Formaldehyde eliminating agent and preparation method thereof

A formaldehyde remover and stabilizer technology, used in aldehyde/ketone condensation polymer adhesives, adhesives, adhesive types, etc., can solve the problems of reducing the efficiency and mechanical properties of urea-formaldehyde resin production of wood-based panels, and achieve formaldehyde removal. Long-lasting effect, lower formaldehyde emission, convenient use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Prepare raw materials according to the following weight ratio

[0027] Water-emulsion epoxy resin (50% solid content): 200kg

[0028] Water: 400kg

[0029] Borax: 0.5kg

[0030] Melamine: 400kg

[0031] Sodium hydroxide solution (concentration 30%): appropriate amount

[0032] Formic acid solution (concentration 20%): appropriate amount

[0033] 2. Add water, borax, and melamine to the reaction kettle in turn, start stirring, raise the temperature to 40°C, stir well, and use formic acid to adjust the pH value of the reaction solution to 5.0-5.5;

[0034] 3. Raise the temperature to 70-72°C, react for 30 minutes, adjust the pH value to 6.0-8.0 with sodium hydroxide, cool down to 30°C, and discharge.

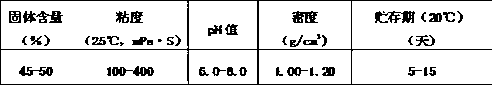

[0035] Table 1 Technical indicators of formaldehyde scavenger products

[0036]

Embodiment 2

[0038] 1. Prepare raw materials according to the following weight ratio

[0039] Water-soluble epoxy resin (50% solid content): 300kg

[0040] Distilled water: 800kg

[0041] Mixture of borax and calcium metaborate: 1kg

[0042] Melamine: 800kg

[0043] 2. The synthesis process is the same as in Example 1.

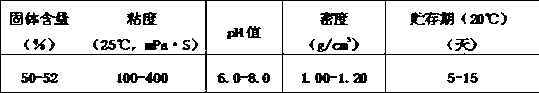

[0044] Table 2 Technical indicators of formaldehyde scavenger products

[0045]

Embodiment 3

[0047] 1. Prepare raw materials according to the following weight ratio:

[0048] Waterborne epoxy resin (50% solid content): 500kg

[0049] Deionized water: 1000kg

[0050] Mixture of borax and sodium metaborate: 8kg

[0051] Melamine: 1000kg

[0052] 2. The synthesis process is the same as in Example 1.

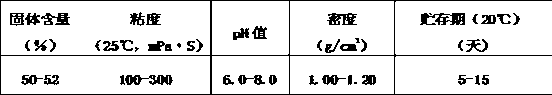

[0053] Table 3 Technical indicators of formaldehyde scavenger products

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com