Metal fusion welding method

A welding method and fusion welding technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of reducing the stability and electrical conductivity of joints, as well as mechanical strength, thermal cracks and pores, etc., so as to achieve stable and firm welding joints, reduce Sensitive, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

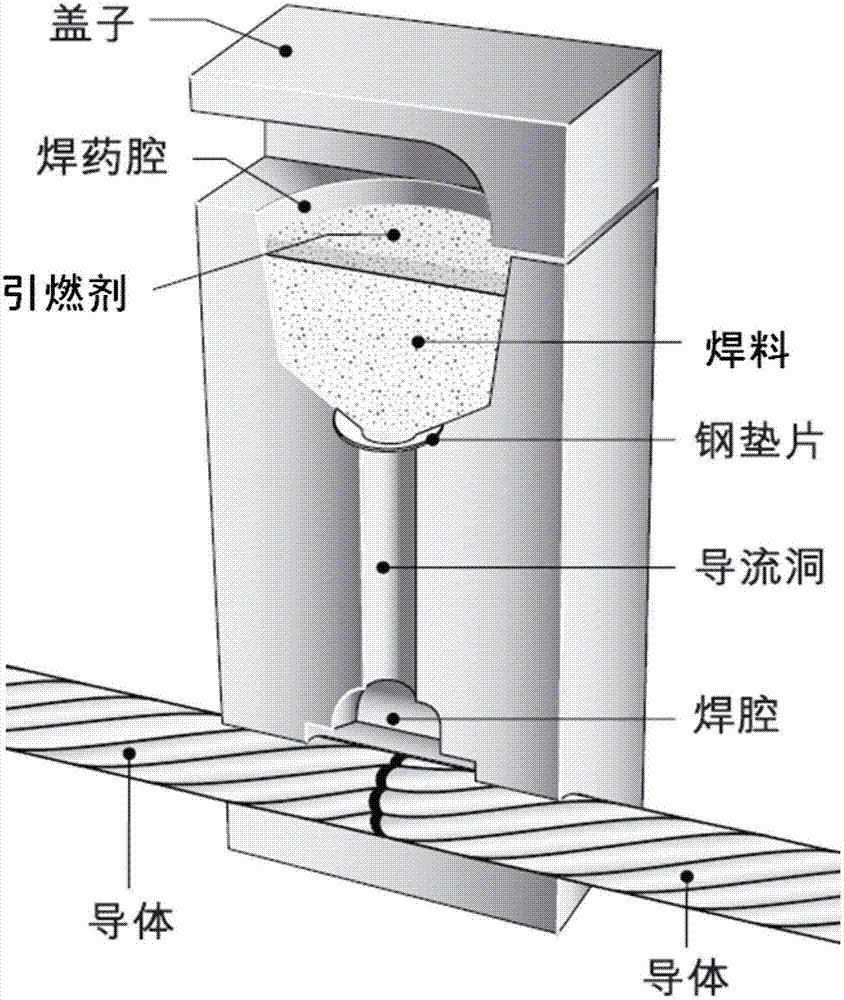

Image

Examples

Embodiment 1

[0026] The metal fusion welding method comprises the following steps:

[0027] To prepare lead-free exothermic solder:

[0028] Take the following raw materials by weight:

[0029] A) oxidation rate 20%-80%, 100 parts of copper oxide of 40 mesh-100 mesh,

[0030] B) 35 parts of 100-200 mesh aluminum powder,

[0031] C) 5 parts of magnesium powder,

[0032] D) Toner 5 copies

[0033] E) 4 parts of metal indium.

[0034] Add all raw materials into WH-500 double cone high-efficiency mixer (Wuxi Haohao Powder Equipment Factory), and mix for 10 minutes to obtain exothermic flux.

[0035] To prepare lead-free exothermic solder igniter:

[0036] Take the following raw materials by weight:

[0037] Magnesium powder 40 mesh-200 mesh 100 parts;

[0038] Copper oxide 100 mesh - 200 mesh 50 parts;

[0039] 15 parts of nano silver powder;

[0040] 12 parts of potassium permanganate;

[0041] 4 parts of nickel powder.

[0042] Add all the raw materials into the WH-500 double con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com