Rice antistaling agent as well as preparation method and application thereof

A preservative and rice technology, which is applied in the field of rice preservatives and its preparation, can solve problems such as destruction, reduction of rice edible and nutritional value, and reduction of rice storage time, so as to achieve the effect of preventing rice spoilage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

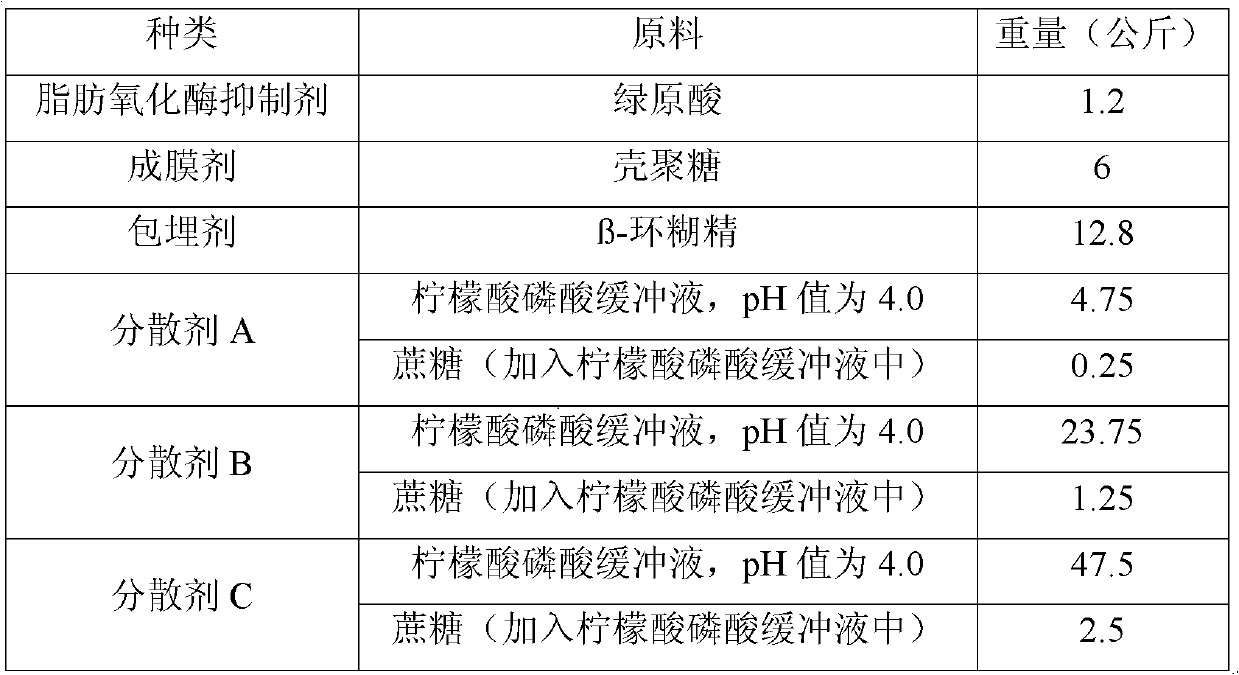

[0039] Weigh the raw materials according to the composition of the table below:

[0040] type

Weight (kg)

lipoxygenase inhibitors

1

Film former

5

10

Dispersant A

Citrate phosphate buffer, pH 4.0

5

Dispersant B

Citrate phosphate buffer, pH 4.0

25

Dispersant C

Citrate phosphate buffer, pH 4.0

54

[0041] Utilize the raw material in the table, carry out the preparation of following process:

[0042] (1) Dissolving the film-forming agent in the dispersant A to form a film-casting liquid, filtering the film-casting liquid to remove impurities, leaving it to stand, defoaming, and obtaining a cross-linked film-forming agent for later use.

[0043] (2) Add the lipoxygenase inhibitor into the dispersant B to make a mother liquor for later use.

[0044] (3) Dissolve the embedding agent in dispersant...

Embodiment 2

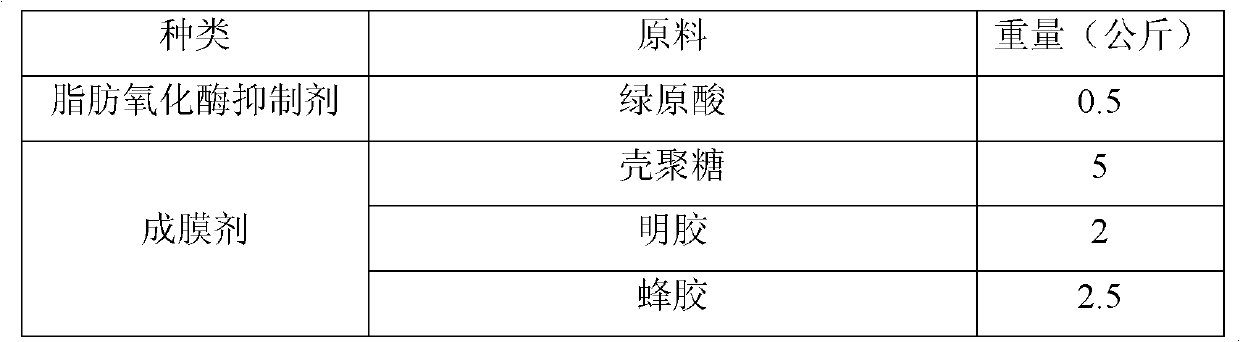

[0048] Weigh the raw materials according to the composition of the table below:

[0049] type

Weight (kg)

lipoxygenase inhibitors

2

[0050] Film former

10

14

Dispersant A

Citrate phosphate buffer, pH 5.0

8

Dispersant B

Citrate phosphate buffer, pH 5.0

25

Dispersant C

Citrate phosphate buffer, pH 5.0

41

[0051] Utilize the raw material in the table, carry out the preparation of following process:

[0052] (1) Dissolving the film-forming agent in the dispersant A to form a film-casting liquid, filtering the film-casting liquid to remove impurities, leaving it to stand, defoaming, and obtaining a cross-linked film-forming agent for later use.

[0053] (2) Add the lipoxygenase inhibitor into the dispersant B to make a mother liquor for later use.

[0054] (3) Dissolve the embedding age...

Embodiment 3

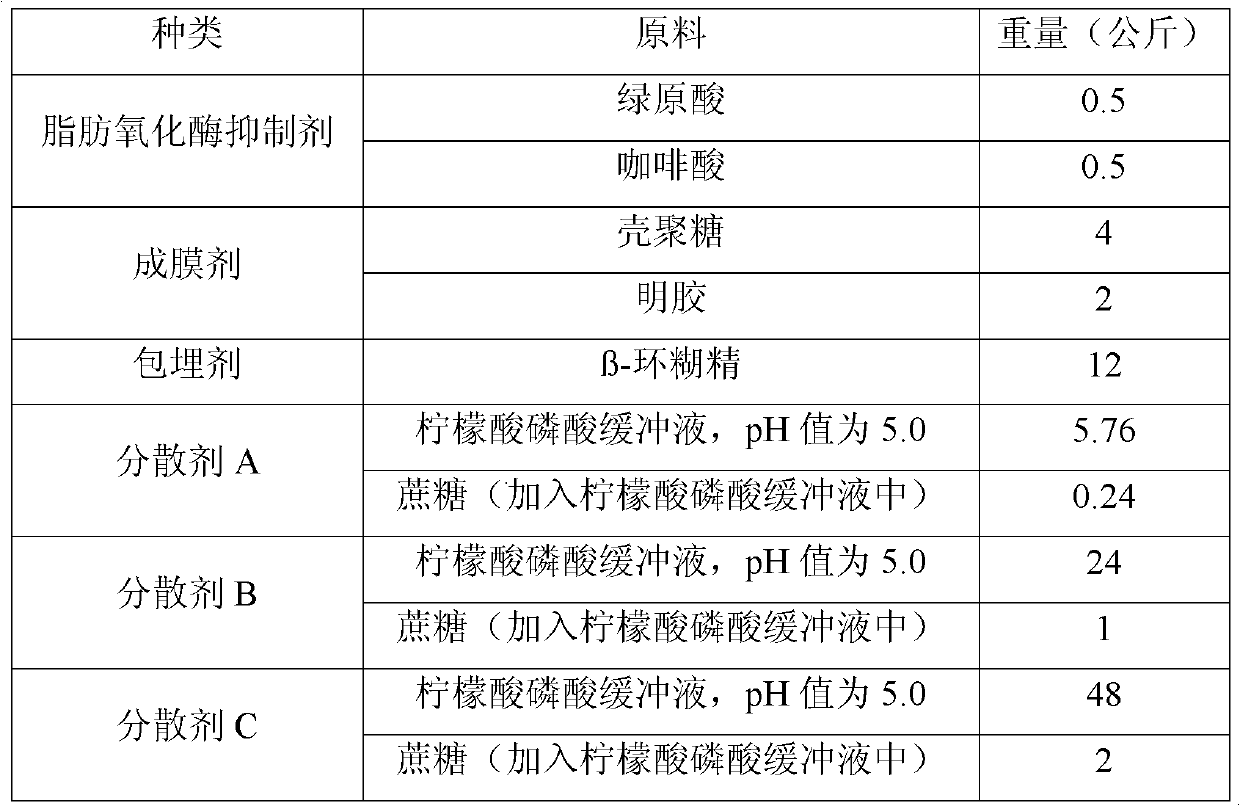

[0058] Weigh the raw materials according to the composition of the table below:

[0059]

[0060]

[0061] Utilize the raw material in the table, carry out the preparation of following process:

[0062](1) Dissolving the film-forming agent in the dispersant A to form a film-casting liquid, filtering the film-casting liquid to remove impurities, leaving it to stand, defoaming, and obtaining a cross-linked film-forming agent for later use.

[0063] (2) Add the lipoxygenase inhibitor into the dispersant B to make a mother liquor for later use.

[0064] (3) Dissolve the embedding agent in dispersant C, heat to 55°C and keep it warm for 10 minutes, then add the cross-linked film-forming agent obtained in step (1) and the mother liquor obtained in step (2), and stir for 1.5 h, the rotating speed of the stirring paddle is 450 rpm, and a white turbid liquid rice preservative is obtained.

[0065] When the rice is polished, the rice preservative prepared in this embodiment is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com