Continuous production process of polyethylene (PE) breathable film

A production process and technology of breathable film, applied in the field of continuous PE breathable film production process, can solve the problems of difficult quality assurance, increased cost, and high packaging costs, and achieve the effect of improving performance and quality, reducing capital occupation, and reducing warehouse occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail by the following examples.

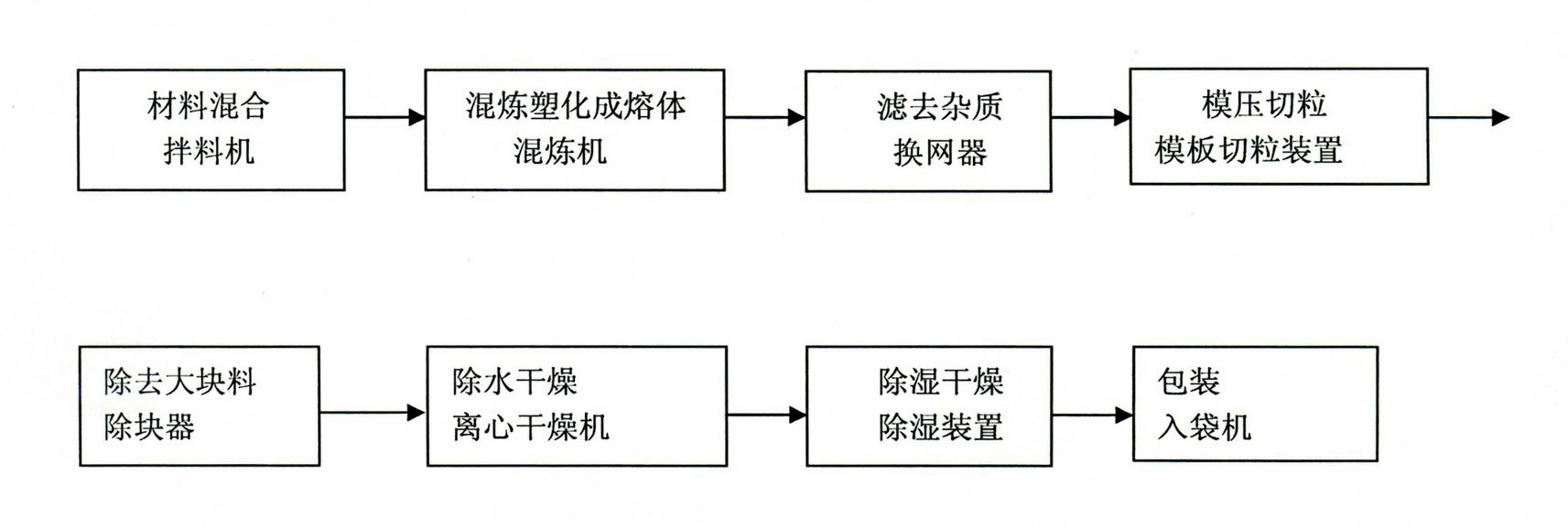

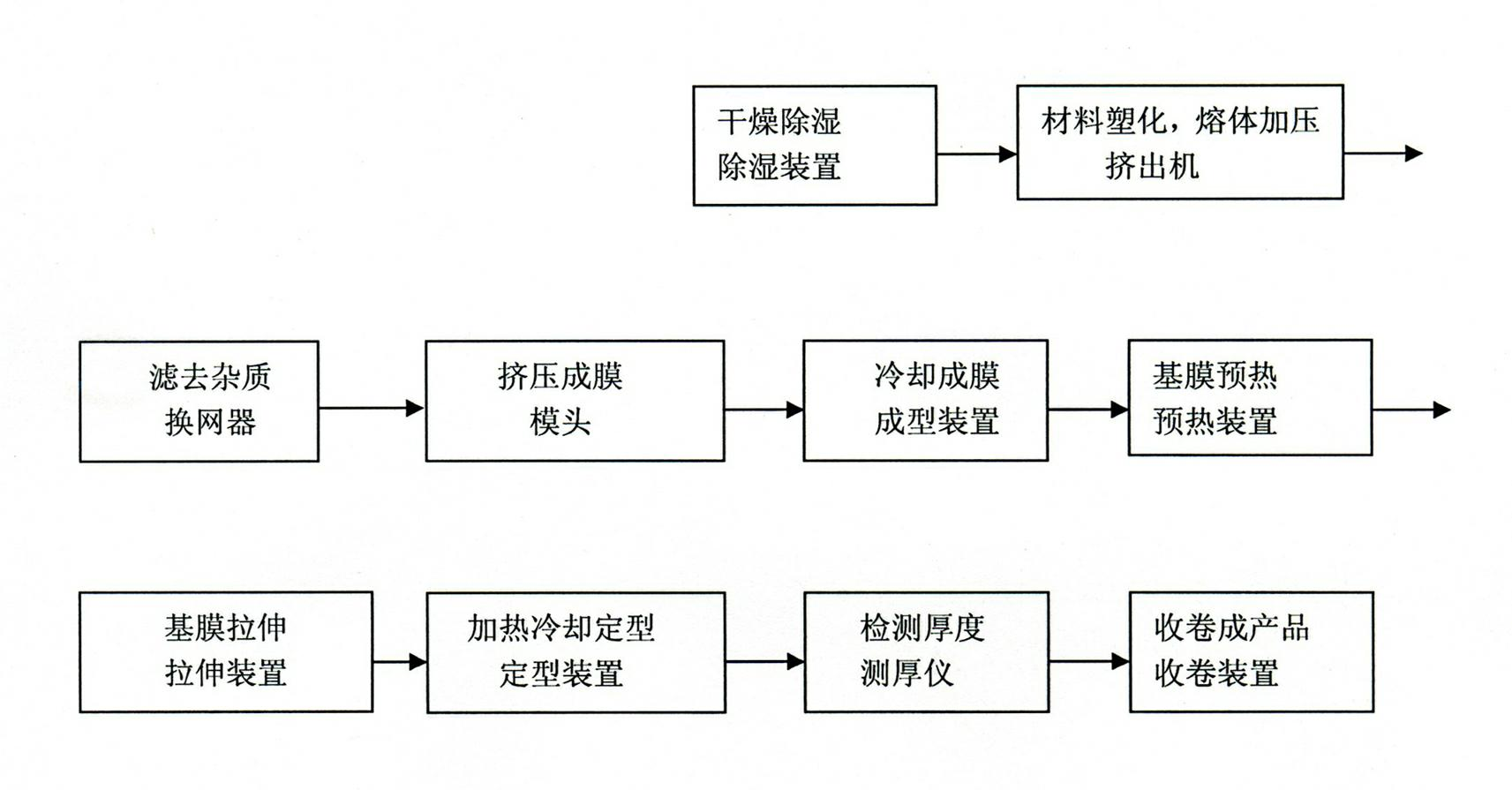

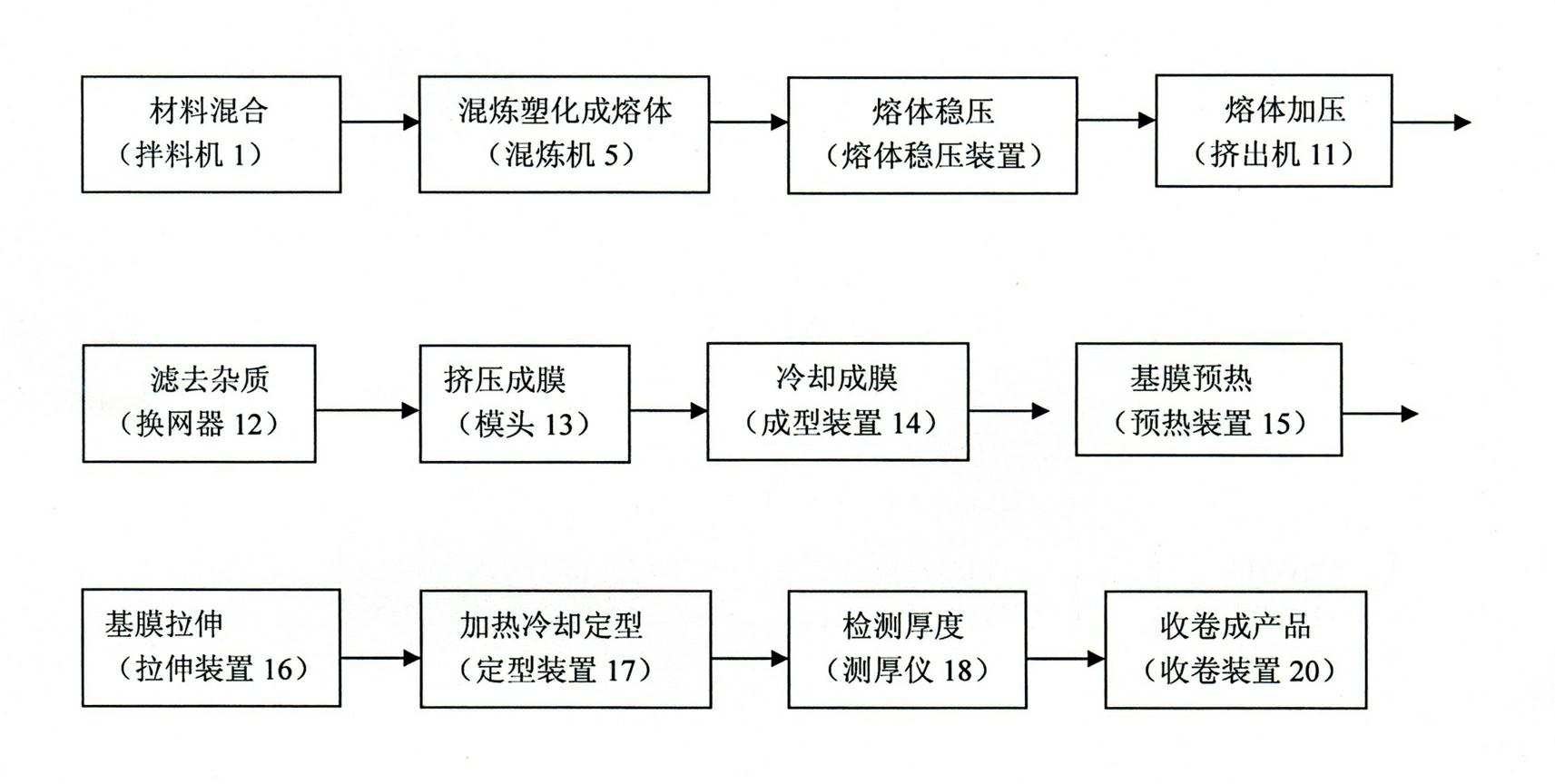

[0032] refer to image 3 , Figure 4 As shown, the production process of a continuous PE breathable membrane is as follows:

[0033](1) Put the conventional ratio of 44.5-54.5% polyethylene by weight, 45-55% calcium carbonate, and 0.5% additives (including lubricants and antioxidants) into the mixer Mix evenly in 1 mile, then add in the kneader 5 through the hopper 2, the kneader 5 is driven by the frequency conversion motor 3 and the gear box 4, and the kneader 5 is provided with feeding section 5-1, kneading plastic Chemical section 5-2, emptying section 5-3. The mixed material is gradually heated to about 130°C while advancing through the feeding section 5-1 of the mixer 5, and then advanced to the mixing and plasticizing section 5-2, and the temperature of the material is gradually heated from 140°C to about 180°C , because this section has a strong kneading, shearing and kneading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com