Catalysts for olefin polymerization, process for production of the catalysts, and method for preservation thereof

A technology of olefin polymerization and manufacturing method, which is applied in the field of catalysts for olefin polymerization, can solve the problems of high energy consumption, poor dispersion of antioxidants, low efficiency, etc., and achieve the effects of energy reduction, excellent long-term preservation, and good powder properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

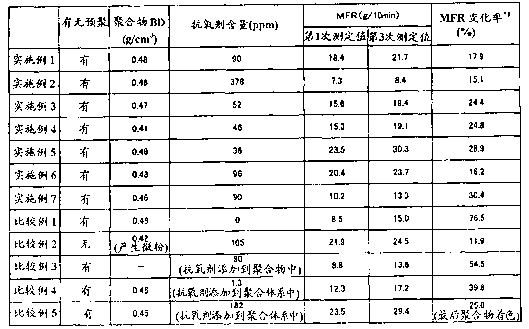

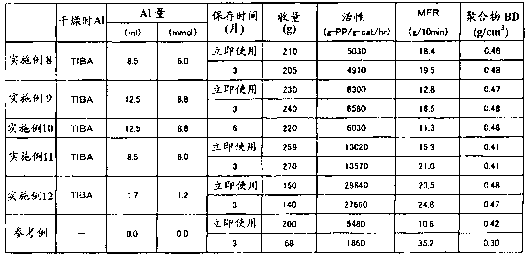

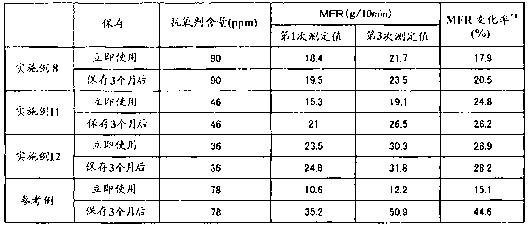

Examples

Embodiment 1

[0271] (1) Synthesis of catalyst

[0272] 1700 g of pure water was added to a 5 L detachable flask equipped with a stirring blade and a reflux device, and 500 g of 98% sulfuric acid was added dropwise. Further, 300 g of granulated montmorillonite (manufactured by Mizusawa Chemical Industry Co., Ltd., Benclay SL) with an average particle diameter of 45 μm was added, followed by stirring. Then, it was reacted at 90° C. for 2 hours. The slurry was filtered and washed. 1230 g of 27% lithium sulfate aqueous solution was added to the recovered filter cake, and it was made to react at 90 degreeC for 2 hours. The slurry was filtered, and then washed so that the pH of the filtrate became 4 or higher. The recovered filter cake was pre-dried at 100°C and then dried at 200°C for 2 hours. As a result, 275 g of chemically treated montmorillonite was obtained. The average particle diameter was 43 μm, the shape was spherical, and the number of particles whose M / L value was 0.8 to 1.0 was...

Embodiment 2

[0283] A polymer was obtained in the same manner as in Example 1 except that the polymerization time in Example 1(3) was changed to 15 minutes. The polymer produced was 50 g. This polymer was evaluated for stabilization in the same manner as in Example 1. Table 1 shows the evaluation results. MFRs are stable.

Embodiment 3

[0291] (1) Prepolymerization

[0292] After preparing the catalyst in the same manner as in Example 1, tetrakis[methylene-3-(3', 5'-di-tert-butyl-4'-hydroxyphenyl) was used as a phenolic stabilizer in a 50 ml flask. ) propionate] 5 ml of 30% by weight heptane solution of methane and 5 ml of 30% by weight heptane solution of tris(2,4-di-tert-butylphenyl phosphite) as a phosphorus stabilizer were mixed, and then added to Stir in the above 1 L flask for 30 minutes.

[0293] All of the above-mentioned slurry was introduced into a stirring autoclave having an internal volume of 1.0 L after being sufficiently replaced with nitrogen. When the temperature was stabilized at 40°C, propylene was supplied at a rate of 10 g / hour to maintain the temperature. After 2 hours, the supply of propylene was stopped and maintained for another 1 hour. After the prepolymerization was finished, the residual monomers were removed, the stirring was stopped, and the slurry was pumped into a 1L flask f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com