Patents

Literature

31results about How to "Chemically reactive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

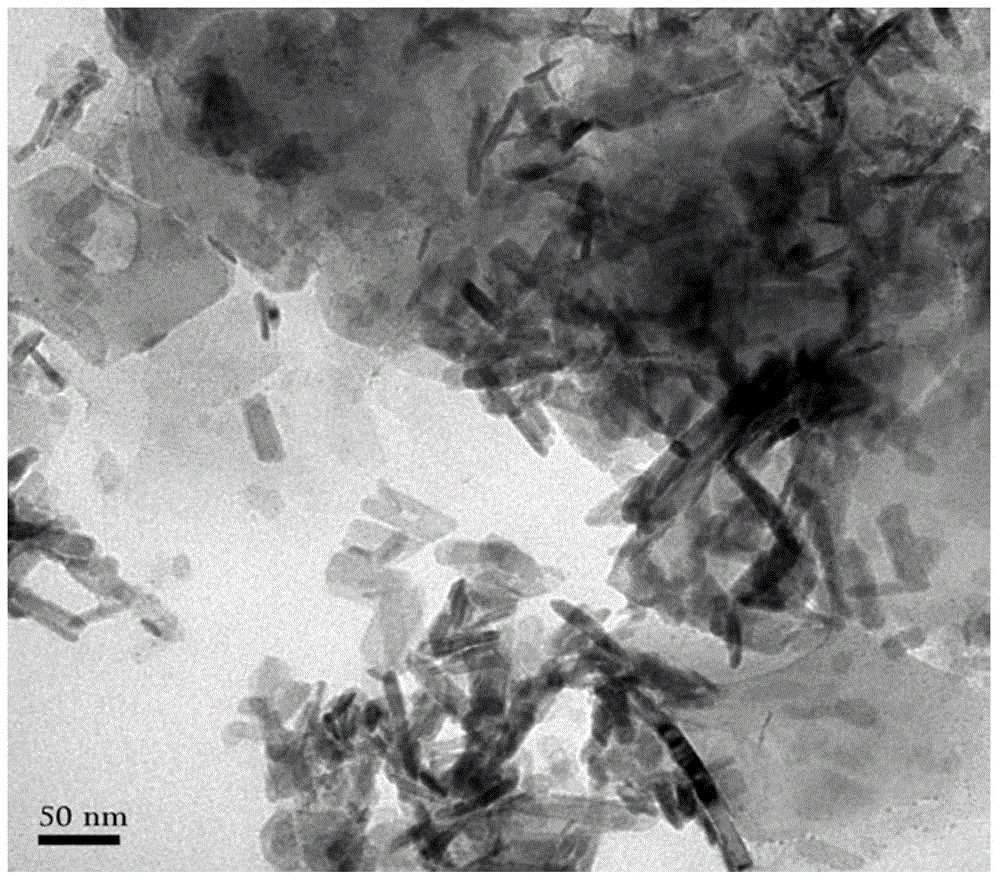

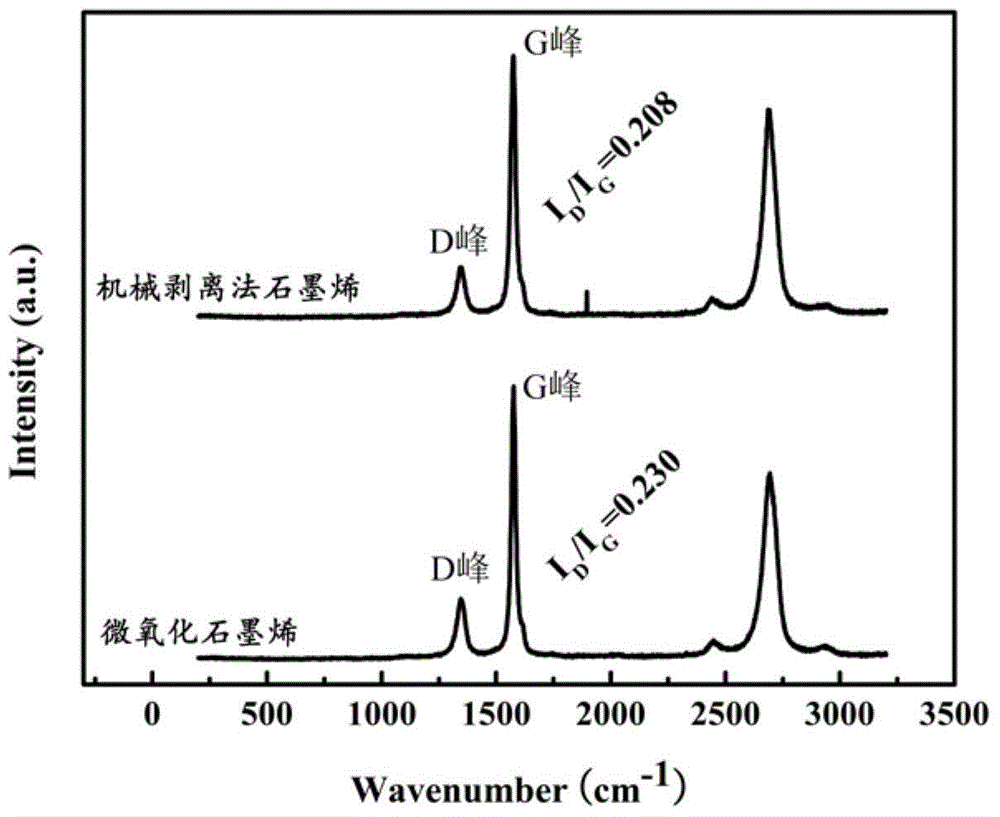

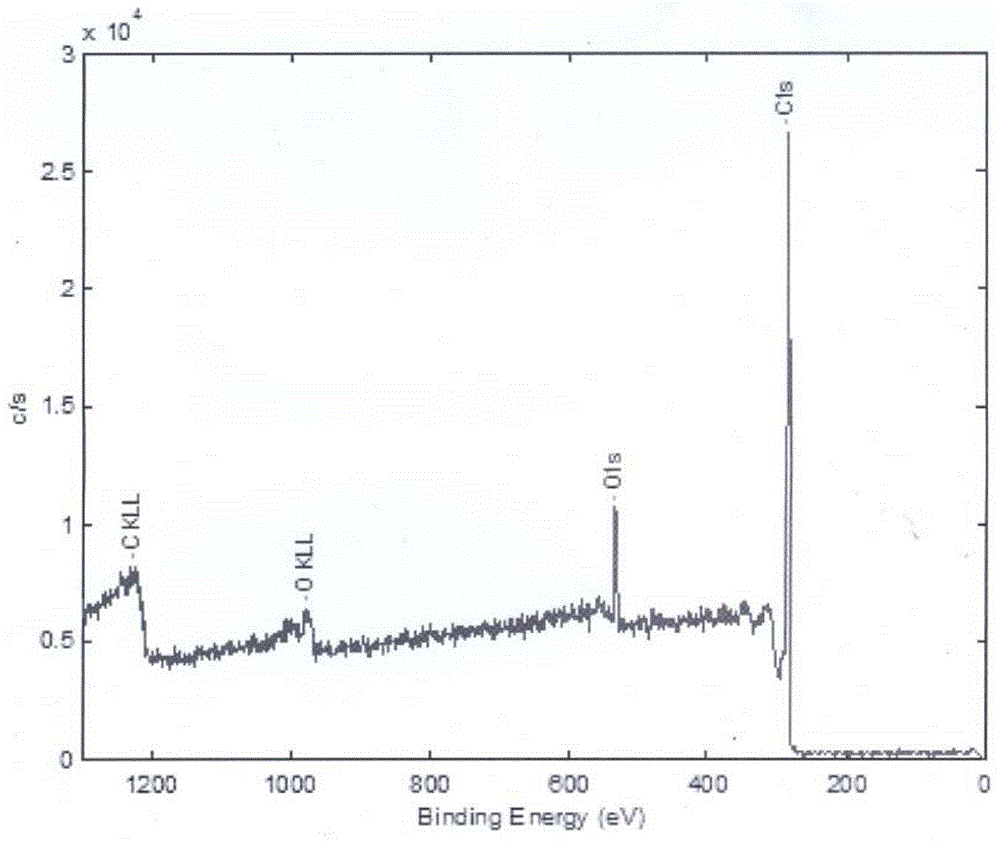

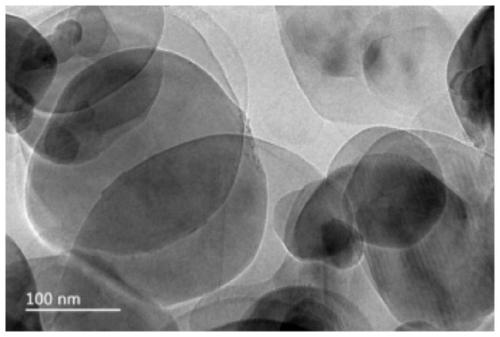

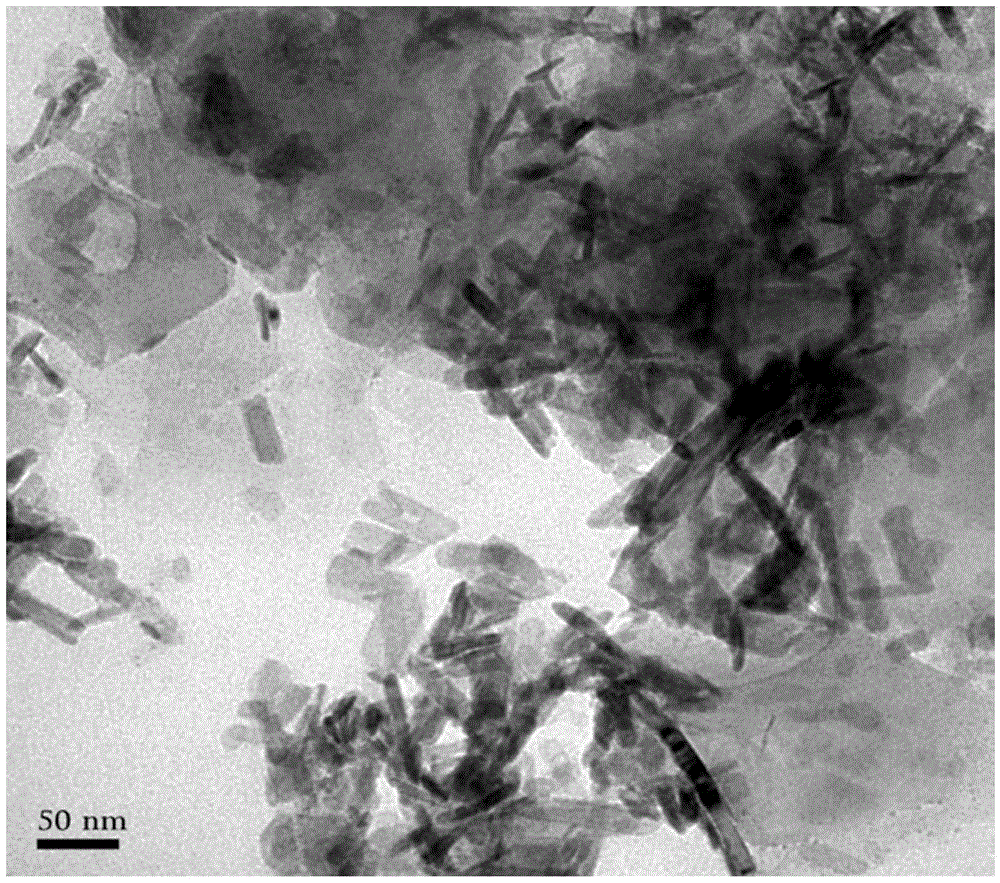

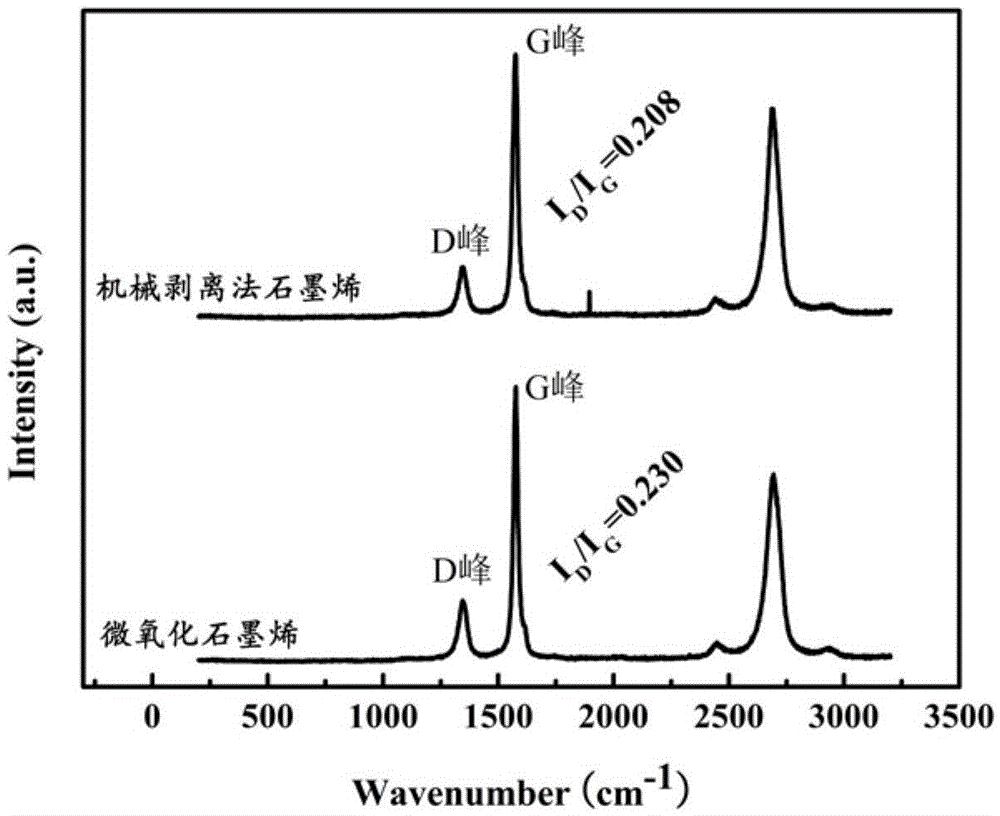

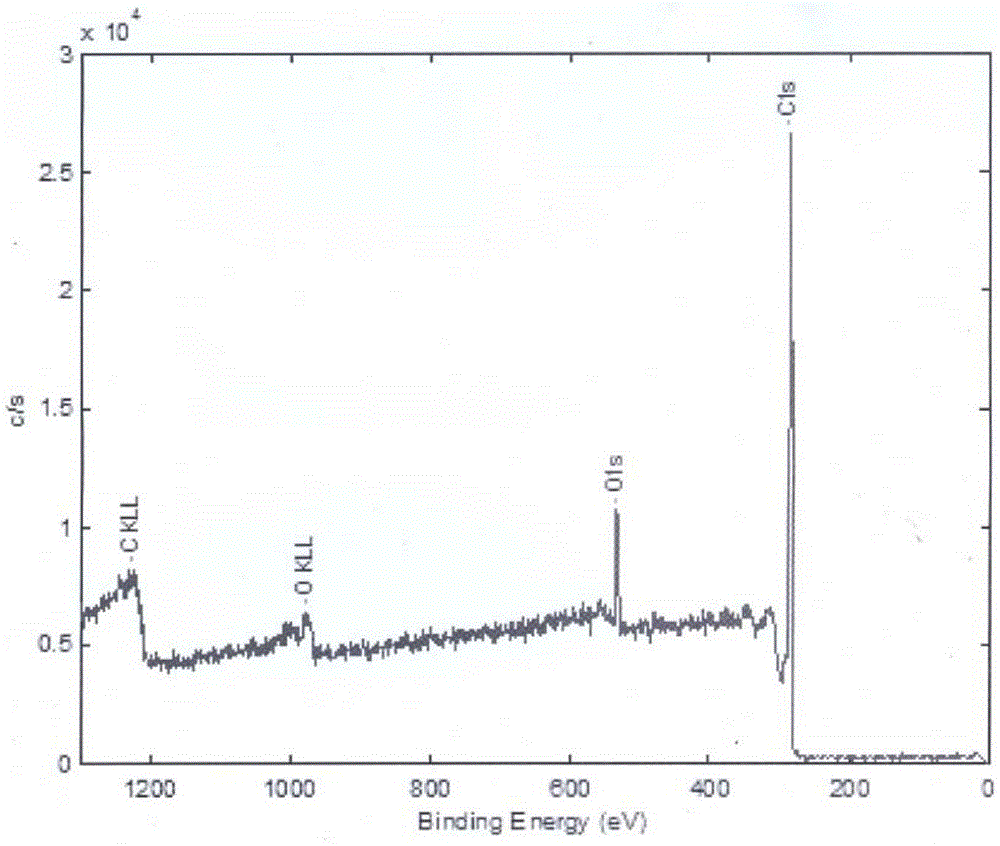

Micro-oxidized graphene and preparation method thereof

ActiveCN104386677AReduce the degree of oxidationReduce lattice defectsCvd grapheneFunctional composite

The invention belongs to the technical field of graphene materials and in particular relates to micro-oxidized graphene and a preparation method thereof. The micro-oxidized graphene contains a small amount of active groups, is low in degree of oxidation, and has the oxygen element content of 1-10wt% and the bulk density of 0.01-0.1g / ml. The micro-oxidized graphene contains a proper amount of chemical reaction active group points, and meanwhile, a relatively complete graphene lattice structure is remained so that the micro-oxidized graphene has excellent dispersibility, special reactivity and excellent physical properties. The invention provides an industrial micro-oxidized graphene preparation route which is efficient, stable, economical, controllable and environment-friendly and the defects of uncontrollable graphene activation, great operation risks, serious environmental pollution, serious equipment corrosion, high cost investment and the like of a traditional acid oxidation method can be overcome. The micro-oxidized graphene prepared by use of the preparation method has extremely wide prospect in the fields of functional composites, coatings, ink, photoelectric materials, biological medicine and the like.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

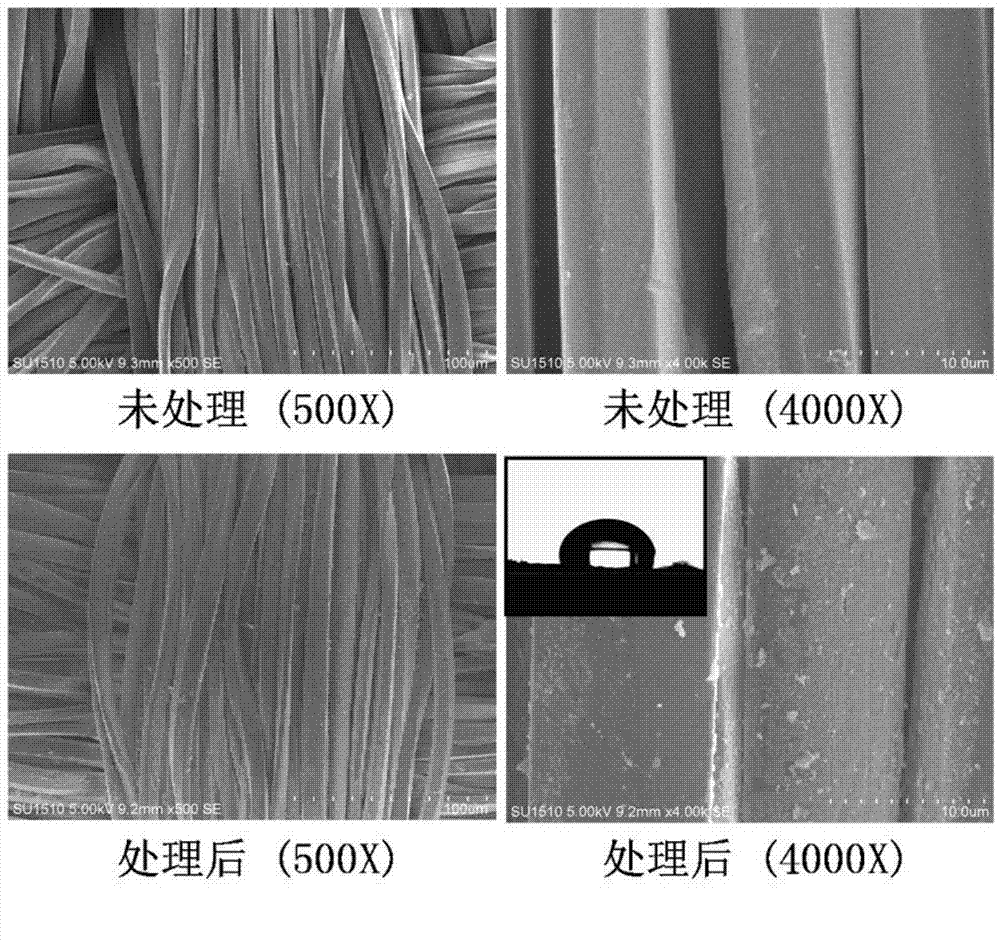

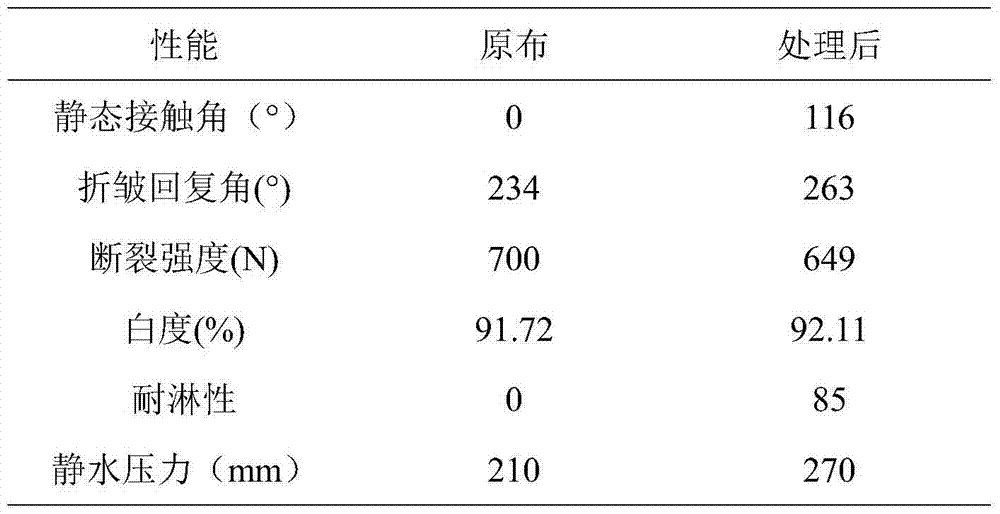

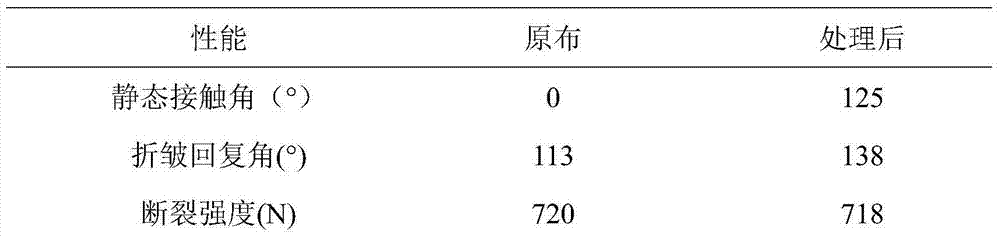

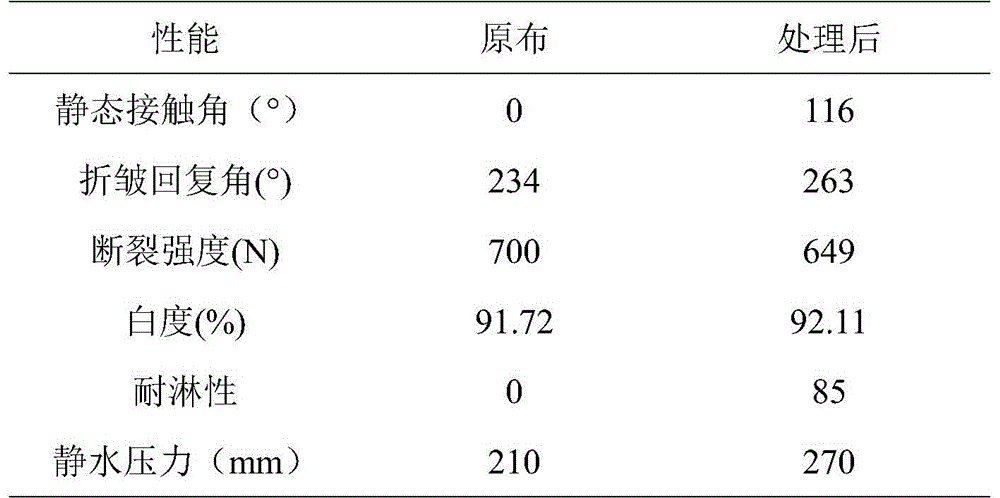

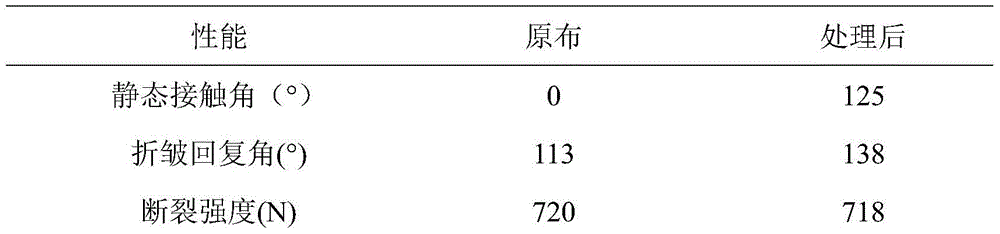

PAA-TEOS-OA combined treatment-based finishing method for polyester or polyamide hydrophobic fabric

The invention discloses a PAA-TEOS-OA combined treatment-based finishing method for a polyester or polyamide hydrophobic fabric, and belongs to the technical field of functional textiles. A fabric is subjected to pretreatment by utilizing polyacrylic acid, so that the capability of the fabric in the aspect of reacting with a subsequent chemical reagent is improved, and a bridge function is achieved; tetraethyl orthosilicate is hydrolyzed and polycondensed under an acid or alkali condition, and particular matters are formed on the surface of the fabric, so that a function of roughening the fabric is achieved; long-chain alkane type octadecylamine can effectively reduce surface energy of the fabric, and meanwhile, the environment problem caused by perfluoronic compounds is avoided; in the finishing treatment, traditional soaking, rolling, baking and roasting processes are utilized, so that the homogeneity and the repeatability of products are good, and the cost is low; the polyacrylic acid, the tetraethyl orthosilicate and the octadecylamine, which are utilized in the whole finishing process, need to be utilized under weak acid and weak alkali conditions, and the baking temperature is low, so that the damage to the fabric is small; the finishing method can be applied to finishing a hydrophobic function of the polyester or polyamide fabric.

Owner:高青如意纺织有限公司

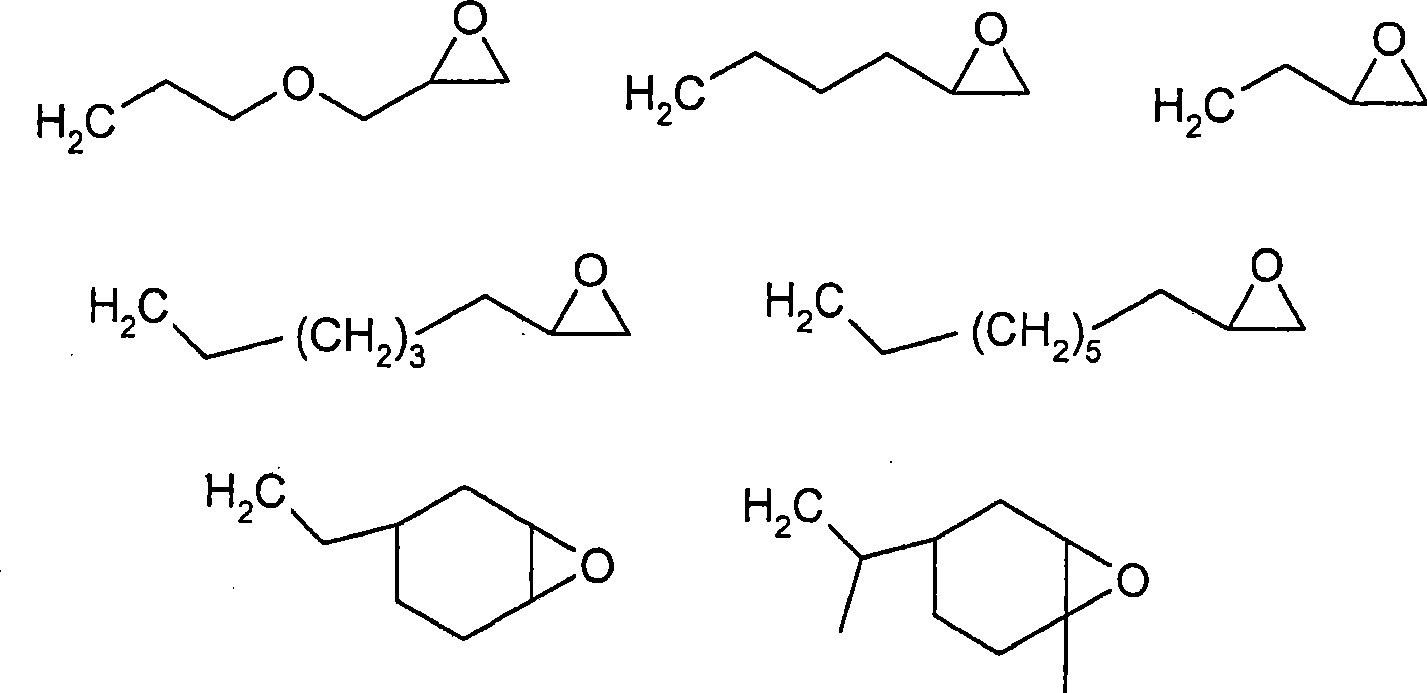

Hyperbranched polyether modified polysiloxane defoamer containing nanosilicon dioxide and preparation method thereof

InactiveCN106474775AImprove shear resistanceSuitable for many occasionsFoam dispersion/preventionEnd-groupAluminum silicate

The invention discloses a hyperbranched polyether modified polysiloxane defoamer containing nanosilicon dioxide. The hyperbranched polyether modified polysiloxane defoamer is prepared from, by weight, 25-40 parts of polysiloxane, 13-23 parts of hyperbranched polyether, 16-26 parts of allyl glycidyl ether, 38-58 parts of epoxypropane, 0.3-0.5 part of double metal cyanide, 50-70 parts of isopropanol, 0.2-0.5 part of a chloroplatinic acid catalyst, 2-6 parts of ultra-fine aluminum silicate, 1-2 parts of sorbitol, 1-2 parts of tween-60, 2-4 parts of sodium carboxymethylcellulose, an appropriate amount of deionized water, 4-11 parts of nanosilicon dioxide powder and 45-60 parts of dodecyl alcohol. The hyperbranched polyether containing a large number of hydroxyls at the tail end is adopted as a raw material, end-allyl hyperbranched polyether is prepared, a modified polyether end group double-bond structure and polysiloxane are adopted for performing a hydrosilylation reaction, the hyperbranched polyether modified polysiloxane is synthesized, and the defoamer prepared through the hyperbranched polyether modified polysiloxane has the excellent anti-shearing performance.

Owner:合肥新万成环保科技有限公司

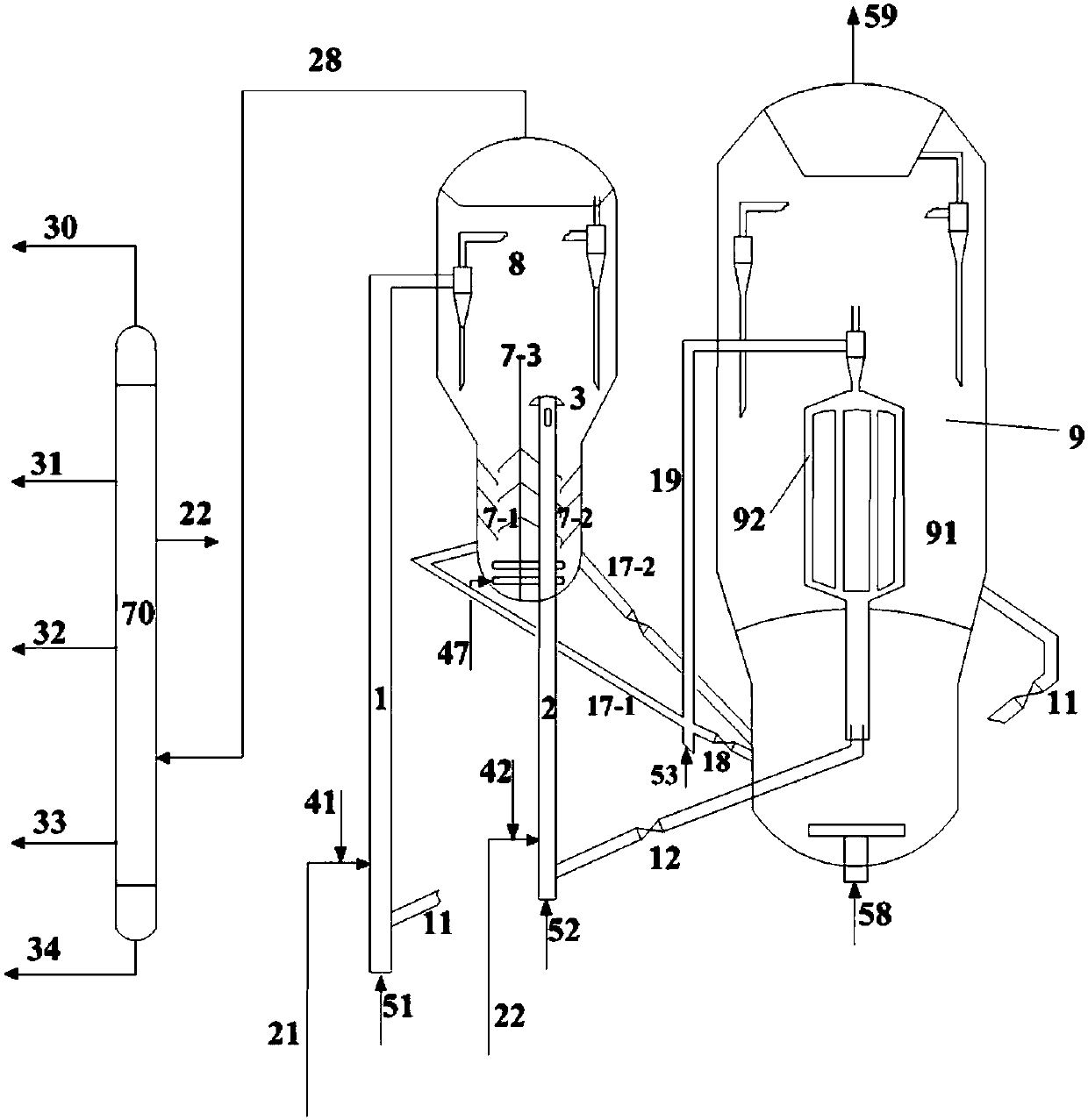

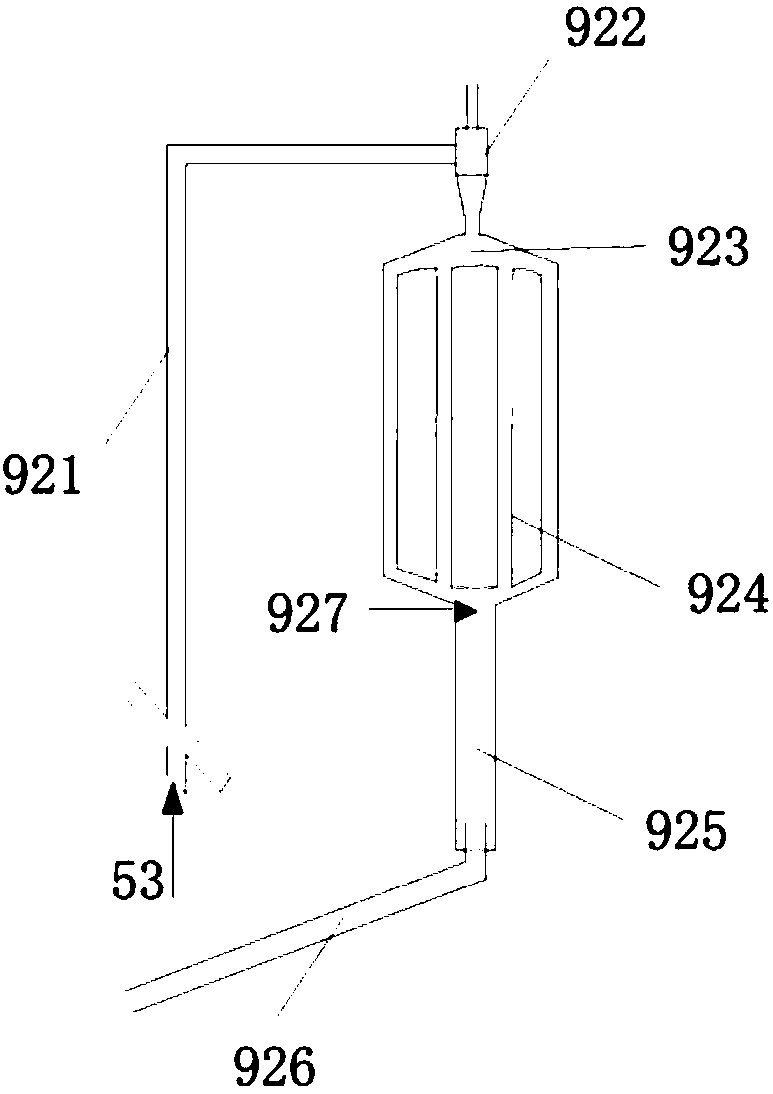

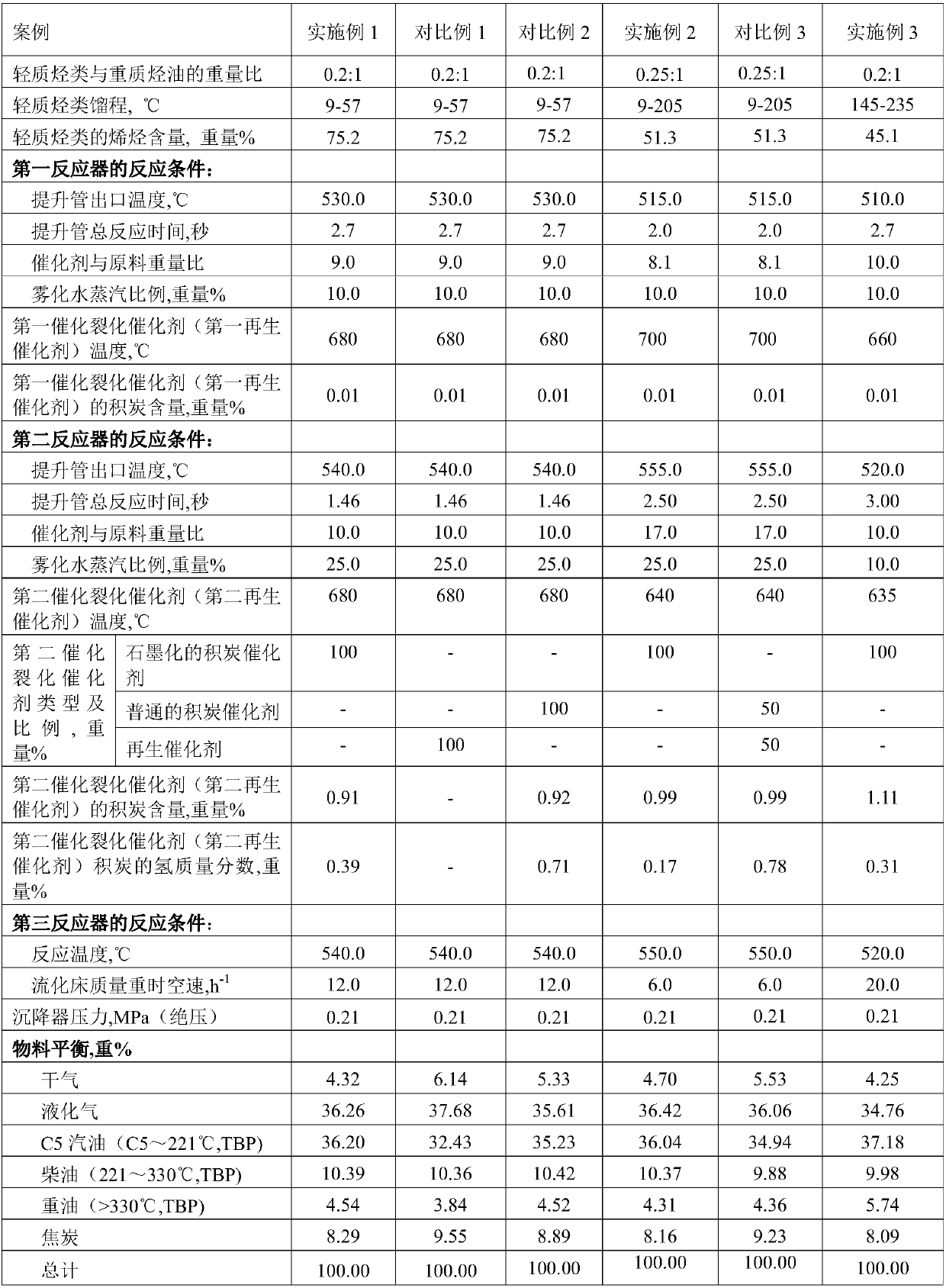

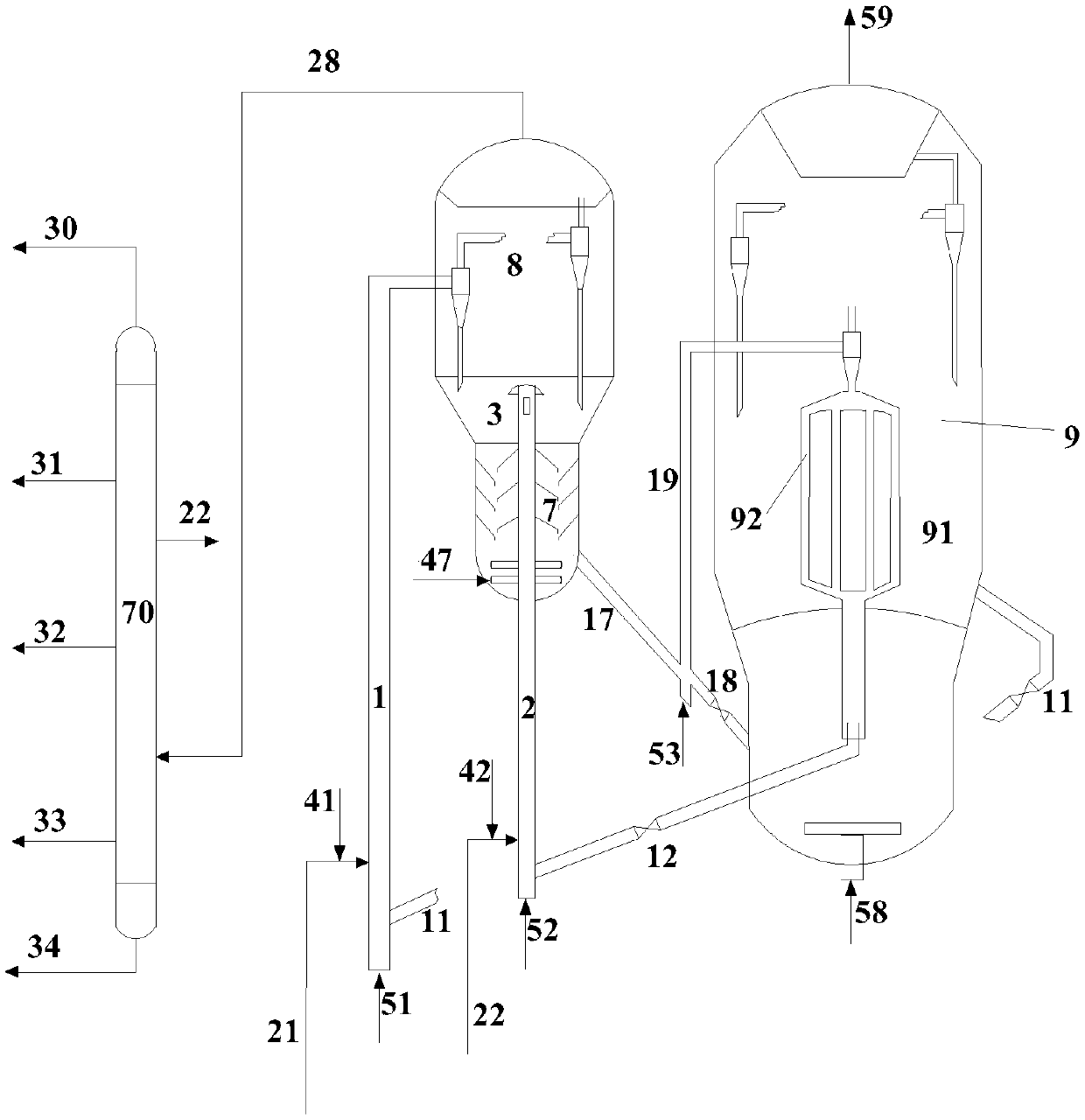

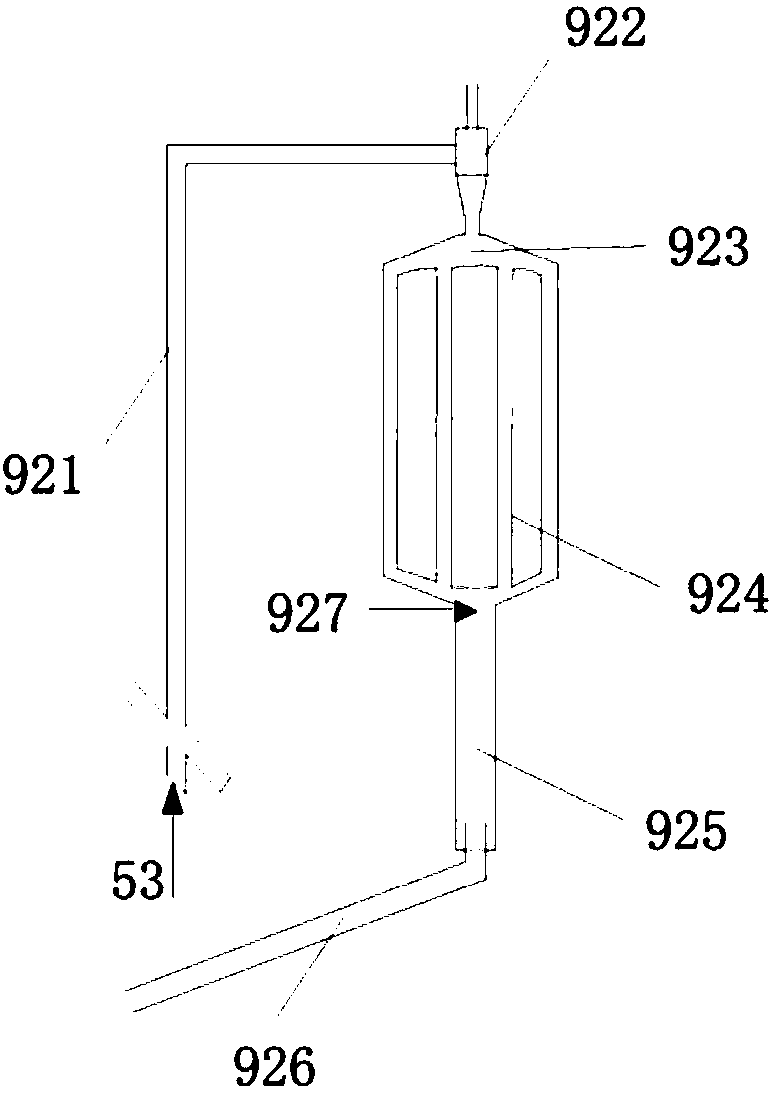

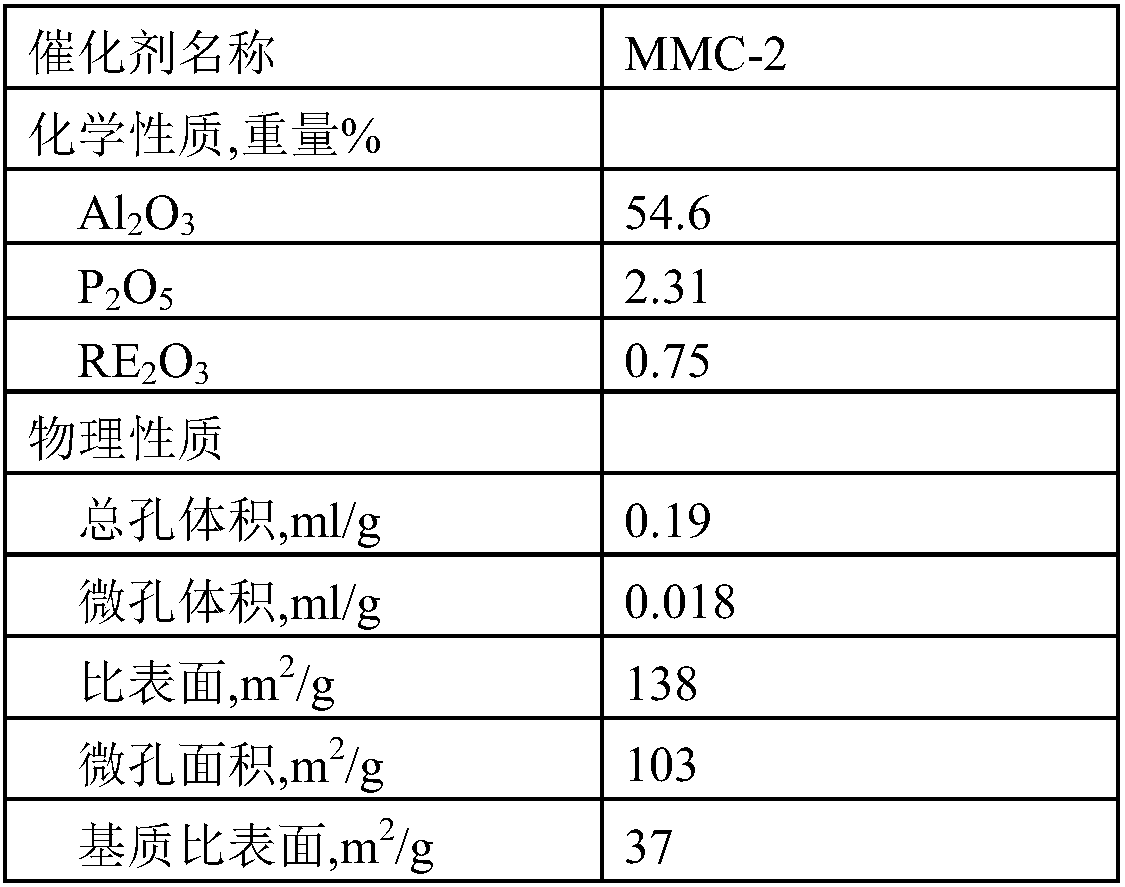

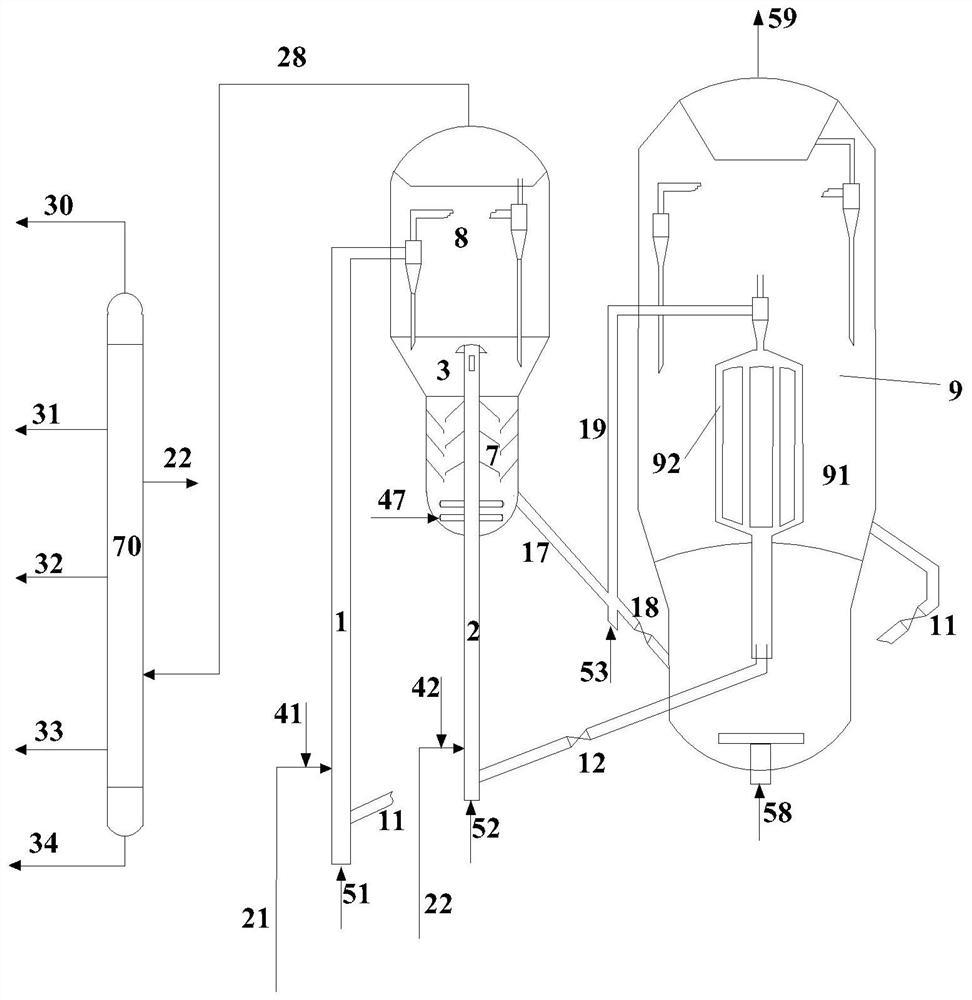

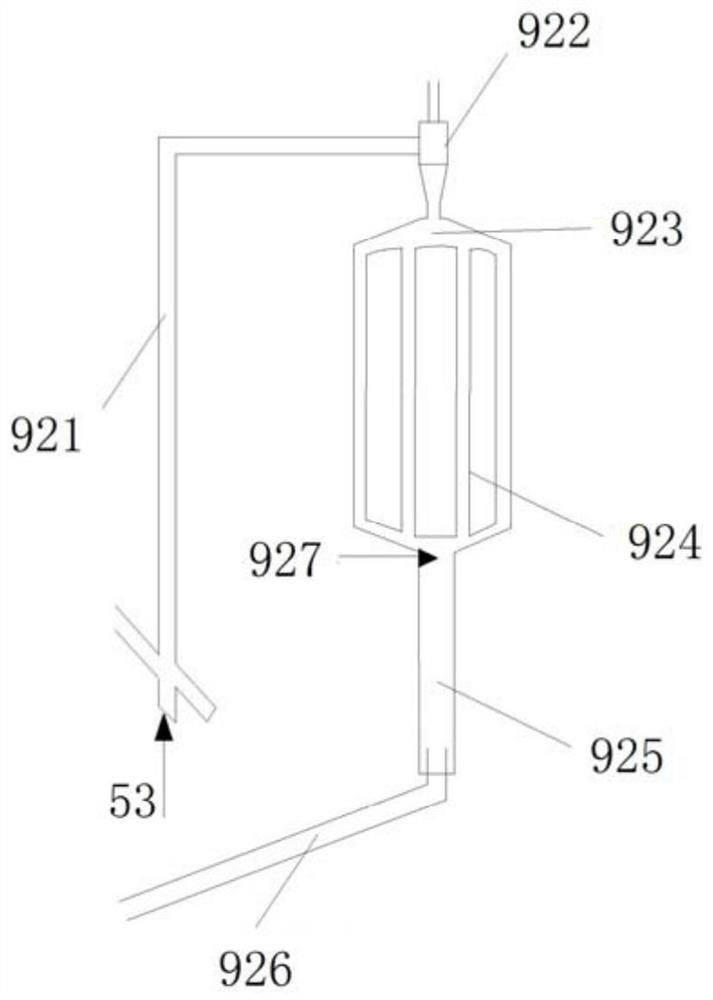

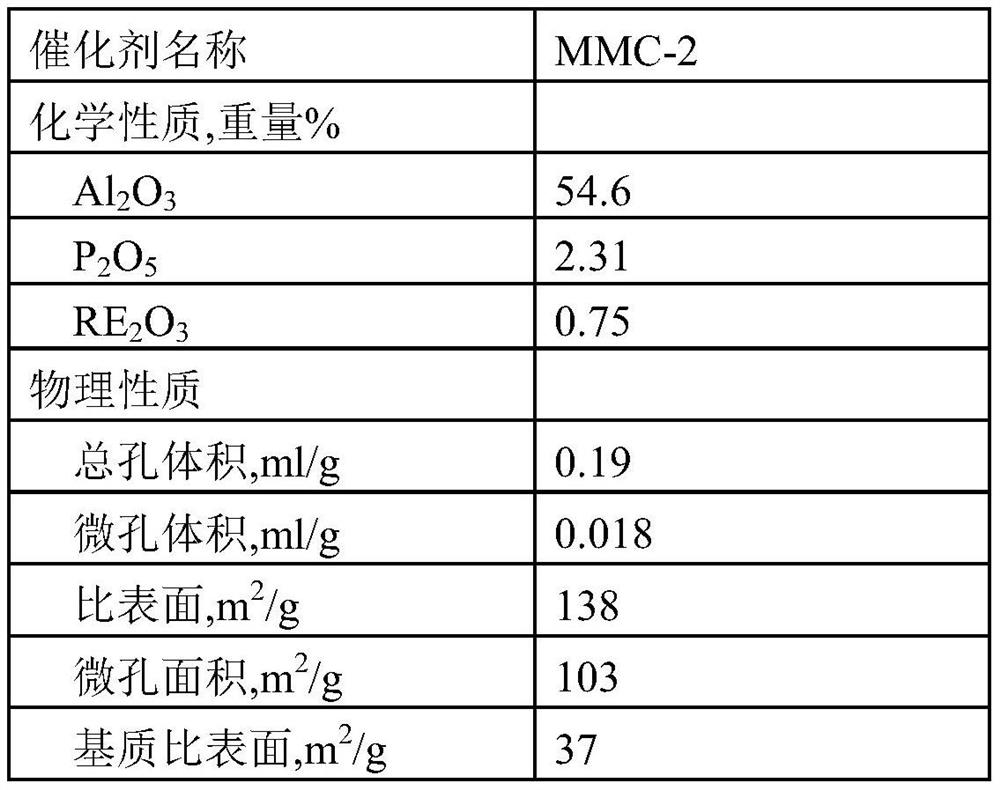

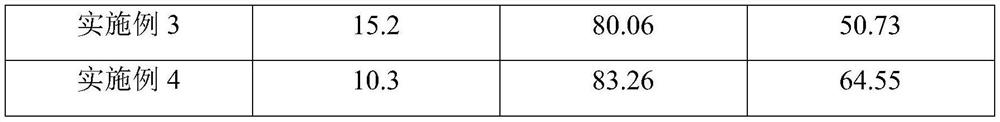

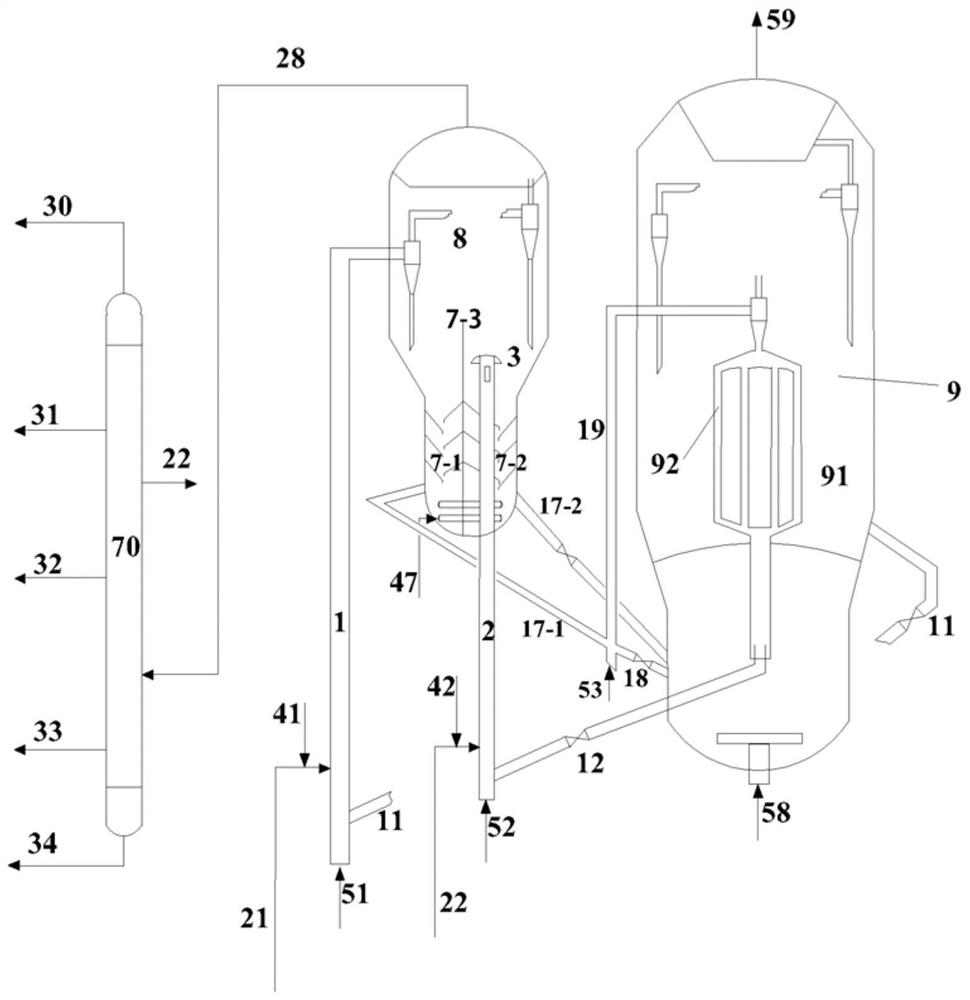

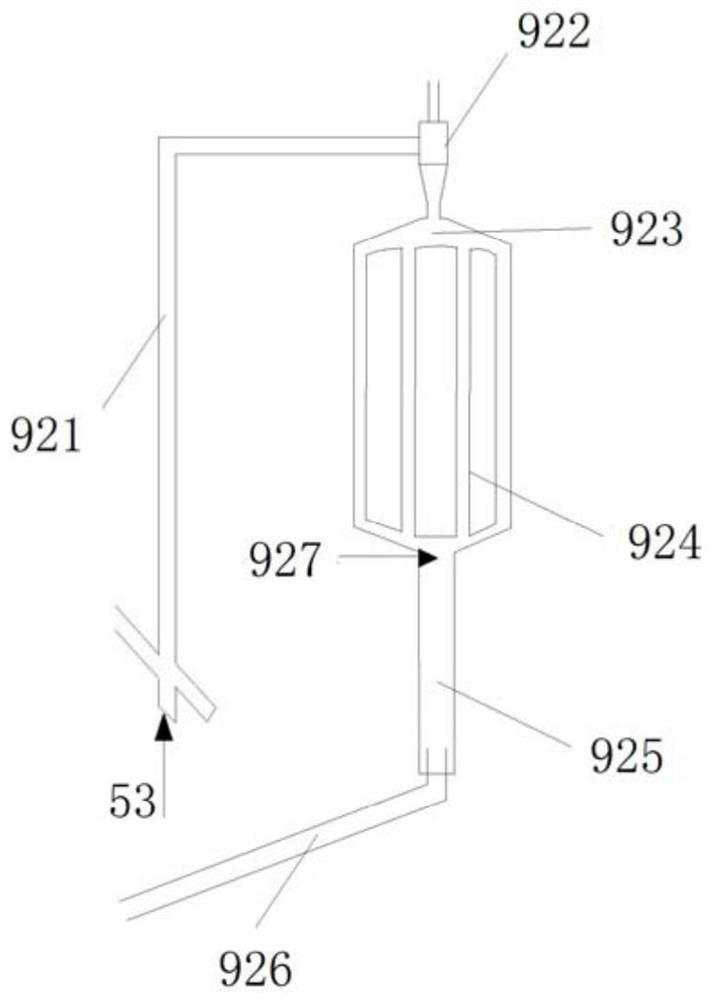

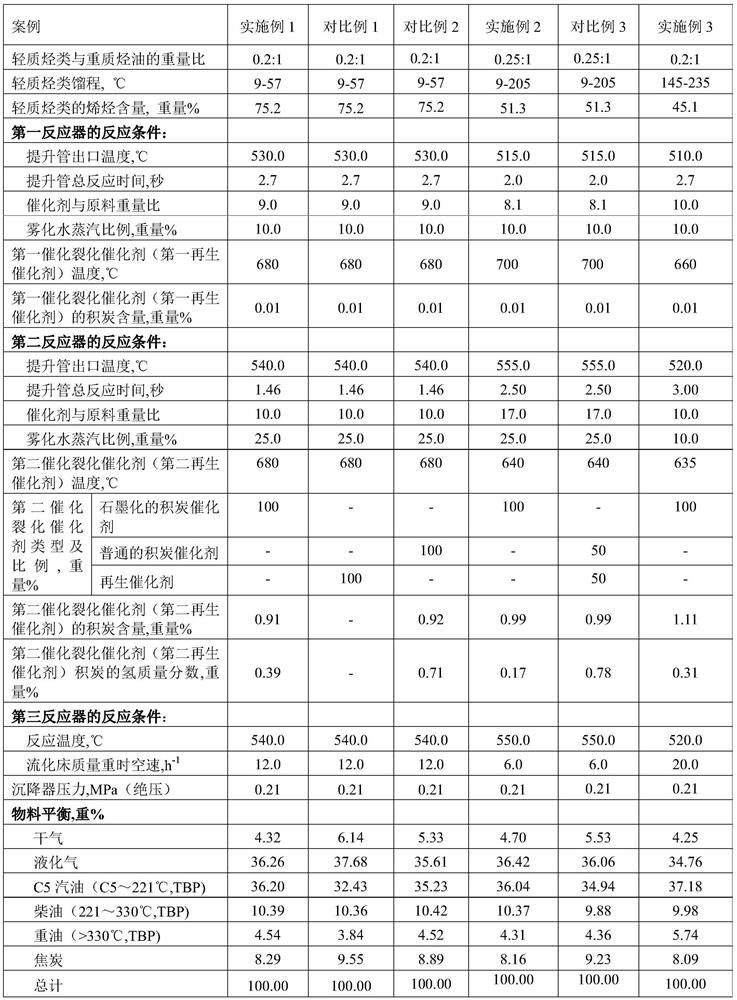

Catalytic cracking method for reducing yields of dry gas and coke

ActiveCN109722289AReduce yieldChange the nature of carbon depositsCatalytic crackingTreatment with plural serial stages onlyPolycyclic aromatic hydrocarbonOxygen

The present invention relates to a catalytic cracking method for reducing the yields of dry gas and coke. The method comprises: carrying out a first catalytic reaction on a heavy hydrocarbon oil raw material in a first reactor to obtain a first carbon deposition catalyst and a first product; carrying out a second catalytic reaction on a light hydrocarbon in a second reactor to obtain a second carbon deposition catalyst and a second product; introducing the steam-stripped second carbon deposition catalyst and the first part of the steam-stripped first carbon deposition catalyst into the oxygen-containing fluidization zone of a regenerator, and carrying out aerobic regeneration; and introducing the second part of the steam-stripped first carbon deposition catalyst into the oxygen-free fluidization zone of the regenerator, and carrying out oxygen-free regeneration at a temperature of 600-800 DEG C. According to the present invention, the key problem that the polycyclic aromatic hydrocarbons in the carbon deposit participate in the hydrogen transfer reaction and hinder the cracking reaction of the light hydrocarbons when the carbon deposition catalyst directly reacts with the light hydrocarbon oil in the prior art can be overcome, the high yield of low-carbon olefins in the catalytic conversion of heavy hydrocarbon oil can be achieved, and the yields of dry gas and coke are low.

Owner:CHINA PETROLEUM & CHEM CORP +1

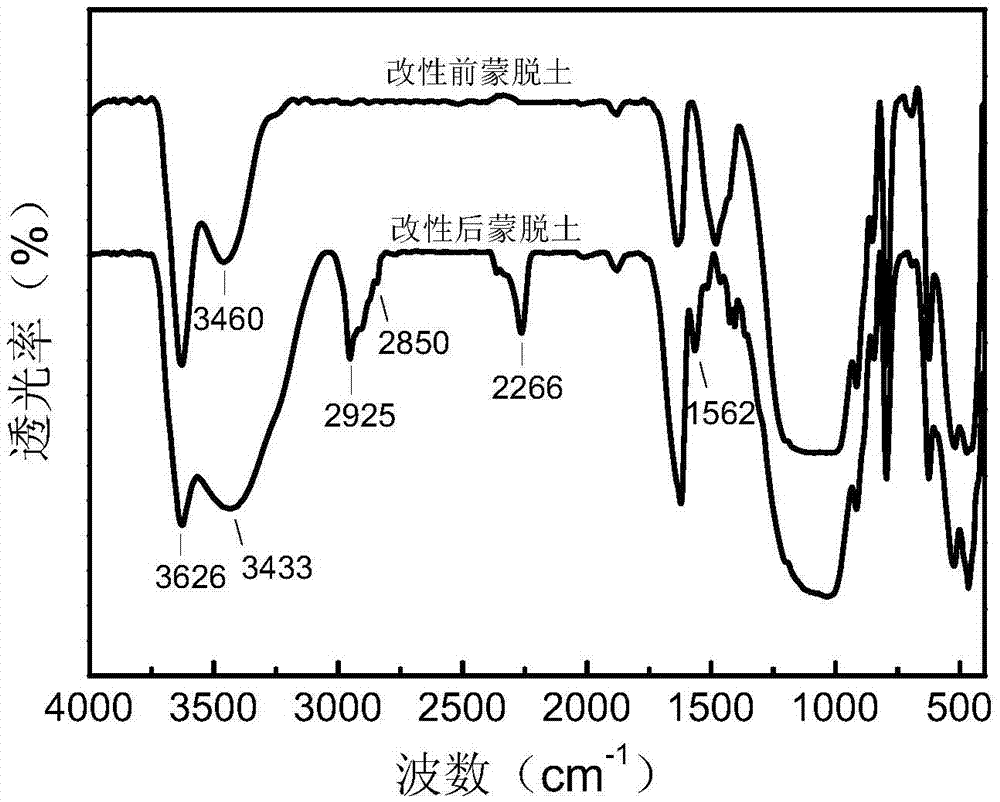

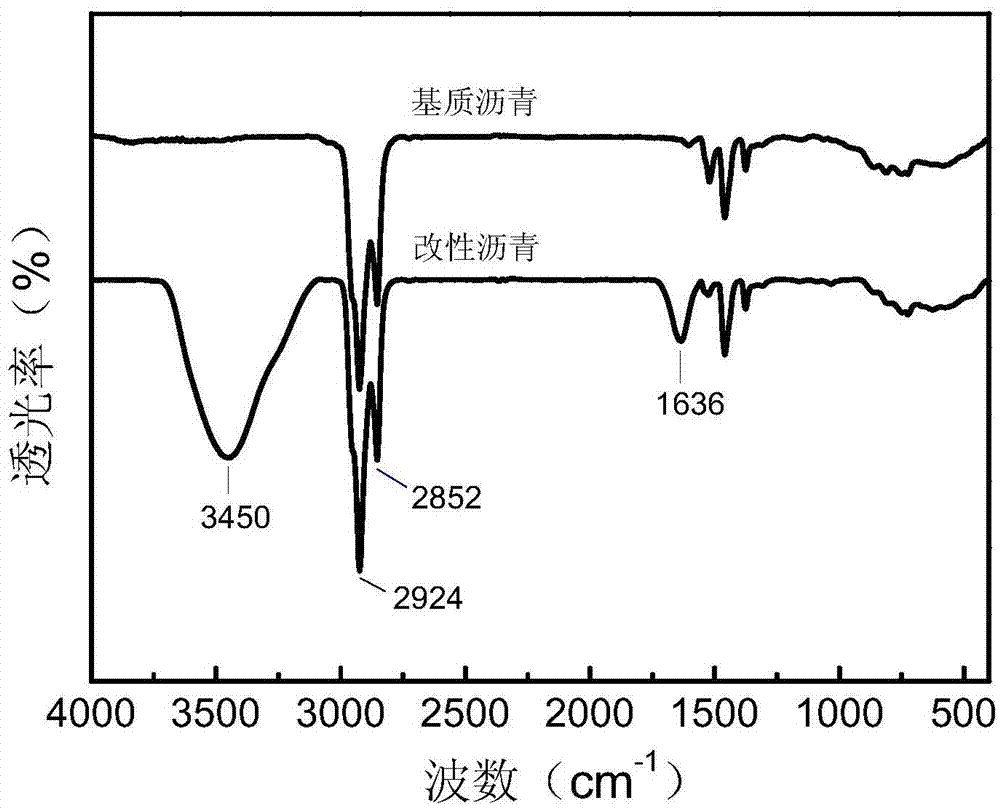

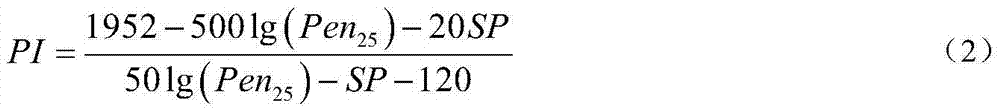

Preparation methods for diisocyanate-modified montmorillonite and modified asphalt by employing diisocyanate-modified montmorillonite

InactiveCN105440708AImprove performanceSimple internal structureBuilding insulationsChemical LinkageChemical reaction

The invention discloses preparation methods for diisocyanate-modified montmorillonite and modified asphalt by employing diisocyanate-modified montmorillonite. The modified montmorillonite is obtained by performing chemical reaction on a diisocyanate possessing isocyanate group (-NCO) and montmorillonite containing hydroxyl (-OH) for expanding the interlamellar spacing of montmorillonite and grafting montmorillonite with active -NCO. According to the preparation method for the modified asphalt material by employing the above modified montmorillonite. The modified montmorillonite is reacted with polar molecules in asphalt, the interlamellar spacing is further expanded and peeling happens, a peeled layer and asphalt form a chemical bond, and thus modified montmorillonite is stably dispersed in the asphalt system, and the modified asphalt material possesses superior high-temperature stability, heat storage stability and ageing resistance. Through the chemical reaction of modified montmorillonite and asphalt, the chemical composition of asphalt is improved, and the comprehensive performances are improved. The prepared modified asphalt material is applicable to fields such as laying of high-grade roads of bridges, highways and airports, and building surface water prevention and the like.

Owner:SOUTH CHINA UNIV OF TECH

Contaminated soil-based soil conditioner and preparation method thereof

InactiveCN112210384AGood restorativeImprove fertilityCalcareous fertilisersAnimal corpse fertilisersMicrobial agentCalcium magnesium phosphate

The invention belongs to the technical field of soil remediation, and provides a contaminated soil-based soil conditioner which comprises the following components in parts by weight: 50-100 parts of plant ash, 50-100 parts of quick lime, 30-80 parts of an organic fertilizer, 40-70 parts of a calcium magnesium phosphate fertilizer, 20-60 parts of zeolite, 5-10 parts of a compound microbial agent, 0.5-1 part of biomass charcoal and 1-2 parts of urea. The contaminated soil-based soil conditioner integrates plant ash, quick lime, organic fertilizer, calcium magnesium phosphate, zeolite fertilizer,composite microbial agent, biomass charcoal and urea, not only is simple in material obtaining and low in cost, but also is good in remediation effect on heavy metal contaminated soil and quick in effect taking, and meanwhile, the soil fertility is improved.

Owner:浙江和宸环保科技有限公司

High temperature resistant defoaming agent and application thereof in delay coking

ActiveCN103768830AReduce surface tensionLow chemical inertnessThermal non-catalytic crackingFoam dispersion/preventionSilazanePolysilazane

The invention relates to a high temperature resistant defoaming agent and application thereof in delay coking, the defoaming agent is prepared by compounding fluorine-containing polysiloxane, hyperbranched polyether, modified nano silica, vinyl-containing polysilazane and a solvent under certain conditions. A preparation method of the defoaming agent is as follows: dispersing required specifications of the fluorine-containing polysiloxane, the hyperbranched polyether and the modified nano silica in the solvent at a constant temperature of 60-100 DEG C, then cooling to room temperature, mixing, simultaneously adding the vinyl-containing polysilazane, and then filtering away non-homogeneous impurities to obtain the defoaming agent finished product. The efficient multi-active-component defoaming agent used in the delay coking process has good defoaming and anti-foaming properties at a high use temperature, also can maintain the high chemical stability, and is not easy to generate low-boiling-point silicon-containing small molecules cyclized compounds, and the adverse influence of the defoaming agent on the subsequent processing process can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Zeolite diatom ooze coating

The invention relates to a zeolite diatom ooze coating. According to the technical scheme, the zeolite diatom ooze coating mainly comprises the following components in percentage by mass: 15-35% of zeolite powder, 10-30% of diatomite, 10-20% of sea-foam stone powder, 10-25% of titanium dioxide, 5-20% of dolomite dust, 3-10% of white carbon black, 3-10% of kaolin, 3-8% of ash calcium powder, 0.3-1% of cellulose ether, and 0-10% of dispersible latex powder. The zeolite diatom ooze coating is prepared by combining zeolite and sepiolite with diatomite and adding a plurality of auxiliaries through a scientific formula, wherein zeolite with most molecular sieve representativeness and ion exchange, adsorption and dispersion, catalysis, chemical reaction and reversible dehydration properties is used as a main raw material, sepiolite with maximum specific surface area as a non-metallic mineral, unique content porous structure and the known strongest adsorption capability is used as an auxiliary raw material, and the technical effects of greatly improving the adsorption performance and ion exchange performance, increasing the removal of harmful substances such as formaldehyde, benzene, ammonia and the like, purifying air and eliminating peculiar smell are achieved.

Owner:李长松 +1

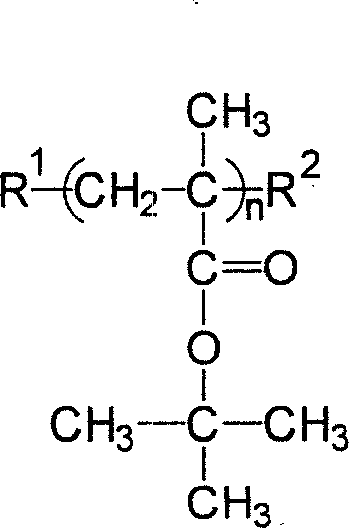

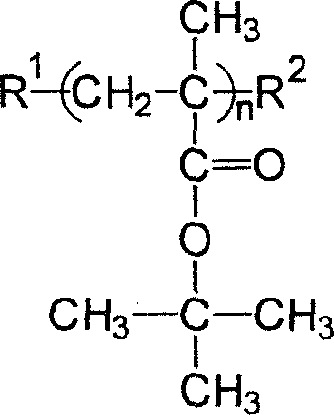

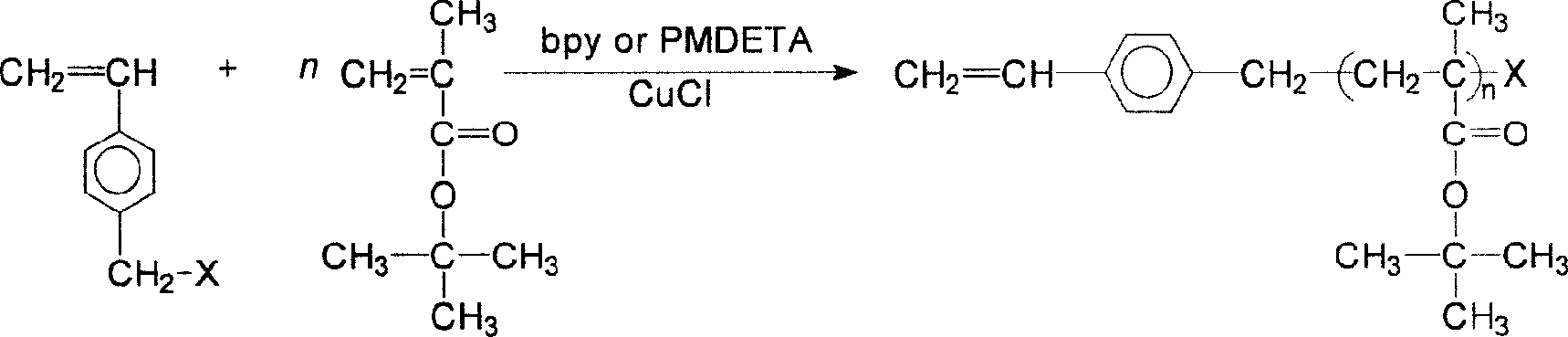

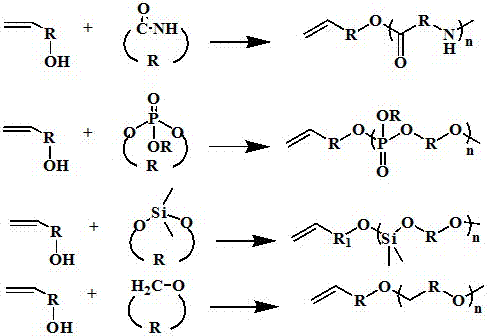

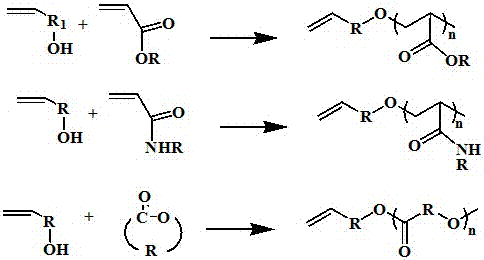

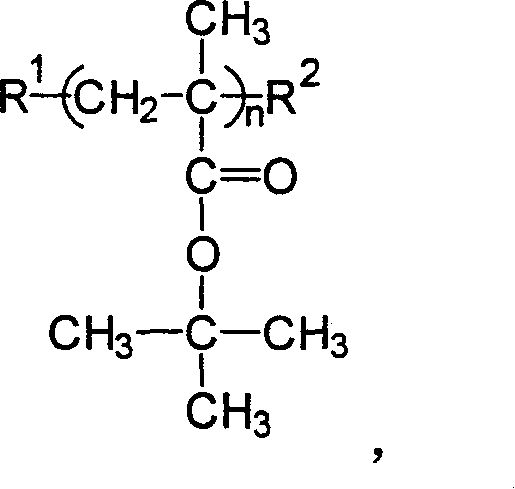

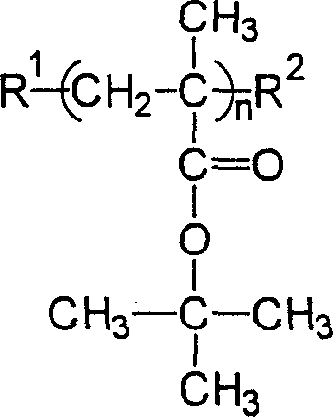

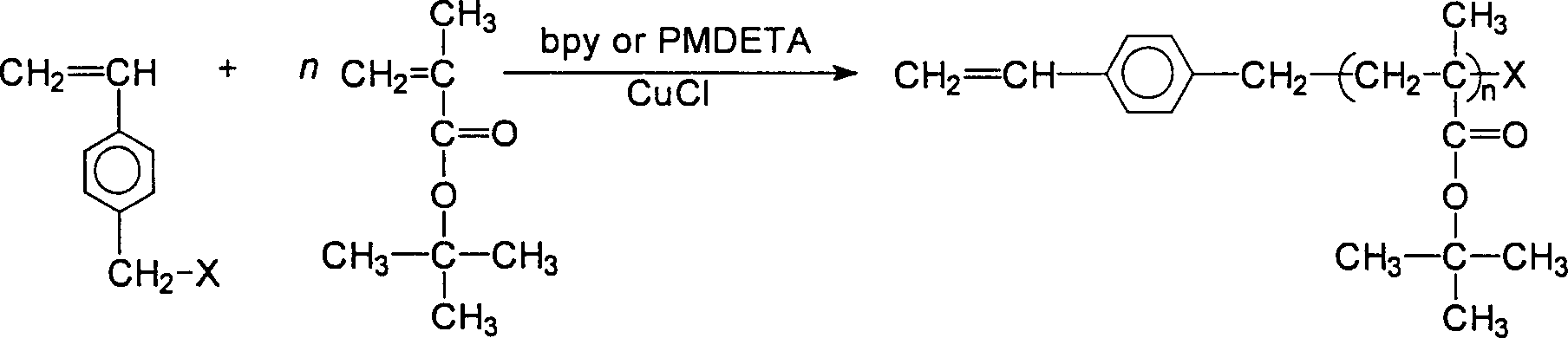

Preparation of polymethyl tert-butyl acrylate large molecular monomer by atom transfer radial

InactiveCN1709926AHigh reactivityChemically reactiveChemical reactionAtom-transfer radical-polymerization

This is a preparation of polytert-butyl methacrylic (PBMA) macromolecule monomer through atom transfer free radical polymerization (ATRP), belonging to macromolecule monomer preparation technology field. The invention provides the PBMA macromolecule monomer, including the styrene end-sealed one and crylic acid or methacrylic acid (MAA) end-sealed one. This kind of macromolecule monomer has the physical property and chemical reactive property, so it is very suitable for the structure design of macromolecule, and is widely used in the preparation of stem grafting macromolecule, segment embedded macromolecule and nanometer macromolecule grain material system. ATRP is a kind of active / controllable free radical polymerization., which has wide suitable monomers, simple operation, mild reaction condition, and can obtain high polymers of accurate structure and equably distributed molecular weights(Mw / Mn < 1.20). Applying the ATRP method can synthesize macromolecule monomers of uniformly distributed molecular weight.

Owner:JIANGNAN UNIV

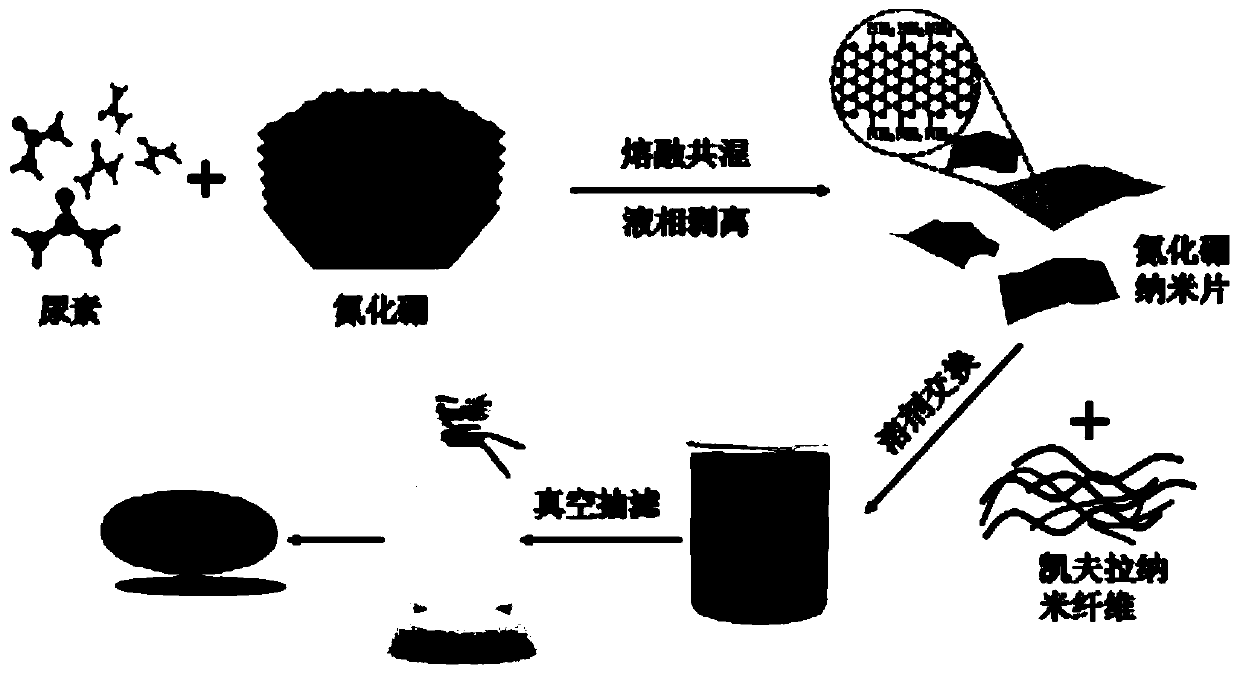

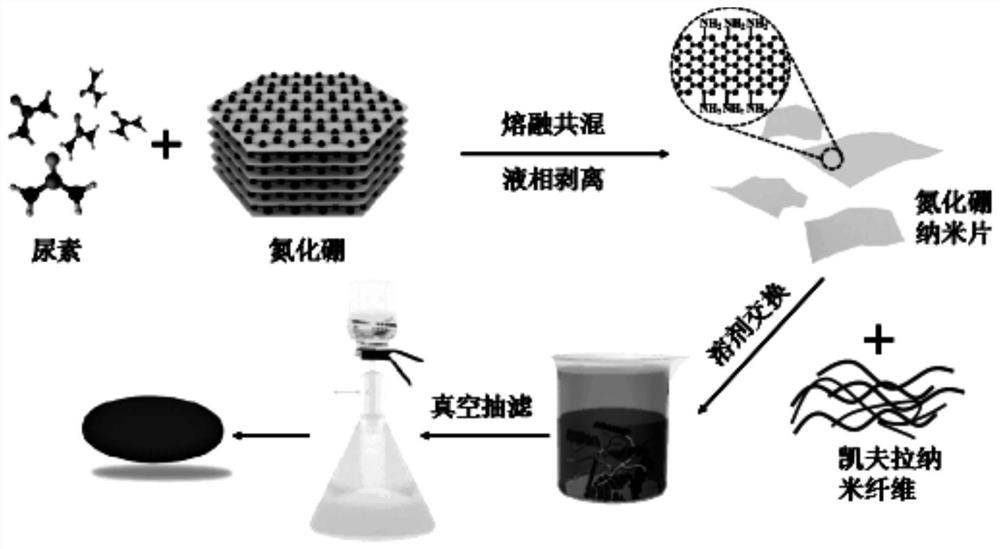

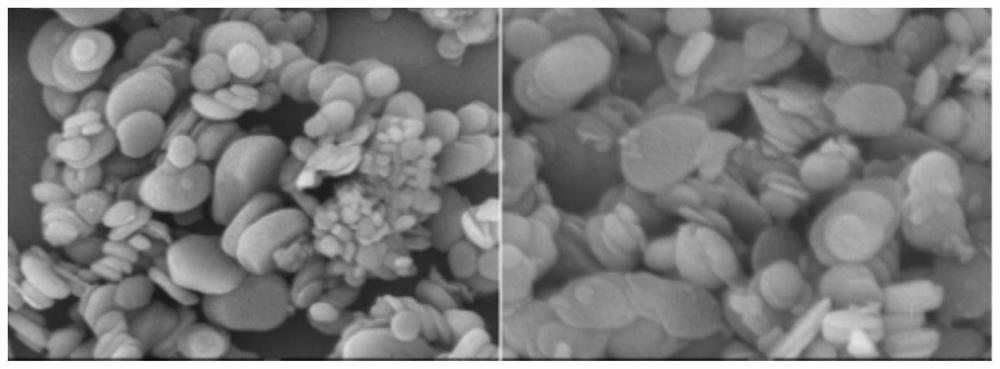

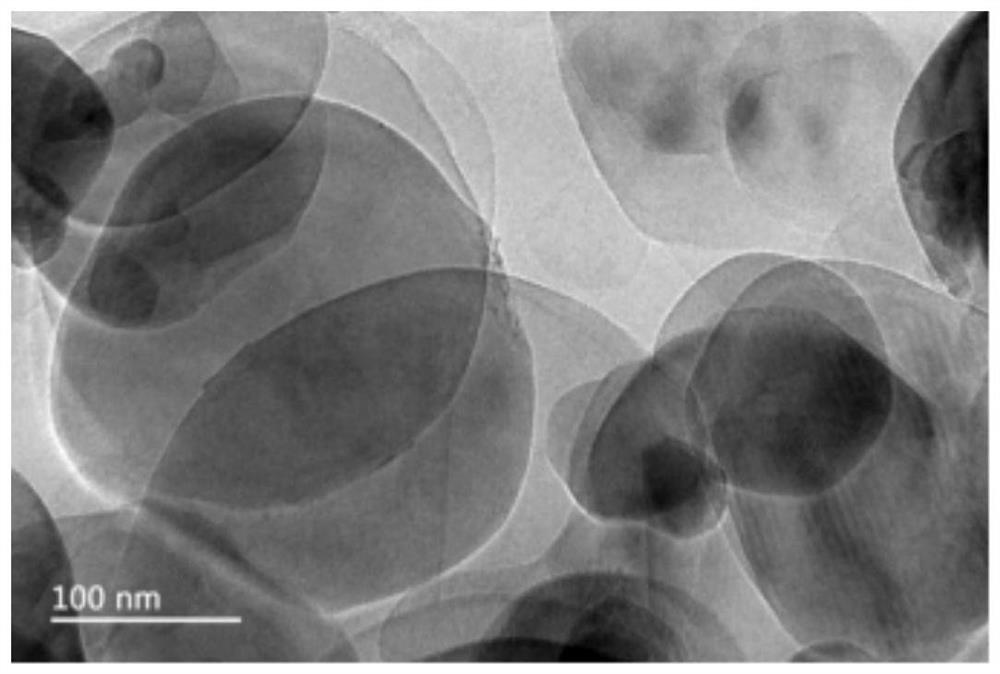

Kevlar nanofiber based high-strength heat conducting film preparation method

ActiveCN110004712AFast heat conductionImprove mechanical propertiesFibre typesHeat-exchange elementsBoron nitrideHigh intensity

The invention discloses a Kevlar nanofiber based high-strength heat conducting film preparation method. The method is characterized by including that urea functionalized boron nitride nanosheets and functionalized Kevlar nanofibers are adopted as a film assembly, a boron nitride nanosheet / functionalized Kevlar nanofiber composite thin film is obtained through vacuum suction filtration self-assembly, and then a boron nitride nanosheet / functionalized Kevlar nanofiber composite film namely a Kevlar nanofiber based heat conducting film is obtained through glutaraldehyde crosslinking for improvement of heat conducting and mechanical performances. By adoption of the functionalized boron nitride nanosheets and the surface modified Kevlar nanofibers as the assembly, a chemical crosslinking structure of the boron nitride nanosheets and the Kevlar nanofibers is realized through glutaraldehyde crosslinking, and accordingly tensile strength of the composite film is remarkably improved while the composite film is endowed with the excellent heat conducting performance. The method is simple and effective, and the high-strength heat conducting film prepared according to the method can be hopefullyapplied to fields of energy sources, electronics and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

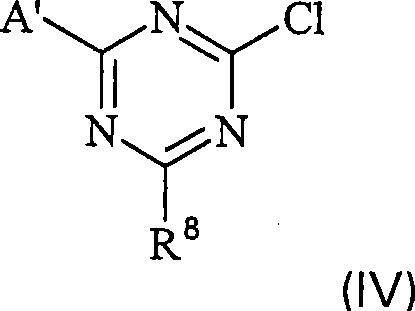

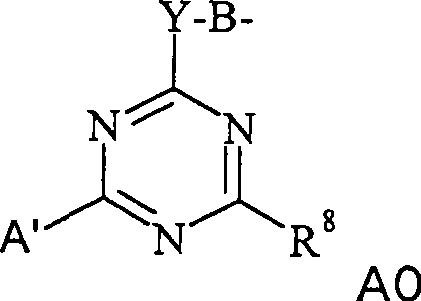

Colored organopolysiloxanes

InactiveCN101490136AGood colorChemically reactiveCosmetic preparationsToilet preparationsCombinatorial chemistry

The present invention relates to colored organopolysiloxanes containing units of the general formula (I) in which R, R, R, A, a, b, c and d are each defined as specified in claim 1, to processes for their preparation and to their use.

Owner:DYSTAR TEXITILFARBEN GMBH & CO

A kind of zeolite sea foam mud coating

The invention provides a zeolite-sepiolite powder coating. The coating is characterized in that the zeolite-sepiolite powder coating is prepared from 10-40% of zeolite powder, 10-40% of sepiolite powder, 10-25% of titanium dioxide, 10-20% of dolomite powder, 3-10% of white carbon black, 3-10% of kaolin, 3-8% of ash calcium powder, 0.3-1% of cellulose ether and 0-10% of redispersible latex powder.A preparation method of the zeolite-sepiolite powder coating comprises the following steps: taking zeolite with highest molecular sieve representativeness, ion exchange property, adsorption and dispersion properties, catalytic property, chemical reactivity and reversible dehydration property as a main raw material, taking sepiolite with largest specific surface area of non-metallic minerals, special internal porous structure and acknowledged highest adsorption capacity as an auxiliary raw material, adding a plurality of additives and preparing a zeolite-sepiolite powder coating through scientific formulation; the technical effects of greatly improving the adsorption performance and the ion exchange performance, improving harmful materials such as formaldehyde, benzene and ammonia and the like, purifying air and eliminating peculiar smell can be achieved.

Owner:李长松 +1

Catalytic conversion process capable of reducing yields of dry gas and coke

ActiveCN109722283AReduce yieldOvercoming strict bindingTreatment with plural serial cracking stages onlyOxygenLight hydrocarbons

The present disclosure relates to a catalytic conversion process capable of reducing yields of a dry gas and coke. The method comprises the following steps: performing a first catalytic reaction on aheavy hydrocarbon oil raw material in a first reactor to obtain a first coked catalyst and a first product; performing a second catalytic reaction on a light hydrocarbon in a second reactor to obtaina second coked catalyst and a second product; introducing the first coked catalyst and the second coked catalyst into strippers, performing stripping, introducing a first stripped catalyst into an oxygen-containing fluidization zone of a regenerator, and performing aerobic regeneration; and introducing a second stripped catalyst into an anaerobic fluidization zone of a regenerator, and performinganaerobic regeneration at 600-800 DEG C. Compared with the prior art, the method disclosed in the invention can prepare more low-carbon olefins in catalytic conversion of heavy hydrocarbon oil, and the yields of the dry gas and the coke are lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

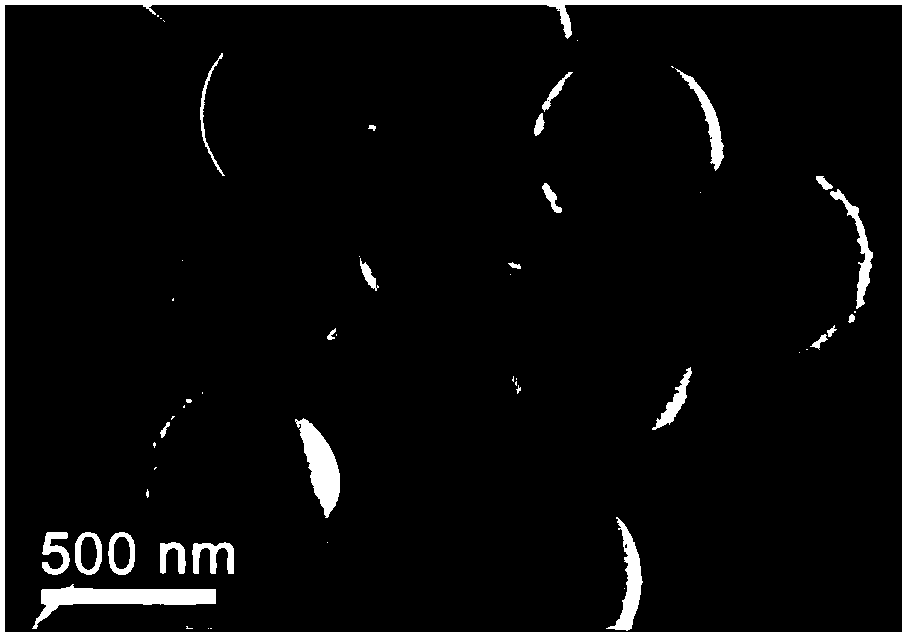

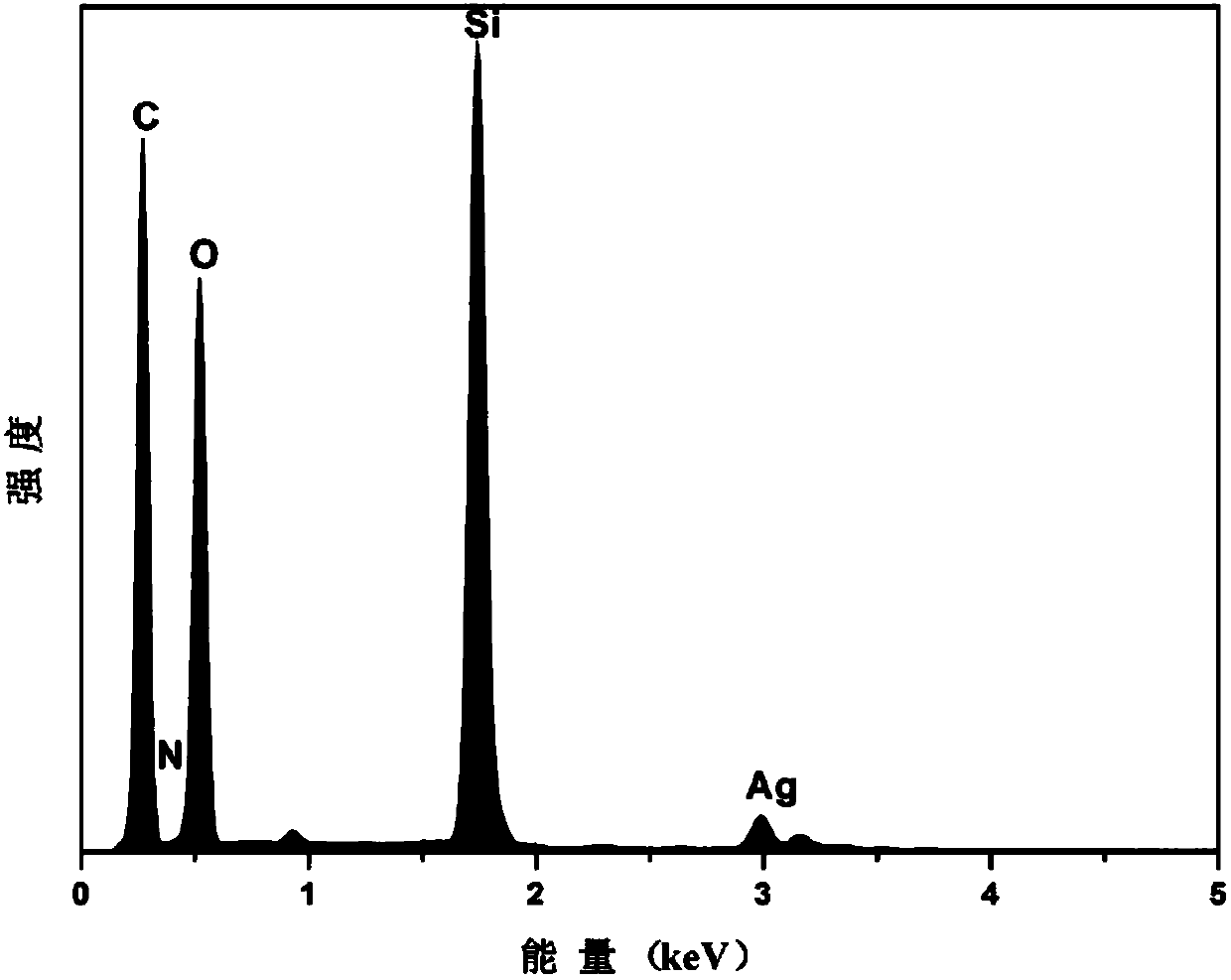

Method for Bionic Construction of Functionalized Janus Particles

InactiveCN106084215BEmbedding depth adjustableWide range of geometriesJanus particlesChemical reaction

The invention discloses a method for bionic construction of functional Janus particles. The method comprises the steps that two silane coupling agents with different hydropathy types are used for modifying SiO2, modified SiO2 with different wettabilities is obtained, the modified SiO2 is adopted as a particle emulsifier, and different types of Pickering emulsions are prepared under the effect of high-speed homogenization; then, on the basis of the mussel bionic principle, adhering characteristics and chemical reactivity of polydopamine or analogues thereof are used, so that the functional Janus particles with specific chemical regions can be obtained. According to the Pickering emulsion method, the yield of Janus particles is ensured, multi-functionalization of the Janus particles is achieved due to the auxiliary effects of polydopamine or analogues thereof, and more types of Janus particles, such as Janus / metal nanoparticles, Janus / inorganic compounds, Janus / organic compounds and the like are prepared.

Owner:SHAANXI NORMAL UNIV

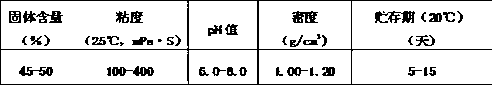

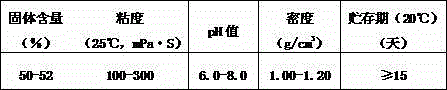

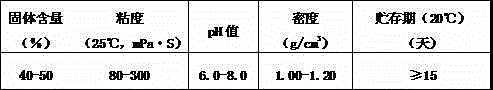

Formaldehyde eliminating agent and preparation method thereof

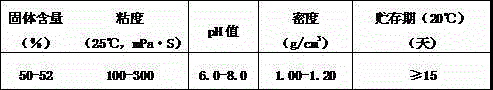

InactiveCN102399514BReduce releaseImprove elimination effectNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesEpoxyProcess engineering

The invention discloses a formaldehyde eliminating agent and a preparation method thereof. The formaldehyde eliminating agent consists of the following raw materials in part by weight: 100 to 300 parts of water borne epoxy resin (solid), 200 to 1,000 parts of melamine, 100 to 1,000 parts of water, and 0.1 to 10 parts of stabilizing agent. The preparation method for the formaldehyde eliminating agent comprises the following steps of: 1) sequentially adding the raw materials into a reaction kettle according to the raw material proportion of claim 1 or 2 with stirring, controlling the heating temperature at 40 to 60 DEG C, fully stirring the raw materials uniformly, and regulating the pH to be between 5.0 and 5.5 by using acid; and 2) heating the raw materials to the temperature of between 75 and 80 DEG C, reacting for 30 minutes, regulating the pH value to be between 6.0 and 8.0 by using alkali, cooling the reaction product to the temperature of 30 DEG C, and discharging.

Owner:BEIJING FORESTRY UNIVERSITY +1

A preparation method of high-strength thermally conductive film based on Kevlar nanofibers

ActiveCN110004712BImprove thermal conductivityImprove mechanical propertiesFibre typesHeat-exchange elementsComposite filmFilm base

The invention discloses a preparation method of a high-strength heat-conducting film based on Kevlar nanofibers, which is characterized in that urea-functionalized boron nitride nanosheets and functionalized Kevlar nanofibers are used as a film material assembly, Boron nitride nanosheets / functionalized Kevlar nanofiber composite films were firstly obtained by self-assembly under reduced pressure and suction, and then the thermal conductivity and mechanical properties were improved by glutaraldehyde cross-linking to obtain boron nitride nanosheets / functionalized Kevlar composite films. Kevlar nanofiber composite film, that is, a thermally conductive film based on Kevlar nanofibers. The invention uses functionalized boron nitride nanosheets and surface-modified Kevlar nanofibers as assemblies, and realizes the chemical crosslinking structure of boron nitride nanosheets and Kevlar nanofibers through glutaraldehyde cross-linking. The tensile strength of the composite film is greatly improved, and the composite film has excellent thermal conductivity. The method is simple and effective, and the prepared high-strength thermally conductive film is expected to be used in energy, electronics and other fields.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

A kind of synthetic method of macromonomer

The invention relates to a method for synthesizing a macromonomer, which belongs to the technical field of macromonomer preparation. The method uses a strong base and a compound containing double bonds and active hydrogen as an initiating system to initiate homopolymerization or copolymerization of vinyl monomers or cyclic monomers, and synthesize macromonomers containing terminal double bonds in one step. The polymerization reaction conditions of the present invention are mild, and the raw materials used have industrial products, which are suitable for industrial production, and the prepared macromonomer structure is rich, which not only has the physical characteristics of polymers, but also has chemical reactivity. Polymers, degradable polymers and nano-polymer particle materials are widely used.

Owner:CHANGZHOU UNIV

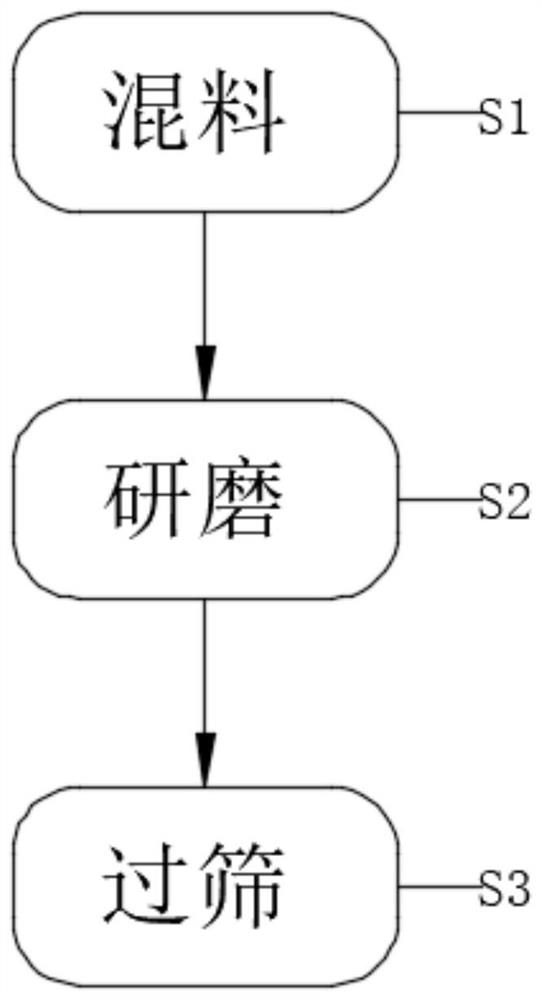

A kind of micro graphene oxide and preparation method thereof

ActiveCN104386677BReduce the degree of oxidationImprove mechanical propertiesChemical reactionOxygen

The invention belongs to the technical field of graphene materials and in particular relates to micro-oxidized graphene and a preparation method thereof. The micro-oxidized graphene contains a small amount of active groups, is low in degree of oxidation, and has the oxygen element content of 1-10wt% and the bulk density of 0.01-0.1g / ml. The micro-oxidized graphene contains a proper amount of chemical reaction active group points, and meanwhile, a relatively complete graphene lattice structure is remained so that the micro-oxidized graphene has excellent dispersibility, special reactivity and excellent physical properties. The invention provides an industrial micro-oxidized graphene preparation route which is efficient, stable, economical, controllable and environment-friendly and the defects of uncontrollable graphene activation, great operation risks, serious environmental pollution, serious equipment corrosion, high cost investment and the like of a traditional acid oxidation method can be overcome. The micro-oxidized graphene prepared by use of the preparation method has extremely wide prospect in the fields of functional composites, coatings, ink, photoelectric materials, biological medicine and the like.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

Catalytic conversion process to reduce dry gas and coke yields

ActiveCN109722283BReduce yieldChange the nature of carbon depositsTreatment with plural serial cracking stages onlyCatalytic transformationPtru catalyst

The disclosure relates to a catalytic conversion method for reducing the yield of dry gas and coke, the method comprising: making heavy hydrocarbon oil feedstock undergo a first catalytic reaction in a first reactor to obtain a first carbon-deposited catalyst and a first product; Light hydrocarbons are subjected to a second catalytic reaction in the second reactor to obtain a second carbon deposition catalyst and a second product; introducing the first carbon deposition catalyst and the second carbon deposition catalyst into a stripper for stripping , the first part of the stripped catalyst is introduced into the oxygen-containing fluidized zone of the regenerator for aerobic regeneration; the second part of the stripped catalyst is introduced into the anaerobic fluidized zone of the regenerator at 600-800 ° C Anaerobic regeneration. Compared with the prior art, the present disclosure can produce more light olefins in the catalytic conversion of heavy hydrocarbon oil, while the dry gas and coke yields are lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

High temperature resistant defoaming agent and application thereof in delay coking

ActiveCN103768830BReduce surface tensionLow chemical inertnessThermal non-catalytic crackingFoam dispersion/preventionSilazanePolysilazane

The invention relates to a high temperature resistant defoaming agent and application thereof in delay coking, the defoaming agent is prepared by compounding fluorine-containing polysiloxane, hyperbranched polyether, modified nano silica, vinyl-containing polysilazane and a solvent under certain conditions. A preparation method of the defoaming agent is as follows: dispersing required specifications of the fluorine-containing polysiloxane, the hyperbranched polyether and the modified nano silica in the solvent at a constant temperature of 60-100 DEG C, then cooling to room temperature, mixing, simultaneously adding the vinyl-containing polysilazane, and then filtering away non-homogeneous impurities to obtain the defoaming agent finished product. The efficient multi-active-component defoaming agent used in the delay coking process has good defoaming and anti-foaming properties at a high use temperature, also can maintain the high chemical stability, and is not easy to generate low-boiling-point silicon-containing small molecules cyclized compounds, and the adverse influence of the defoaming agent on the subsequent processing process can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

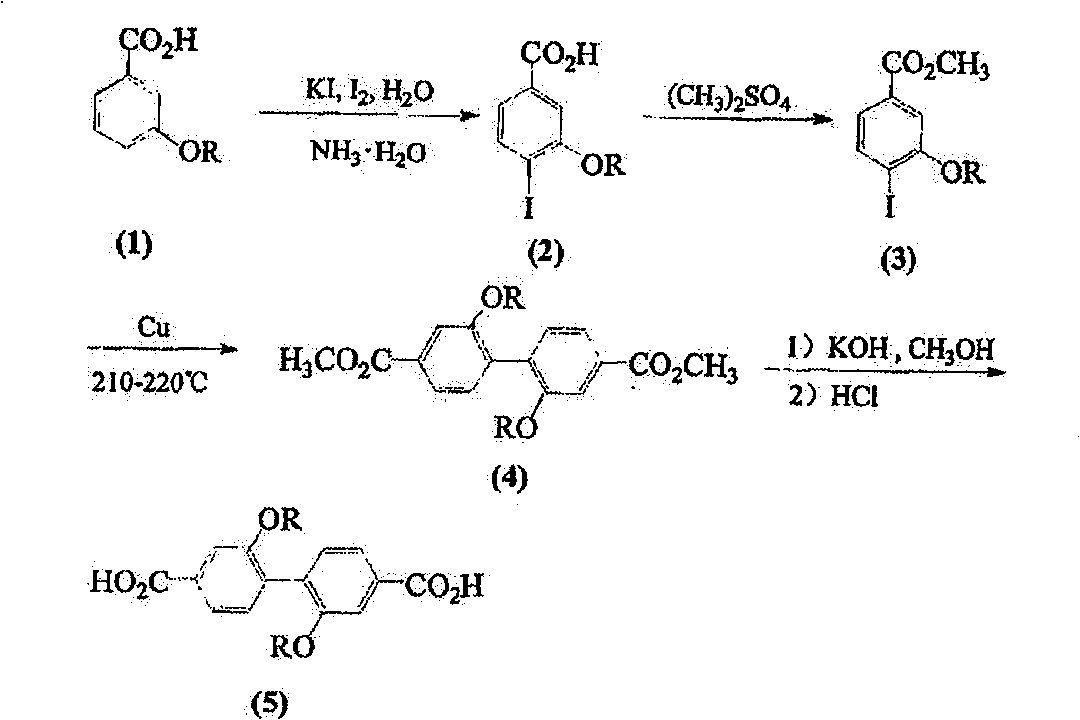

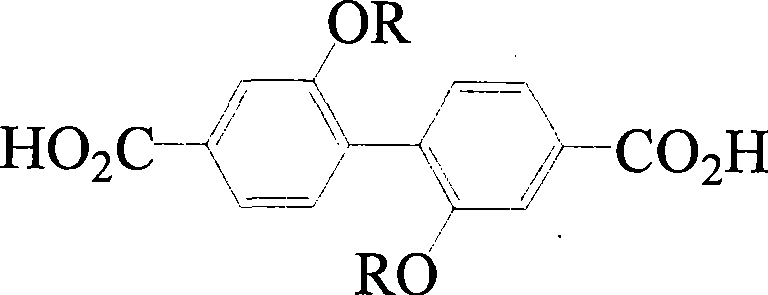

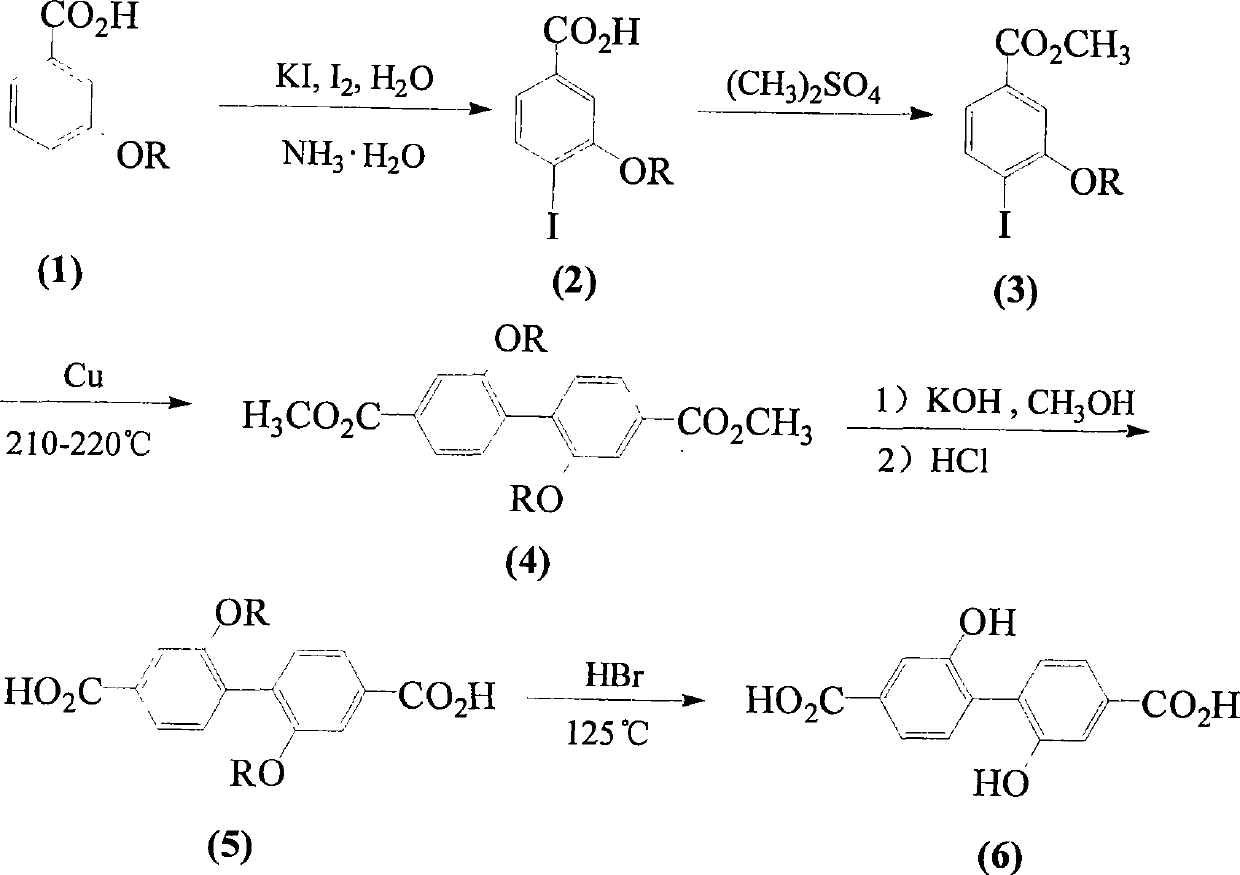

2,2'-bialkoxyl-4,4'-biphenyl dicarboxylic acid and synthesis method thereof

InactiveCN101362688BChemically reactiveImprove practicalityOrganic compound preparationCarboxylic compound preparationSynthesis methodsDicarboxylic acid

The invention relates to a 2,2'-dialkoxyl-4,4'-biphenyl dioctyl phthalate compound and a synthesizing method thereof. The compound has a general formula as the right structure, wherein, R respectively represents -CH3, -CH2CH3 or -CH(CH3)2. The invention has the advantages of available reaction material and mild reaction condition, and is suitable for scale industrial production.

Owner:NANJING TECH UNIV

Preparation of polymethyl tert-butyl acrylate large molecular monomer by atom transfer radial

InactiveCN1286869CChemically reactivePrecise structureChemical reactionAtom-transfer radical-polymerization

Owner:JIANGNAN UNIV

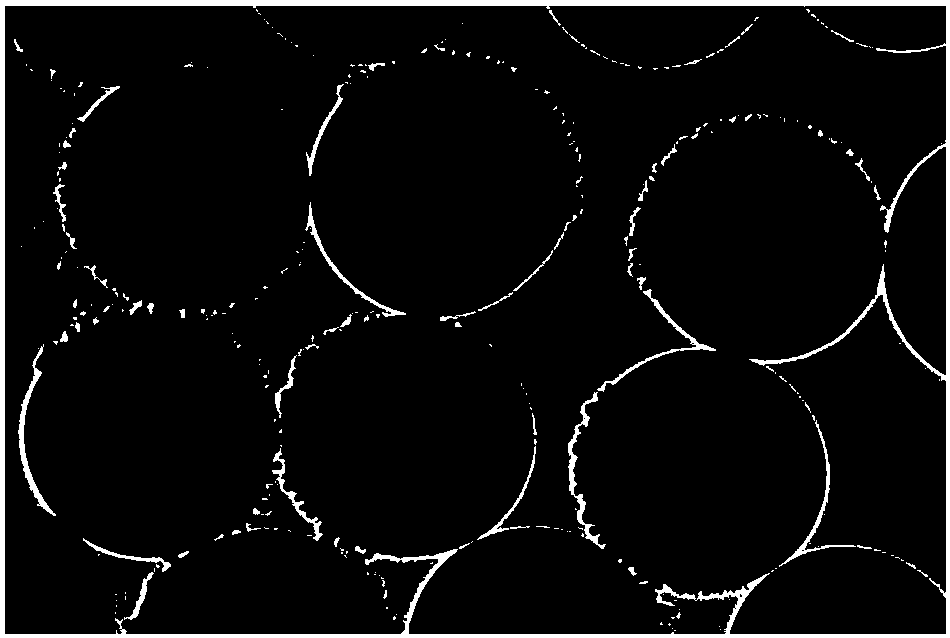

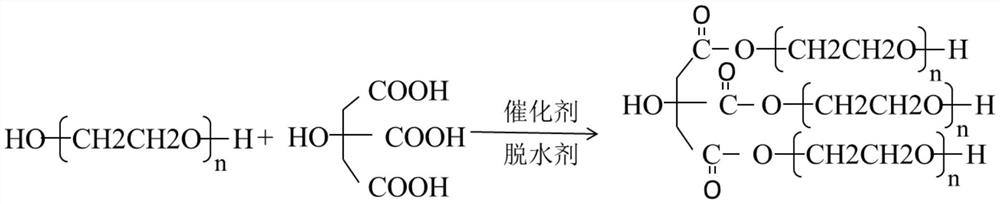

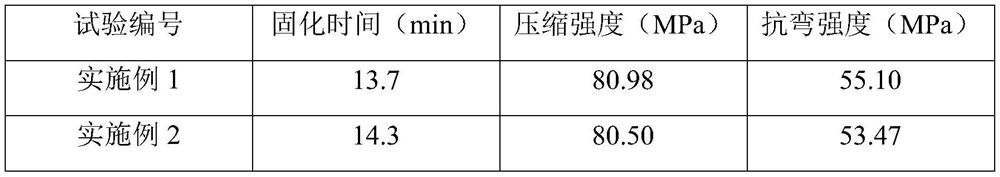

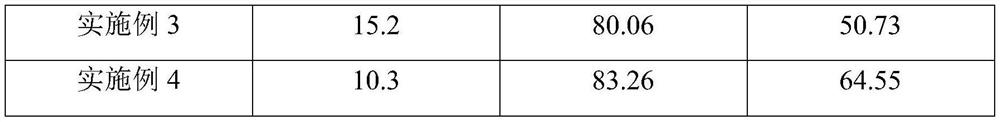

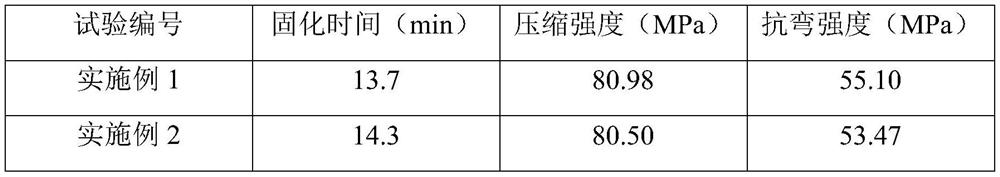

Porous composite bone cement and preparation method thereof

ActiveCN113577369ADoes not affect mechanical propertiesImprove water absorptionSurgical adhesivesTissue regenerationBenzoyl peroxideToluidine

The invention relates to the technical field of biomedical materials, in particular to porous composite bone cement and a preparation method thereof. The porous composite bone cement is mainly composed of a powder part and a liquid part, the ratio of the powder part to the liquid part is 2: 1 g / mL. The powder part is mainly composed of the following raw materials in percentage by mass: 29.5-84% of a methacrylic acid polymer, 10-40% of a degradable biological material, 5-30% of barium sulfate and 0.01-0.5% of benzoyl peroxide; the liquid is mainly prepared from the following raw materials in percentage by mass: 93-99.45% of methyl methacrylate, 0.5-5% of N, N-dimethyl p-toluidine and 0.05-2% of hydroquinone. The problems that the interface bonding force between traditional bone cement and autologous bone is low, bone cells cannot grow into the bone cement, and the mechanical property and biocompatibility of the bone cement are affected by reactants left in a pore-foaming agent after the existing porous bone cement is cured are solved.

Owner:山东明德生物医学工程有限公司

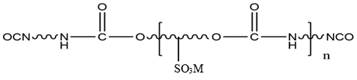

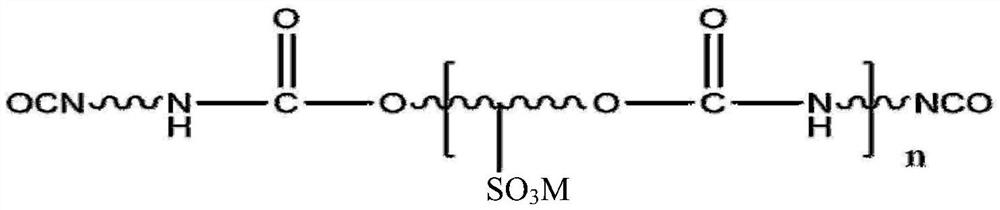

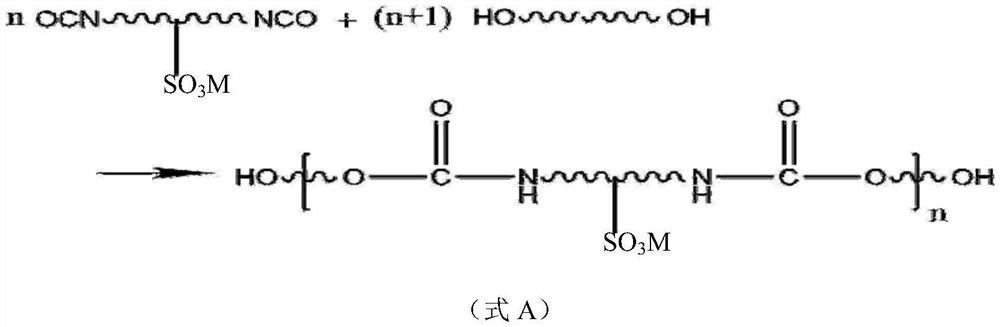

A kind of hydrophilic diisocyanate and its preparation method and application

ActiveCN111423343BChemically reactiveCan be mass producedFibre treatmentPolyureas/polyurethane adhesivesSulfonatePolymer science

The invention belongs to the field of polyurethane, and the invention provides a hydrophilic diisocyanate, which comprises at least one structural unit containing the following general formula: In the formula: SO 3 M is a sulfonate group, M is a K ion or a Na ion or an ammonium ion; n is 1-6; the hydrophilic diisocyanate is formed by reacting at least one hydrophilic chain extender with a diisocyanate. The sulfonate group in the hydrophilic diisocyanate structure of the present invention is a salt of strong acid and strong alkali, which has good hydrophilicity, and the isocyanate group at both ends retains the performance of the original diisocyanate, so it has the chemical reaction of diisocyanate characteristics; and using the hydrophilic diisocyanate of the present invention to prepare water-based polyurethane has changed the existing process and greatly simplifies the operation.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

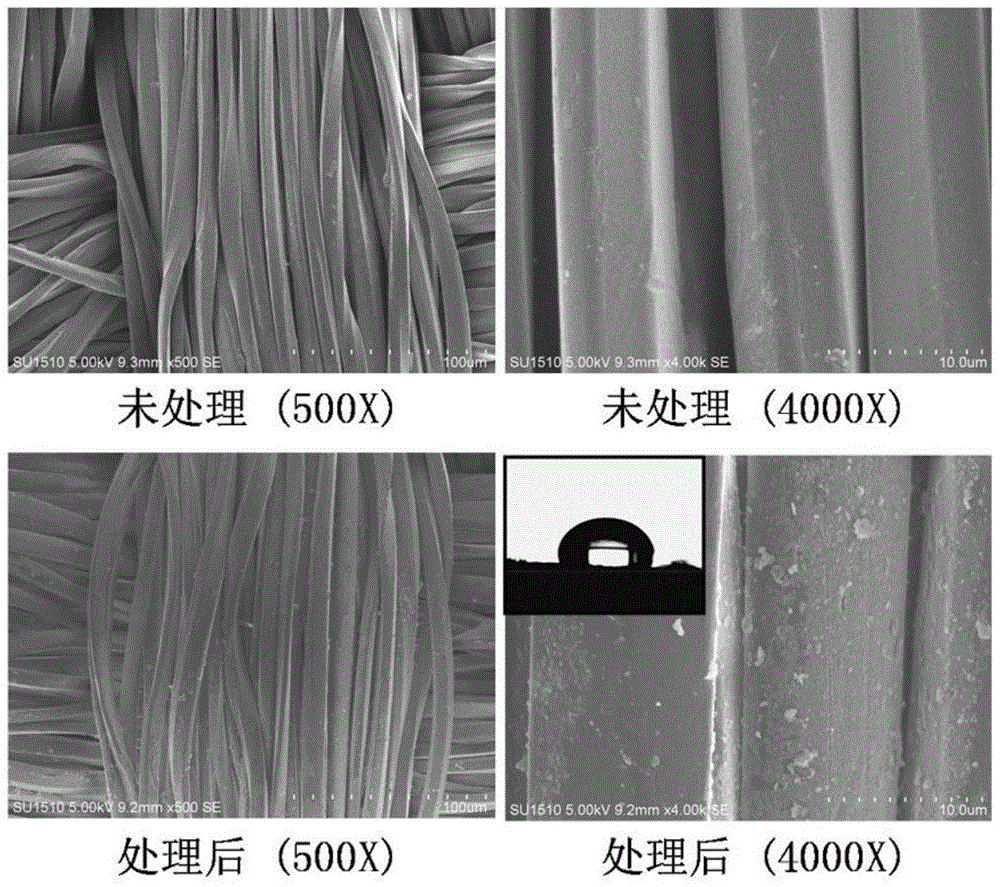

A kind of finishing method of polyester or brocade hydrophobic fabric based on paa-teos-oa joint treatment

The invention discloses a PAA-TEOS-OA combined treatment-based finishing method for a polyester or polyamide hydrophobic fabric, and belongs to the technical field of functional textiles. A fabric is subjected to pretreatment by utilizing polyacrylic acid, so that the capability of the fabric in the aspect of reacting with a subsequent chemical reagent is improved, and a bridge function is achieved; tetraethyl orthosilicate is hydrolyzed and polycondensed under an acid or alkali condition, and particular matters are formed on the surface of the fabric, so that a function of roughening the fabric is achieved; long-chain alkane type octadecylamine can effectively reduce surface energy of the fabric, and meanwhile, the environment problem caused by perfluoronic compounds is avoided; in the finishing treatment, traditional soaking, rolling, baking and roasting processes are utilized, so that the homogeneity and the repeatability of products are good, and the cost is low; the polyacrylic acid, the tetraethyl orthosilicate and the octadecylamine, which are utilized in the whole finishing process, need to be utilized under weak acid and weak alkali conditions, and the baking temperature is low, so that the damage to the fabric is small; the finishing method can be applied to finishing a hydrophobic function of the polyester or polyamide fabric.

Owner:高青如意纺织有限公司

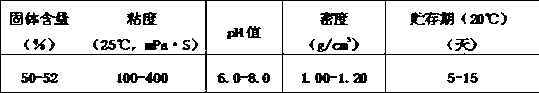

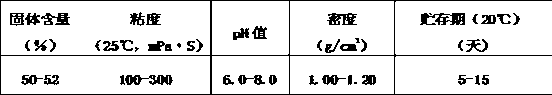

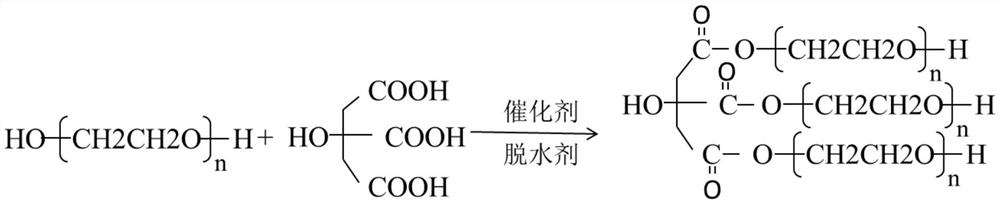

Urea resin additive and preparation method and application thereof

InactiveCN102391796BReduce releaseImprove elimination effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses a urea resin and a preparation method thereof. The urea resin additive comprises the following raw materials in parts by weight: 100-300 parts of waterborne epoxy resin (solid), 100-1000 parts of urea, 50-1000 parts of water and 0.1-10 parts of stabilizing agent. The preparation method comprises the following steps: 1) adding the raw materials to a reaction kettle in sequence according to the proportion in claim 1 or 2, beginning stirring when the raw materials are added, raising the temperature and controlling the temperature at 40-60 DEG C, fully stirring the raw materials until the raw materials are uniform and regulating the pH value of the reaction liquid to be 5.0-5.5 with acid; and 2) raising the temperature to 70-72 DEG C and reacting for 30 minutes, regulating the pH value of the reaction liquid to be 6.0-8.0 with alkali, lowering the temperature to 30 DEG C and discharging the material.

Owner:BEIJING FORESTRY UNIVERSITY +1

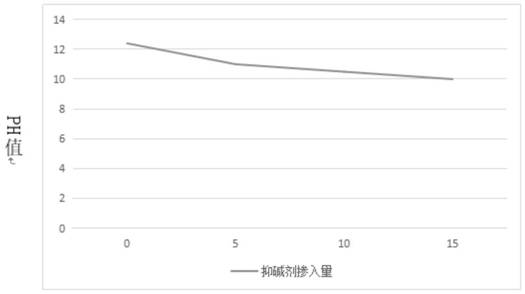

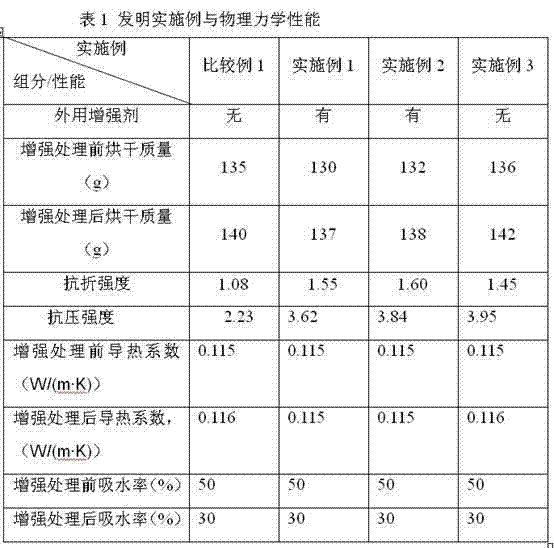

Method for reinforcing autoclaved aerated concrete by using external reinforcing agent

The invention discloses a method for reinforcing autoclaved aerated concrete by using an external reinforcing agent. The method comprises the following steps of: cleaning the autoclaved aerated concrete, then totally permeating the inorganic reinforcing agent into the dried to constant-weight autoclaved aerated concrete in a mode of impregnation, spraying or brushing, and naturally airing the autoclaved aerated concrete at room temperature. The external inorganic reinforcing agent consists of 10 to 30 mass percent of aqueous solution of silicate and water-soluble film forming agent, and the water-soluble film forming agent accounts for 2 to 6 percent of the total weight of the inorganic reinforcing agent. By reasonably selecting the reinforcing agent and controlling the permeating time ofthe two-component reinforcing agent, the dry density of the reinforced aerated concrete is changed little, and pores and heat insulation performance are changed little. The aerated concrete reinforced by adopting the method has high strength and good water resistance, and can keep original properties of light weight and heat insulation. The reinforcing method does not need to change the formula and the preparation process of the original autoclaved aerated concrete, so the method is simple and feasible.

Owner:SOUTHEAST UNIV

A kind of porous composite bone cement and preparation method thereof

ActiveCN113577369BDoes not affect mechanical propertiesImprove water absorptionSurgical adhesivesTissue regenerationBenzoyl peroxideToluidine

The invention relates to the technical field of biomedical materials, in particular to a porous composite bone cement and a preparation method thereof. The porous composite bone cement is mainly composed of powder and liquid. The ratio of powder to liquid is 2:1 g / mL. The powder is mainly composed of the following raw materials by mass percentage: methacrylic acid polymerization 29.5-84% of biodegradable materials, 10-40% of degradable biological materials, 5-30% of barium sulfate, 0.01-0.5% of benzoyl peroxide; the liquid mainly consists of the following raw materials by mass: methyl methacrylate 93 -99.45%, N,N-dimethyl-p-toluidine 0.5-5%, hydroquinone 0.05-2%. The invention solves the problems of low interfacial bonding force between traditional bone cement and autologous bone, inability of bone cells to grow, and the influence of residual reactants of pore-forming agent after the current porous bone cement is solidified on the mechanical properties and biocompatibility of bone cement.

Owner:山东明德生物医学工程有限公司

Catalytic cracking process to reduce dry gas and coke yield

ActiveCN109722289BReduce yieldChange the nature of carbon depositsCatalytic crackingTreatment with plural serial stages onlyPolycyclic aromatic hydrocarbonCatalytic transformation

The disclosure relates to a catalytic cracking method for reducing the yield of dry gas and coke, the method comprising: making heavy hydrocarbon oil feedstock undergo a first catalytic reaction in a first reactor to obtain a first carbon-deposited catalyst and a first product; Light hydrocarbons are subjected to a second catalytic reaction in the second reactor to obtain a second carbon deposit catalyst and a second product; the stripped second carbon deposit catalyst and the first part of the stripped first product are The carbon catalyst is introduced into the oxygen-containing fluidized zone of the regenerator for aerobic regeneration; the second part of the stripped first carbon-deposited catalyst is introduced into the anaerobic fluidized zone of the regenerator for anaerobic regeneration at 600-800°C. The disclosure overcomes the key problem that the polycyclic aromatic hydrocarbons in the carbon deposit participate in the hydrogen transfer reaction and hinder the cracking reaction of light hydrocarbons when the carbon deposit catalyst directly reacts with light hydrocarbon oil in the prior art, and can be used in the catalytic conversion of heavy hydrocarbon oil Medium and high yields of low-carbon olefins, while yields of dry gas and coke are lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com