Polyimide fiber and preparation method thereof

A technology of polyimide fiber and primary amine, applied in the field of organic polymer fiber and its preparation, can solve the problems of inability to use polyimide powder, high energy consumption, etc., achieve excellent dimensional stability, low investment cost, The effect of mild reaction conditions

Inactive Publication Date: 2010-12-22

DONGHUA UNIV +1

View PDF4 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The weak point that this method exists is mainly reflected in the following aspects: (1) the preparation method is only applicable to meltable polyimide systems, and cannot be applied to high-temperature non-melting polyimide powders; (2) The requirements for the extruder are very high, and the extruder must be able to withstand high temperatures above 360°C. Therefore, the extruder needs to be specially designed; (3) The energy consumption is relatively large

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

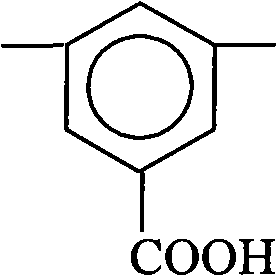

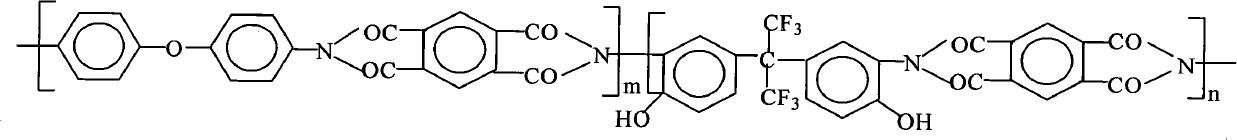

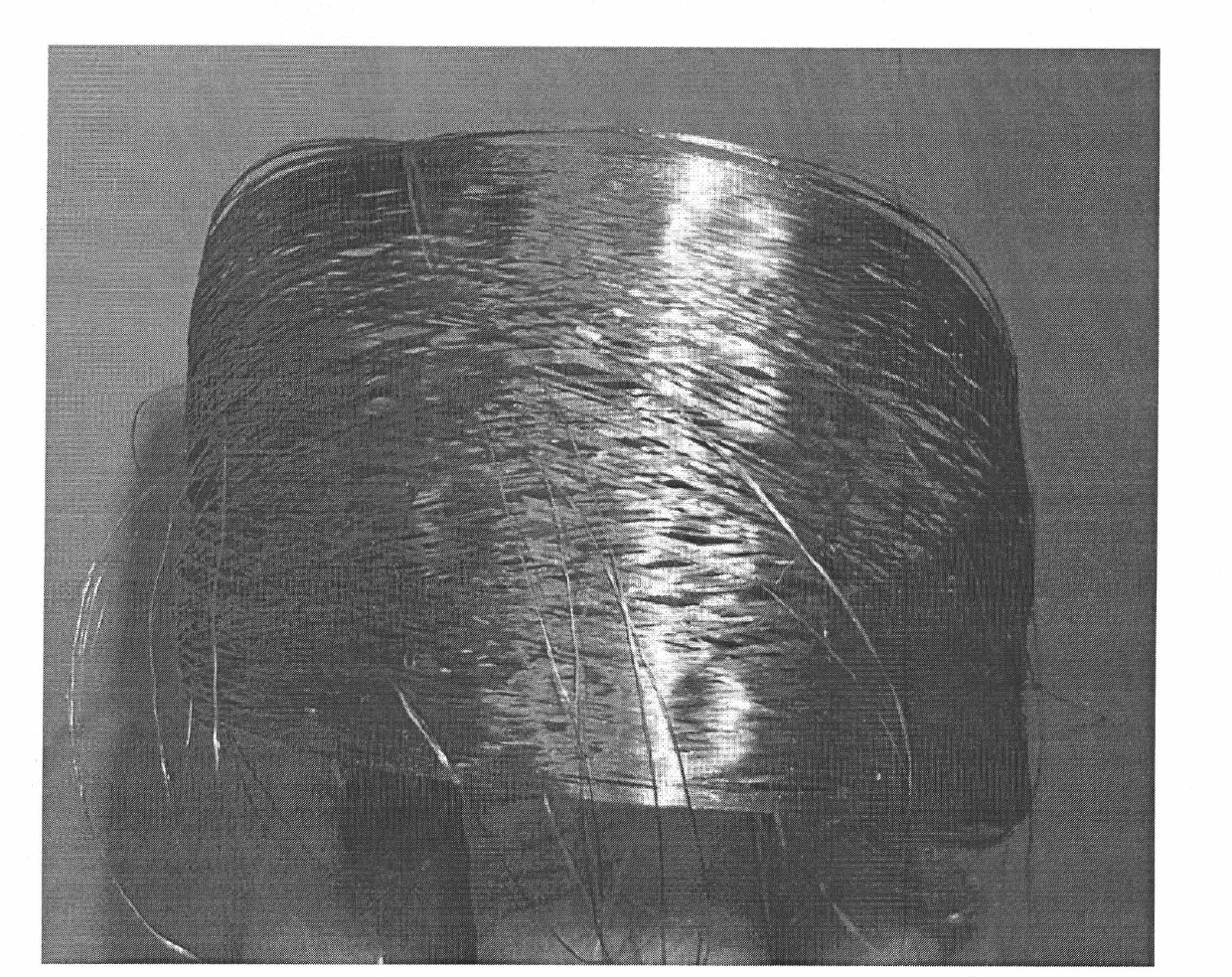

The invention relates to a polyimide fiber. The polyimide fiber has a molecular structure general formula shown in the specifications, wherein -Q1- is an aromatic binary primary amine residue without a phenolic hydroxyl group; =Ar= is an aromatic binary anhydride residue; and -Q2- is a phenolic hydroxyl group-containing linker of aromatic binary primary amine. The preparation of the polyimide fiber comprises the following steps of: firstly, stirring the aromatic binary primary amine and aromatic binary anhydride in an organic solvent system at room temperature and reacting for 2 to 4 hours toobtain homogeneous, transparent and viscous polyamic acid solution; secondly, pouring the solution into a spinning machine, performing screw extrusion, forming the fiber by using a spinneret and a coagulating bath, drawing and winding to obtain an as-spun fiber; and finally, treating the as-spun fiber at a high temperature to obtain the polyimide fiber. The polyimide fiber has high resistance to high temperature and high mechanical property; and the preparation process has the advantages of no need of special production equipment, capability of producing on the conventional polyimide resin production line and the spinning machine, easy recycling of an organic solvent, environmental friendliness and suitability for industrial production.

Description

technical field The invention relates to the technical field of organic polymer fiber and its preparation, in particular to a polyimide fiber and its preparation method. Background technique Polyimide is a kind of polymer with excellent comprehensive performance, which has excellent heat resistance, low temperature resistance, solvent resistance, self-lubricating property and flame retardancy. At the same time, it also has very good mechanical properties and Dielectric properties. Therefore, it is widely used in photovoltaic materials, nonlinear optical materials; high temperature resistant materials for spacecraft, satellites or space vehicles; advanced structural composite materials in aerospace, automobiles, electromechanical, etc.; Insulating materials, high temperature resistant adhesives, etc.; and FPC or PCB substrate materials in the field of electronic microelectronics, IC interlayer insulating materials, VLSI passivation coatings and alpha particle barrier coating...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01F6/74C08G73/10

Inventor 虞鑫海赵炯心陈梅芳

Owner DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com