Preparation process of high-physical-property cowhide base cloth

A technology of preparation process and high physical properties, applied in the field of leather, can solve the problem of low bonding strength between bovine fiber leather base cloth and PU film layer, large difference in strength of bovine fiber skin base cloth, and reduced mechanical properties of bovine fiber leather base cloth, etc. problems, to achieve the effect of improving the alignment direction, improving the comprehensive physical properties, and improving the tensile strength and peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

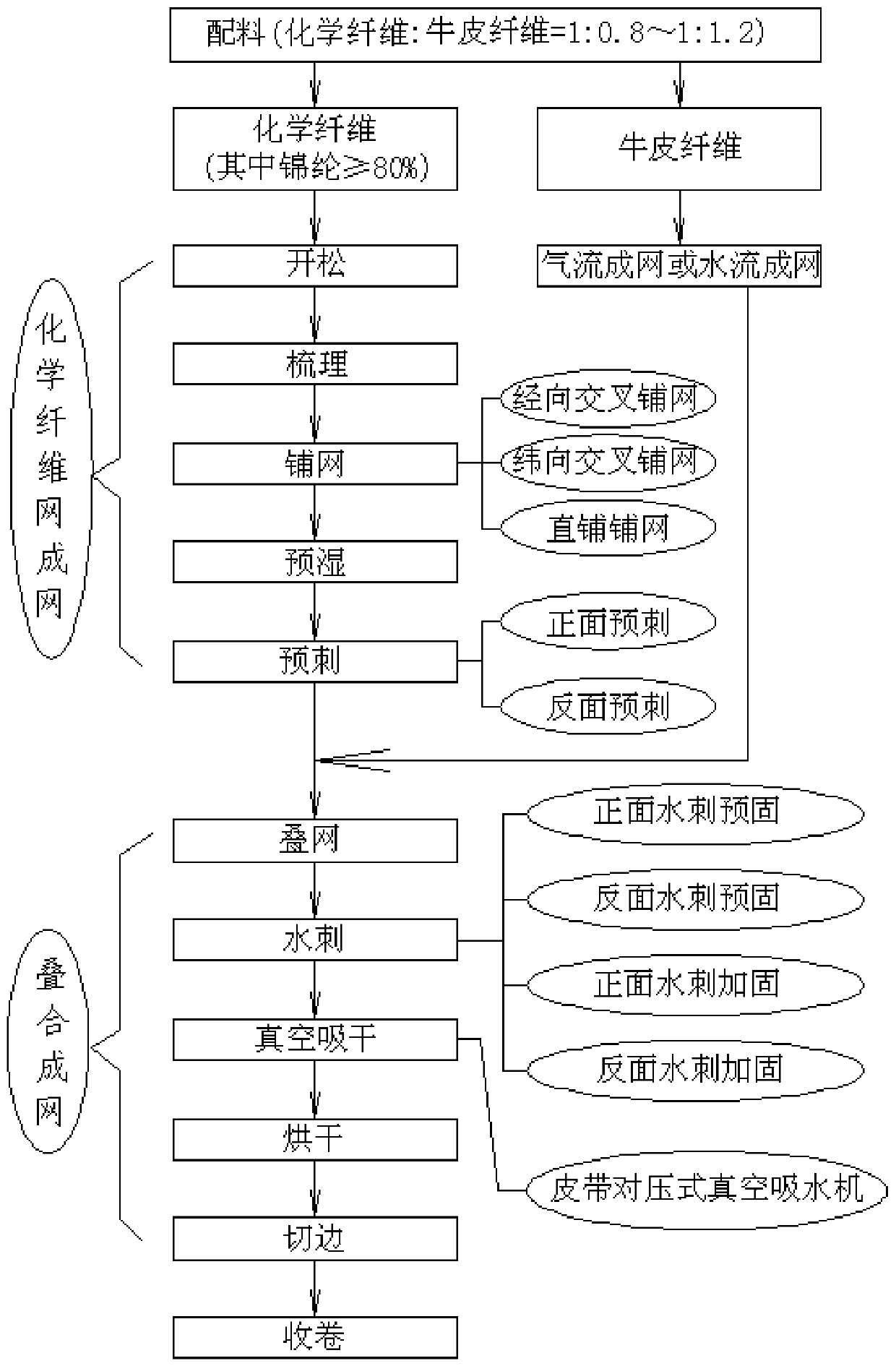

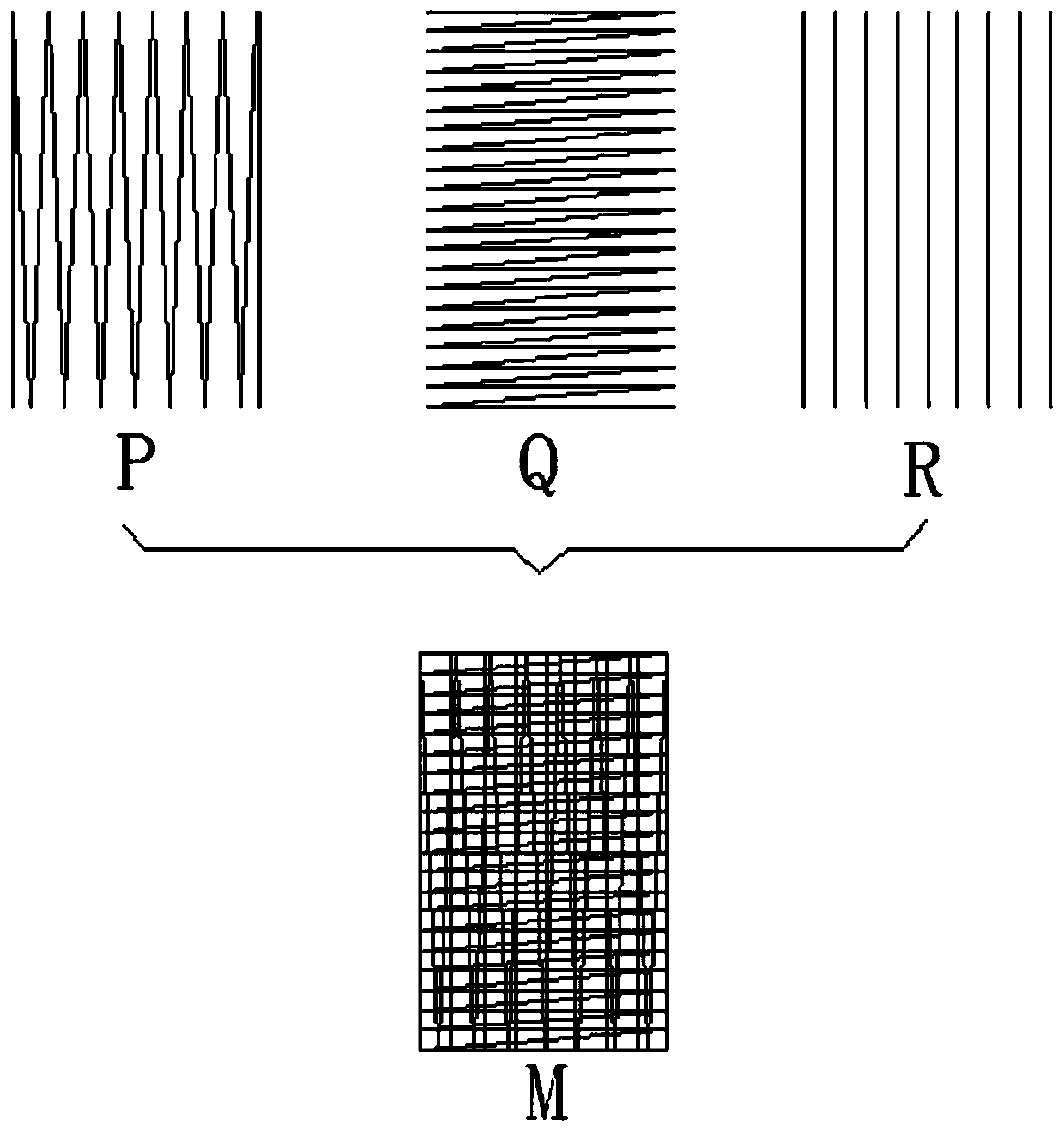

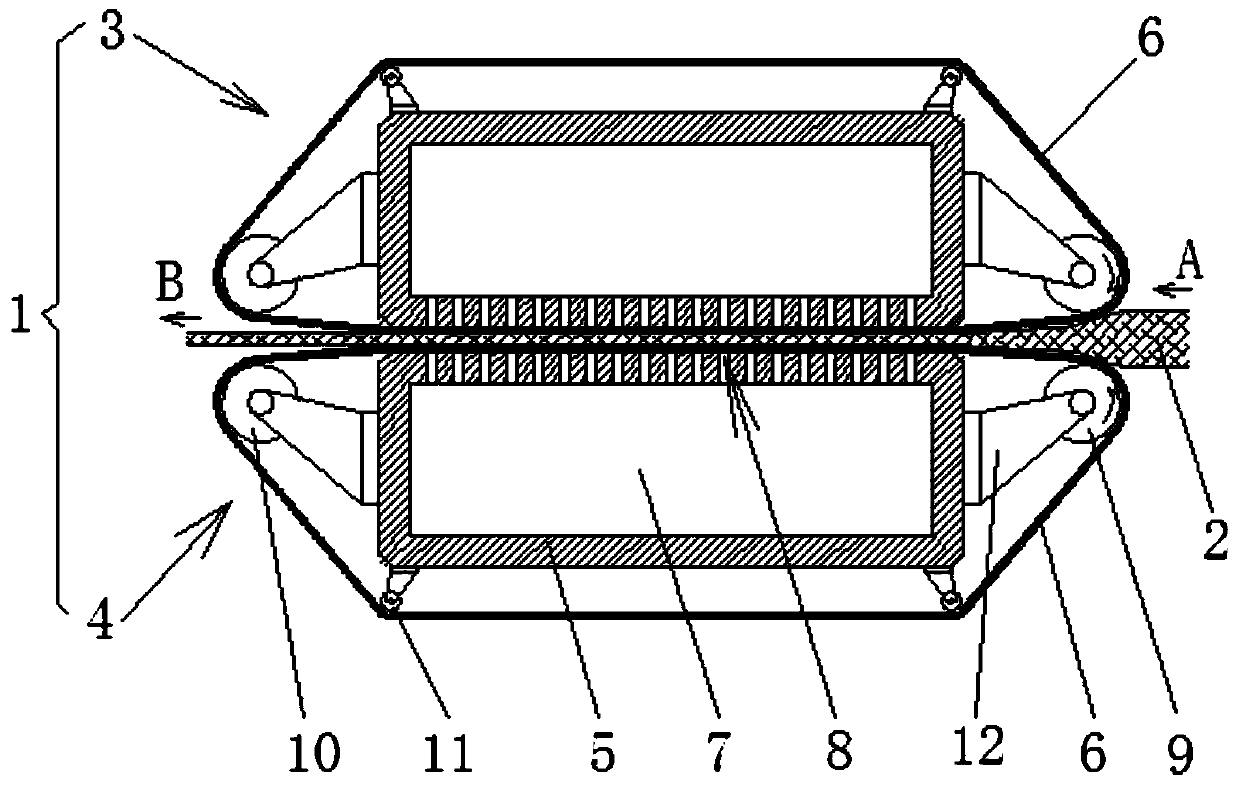

[0044] Such as Figures 1 to 3 Shown is an embodiment of the preparation process of a high-physical cowhide leather base cloth of the present invention, including a batching process, a chemical fiber netting process, a kraft fiber netting process, and a chemical fiber net and a kraft fiber net. process; the batching process includes taking chemical fiber and cowhide fiber as raw materials for preparing fully pierced cowhide leather base cloth, and performing batching in a weight ratio of 1:0.8 to 1:1.2; the chemical fiber netting The process sequentially includes the steps of opening, carding, web laying, pre-wetting, and pre-stabbing: in the kraft fiber web forming process, kraft fiber raw materials are made into kraft fiber webs by air-laid or water-laid; the chemical The fiber web and kraft fiber web lamination process includes the steps of lamination, spunlace, vacuum drying, and drying in sequence;

[0045] Wherein, the chemical fiber is nylon fiber, or a mixed fiber of ...

Embodiment 2

[0066] Get some quantity by the bovine fiber leather base cloth that embodiment 1 prepares as sample, and sample specification is that length is 150mm, width 30mm, thickness 2.5mm, carries out peeling load test then, and carries out with conventional process manufacturing bovine fiber leather base cloth For comparison (the ambient temperature of the test is 23°C ± 2°C, and the relative humidity is 50% ± 10%), the results are as follows:

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com