Paint of silicon-ceramic capable of resisting 900-1200 deg.C. organic high temp

A technology of ceramic coatings and high temperature resistant pigments, applied in the direction of coating, can solve problems such as inconvenience of coating, and achieve the effects of convenient coating, good adhesion and excellent coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

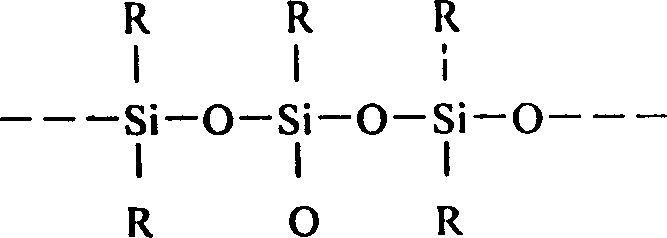

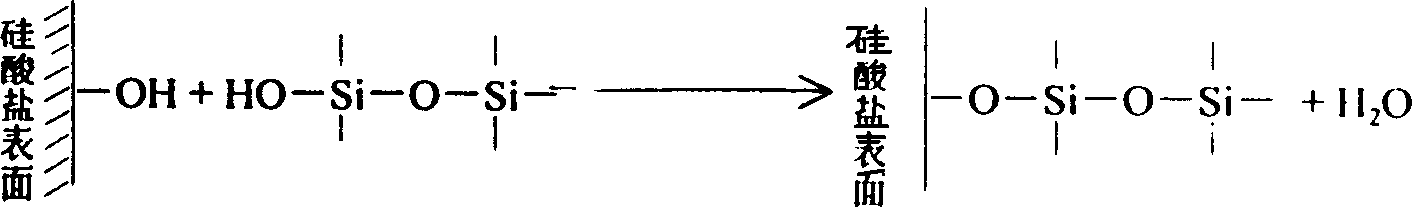

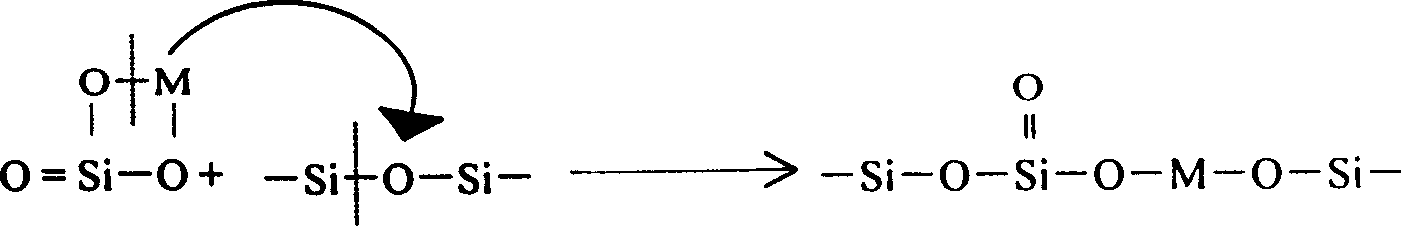

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Mix 300kg of pure silicone resin, 120kg of high temperature-resistant coloring pigments, 350kg of metal oxide and silicate type fillers, and 230kg of solvent xylene, and grind at a high speed to form the 900-1200°C high-temperature resistant pigment described in the present invention. silicone-ceramic coatings.

Embodiment 2

[0028] Embodiment 2: Mix 220kg of pure silicone resin, 100kg of high-temperature-resistant coloring pigment, 500kg of metal oxide and silicate type fillers, 150kg of solvent xylene, and 30kg of anti-sedimentation agent, and grind at a high speed to prepare the anti-settling agent described in the present invention. 900~1200℃ high temperature organosilicon-ceramic coating.

Embodiment 3

[0029] Example 3: Mix 150kg of pure silicone resin, 150kg of high-temperature-resistant coloring pigments, 600kg of metal oxide and silicate type fillers, and 100kg of solvent xylene, and grind at a high speed to form the high-temperature resistant 900-1200°C described in the present invention. silicone-ceramic coatings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com