Faster welding method for armored vehicle aluminium alloy part for emergency in battlefield

A technology for rapid welding of aluminum alloy parts, applied in aluminothermic welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific examples of emergency rapid welding of aluminum alloy parts for armored vehicles on the battlefield:

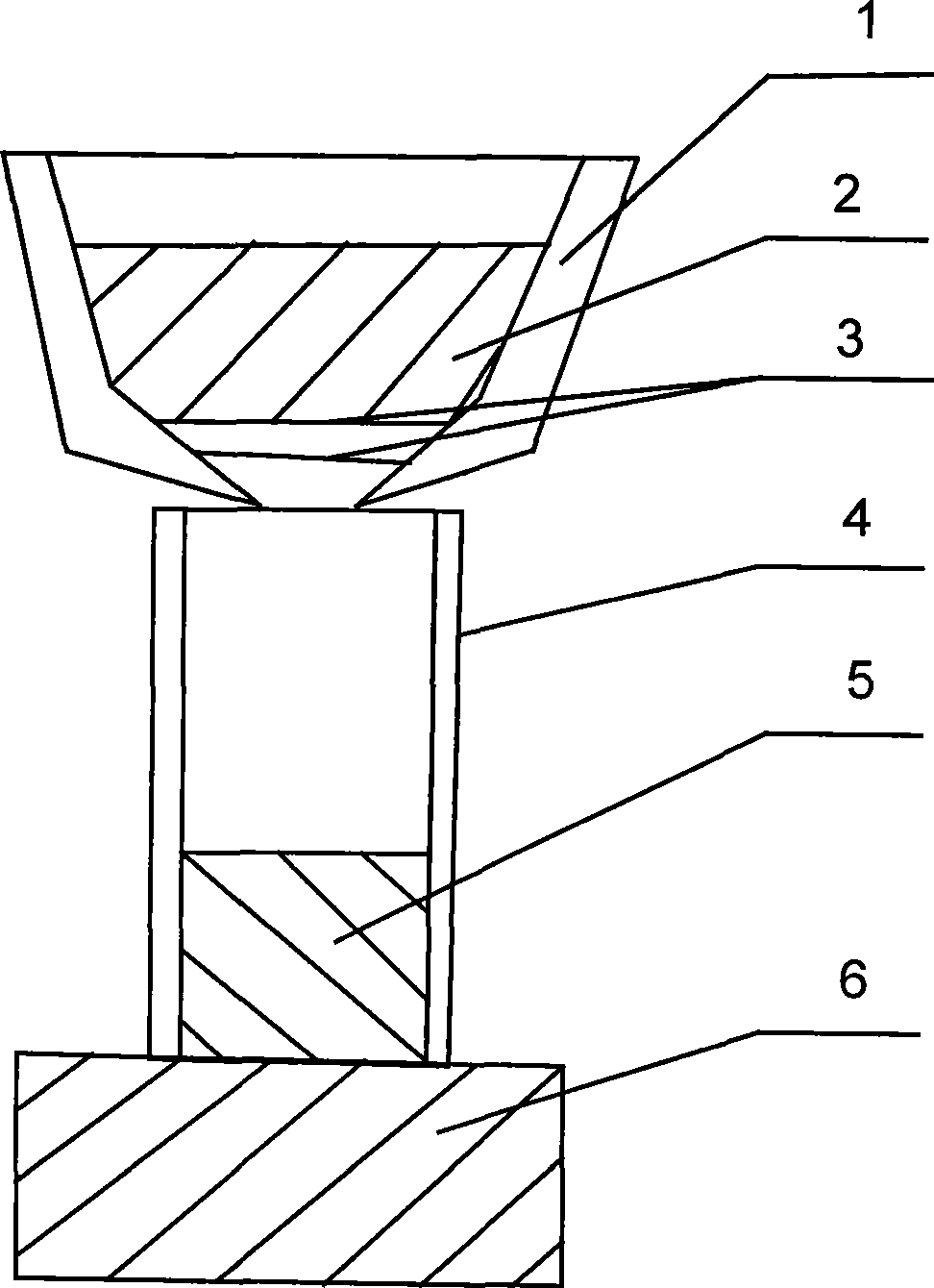

[0014] 1. The resin crucible 1 is filled with thermite flux, and the lower hole of the resin crucible is blocked with a 3mm thick asbestos pad, and 2mm of titanium powder is spread between the asbestos pad and the aluminotherm flux. Set aluminum sheet. The bottom is refractory material 6, which is used for heat preservation. When welding, use a windproof lighter to ignite the TiC powder, and then ignite the aluminothermic casting flux through the ignited TiC powder to produce a mixture liquid of iron and titanium. When it burns through the asbestos pad, it flows down and contacts the solid aluminum alloy to melt it. , through the chemical reaction of titanium in the liquid with the aluminum below and the iron above, the rapid welding of dissimilar metals of steel-titanium-aluminum is realized. In order to increase the density of welded joints, refine the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com