Soaking plate structure without wick and preparation method thereof

A technology of soaking plate and liquid absorbing core, which is used in lighting and heating equipment, indirect heat exchangers, etc., can solve problems such as thickness limit and limit soaking plate, and achieve the effect of reducing thickness, reducing demand and shortening process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

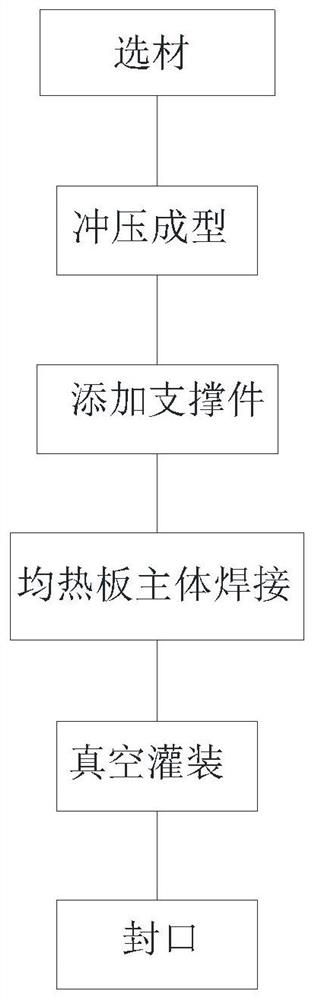

[0019] figure 1 It schematically shows the processing flow of the vapor chamber structure without a liquid-absorbing core according to an embodiment of the present invention, and the specific steps are as follows:

[0020] S1. Select two plates, which are the first cover plate 10 and the second cover plate respectively.

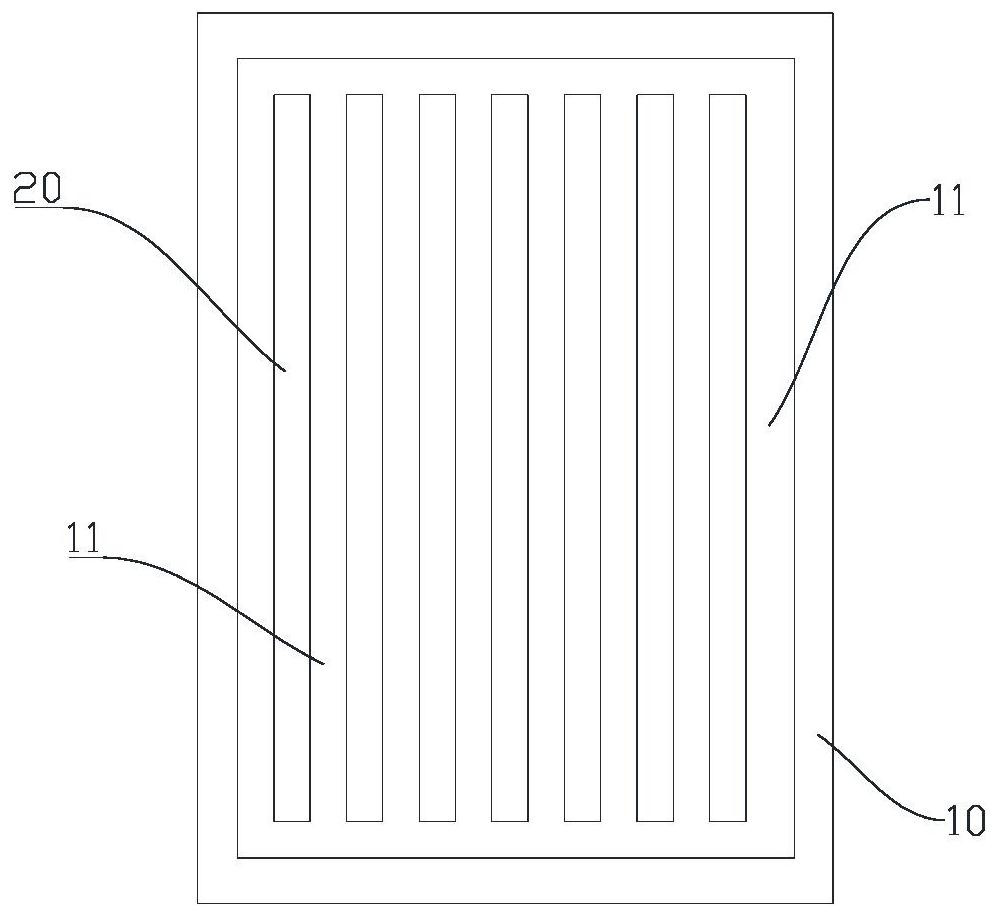

[0021] S2. After cutting the first cover plate 10 and the second cover plate into a symmetrical rectangle of suitable size, use a punching machine to punch out a groove in the middle of the inner surface of the first cover plate 10 and the second cover plate respectively, They are respectively the first recess 11 and the second recess. The first recess 11 and the second recess are arranged symmetrically, and the inner surface of the first cover 10 and the inner surface of the second cover are attached to each other. The first recess 11 and the second recess can jointly define a cavity. Stamping can ensure that the shapes of the first cover plate 10 and the ...

Embodiment 2

[0026] The difference between this embodiment and embodiment 1 is:

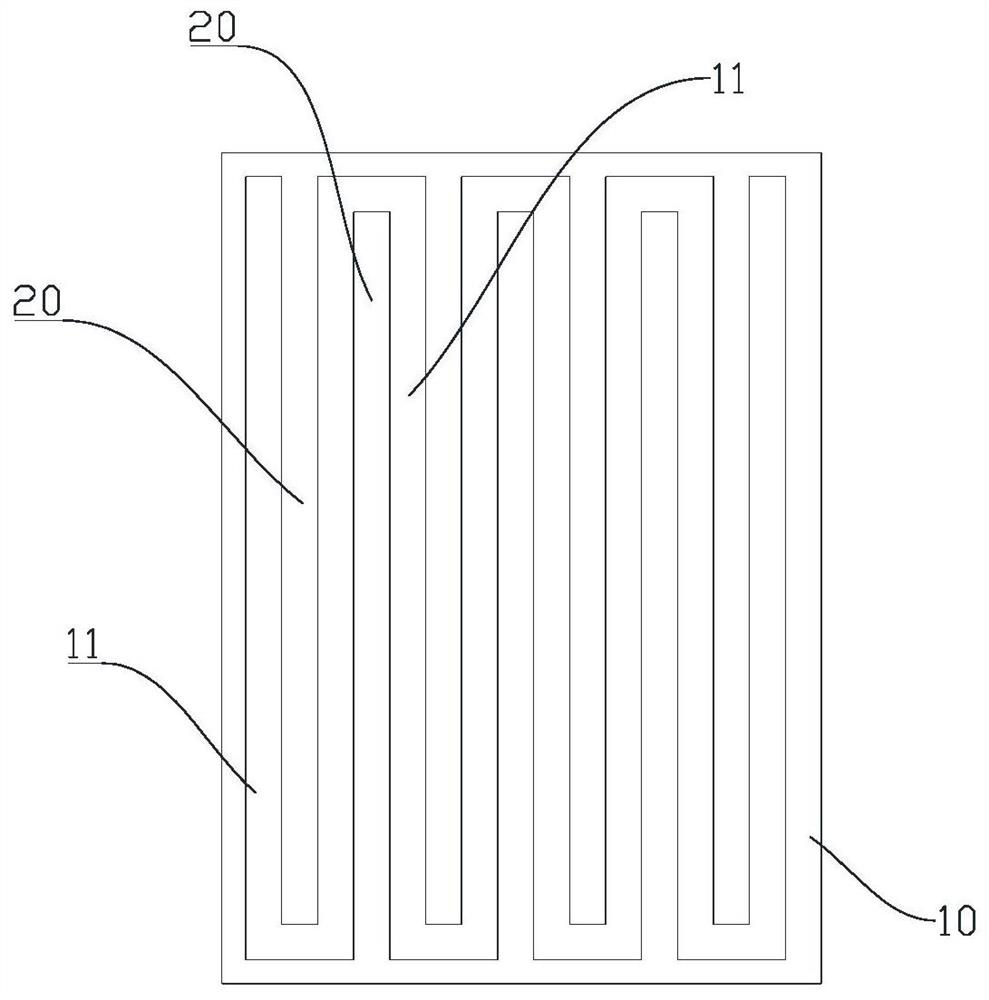

[0027] In S2 and S3, the first recess 11 and the second recess on the first cover 10 and the second cover, as well as the structure of the supporting member 20 located in the first recess 11 and the second recess are formed by etching at one time. The etching process is mature, and the shape and internal structure of the first cover plate 10 and the second cover plate can be processed in one step, which simplifies the process flow.

[0028] Both the first recess 11 and the support 20 in the second recess have one end connected to the edge of the cavity, and the other end is not connected to the edge of the cavity, and the support 20 alternates the connection position with the cavity at intervals, Arranged crosswise in the shape of "back", the internal structure of the first cover plate 10 is as follows: image 3 The internal structure of the second cover shown is symmetrical thereto.

[0029] In S4 and S5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com