LED packaging glue and preparation method thereof

A technology of LED packaging and base glue, applied in the direction of adhesives, etc., can solve the problems of less than 90% light transmittance, poor high and low temperature resistance, poor yellowing resistance, etc., and achieve good water resistance, good bending performance, and good UV resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

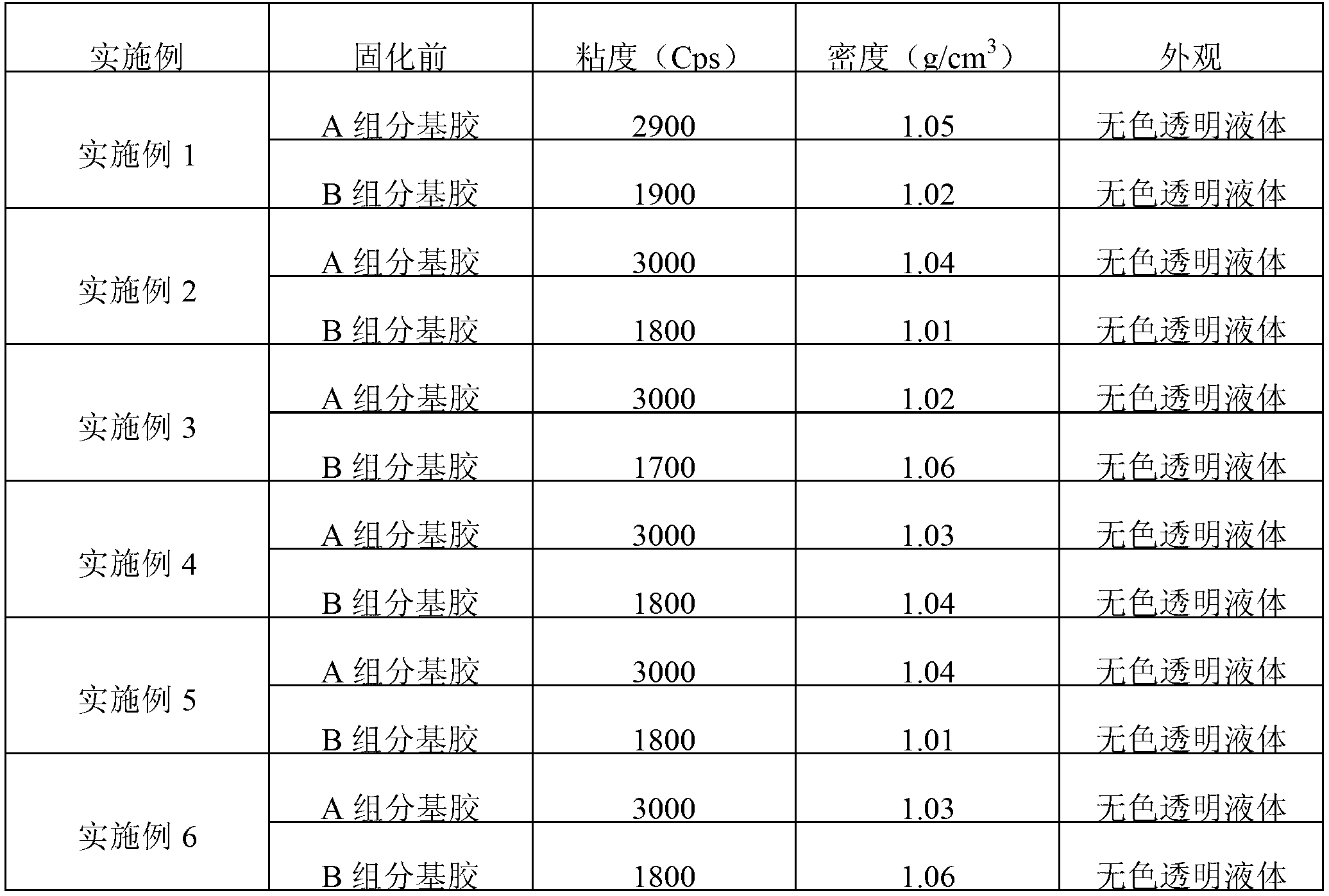

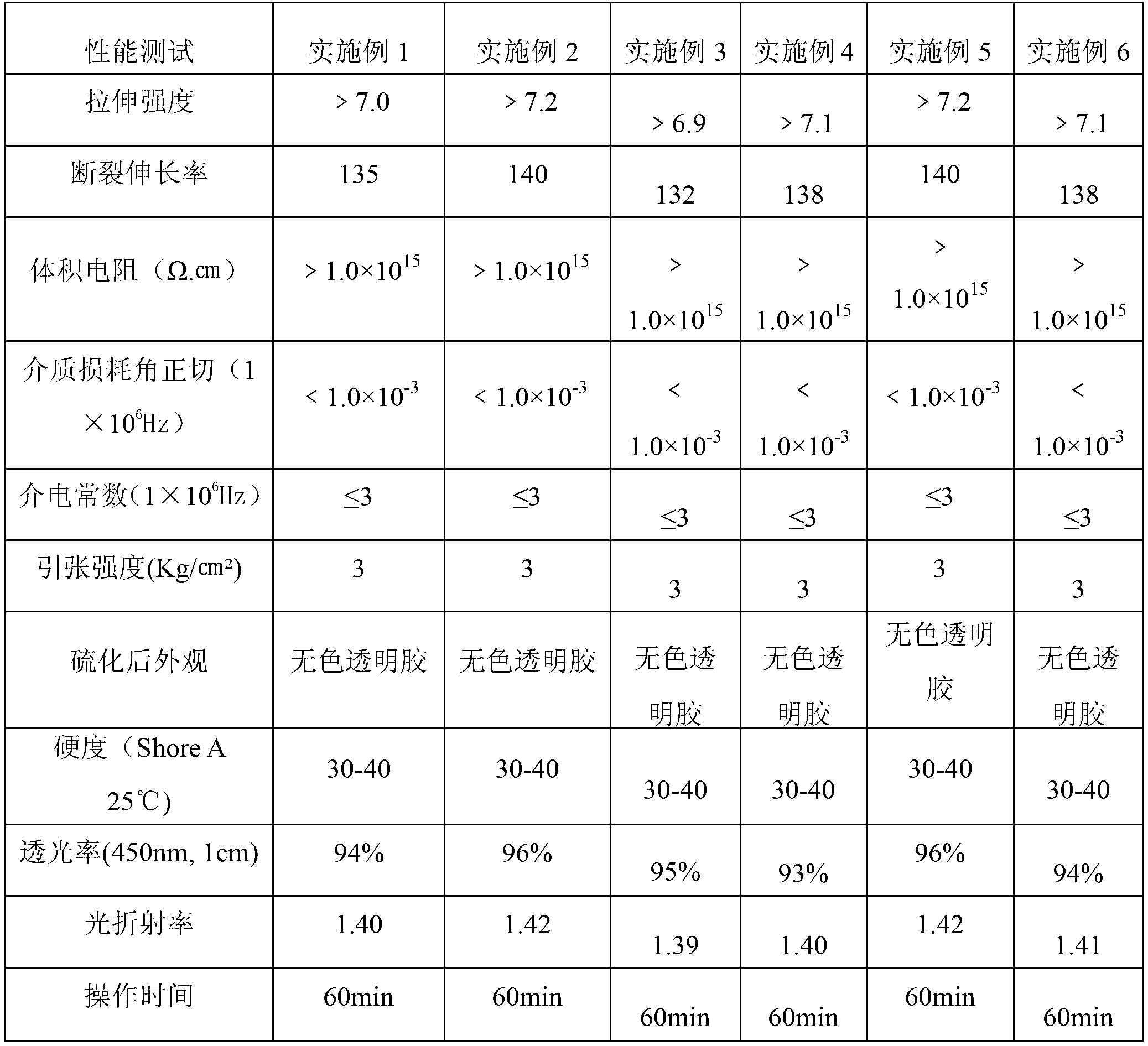

Examples

Embodiment 1

[0026] A preparation method of LED encapsulation glue, is characterized in that, comprises the steps:

[0027] a) Preparation of component A base glue: Add 15% by mass percentage of the first vinyl silicone oil and 83% by mass percentage of the first vinyl MQ silicone resin into the reaction vessel, and pump it under normal temperature of 20-25°C Vacuum stirring, until the stirring is uniform, add the platinum catalyst with a mass percentage of 2% into the reaction vessel, and obtain the A-component base glue;

[0028] b) Preparation of B-component base glue: add 20% by mass of methyl hydrogen silicone oil, 14.95% by mass of second vinyl silicone oil and 60% by mass of second vinyl in the reaction vessel MQ silicone resin, under the condition of normal temperature 20-25°C, vacuumize and stir it, and after stirring evenly, add 0.05% by mass of ethynylcyclohexanol and 5% by mass of tackifier to the reaction vessel in sequence, That is, the B-component base glue is obtained;

...

Embodiment 2

[0037] Same as Example 1, the difference is:

[0038] In step a: (by mass percentage) the first vinyl silicone oil is 20%, the first vinyl MQ silicone resin is 79%, and the platinum catalyst is 1%, wherein the vinyl content in the first vinyl MQ silicone resin is 2.3%;

[0039] In step b: (by mass percentage) methyl hydrogen-containing silicone oil is 25%, the second vinyl silicone oil is 15.95%, the second vinyl MQ silicone resin is 55%, ethynyl cyclohexanol is 0.05%, SC- 101 is 4%.

[0040] In step c: the mass ratio of the A-component base glue to the B-component base glue is 1:1, and the curing conditions are a curing temperature of 25°C and a curing time of 18 hours.

Embodiment 3

[0042] Same as Example 1, the difference is:

[0043] In step a: (by mass percentage) the first vinyl silicone oil is 25%, the first vinyl MQ silicone resin is 74.5%, and the platinum catalyst is 0.5%, wherein the vinyl content in the first vinyl MQ silicone resin is 2.3%;

[0044] In step b: (by mass percentage) 30% of methyl hydrogen-containing silicone oil, 16.95% of second vinyl silicone oil, 50% of second vinyl MQ silicone resin, 0.05% of ethynyl cyclohexanol, SC- 101 is 3%.

[0045] In step c: the mass ratio of the A-component base glue to the B-component base glue is 2:1, and the curing conditions are a curing temperature of 30°C and a curing time of 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com