Grouting method for ultrathin high polymer cutoff wall

A technology of high polymer and anti-seepage wall, applied in water conservancy projects, marine engineering, protection devices, etc., can solve problems such as difficulty in ensuring anti-seepage systems, and achieve the effects of fast construction, broad social benefits, and huge economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

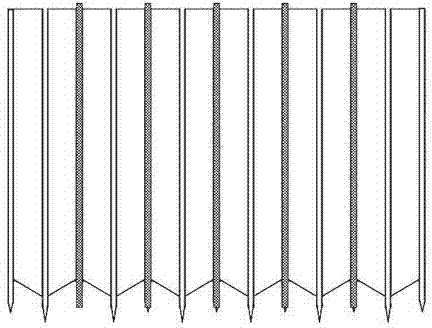

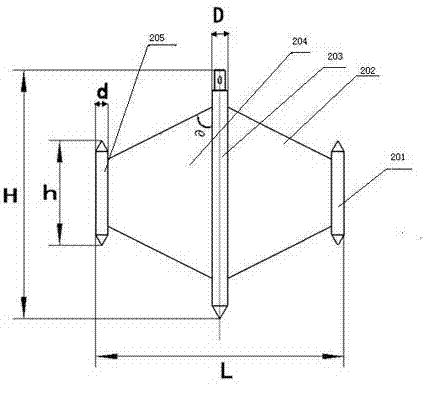

[0034] According to the requirements of dyke seepage control design, three cone-head pressure grooved plates and pressure grooved equipment are used to form continuous grooves in the dams and foundations that need anti-seepage reinforcement; two-component expansibility is injected into the grooves through a grouting pipe Polymer grouting material; the volume of the polymer grouting material expands rapidly after chemical reaction, fills the slots and solidifies to form a polymer sheet; the polymer sheets of adjacent slots are tightly glued together , To form a continuous, uniform and regular ultra-thin polymer anti-seepage wall, so as to achieve the purpose of improving the anti-seepage performance of the dam.

[0035] The specific implementation steps are:

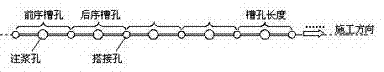

[0036] (1) Slot hole arrangement: In the dam body and foundation that need anti-seepage reinforcement, the slot holes are arranged according to the design, and the slot holes are numbered.

[0037] (2) Slot hole construction: u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com