Electroless welding type welding rod and preparation and welding method thereof

A welding rod and bonding technology, applied in the field of electroless welding electrode and its preparation and welding, can solve the problems of long bonding and curing time, large engineering, limited application, etc., to solve emergency welding maintenance, simple and rapid operation , The effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

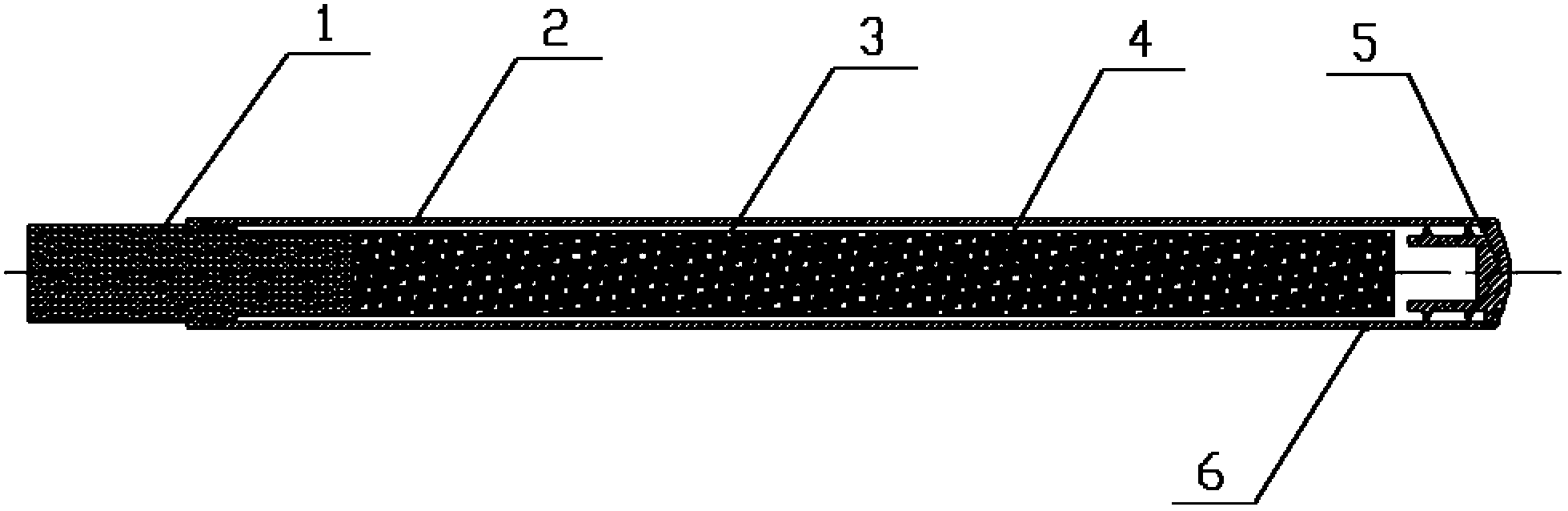

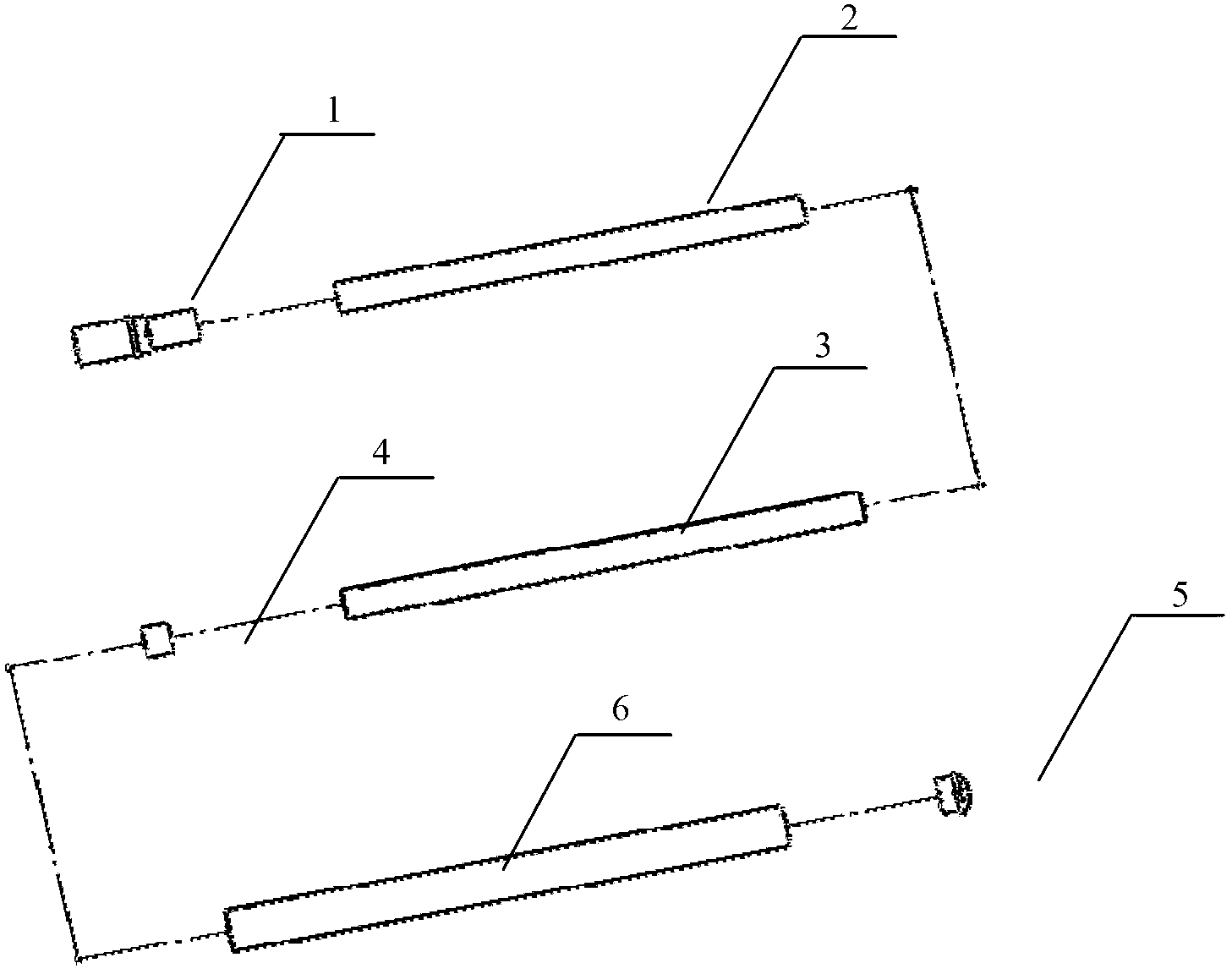

[0019] see figure 1 and figure 2 , the electroless welding electrode of the present invention comprises a plug 1, a powder column 2, a paper tube 3, a fire cap 4, a tube plug 5 and a sleeve 6; the plug 1 and the paper tube 3 are coaxially bonded by latex Together, the powder column 2 and the fire starter 4 are formed in the paper tube 3, the sleeve 6 is set on the paper tube 3, one end of the sleeve 6 is tightly connected with the plug 1, and the other end is sealed by the tube plug 5 . The main system of grain 2 is CuO+Al, Fe 2 o 3 +Al, SiO 2 , CaO, TiO 2 and silicates. In terms of mass percentage, the composition ratio of the powder column is: CuO+Al: 40.03-40.60%; Fe 2 o 3 +Al: 30.05~30.90%; CaO: 12.4~13.40%; SiO 2 : 6.2~7.50%; CaF 2 : 0.5~0.90%; TiO 2 Ni: 4.3~5.6%; Ni: 1.02~1.40%; Mn: 2~3%; Ti: 2~3.4%.

[0020] The present invention proposes a method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com