Method for preparing dry adhesive

A production method and adhesive technology, applied in the direction of nanostructure manufacturing, manufacturing microstructure devices, and techniques for producing decorative surface effects, etc., can solve the problems of wet adhesives that are easy to degrade, easy to pollute, and difficult to use again , to achieve the effect of clear outline and deepening groove depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

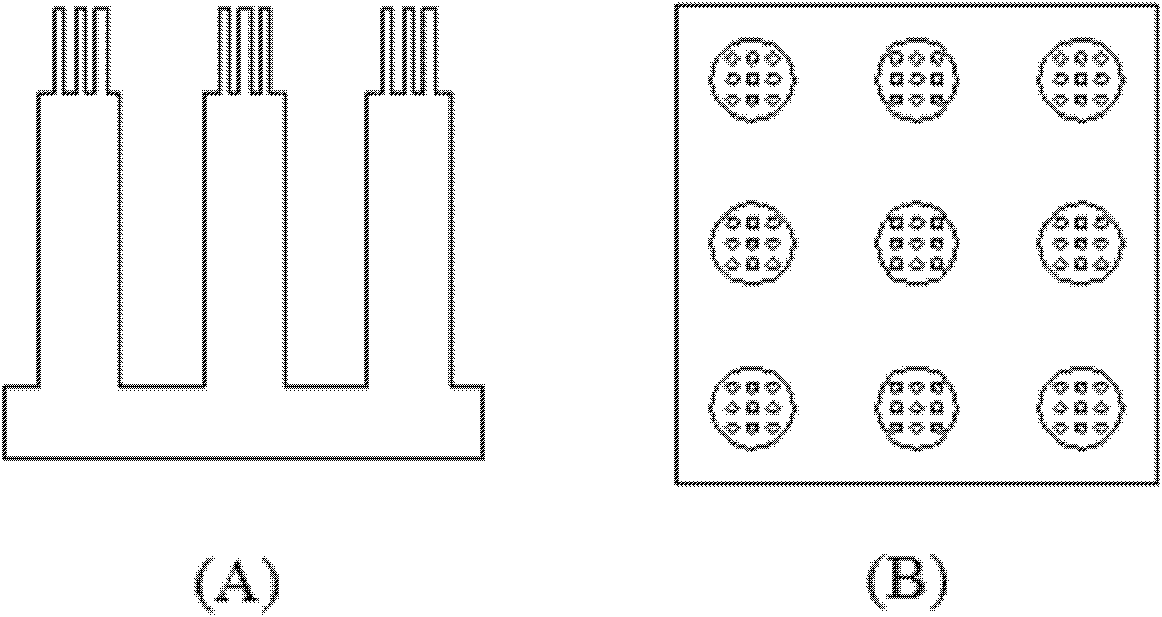

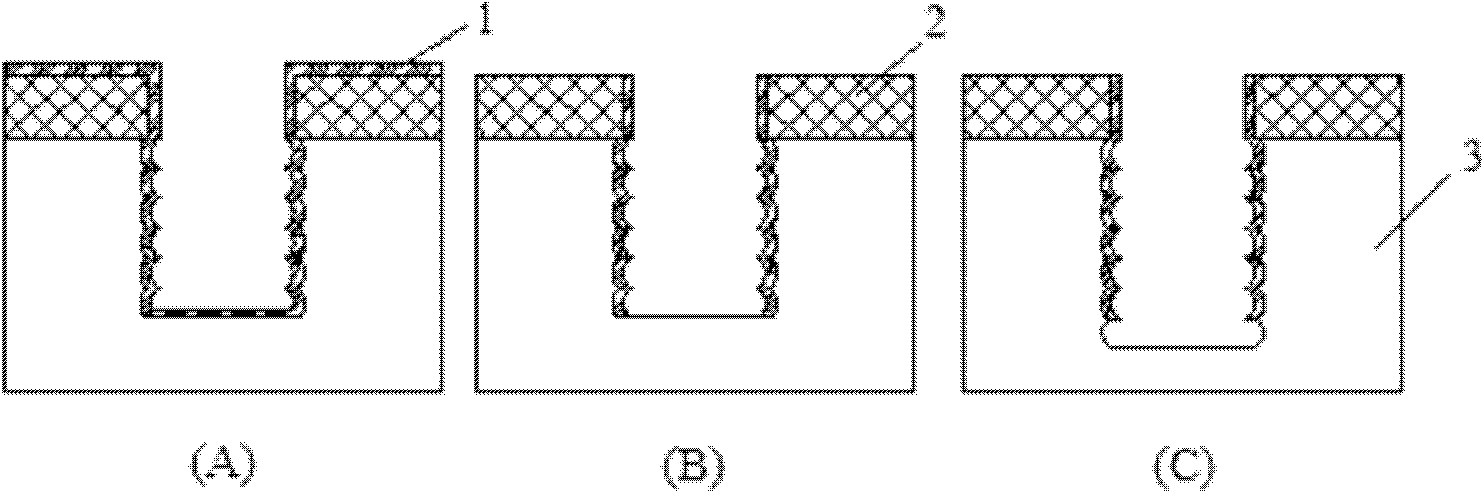

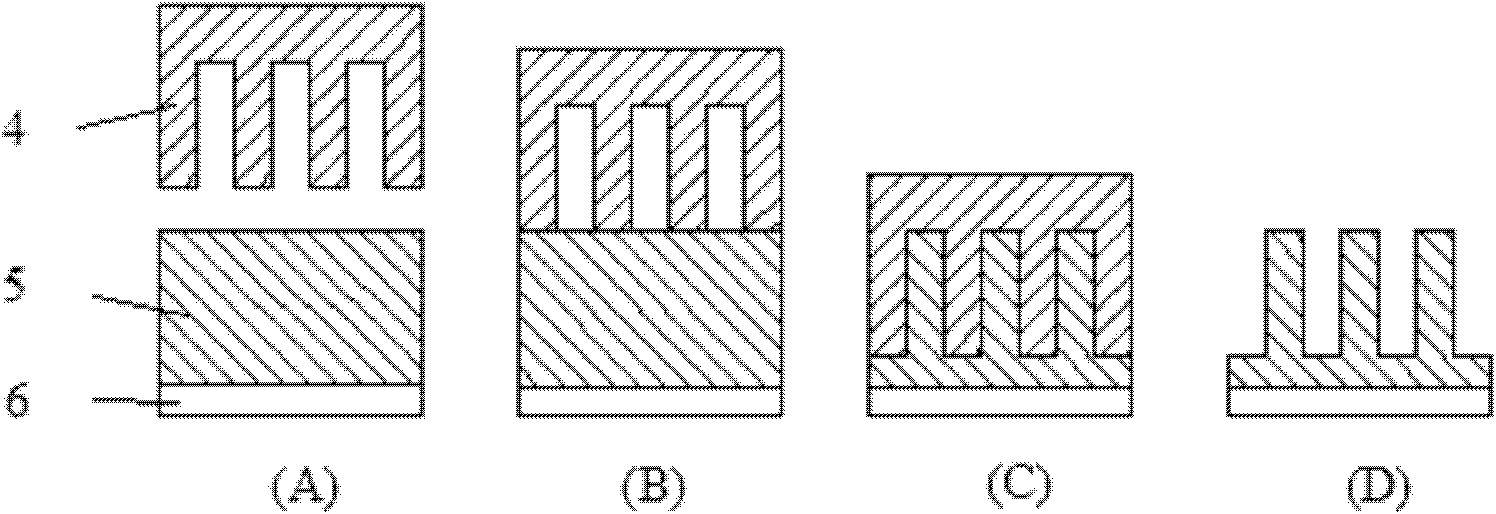

[0039] In the present invention, the diameter of the micron-scale fiber is 6 μm, the length is 40 μm, and the spacing is 6 μm; the diameter of the nano-scale fiber is 0.4 μm, the length is 3 μm, and the spacing is 0.4 μm. The specific implementation steps are as follows:

[0040] (1). Fabrication of micron-scale silicon master: first process the silicon wafer with RCA cleaning method, then evenly coat the surface with a negative photoresist with a thickness of 1.5 μm, model SU-8, and bake it at 95 ° C with a hot plate process 1 minute; place the prepared photolithography mask on the surface of the mold for ultraviolet light exposure, the exposure energy is 110mJ / cm2, then use SU-8 developer to wash away the photoresist on the part to be etched, and use pure water Clean and dry with nitrogen gas, and age the photoresist on the surface of the silicon wafer at 150°C for 10 minutes to form an etching-resistant protective layer; use ICP dry etching, and introduce a passivation cycl...

example

[0047]

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com