A processing system for the integrated production of α-hemihydrate gypsum with rotary autoclaving and drying

A hemihydrate gypsum and processing system technology, applied in the field of industrial raw material production and processing systems, can solve the problems of large waste of steam, difficulty in ensuring product quality, easy blockage of pipelines, etc., to achieve improved production capacity, improved recovery rate, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

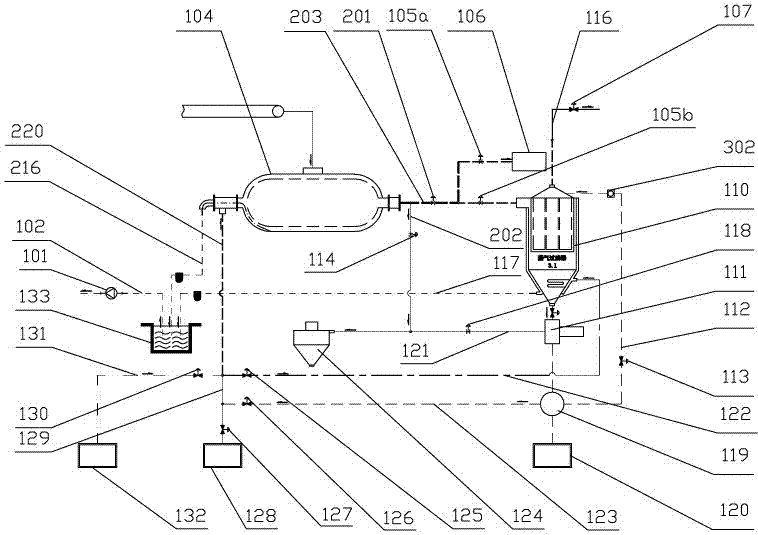

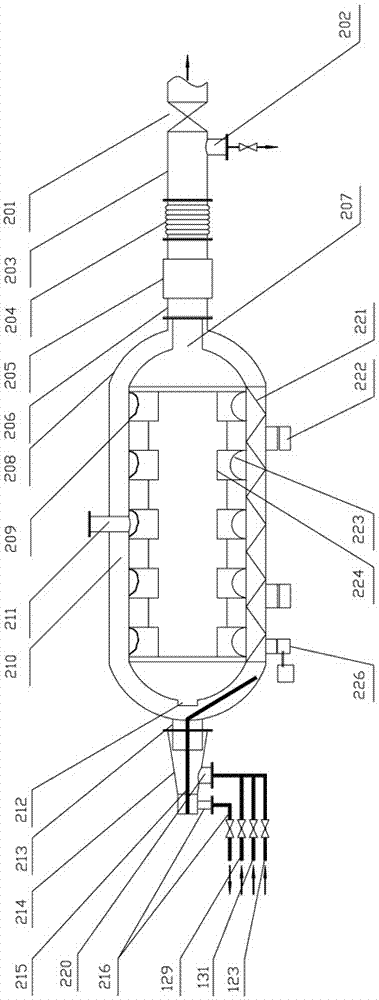

[0038] Example 1: Scheme one of the present invention, see figure 1 , it includes a special rotary autoclave drying kettle 104 and two steam filter dust collectors A, B 106 and 110, as well as saturated steam boiler 128, superheated steam boiler 132, air compressor 120, gas storage tank 119, powder Silo 124, sump 133; described rotary autoclave drying kettle 104, see image 3 , it has a horizontal cylindrical housing 208, equipped with a rotating supporting wheel set 222 and a rotating drive mechanism 226, especially: the right end of the housing 208 is provided with an air intake main pipe 213, and the left end is provided with a discharge air pipe 206. The main pipe is covered with a rotary joint A214, and the rotary joint A214 is equipped with an air intake main pipe 220 and a condensed water discharge pipe A216; the condensed water discharge pipe A216 is connected to the sump 133 for recycling. A material tank 209 is installed in the housing 208 through a bracket. A steam...

example 2

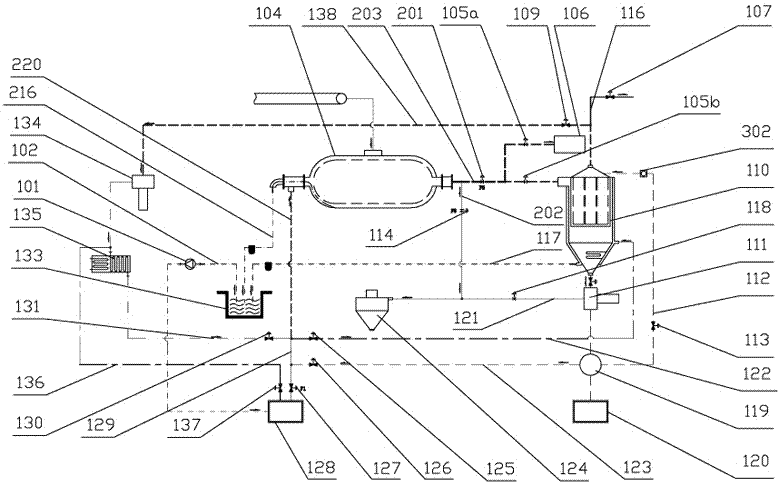

[0059] Example 2: see figure 2 , the second solution of the present invention is to improve and improve the solution of example 1, to recycle the steam in the system, so as to realize energy saving and consumption reduction. Its basic structure is the same as Example 1, the difference is that a simple steam boiler is used to provide saturated steam, the superheated steam boiler 132 is removed, and a superheated steam generator 135 is added in the system to provide a superheated steam source for the rotary autoclave drying kettle 104, and an additional steam boiler is added. The compressor 134 provides the source of circulating steam for the superheated steam generator, and the inlet end of the supercharger 134 is connected to the purification discharge port of the steam filter dust collector 110 through the air return pipe A and the valve 109 for steam recovery; and the superheated steam generator 135 The saturated steam boiler 128 is connected through the air supply pipe 136...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com