Stock rack set, storage system, robot control method, and robot

A technology of robots and bracket groups, applied in the field of warehousing, can solve problems such as low picking efficiency and inability to meet fast shipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

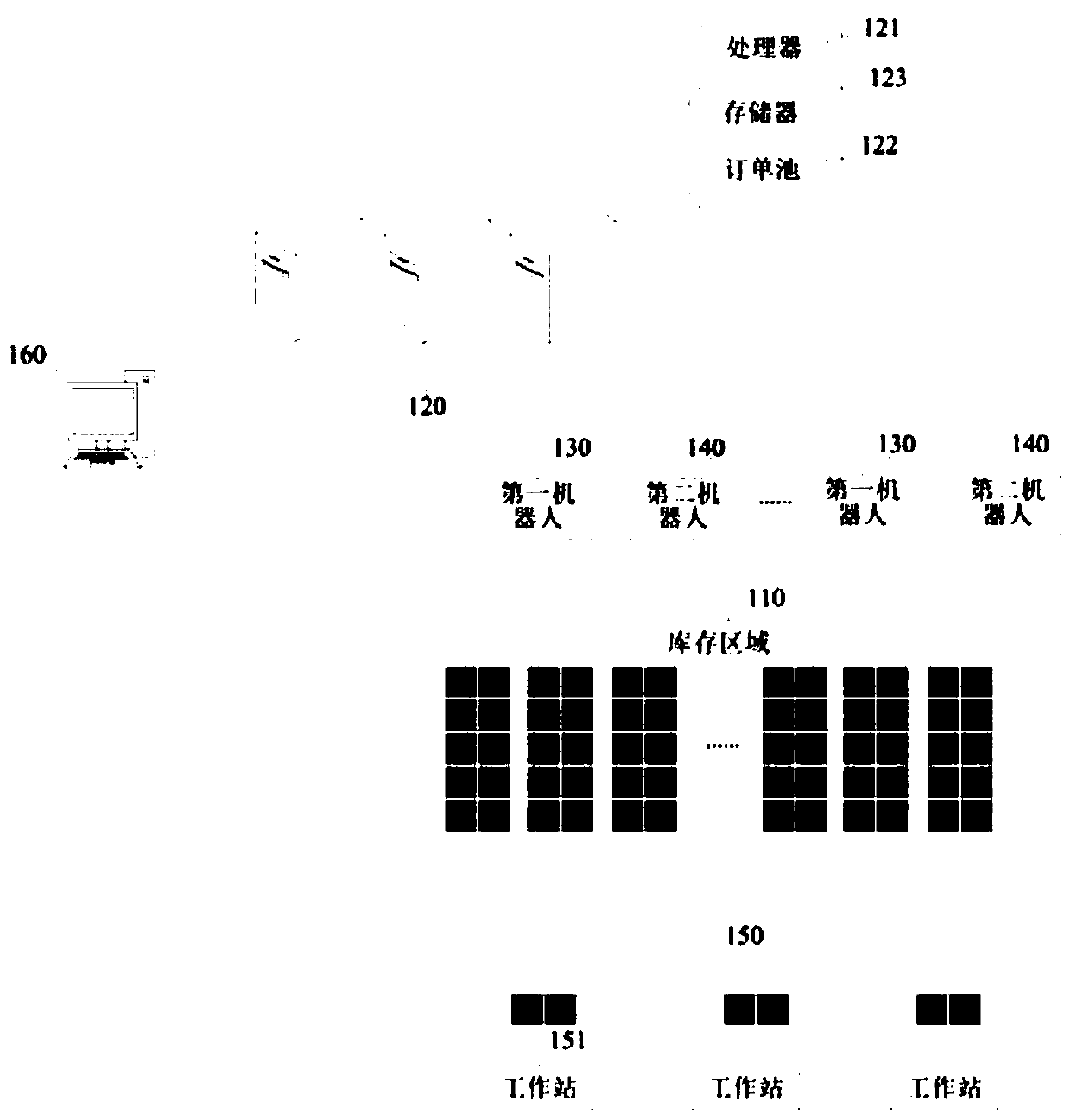

[0079] see figure 1 A schematic structural diagram of a storage system is shown, the system includes: a storage area 110 , a control server 120 , a first robot 130 , a second robot 140 and a workstation 151 .

[0080] The control server 120 communicates wirelessly with the first robot 130 and the second robot 140, and the staff can make the control server 120 work through the console 160, and the first robot 130 and the second robot 140 are controlled by the control server 120. Next, perform their respective tasks. The control server 120 is a software system that runs on the server and has data storage and information processing capabilities, and can be connected to access devices, robots, hardware input systems, and other software systems through wireless or wired connections. The control server 120 may include one or more servers, and may be a centralized control architecture or a distributed computing architecture. The control server 120 has a processor 121 and a memory 1...

Embodiment 2

[0097] In this embodiment, on the basis of the first embodiment, how to carry the storage container is described in detail when the storage system is running in a specific scenario.

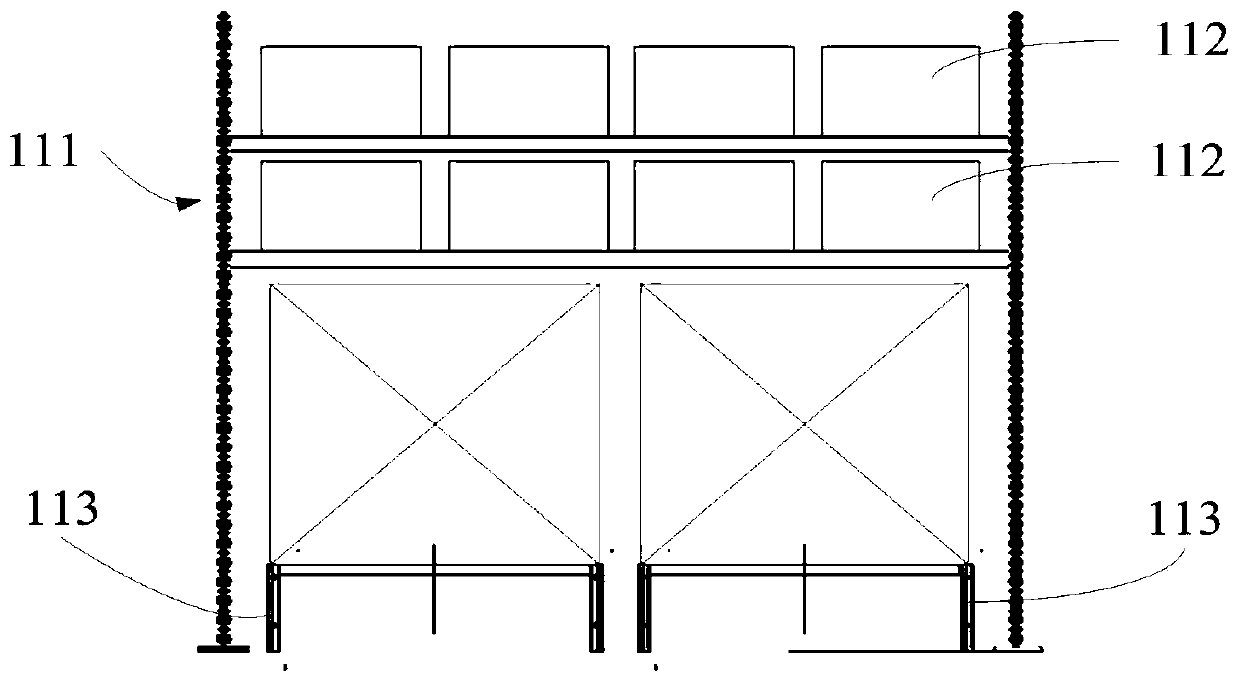

[0098] see Figure 5a Showing the top view of the inventory holder 111, the width direction of the first storage container 112 on the other layers of the inventory holder 111 in the inventory area 110 except the bottom layer is consistent with the depth direction of the laminate of the inventory holder 111, along In the depth direction of the laminate, two first storage containers are placed next to each other on the laminate.

[0099] The control server 120 is further configured to respond to at least two order tasks, wherein the target storage container corresponding to the first order task in the at least two order tasks is the same as the second order task in the at least two order tasks The target storage container corresponding to the order task is at least one of the two first storage con...

Embodiment 3

[0112] This embodiment provides a storage system on the basis of the first embodiment above.

[0113] The control server 120 is configured to, in response to the first order task, determine a first target workstation, a first target storage container, and a first robot 130a for executing the first order task, the first target storage container being the first storage container The container plans a first walking path for the first robot, and sends a first control instruction corresponding to the execution of the first order task to the first robot;

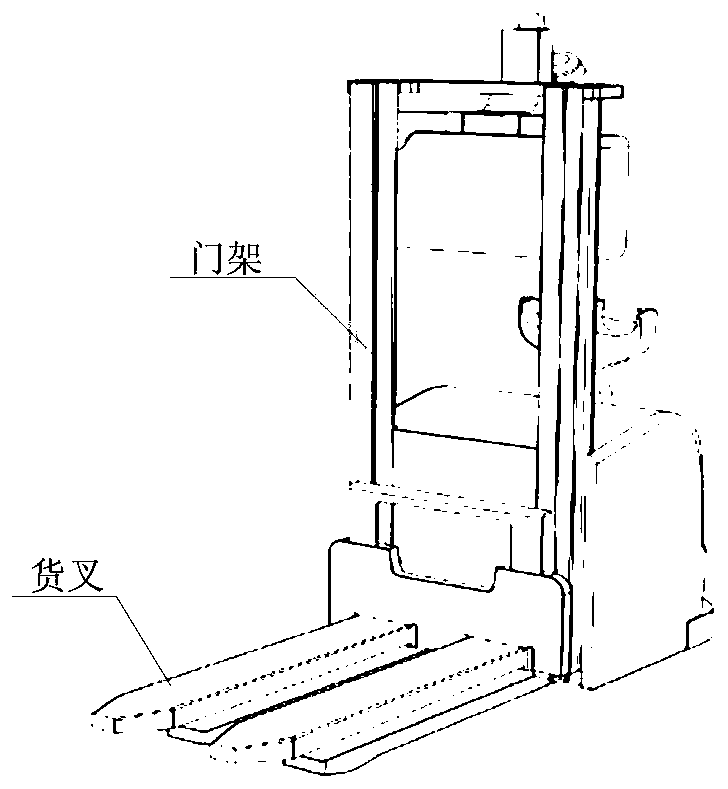

[0114] The first robot 130a is configured to, in response to the first control instruction, walk to the position of the inventory rack where the first target storage container is located according to the planned first walking path, and remove the bottom layer from the inventory rack. Take out the first target storage container and the first storage container adjacent to the first target storage container in the depth direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com