Colored organopolysiloxanes

A polysiloxane, organic technology used in the field of colored organosilicon compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

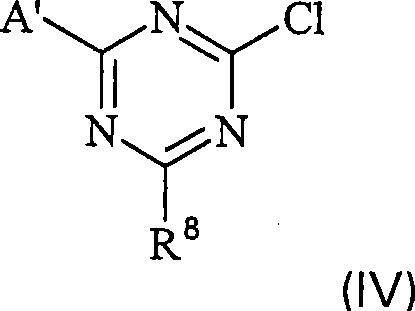

[0173] 2.06 parts of dyes with the following structure

[0174]

[0175] Suspended in 45 parts of completely demineralized water. Use a high-performance disperser (such as Ika ) 50 parts of polydimethylsiloxane with amino groups (amine value: 92 micromole amine groups per gram; viscosity: 300 mm2 / s) were processed for 3 minutes, thereby heated to about 30° C., and then The aqueous dye solution was uniformly dispersed in the silicone using a high performance disperser for 10 minutes, during which time the reaction mixture was heated to about 60°C. The remaining water was removed under reduced pressure and after cooling to room temperature the product was filtered through a depth filter. 100 parts of yellow silicone oil can be obtained.

Embodiment 2

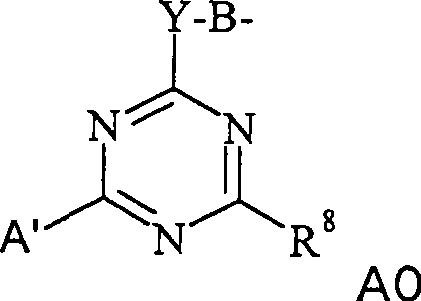

[0177] A mixture of 4.52 parts of three dyes with the following structure

[0178]

[0179] Suspended in 9 parts of completely demineralized water. With a high-performance disperser (such as Ika ) 100 parts of polydimethylsiloxane with amino groups (amine value: 92 micromole amine groups per gram; viscosity: 300 mm2 / s) were processed for 3 minutes, thereby heated to about 30° C., and then The aqueous dye solution was uniformly dispersed in the silicone using a high performance disperser for 10 minutes, during which time the reaction mixture was heated to about 60°C. The remaining water was removed under reduced pressure and after cooling to room temperature the product was filtered through a depth filter. 99 parts of black silicone oil can be obtained.

Embodiment 3

[0181] 7.37 parts of the dye mixture described in Example 2 were suspended in 15 parts of completely demineralized water. Use a high-performance disperser (such as Ika ) 50 parts of polydimethylsiloxane with amino groups (amine value: 300 micromole amine groups per gram; viscosity: 301 mm2 / s) were processed for 3 minutes, thereby heated to about 30° C., and then The aqueous dye solution was uniformly dispersed in the silicone using a high performance disperser for 10 minutes, during which time the reaction mixture was heated to about 60°C. The remaining water was removed under reduced pressure and after cooling to room temperature the product was filtered through a depth filter. You can get 100 parts of black silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com