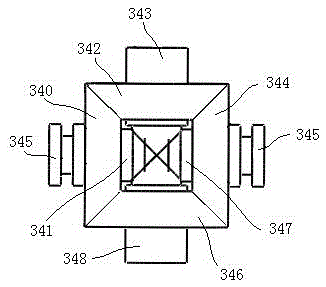

[0034] Figure 1 to Figure 5 A five-finger end effector is shown, including thumb 1 , palm 2 , index finger 3 , middle finger 4 , ring finger 5 and little finger 6 . Thumb 1, index finger 3, middle finger 4, ring finger 5, little finger 6 and palm 2 are firmly connected. Wherein, index finger 3, middle finger 4, ring finger 5 and little finger 6 have the same structure, as in the present embodiment figure 2 As shown, the index finger 3 is taken as an example to illustrate their structural features. Index finger 3 comprises base joint first motor 30, motor slot 31, base joint second motor 32, belt 33, differential mechanism 34, proximal knuckle 35, proximal knuckle motor 36, middle knuckle 37, middle knuckle motor 38, far Knuckles 39 and two connecting shafts 40 . The first motor 30 of the base joint and the second motor 32 of the base joint are installed in the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com