Shaking stopping device for B-type enclosure system of large-scale LNG ship

An LNG ship and anti-rolling technology, applied in the direction of ship hull, ship construction, transportation and packaging, can solve the problems of increasing the evaporation rate of liquid cargo, sloshing of liquid cargo, damage to the structure of the containment system, etc. Easy to install and create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to understand the technical content of the present invention more clearly, the specific implementation methods of the present invention will be further described below.

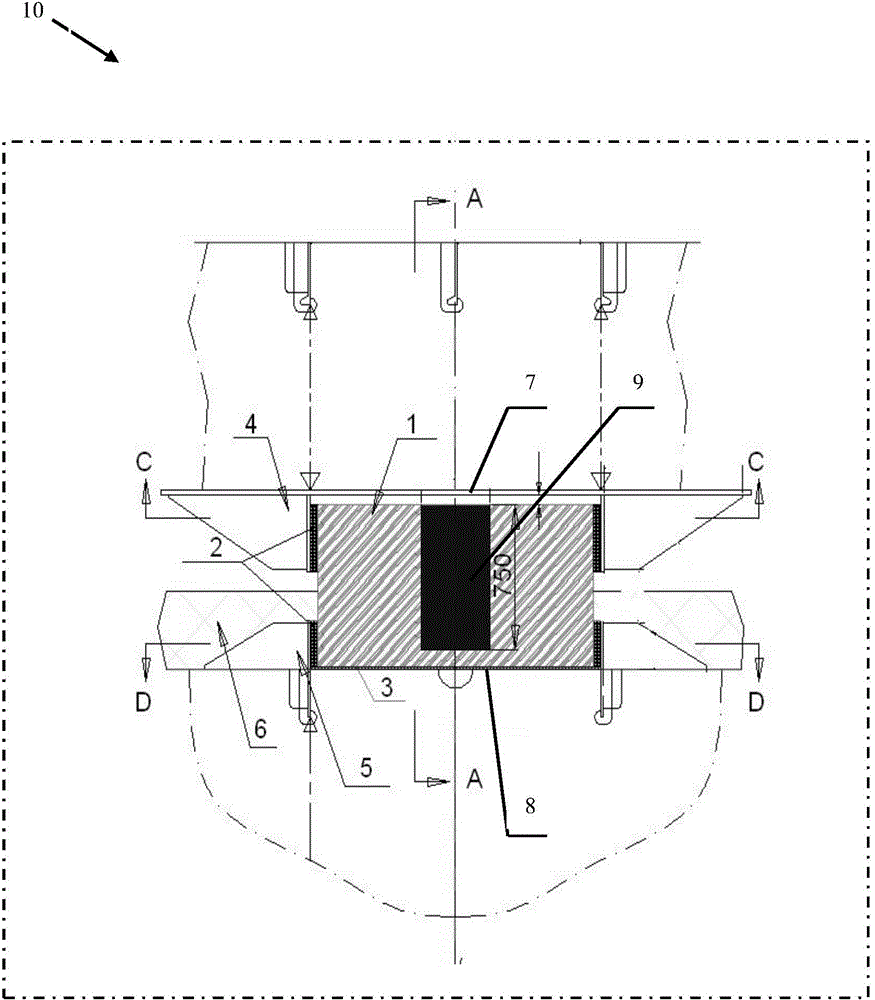

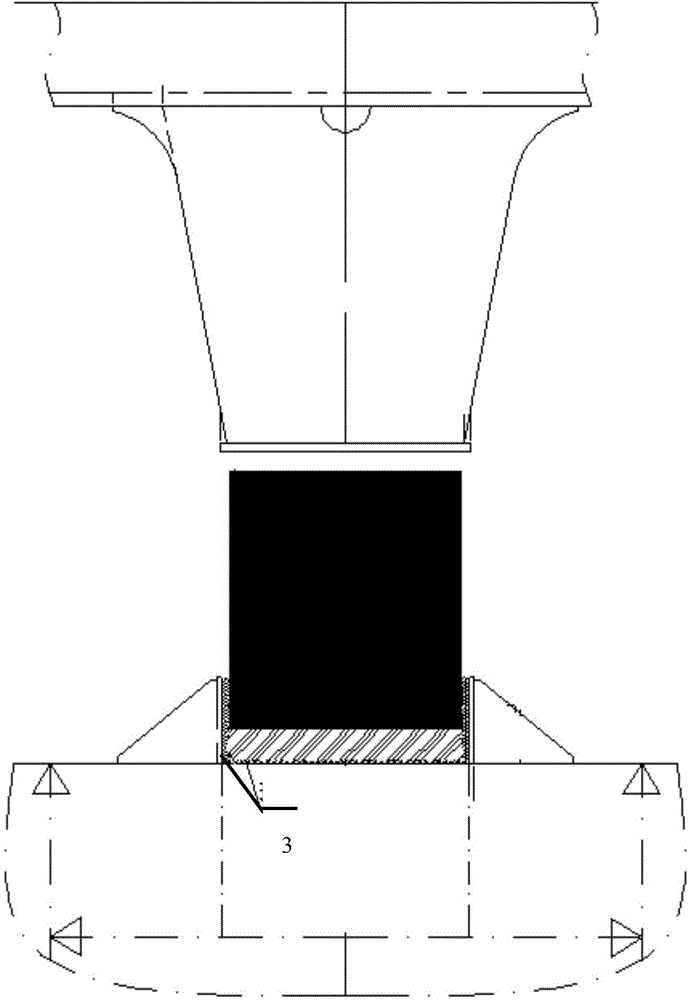

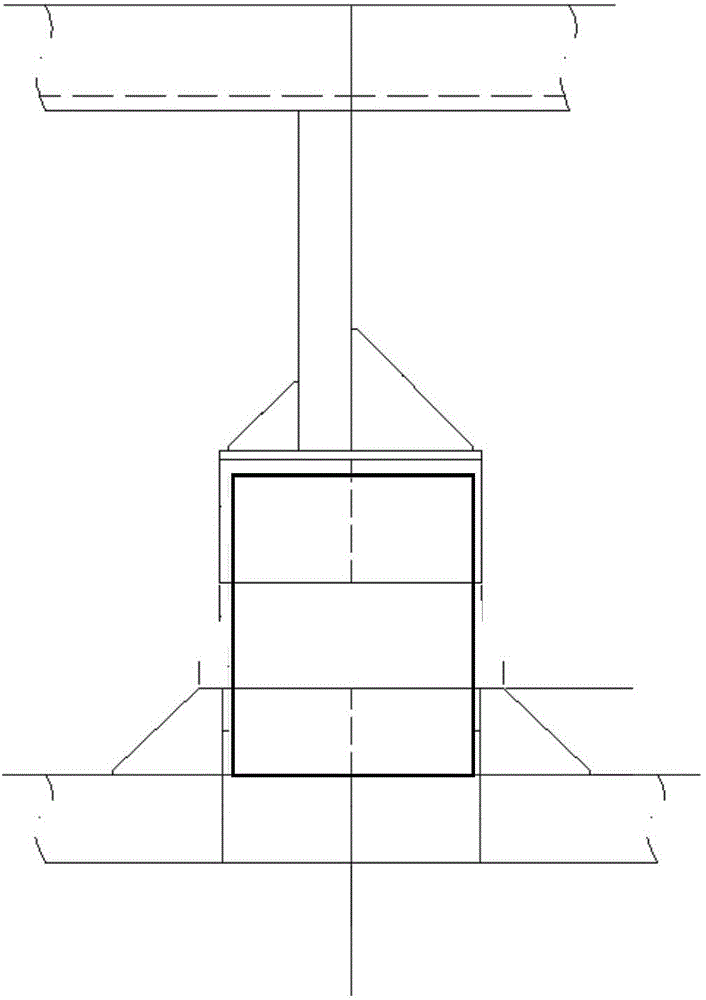

[0035] Such as Figure 1-6 As shown, the anti-sway device 10 of the B-type containment system of the large LNG ship of the present embodiment, the anti-sway device 10 is located above the containment system, and includes a lower retaining ring and a laminated wooden square 1 arranged inside the lower retaining ring. And the upper baffle plate wedged on the upper part of the laminated wood side 1,

[0036] Wherein, the laminated wooden square 1 is embedded with a metal material 9;

[0037] The upper baffle includes an upper bracket 4 and an upper panel 7, and the lower retaining ring includes a lower bracket 5 and a lower panel 8. There is a first gap between the upper sides of the laminated wooden square 1 and the upper bracket 4, and the laminated There is a second gap between the bottom si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com