Motor end cover as well as manufacture method and applied motor thereof

A technology for motor end caps and integrated circuits, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of complex processing procedures, poor heat resistance, and low production efficiency, and achieve simple procedures and production efficiency. High, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

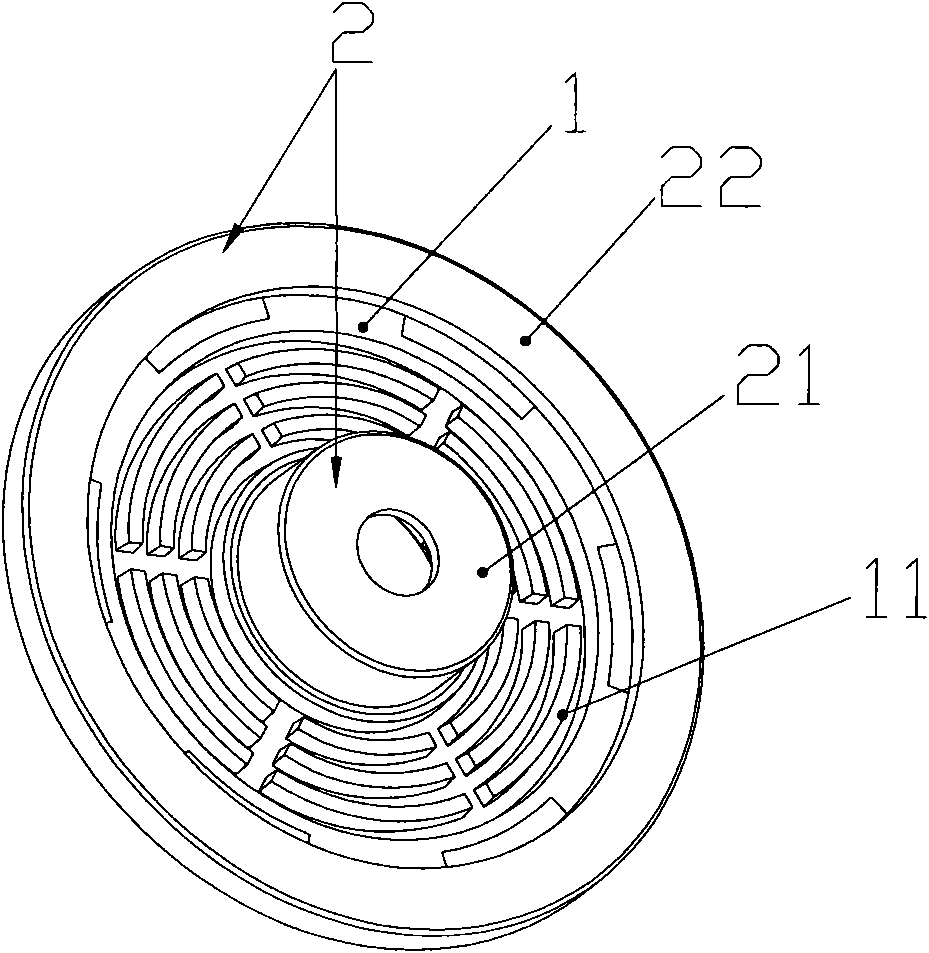

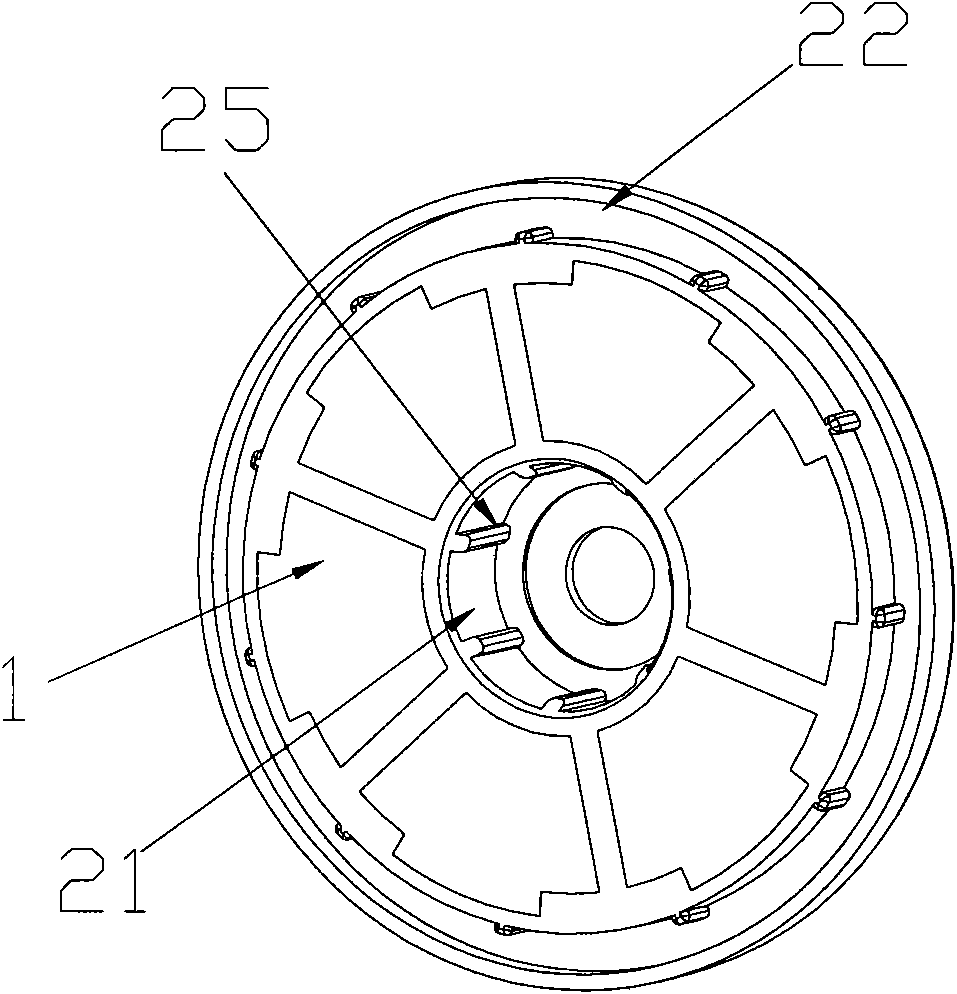

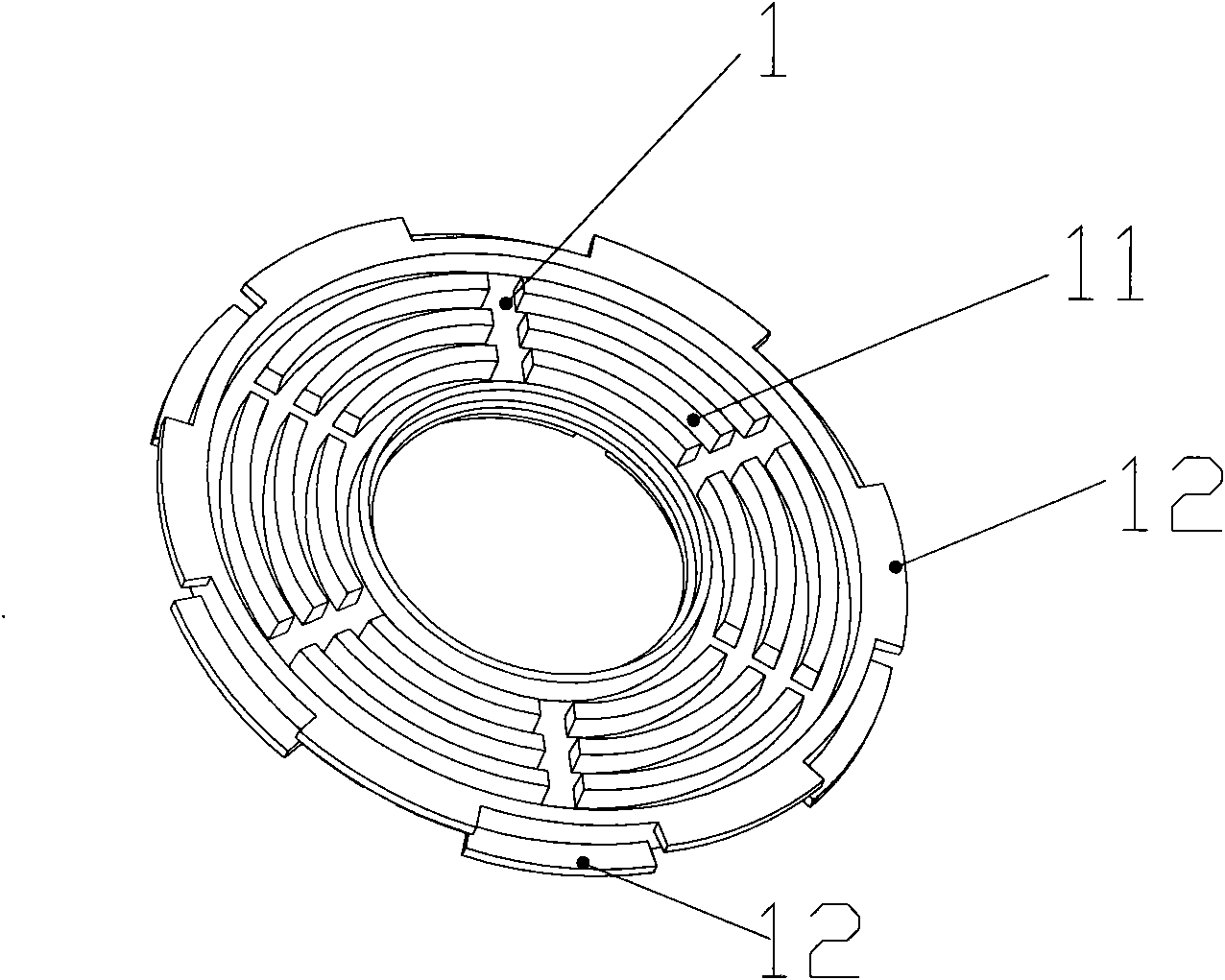

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is composed of a metal heat sink 1 and an injection molded part 2, wherein the injection molded part 2 includes a bearing chamber 21 located in the center and a positioning notch 22 located on the periphery, and is embedded between the bearing chamber 21 and the positioning notch 22 The metal heat sink 1, the metal heat sink 1 is more suitable to be aluminum. The outer surface 12 of the metal heat sink 1 is provided with multiple rows of raised fins 11 , the inner surface of the metal heat sink 1 is flat, the fins 11 can be arc-shaped and radially distributed, and the fins 11 can increase the heat dissipation area. There are several blocks 12 protruding from the side of the metal heat sink 1, and the blocks 12 are embedded in the bearing chamber 21 and the positioning notch 22. The several blocks 12 protruding from the side can be divided into two rows according to the height, and the...

Embodiment 2

[0035] In the first embodiment, all gaps between the bearing chamber 21 and the positioning notch 22 are embedded with a whole metal heat sink 1 . However, in order to save costs and meet the heat dissipation requirements, a part of the gap between the bearing chamber 21 and the positioning notch 22 is embedded in the metal heat sink 1 , and the rest of the gap is sealed by injection molding to form a baffle 23 .

[0036] The manufacturing method of the motor end cover of the present invention is characterized in that the end cover is manufactured by injection molding process, and the metal radiator 1 is embedded in the injection molded part 2 during the injection molding process, so that it can be formed as a whole after injection molding. The motor of the present invention is equipped with a motor end cover at the end of the motor, and the motor end cover is composed of a metal heat sink 1 and an injection molded part 2, wherein the injection molded part includes a bearing ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com