Preparation methods for diisocyanate-modified montmorillonite and modified asphalt by employing diisocyanate-modified montmorillonite

A technology of diisocyanate and modified asphalt, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of agglomeration deposition, lower road performance, easy occurrence of modifiers, etc., and achieve good physical properties, low cost, Effect of good thermal storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

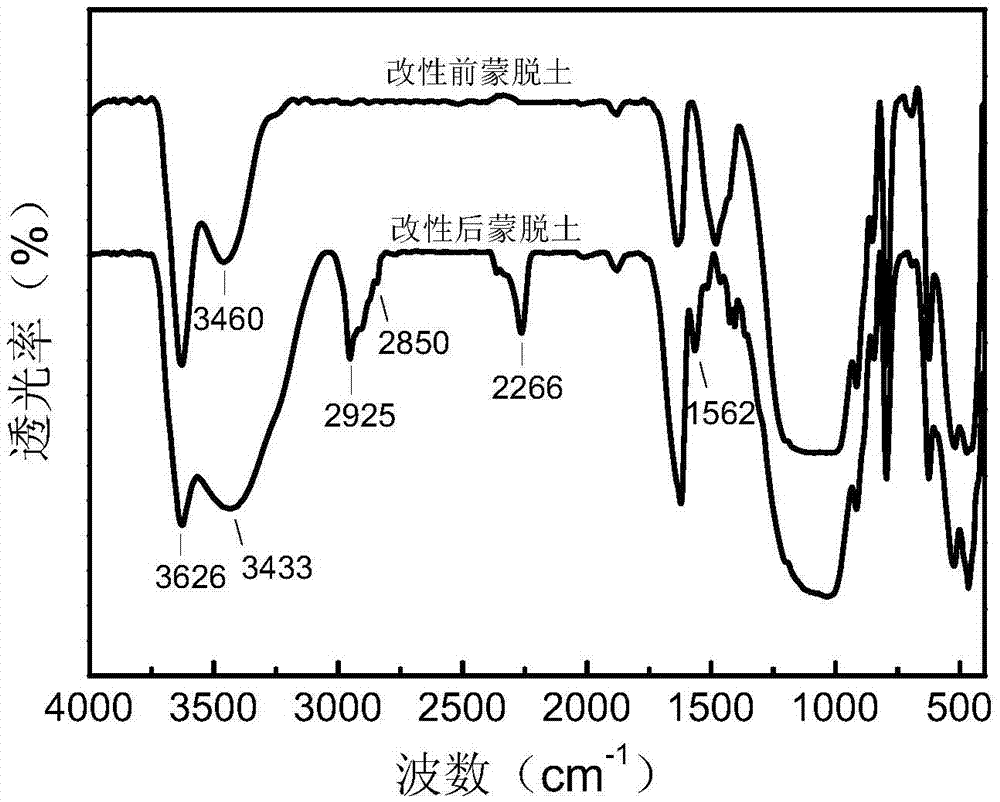

[0029] Mix 100g of N,N-dimethylformamide, 10g of Na-montmorillonite and 4g of isophorone diisocyanate, heat up to 90°C, stir and react at a rate of 500r / min for 6h, filter and wash with anhydrous toluene The filtered matter was 6 times, and the modified montmorillonite A was obtained after the filtered matter was dried.

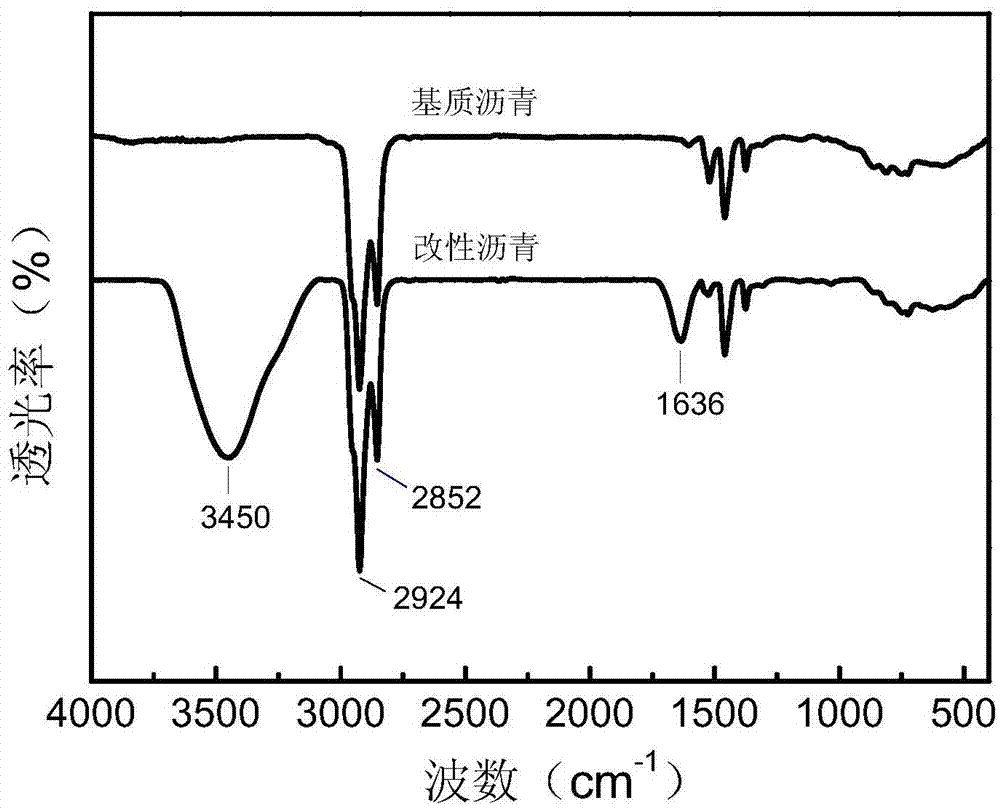

[0030] Will contain 100g base asphalt (Maoming Petrochemical AH90 # ) stainless steel tank in a constant temperature oil bath, heated to 120°C to fully melt the base asphalt. After the base asphalt was completely melted, 10 g of modified montmorillonite A was added, and a high-speed shear emulsifier was used to shear and mix at a rate of 4000 r / min for 90 minutes to finally obtain a modified asphalt material.

Embodiment 2

[0032] Mix 100g of N,N-dimethylformamide, 10g of DK3 organic montmorillonite and 6g of 4,4'-dicyclohexylmethane diisocyanate, heat up to 85°C, stir and react at a rate of 600r / min for 6h, and filter The filtrate was washed 8 times with anhydrous toluene, and the modified montmorillonite B was obtained after the filtrate was dried.

[0033] Will contain 100g base asphalt (U.S. Shell 70 # ) stainless steel tank in a constant temperature oil bath, heated to 150°C to fully melt the base asphalt. After the base asphalt was completely melted, 8 g of modified montmorillonite B was added, and a high-speed shear emulsifier was used to shear and mix at a rate of 4000 r / min for 60 minutes to finally obtain a modified asphalt material.

Embodiment 3

[0035] Mix 100g of N,N-dimethylformamide, 15g of DK3 organic montmorillonite and 8g of 4,4'-diphenylmethane diisocyanate, heat up to 80°C, stir and react at 800r / min for 4h, filter The filtrate was washed 8 times with anhydrous toluene, and the modified montmorillonite C was obtained after the filtrate was dried.

[0036] Will contain 100g base asphalt (Maoming Petrochemical AH90 # ) stainless steel tank in a constant temperature oil bath, heated to 140°C to fully melt the base asphalt. After the base asphalt was completely melted, 6 g of modified montmorillonite C was added, and a high-speed shear emulsifier was used to shear and mix at a rate of 5000 r / min for 60 minutes to finally obtain a modified asphalt material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com