Method for reinforcing autoclaved aerated concrete by using external reinforcing agent

An autoclaved air-entraining and reinforcing agent technology is applied in the field of lightweight thermal insulation building materials, which can solve the problems of reducing the performance of aerated concrete - thermal insulation performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Use of inorganic and organic topical enhancers. Prepare the same autoclaved air-entrained concrete as in Comparative Example 1, after drying, immerse in the inorganic external surface enhancer for 6 hours, dry it at room temperature, put it into the organic external surface enhancer for 20 minutes, and bake it at 40°C After drying to constant weight, the same physical and mechanical properties as in Comparative Example 1 were tested.

[0032] The inorganic external strengthening agent is composed of a lithium silicate aqueous solution with a mass percent concentration of 18% and diethylene glycol butyl ether accounting for 5% of the total weight of the inorganic external strengthening agent.

[0033] The organic topical enhancer is composed of 35% RMAT, 50% xylenone, and 15% propylene oxide phenyl ether.

Embodiment 2

[0035] Prepare the same autoclaved aerated concrete as Comparative Example 1, after drying, after drying, dip in the inorganic exterior surface enhancer for 8 hours, dry at room temperature, put into the organic exterior surface enhancer and soak for 30 minutes, After drying at 40° C. to constant weight, the same physical and mechanical properties as in Comparative Example 1 were tested.

[0036] The inorganic external strengthening agent is composed of aqueous solution of lithium silicate and sodium silicate with a mass percent concentration of 30% and ethylene glycol butyl ether accounting for 2% of the total weight of the inorganic external strengthening agent.

[0037] The organic external enhancer is composed of 20% PGCN-702, 72% acetone, and 8% propylene oxide butyl ether.

Embodiment 3

[0039]Prepare the same autoclaved aerated concrete as in Comparative Example 1, after drying, immerse in the inorganic external surface enhancer for 10 hours, dry it at room temperature, put it into the organic external surface enhancer for 40 minutes, and test it after drying The same physical and mechanical properties as Comparative Example 1.

[0040] The inorganic external strengthening agent is composed of a lithium silicate aqueous solution with a mass percent concentration of 10% and ethylene glycol butyl ether accounting for 6% of the total weight of the inorganic external strengthening agent.

[0041] The organic external enhancer is composed of 50% 102C-1, 38% styrene, and 12% propylene oxide butyl ether. Styrene can also be replaced with alcohol or toluene.

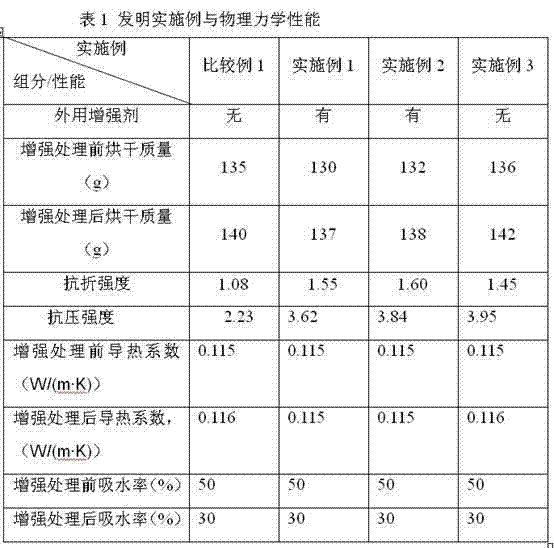

[0042] The test results of strength and expansion degree of above embodiment are shown in Table 1

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com