High-viscosity modified emulsified asphalt and preparation method thereof

An emulsified asphalt, high viscosity technology, used in building components, building insulation materials, construction and other directions, can solve the problems of low viscosity of modified emulsified asphalt, affecting road quality, deformation, etc., to increase viscosity, prevent damage, and achieve dense structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

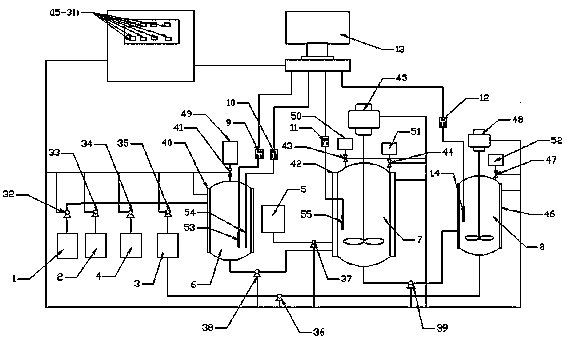

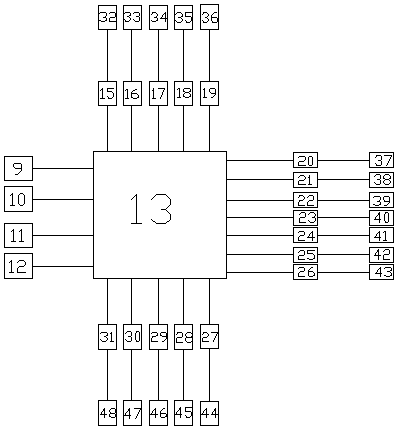

[0028] A device for producing high-viscosity modified emulsified asphalt, which includes a water tank 1, an emulsifier tank 2, a stabilizer tank 3, an additive tank 4, a base asphalt tank 5, a premix tank 6, a reaction tank 7, and a finished product tank 8; Described water tank 1, emulsifier tank 2, additive tank 4 are respectively connected with premix tank 6 through water pump 32, emulsifier pump 33, additive pump 34, and described stabilizer tank 3 is respectively passed through stabilizer pump a35, stabilizer Pump b36 is connected with described premix tank 6, finished product tank 8, and described base asphalt tank 5 is connected with reaction tank 7 by base asphalt pump 37, and described premix tank 6 is connected with reaction tank 7 by feed pump 38, so The reaction tank 7 is connected with the finished product tank 8 by a finished product pump 39;

[0029] The premix tank 6 is surrounded by a premix tank heating jacket 40, the top of the premix tank 6 is provided with ...

Embodiment 2

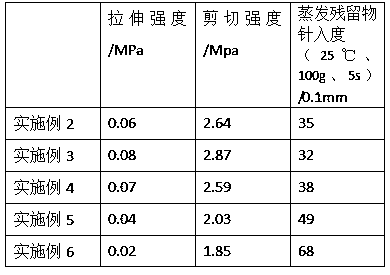

[0034] A high-viscosity modified emulsified asphalt, characterized in that: it consists of the following components in parts by weight: 80 parts of base asphalt, 1 part of modifier block copolymer (SBS) modified asphalt, emulsifier poly 0.1 part of oxyethylene dioleate, 0.02 part of additive tert-dodecyl mercaptan, 0.1 part of foaming agent calcium carbonate, 0.1 part of antifoaming agent simethicone, 0.05 part of stabilizer, γ-aminopropyl triethyl 10 parts of oxysilane, 30 parts of water.

Embodiment 3

[0036] A high-viscosity modified emulsified asphalt, characterized in that: it consists of the following components in parts by weight: 83 parts of base asphalt, 3 parts of modifier block copolymer (SBS) modified asphalt, emulsifier poly 0.3 parts of oxyethylene dioleate, 0.03 parts of additive tert-dodecyl mercaptan, 0.15 parts of foaming agent calcium carbonate, 0.15 parts of antifoaming agent simethicone, 0.08 parts of stabilizer, γ-aminopropyl triethyl 15 parts of oxysilane, 40 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com