Hexavalent-chromium reduction immobilization bacterial agent and preparing method

A technology of hexavalent chromium and bacterial agents, applied in the direction of biochemical equipment and methods, chemical instruments and methods, and methods based on microorganisms, can solve the pollution of heavy metals such as chromium and the secondary pollution of toxic sludge that are not suitable for handling low concentrations , can not remove heavy metals and other problems, to achieve good application potential, not easy to spread, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] (1) Preparation method of microbial embedding agent: Weigh 2.0g, 3.0g, 4.0g, 5.0g, and 6.0g of sodium alginate (SA) solids respectively, dissolve them in 100mL deionized water, heat and stir to make them Dissolve, prepare sodium alginate solutions with mass concentrations of 2.0%, 3.0%, 4.0%, 5.0%, and 6.0%, and sterilize under high pressure at 121° C. for 20 minutes.

[0028] (2) Preparation method of microbial cross-linking agent: Weigh 2.0g, 3.0g, 4.0g, 5.0g CaCl respectively 2 Solid, it was dissolved in 100mL deionized water respectively, and the mass concentration was prepared as 2.0%, 3.0%, 4.0%, 5.0% CaCl 2 Solution, autoclave at 121°C for 20min.

[0029] (3) The preparation method of 0.85% normal saline: weigh 8.5 g of solid sodium chloride, dissolve it in a certain amount of deionized water, wait until it is completely dissolved, and set the volume to 1000 mL. Aliquot and autoclave at 121°C for 20 minutes.

[0030] (4) Preparation method of bacterial suspens...

Embodiment 1

[0036] The method described in this embodiment mainly proceeds according to the following steps:

[0037] 1. Prepare 100mL 2.0% SA, 100mL 3.0% SA, 100mL 4.0% SA, 100mL 5.0% SA, 100mL 6.0% SA. Prepare 100mL 2.0% CaCl 2 , 100 mL 3.0% CaCl 2 , 100mL 4.0% CaCl 2 , 100 mL 2.0% CaCl 2. Prepare 1000 mL of NaCl with a mass concentration of 0.85%, and sterilize under high pressure.

[0038] 2. Take the bacterial solution and centrifuge it at 8000-10000rpm for 10-15min, wash it with sterile water three times, mix it with sodium alginate at a ratio of 1:1, and drop the mixture into different proportions of CaCl with a syringe 2 After being fixed in the solution for a certain period of time, it is washed three times with 0.85% physiological saline to obtain a gelatinous hexavalent chromium reduction immobilized bacterial agent.

[0039] 3. Take a part of the hexavalent chromium reduction-immobilized bacterial agent prepared in different proportions for permeability testing and mecha...

Embodiment 2

[0048] The method described in this embodiment mainly proceeds according to the following steps:

[0049] 1. Prepare 100mL of 3.0% SA. Prepare 100mL 3.0% CaCl 2 . Prepare 1000 mL of NaCl with a mass concentration of 0.85%, and sterilize under high pressure.

[0050] 2. Take the bacterial solution and centrifuge it at 8000-10000rpm for 10-15min, wash it with sterile water three times, mix it with sodium alginate evenly according to the ratio of 1:1, and drop the mixture into CaCl with a syringe 2 solution, after the respective immobilization time, wash three times with 0.85% physiological saline, and obtain the hexavalent chromium reduction immobilization bacterial agent ( figure 1 ).

[0051] 3. Take a part of the prepared hexavalent chromium reduction-immobilized bacterial agent for permeability detection and mechanical strength detection.

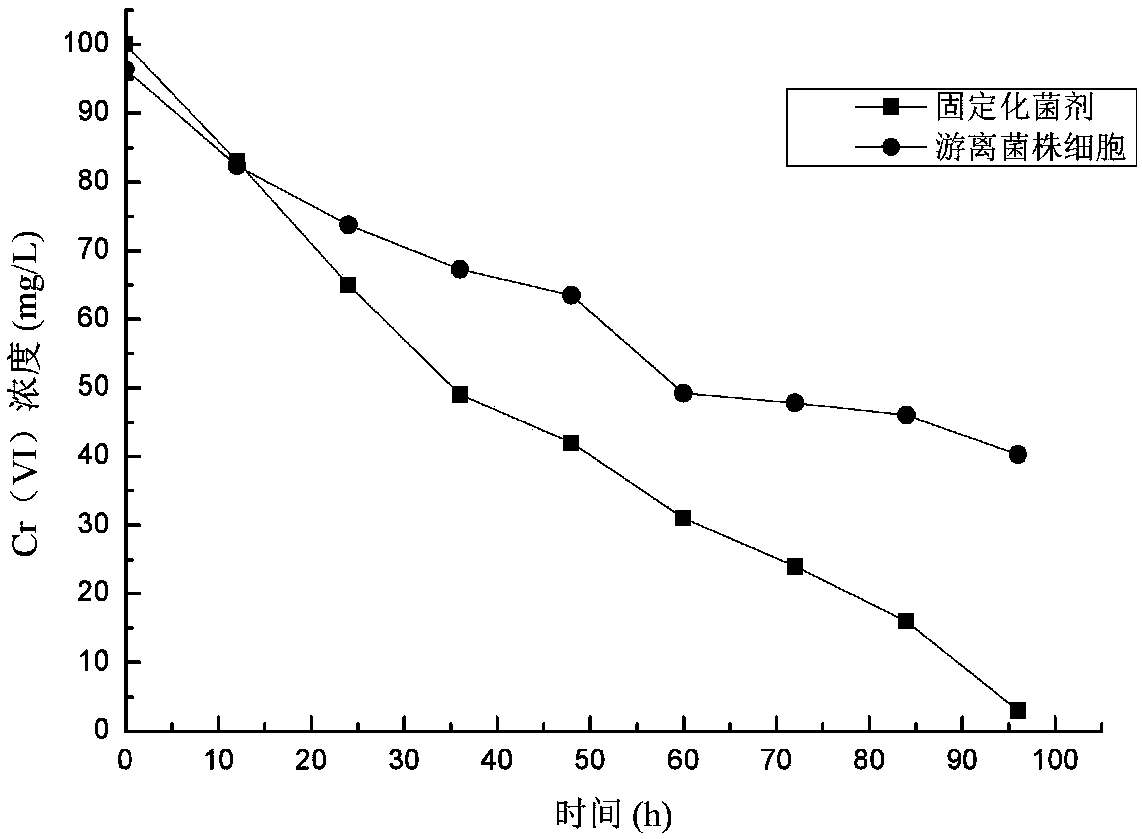

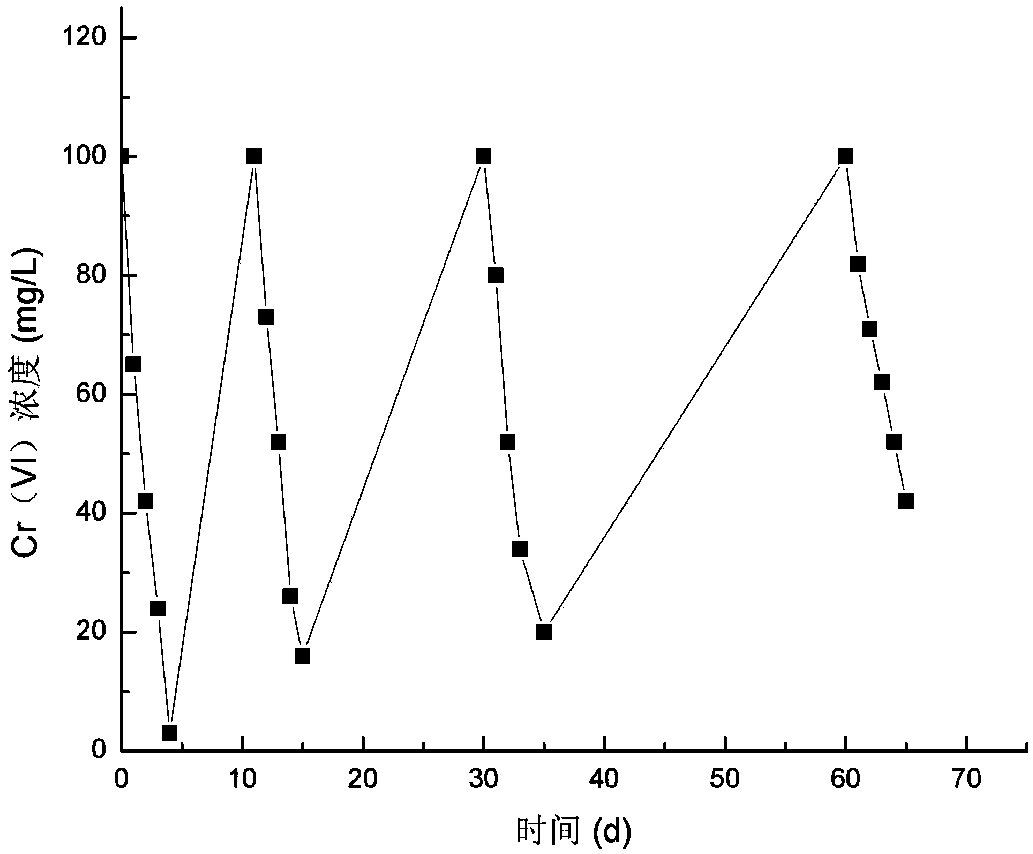

[0052] 4. Weigh 5 g of the prepared hexavalent chromium reduction-immobilized bacterial agent, inoculate it into LB medium containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com