Device and technology for preparing engineering embedding fixing microorganism spheric bodies

A technology of embedding, immobilization and microorganisms, which is applied in the field of remediation of polluted water environment, can solve the problems such as the inability of large-scale engineering of microorganism technology, and achieve the effect of excellent stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

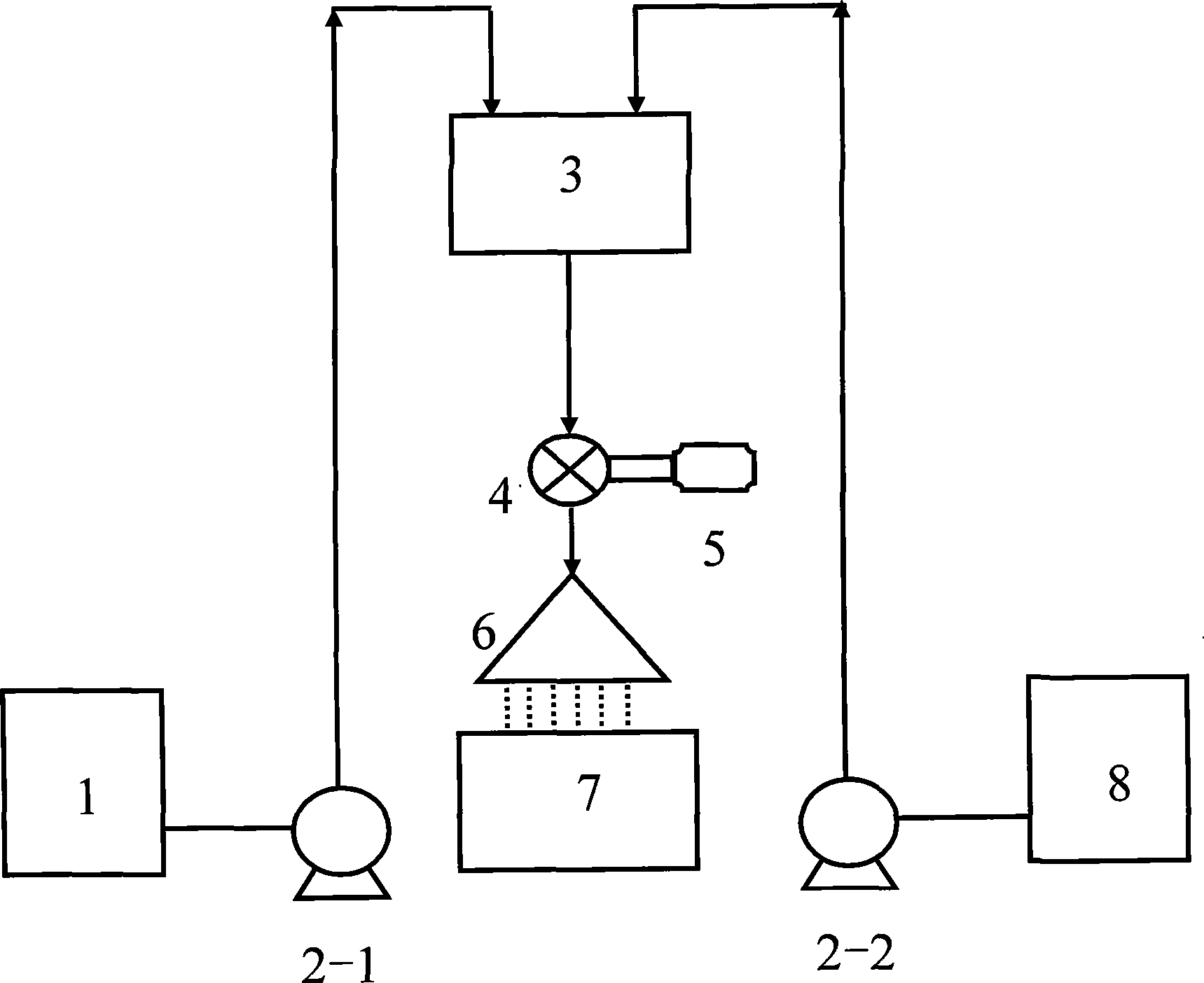

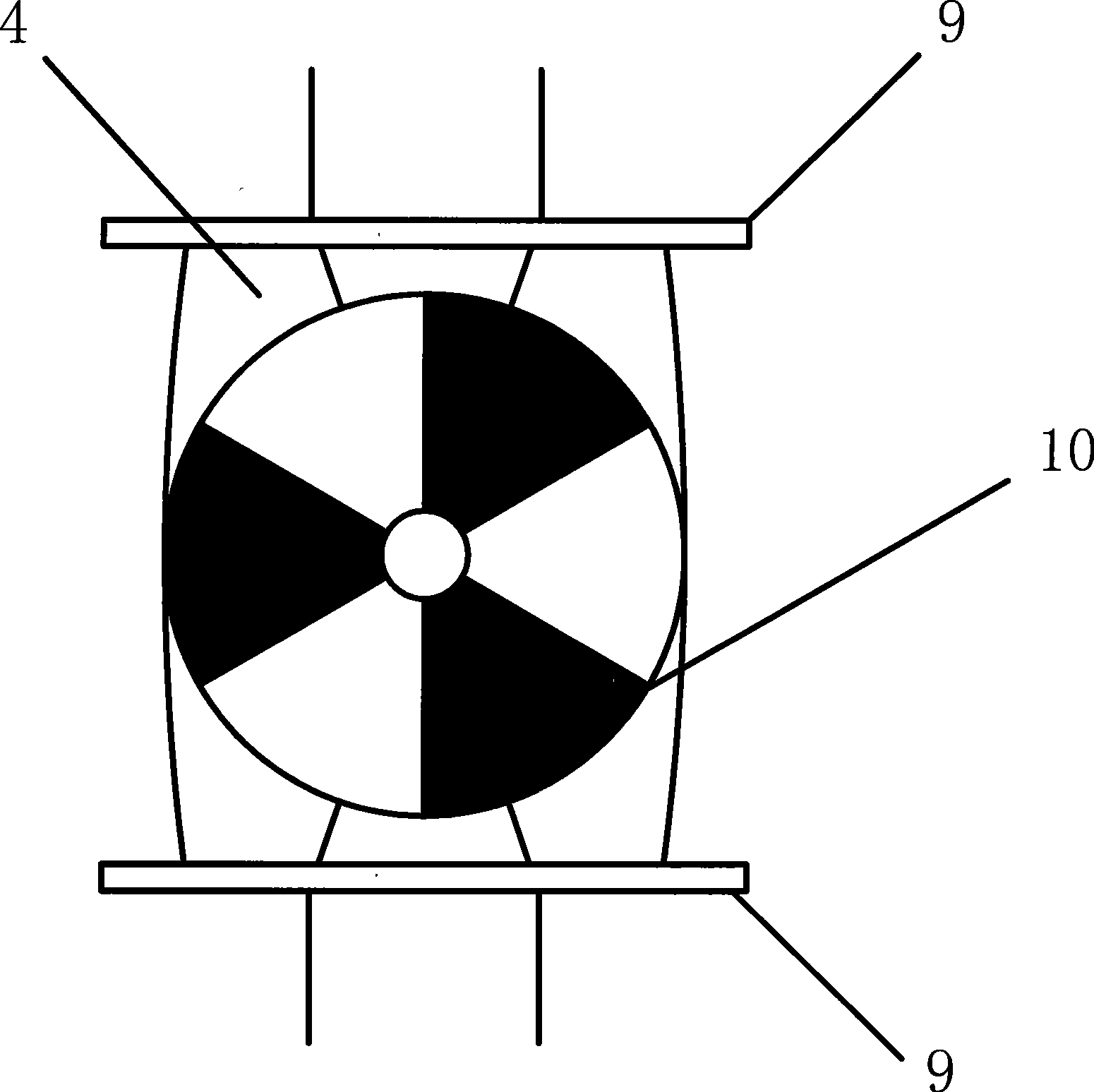

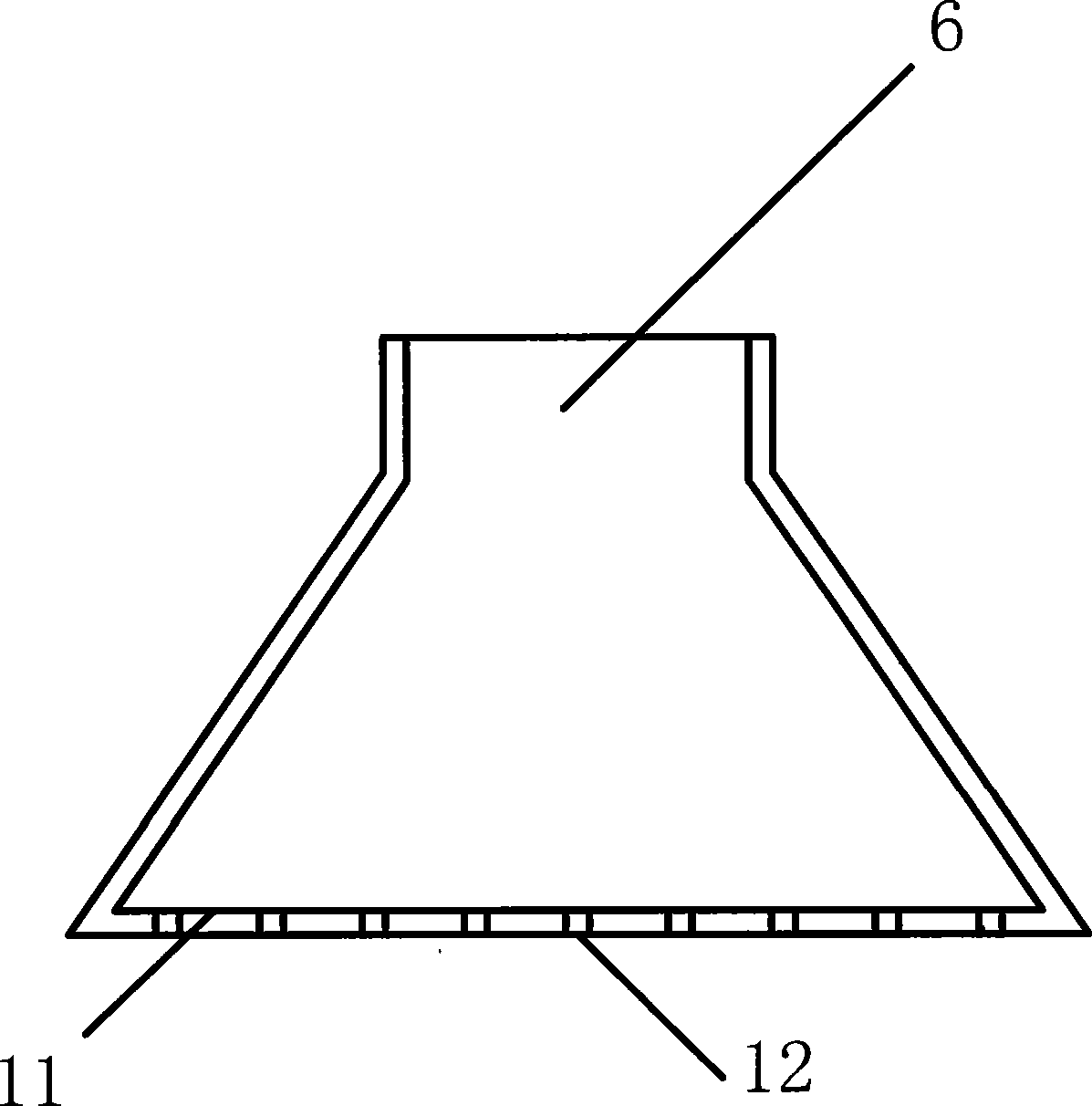

[0022] The delivery pump 2-1 of the embedding agent kettle injects the sodium alginate solution with a mass percentage content of 0.5% in the embedding agent kettle 1 into the mixing kettle 3, and the delivery pump 2-2 of the adsorbent biological kettle transfers the activated carbon in the adsorbent biological kettle 8 A solution with a mass percentage content of 0.5% and a mass percentage content of Pseudomonas aeruginosa of 5% is poured into the mixing tank 3, and the mass flow ratio of the solution delivered by the embedding agent tank 1 and the solution delivered by the adsorbent biological tank 8 is controlled to be 1 : 1; After the two solutions are fully mixed, they enter the splitter 6 through the cutoff valve 4, and then spray into the crosslinking agent kettle 7 that contains 0.5% calcium chloride solution by mass percentage. After the mixed liquid sprayed by the splitter 6 contacts with the cross-linking agent solution in the cross-linking agent tank 7, solid spheri...

Embodiment 2

[0024] The delivery pump 2-1 of the embedding agent kettle injects the sodium alginate solution with a mass percentage content of 3% in the embedding agent kettle 1 into the mixing kettle 3, and the delivery pump 2-2 of the adsorbent biological kettle transfers the activated carbon in the adsorbent biological kettle 8 The solution with a mass percentage content of 2% and a mass percentage content of Acinetobacter baumannii with a mass percentage content of 25% is poured into the mixing tank 3, and the mass flow ratio of the solution delivered by the embedding agent tank 1 and the solution delivered by the adsorbent biological tank 8 is controlled to be 5 : 1; after the two solutions are fully mixed, they enter the splitter head 6 through the cutoff valve 4, and then spray into the crosslinking agent kettle 7 filled with 7% calcium chloride solution by mass percentage. After the mixed solution sprayed by the splitter 6 contacts with the crosslinking agent solution in the crossli...

Embodiment 3

[0026] The delivery pump 2-1 of the embedding agent kettle injects the sodium alginate solution with a mass percentage content of 6% in the embedding agent kettle 1 into the mixing kettle 3, and the delivery pump 2-2 of the adsorbent biological kettle transfers the activated carbon in the adsorbent biological kettle 8 A solution with a mass percentage content of 4.5% and a mass percentage content of Pseudomonas putida of 50% is poured into the mixing tank 3, and the mass flow ratio of the solution delivered by the embedding agent tank 1 and the solution delivered by the adsorbent biological tank 8 is controlled to be 3 : 1; after the two solutions are fully mixed, they enter the splitter head 6 through the cutoff valve 4, and then spray into the crosslinking agent kettle 7 filled with 4% calcium chloride solution by mass percentage. After the mixed solution sprayed by the splitter 6 contacts with the cross-linking agent solution in the cross-linking agent tank 7, solid spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com