Thermal management system with variable-volume material

a technology of variable volume and management system, applied in the direction of indirect heat exchangers, heat storage plants, lighting and heating equipment, etc., can solve the problems of disruption and noise disturbance, nearly 55% of failures of electronic systems, and up-to-date heat flux in the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

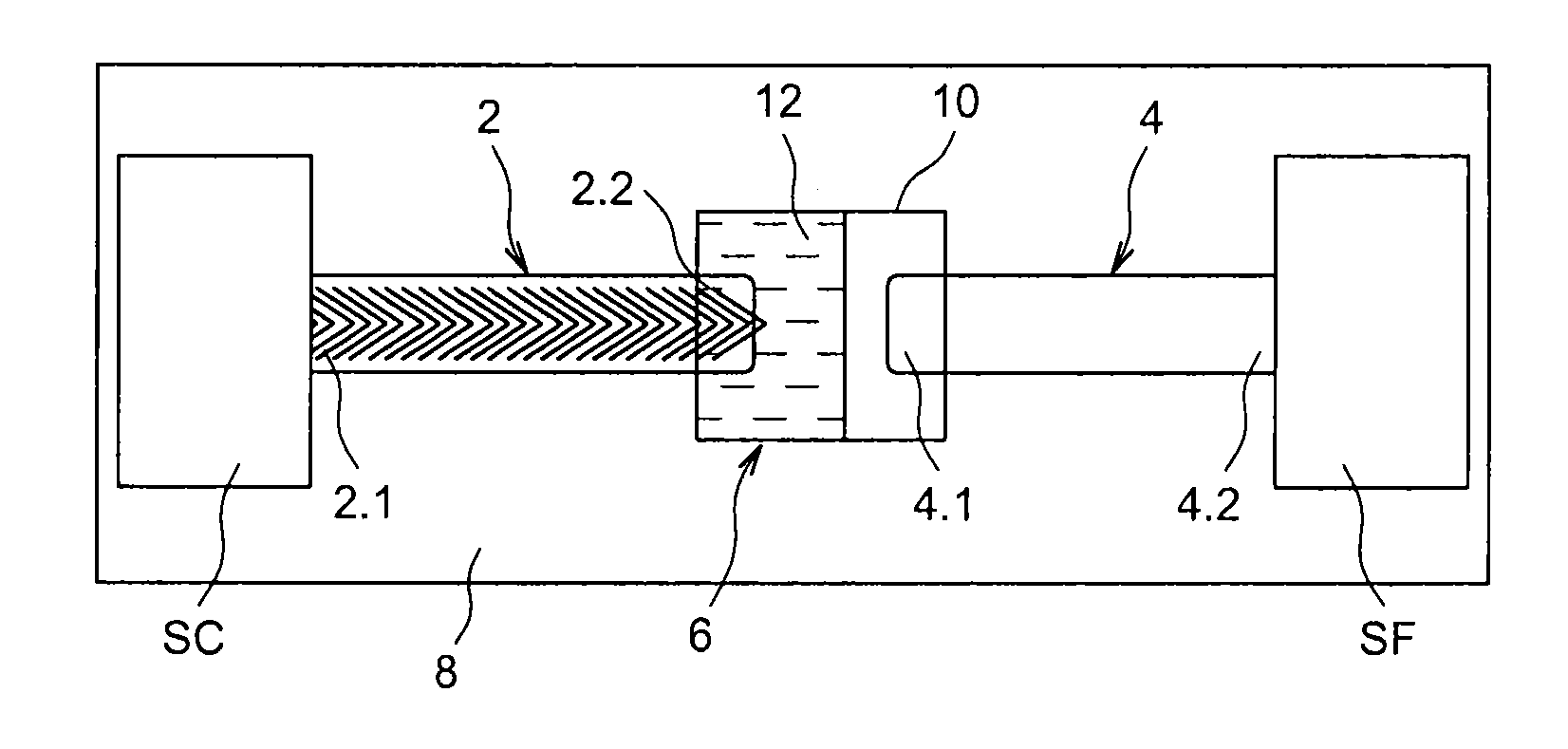

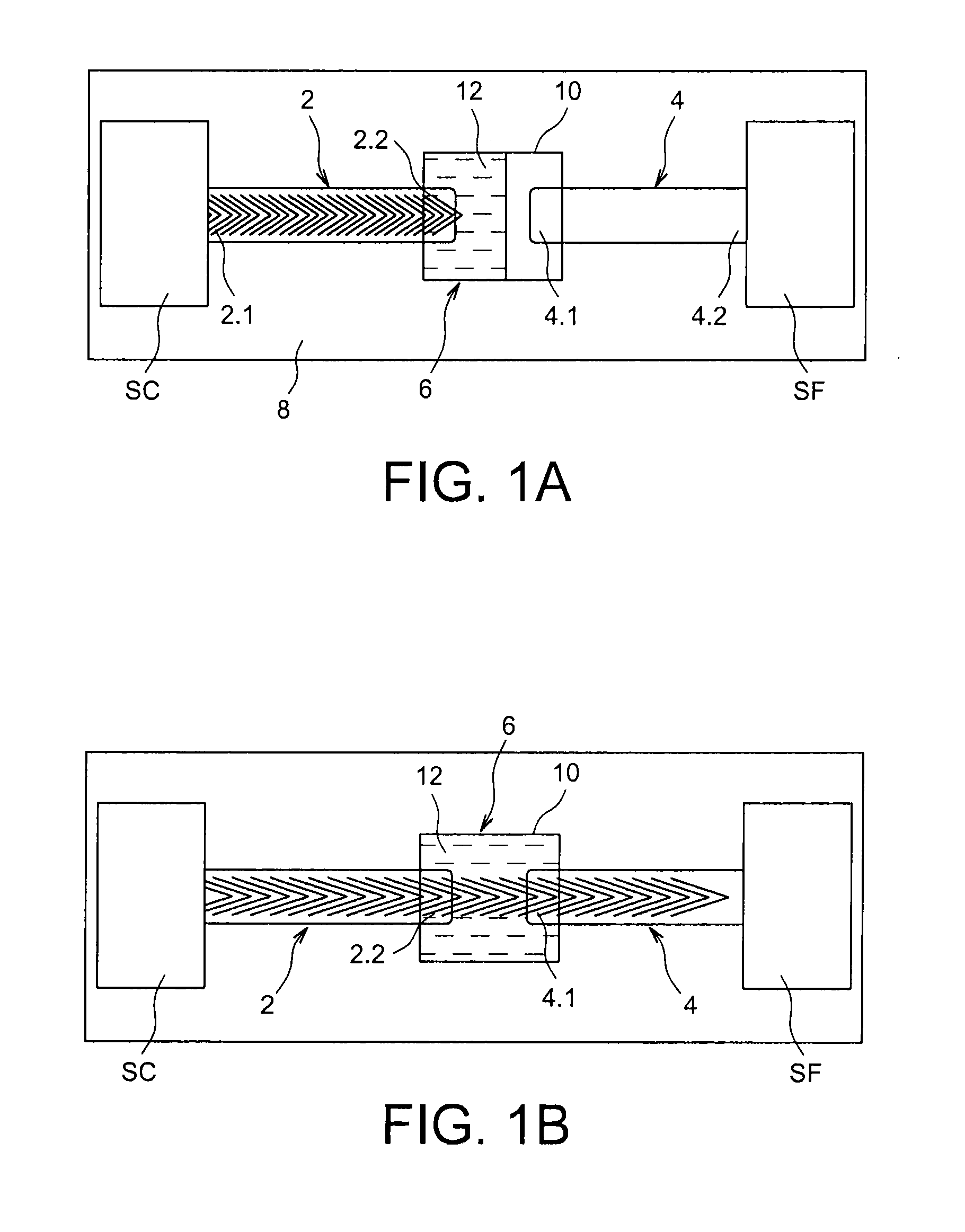

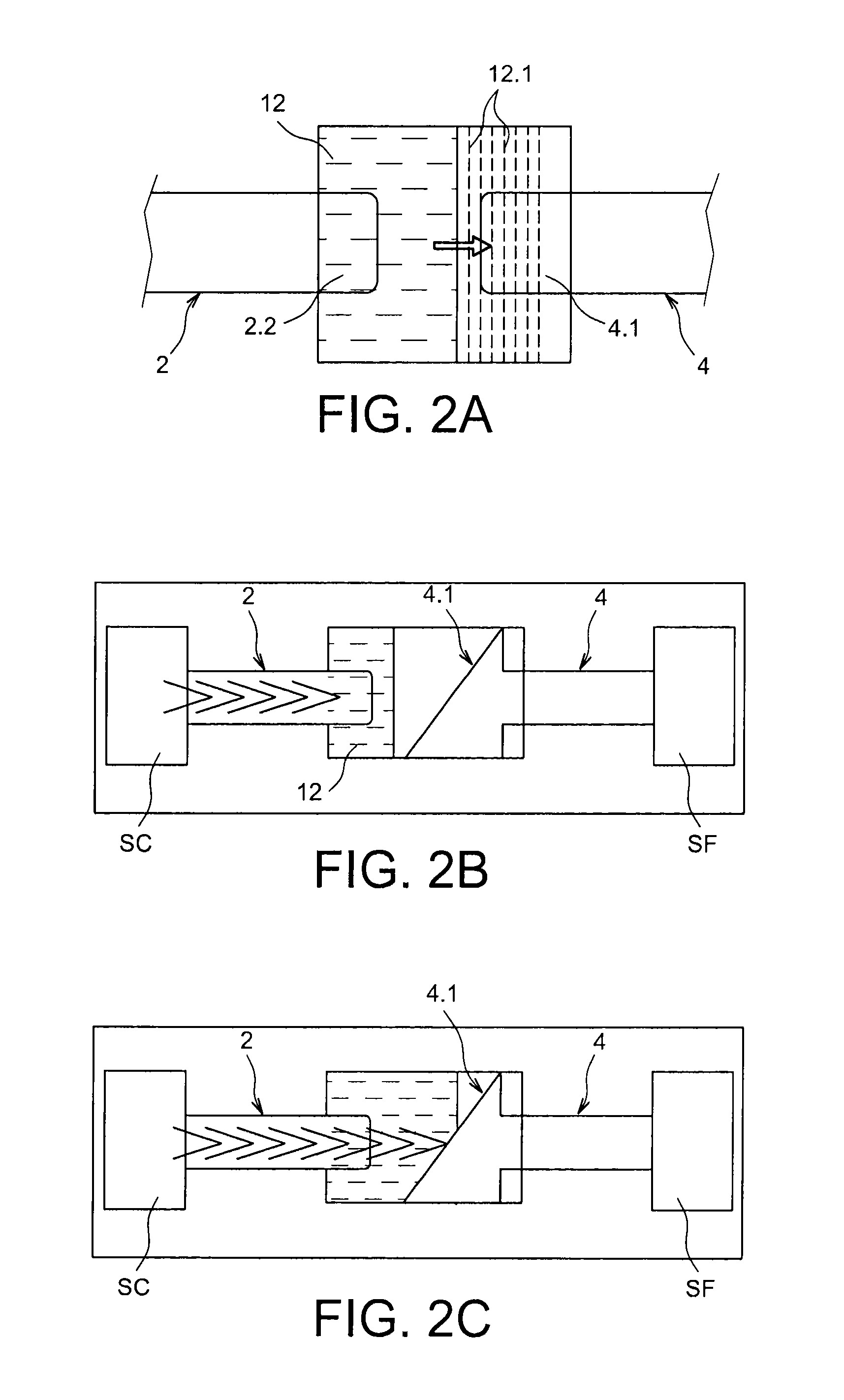

[0012]The aim of the present invention is to provide a simple and robust system for thermal management of the operating heat flux, which is able to guide the heat flux, for example with a view to its dissipation.

[0013]The aim stated above is attained through a thermal management system comprising means able to put two heat conductors in thermal communication, or to prevent such communication these means comprising a material the volume of which varies according to temperature changes. The variable-volume material may therefore be heated for example either by one of the conductors or by an additional heat conductor forming thermal control means.

[0014]Management of the heat transfer between the two conductors can then be accomplished automatically and very safely.

[0015]In one embodiment, the thermal management system according to the invention may then form a thermal switch made of a volume-expansion material, this switch allowing, in its closed state, heat conduction between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com