Friction deformation-triggered self-propagating assistant aluminum/steel friction stirring overlapping method

A friction stir, self-propagating technology, used in aluminothermic welding equipment, welding/welding/cutting items, welding equipment, etc., can solve problems such as welding tool wear, reduce wear, improve joint performance, and increase effective lap area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

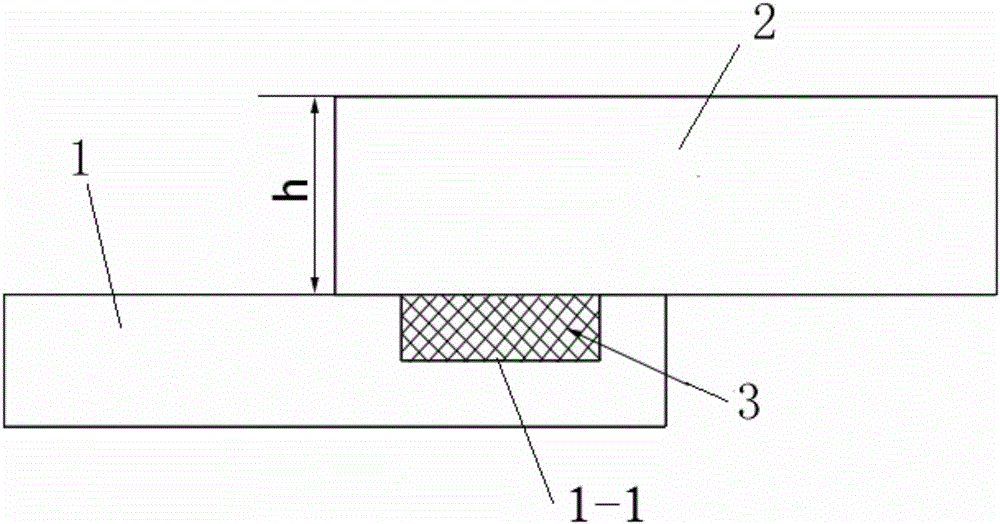

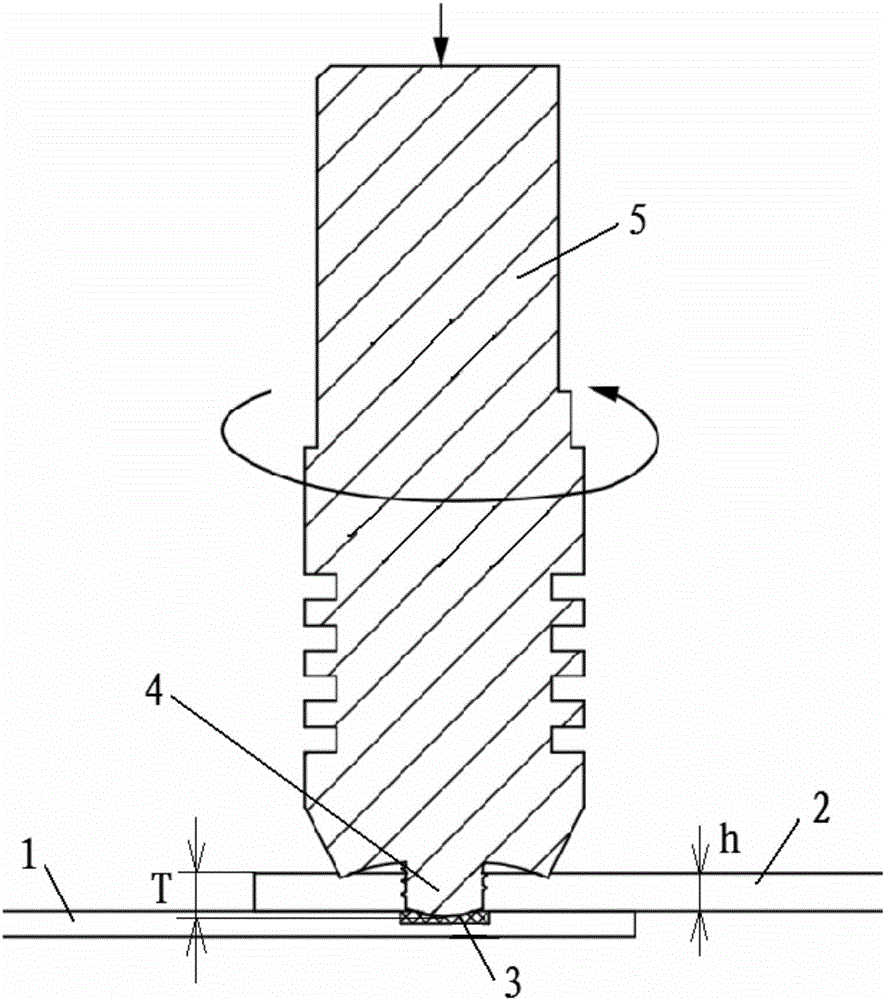

[0019] Specific implementation mode one: combine figure 1 and figure 2 Describe this implementation mode, this implementation mode is realized through the following steps:

[0020] Step 1. Determine the overlapping area of the joint between the steel plate 1 and the aluminum plate 2, and open a square groove 1-1 at the center line of the overlapping part on the steel plate 1;

[0021] Step 2: Clean up the contact surface of the steel plate 1 and the aluminum plate 2 to be welded and the surrounding area of 20 mm to 30 mm, and remove the oxides on the surface of the steel plate 1 and the aluminum plate 2;

[0022] Step 3, using an organic solvent to wipe the surfaces of the mechanically treated steel plate 1 and aluminum plate 2 to remove oil, dust and other sundries;

[0023] Step 4, evenly filling the square tank 1-1 with a certain proportion of the mixture 3 of powdered Fe2O3, aluminum powder and powdered gunpowder;

[0024] Step 5. Combine the processed steel plate ...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 1 To describe this embodiment, in this embodiment, the steel plate 1 in step 1 is ordinary low-carbon steel or low-alloy steel, and the aluminum plate 2 is pure aluminum or aluminum alloy. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 1 Describe this embodiment. In this embodiment, the groove depth of the square groove 1 - 1 in step 1 is 0.1 mm to 0.3 mm, and the groove width is 1 mm to 2 mm larger than the diameter of the stirring pin 4 . Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com