System and method for monitoring sand production rate of oil-gas well

A monitoring system and sand production technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve problems such as not being able to meet production needs, and achieve the effects of improving oil well productivity, enhancing movement speed, and prolonging production life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

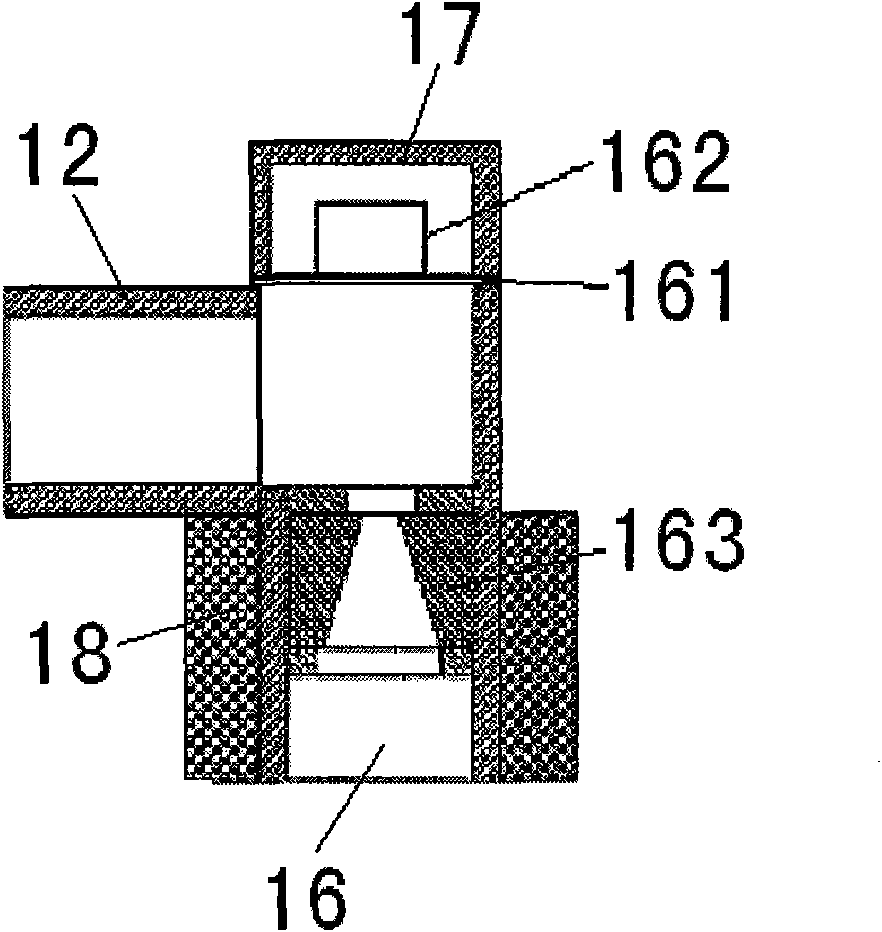

[0018] Since the oil and gas flow flows at a certain speed in the pipeline during the production of oil and gas wells, if there are sand particles of a certain size in the oil and gas flow, the sand particles will move together with the oil and gas flow. When the moving sand meets the barrier, the sand will have a certain impact on the barrier, and the force generated by the impact will cause the barrier to vibrate. The larger the particle size of the sand, the greater the impact on the barrier; the more the sand, the more the impact on the barrier.

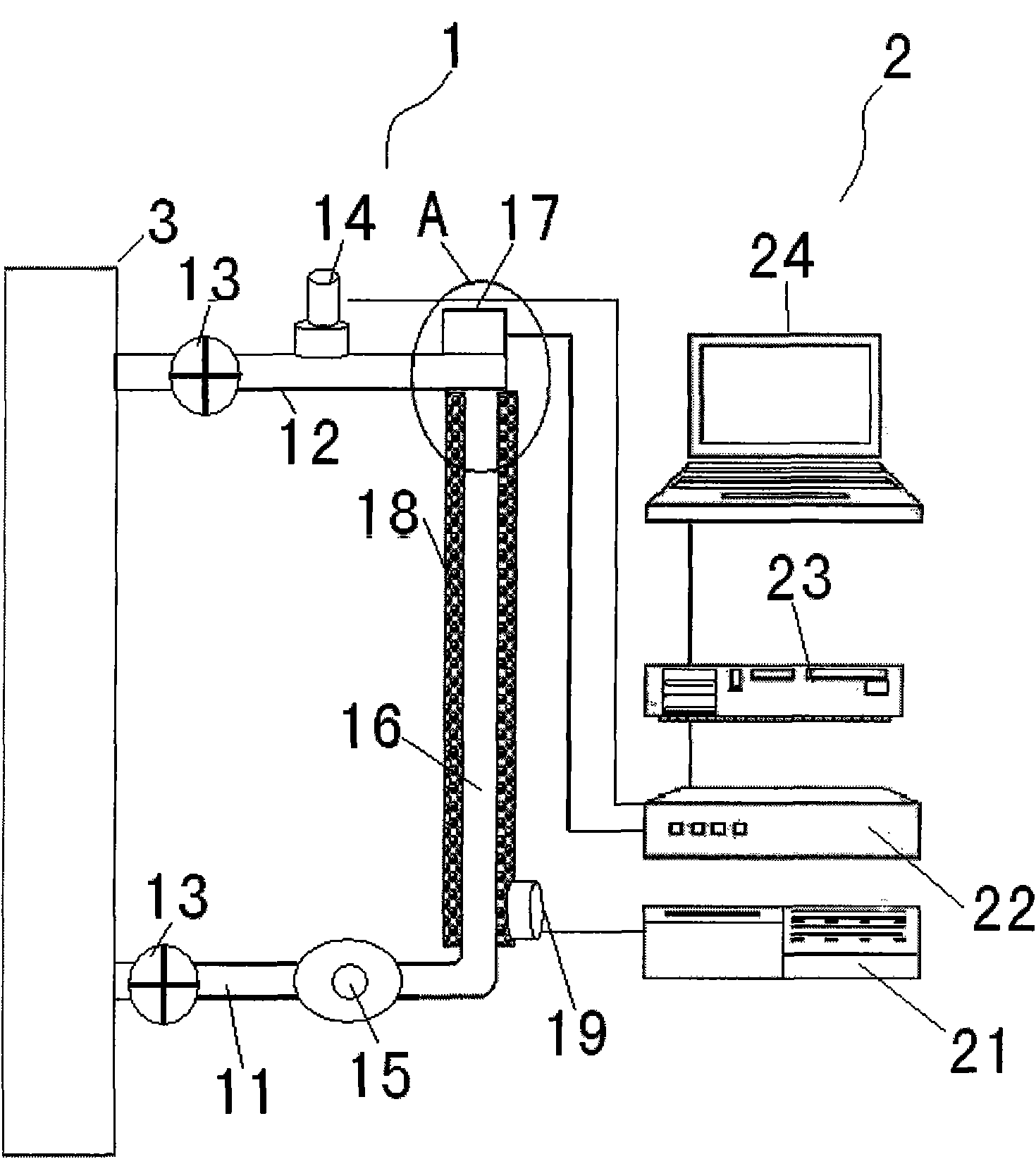

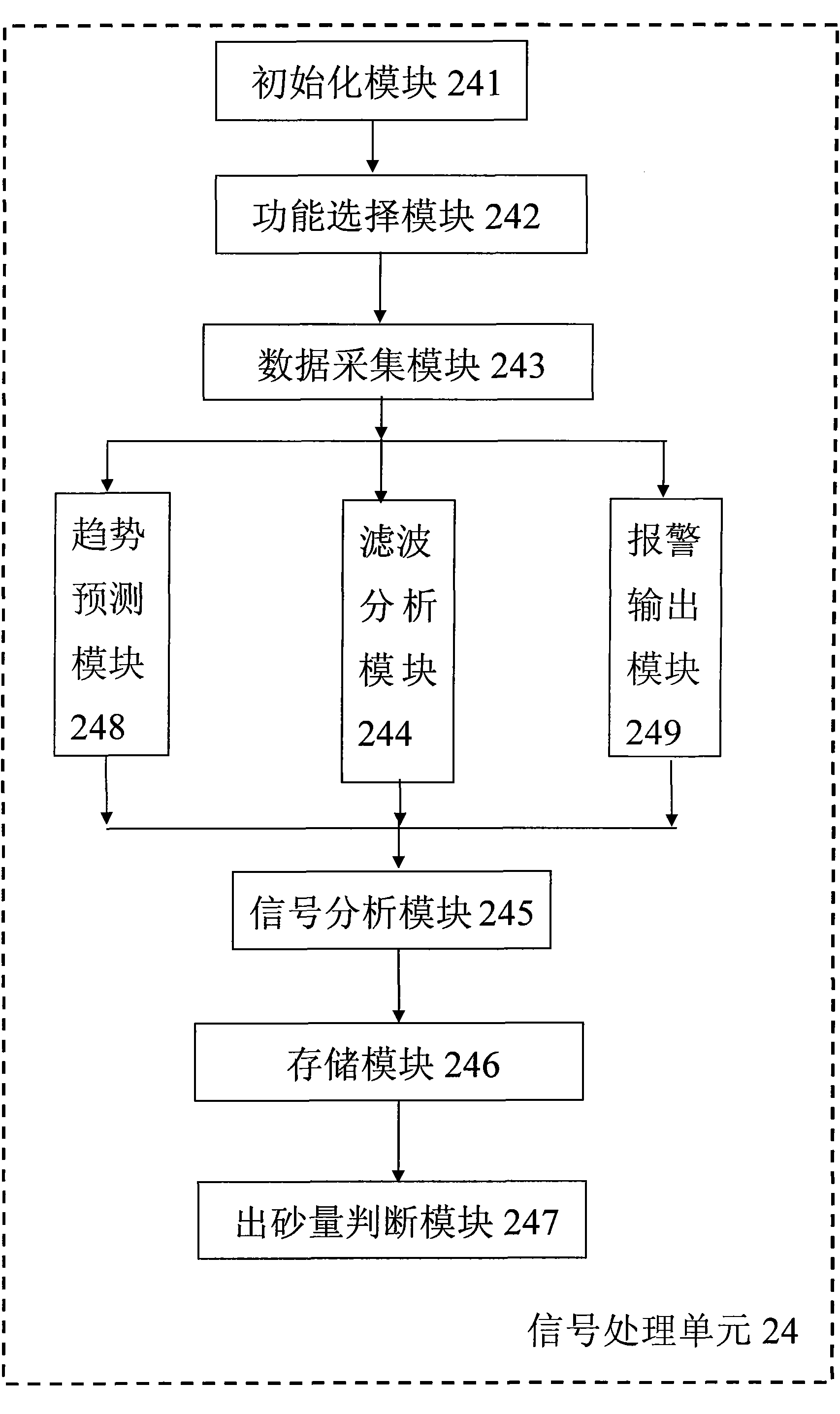

[0019] Such as figure 1 As shown, the oil and gas well sand production monitoring system provided by the present invention includes a high-frequency signal sensing device 1 and a control device 2, and the high-frequency signal sensing device 1 is arranged on the oil and gas production pipeline 3, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com