Manufacturing method of coconut blade freezing slice

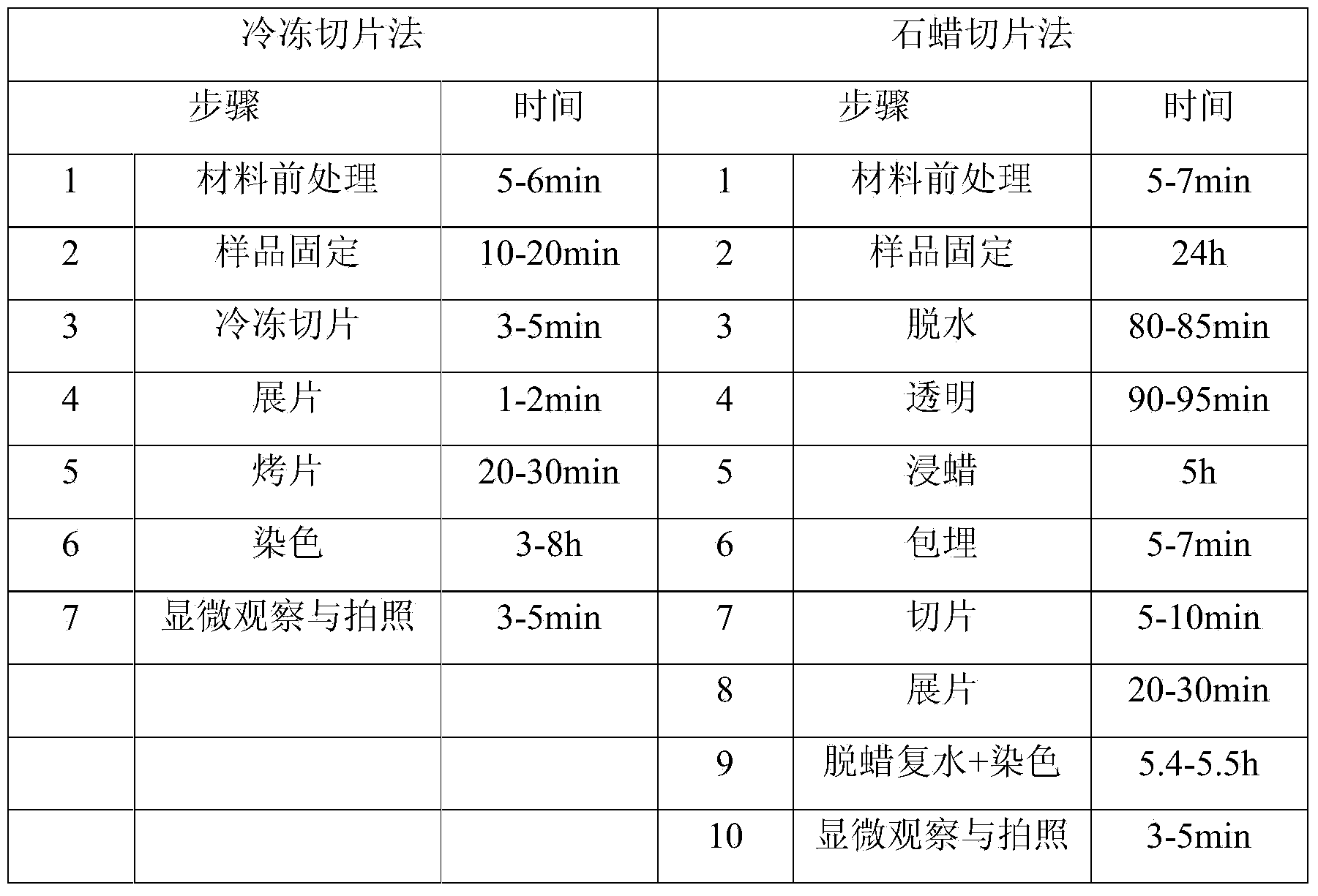

A technology of frozen section and production method, which is applied in the field of production of plant frozen section and coconut leaf frozen section, which can solve the problems of uneven thickness, short production cycle, cumbersome process, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] 1. Material pretreatment: Take the third leaf from the top of the 2-year-old coconut seedling, wash the leaf twice with clean water, and then wash it again with distilled water, wash it lightly, dry it, and quickly cut it into 2mm×4mm pieces with a blade small sample;

[0021] 2. Sample fixation: add 2 drops of tissue OCT freezing embedding agent to the base of the cold stage of the Leica LM1900 cryostat, use hard paper to make a cuboid with a side length of 6mm and a height of 8mm and stick it on the base, and then place the step 1 ) The obtained leaf tissue sample was vertically placed on the sample holder, and 5 drops of frozen embedding agent was added to completely wrap the leaf tissue sample, and placed on the sample stage of the Leica LM1900 cryostat, and placed for 15min, that is Frozen sectioning is possible.

[0022] 3. Frozen section: cut off the outer carton of the sample, and cut the embedding agent block with coconut leaves (hereinafter referred to as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com