Patents

Literature

55results about How to "No reduction in production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of yield strongth 460 MPa grade low alloy high strength structure steel plate

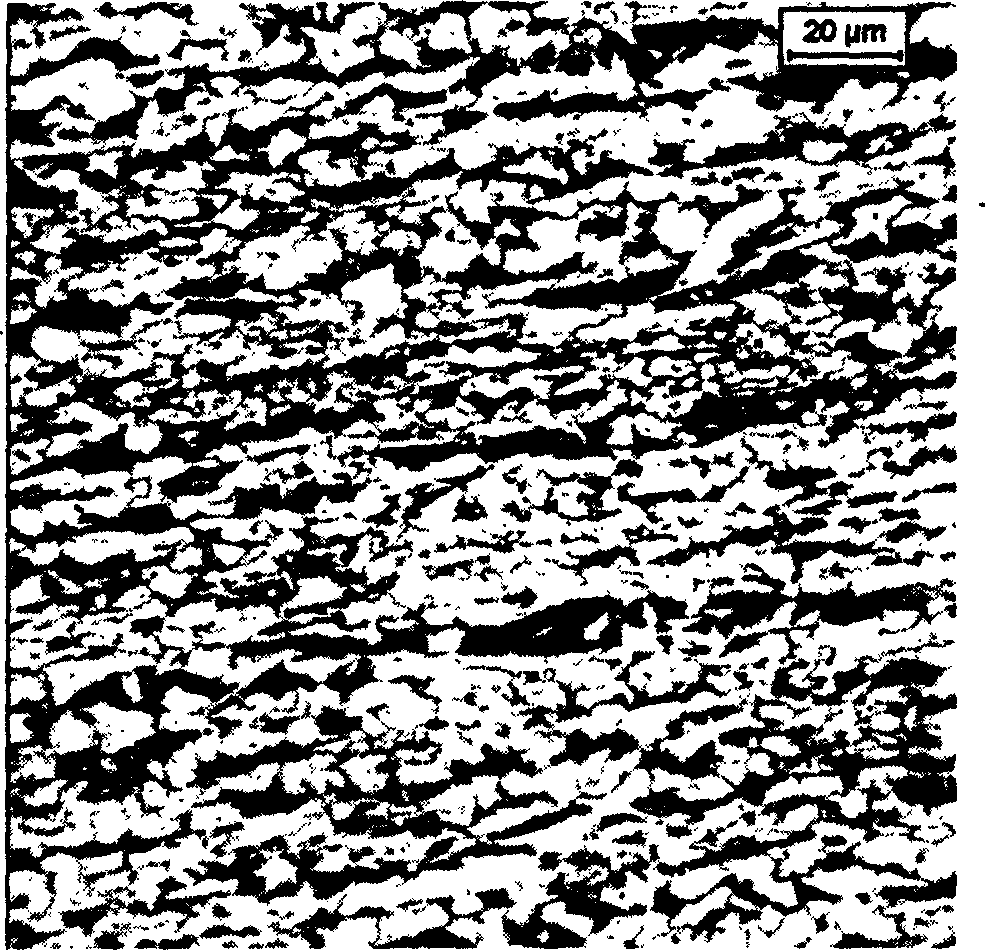

A low-alloy high-strength steel plate with high yield strength (460 MPa) contains C (0.13-0.20 wt.%), Si (0.2-0.5), Mn (1.3-1.7), Nb (0.01-0.02) Ti (0.005-0.01), Al (0.005-0.015) and Fe (rest). Its preparing process features that two-stage rolling at 1200-1250 deg.C and quick cooling. Its advantages are multi-phase structure including polygonal and acicular ferrite, pearlite and bainite, high yield strength and low cost.

Owner:NORTHEASTERN UNIV

Processing method for deodorized soybean milk

InactiveCN105519689AThe process steps are simpleStrong maneuverabilityMilk substitutesFood scienceChemistrySoybean oil

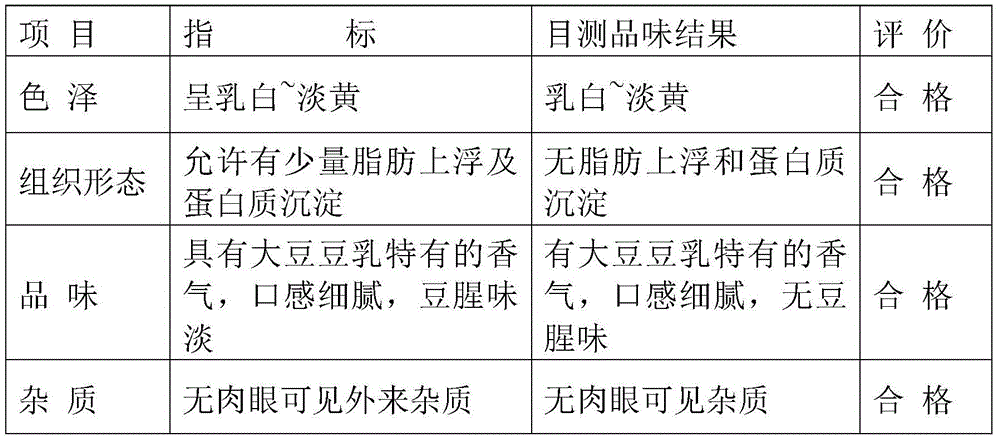

The invention discloses a processing method for deodorized soybean milk. The processing method includes the steps of (1), soaking, (2), grinding, (3), centrifugation for dregs removal, (4), boiling, (5), vacuum degassing, (6), high-pressure homogenization and (7), sterilizing and packing. The processing method for the deodorized soybean milk has the advantages that process steps are simple, operability is high, beany flavor of soybean milk can be eliminated thoroughly without production efficiency reduction, production cost increase and soybean protein modification enhancement, product flavor and taste can be improved, acceptability of customers is greatly improved, and accordingly, the processing method has high promotion and application value.

Owner:包宇青

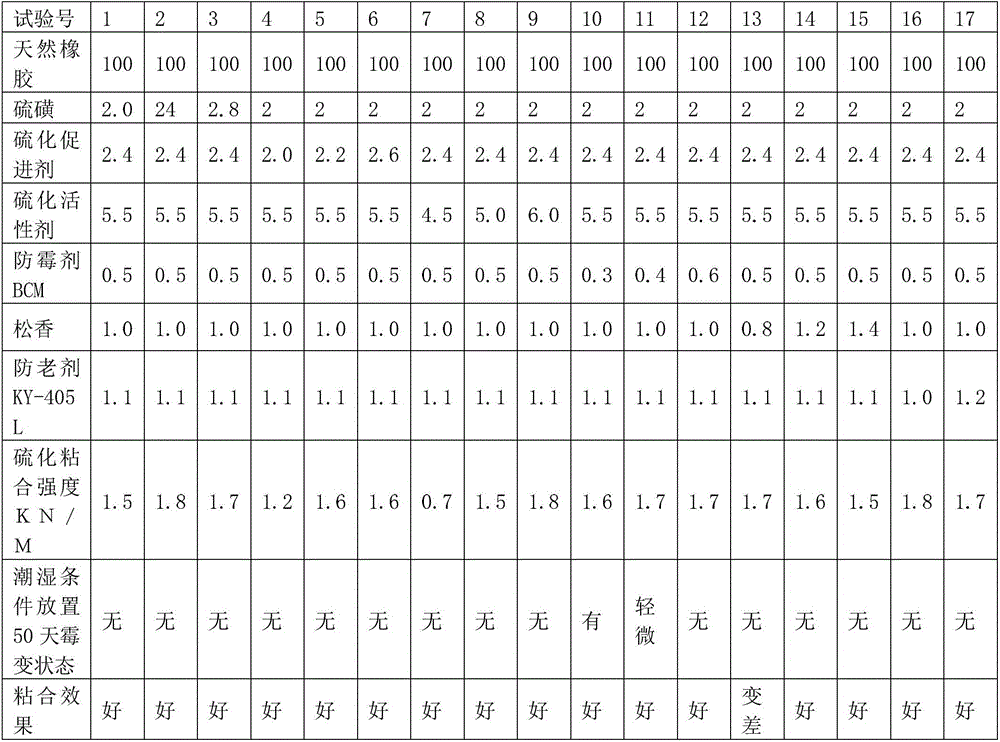

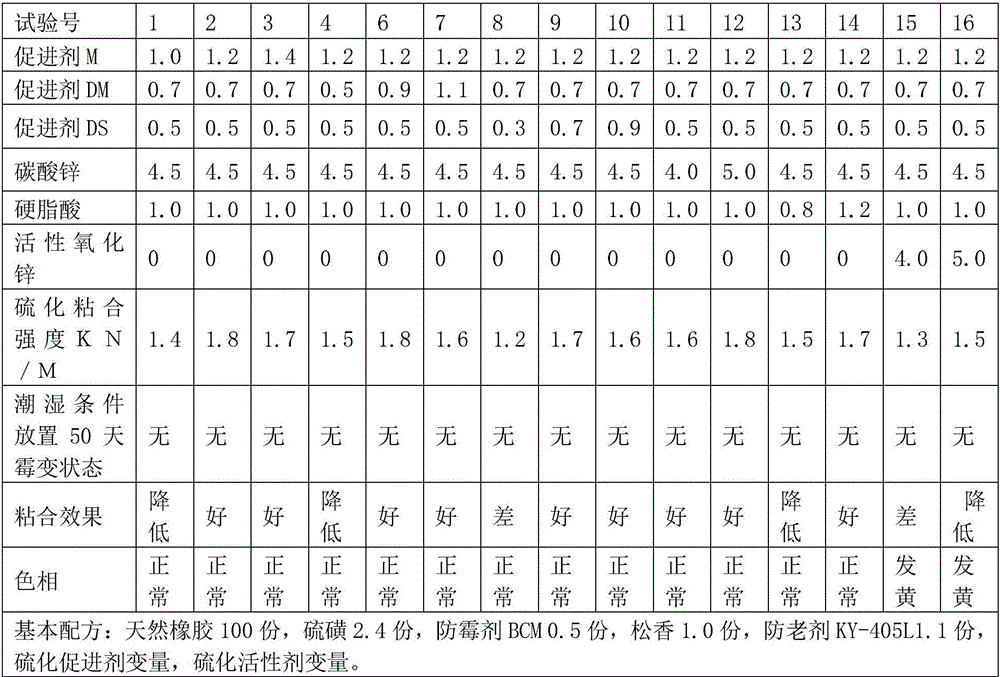

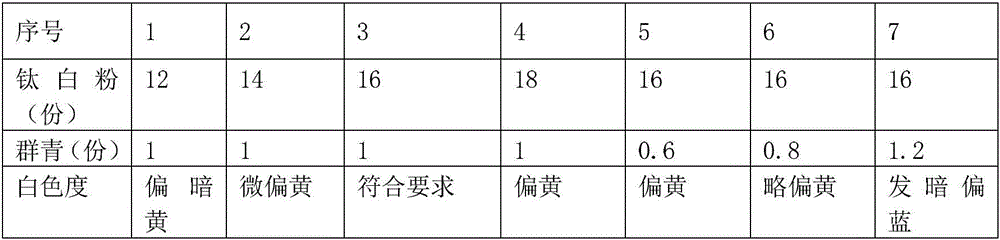

Head covering cloth adhesive for white upper and preparation method and application of head covering cloth adhesive

InactiveCN106189925AEliminate unbeautifulEliminate friction during wearingNatural rubber adhesivesNon-macromolecular adhesive additivesVulcanizationAgricultural engineering

The invention discloses a head covering cloth adhesive for a white upper and a preparation method and application of the head covering cloth adhesive. The head covering cloth adhesive is prepared from natural rubber, a vulcanization agent, an accelerant M, an accelerant DS, an accelerant DM, a vulcanizing activator, rosin, composite resin DS-B, titanium dioxide, ultramarine and 120# gasoline. The reasonable adhesive formula and preparation method are screened out, the adhesive has good adhesion strength and is used for bonding head covering cloth and the upper, the product quality is guaranteed, meanwhile, the problems that a sewing process is not attractive in appearance, friction is large in the wearing process, and consequently toes are injured can be solved, and the appearance quality and wear comfort degree of the product are improved. The production efficiency is not reduced, and the industrialization degree is good. The head covering cloth adhesive is simple and easy to apply, low in cost and good in use effect.

Owner:JIHUA 3537 SHOE MAKING

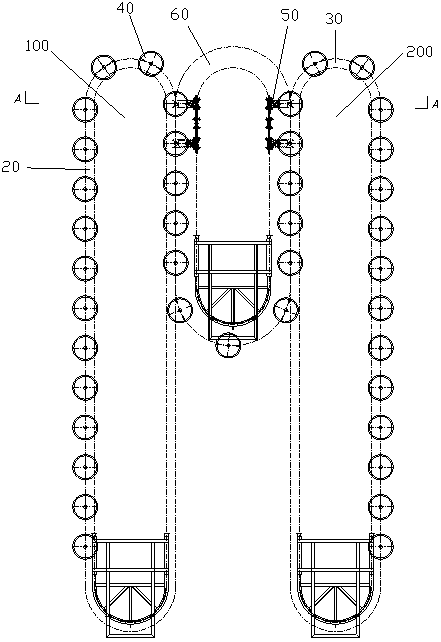

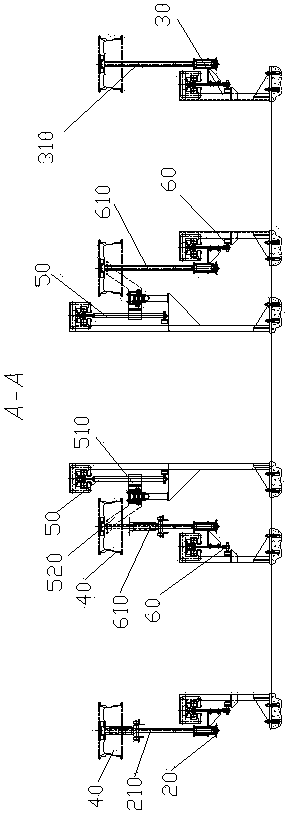

Workpiece spraying and processing device as well as processing method thereof

InactiveCN103962282AAvoid pollutionReduce labor costsLiquid surface applicatorsSpraying apparatusMechanical engineeringEngineering

The invention discloses a workpiece spraying and processing device as well as a processing method thereof. The device comprises a spraying device arranged at a spraying area, a drying chamber for drying workpieces and conveying devices arranged at the spraying area and the drying chamber, wherein the conveying devices comprise a first conveying device and a second conveying device which are respectively arranged at the spraying area and the drying chamber; a piece transferring device which is used for transferring workpieces is arranged between the spraying area and the drying chamber. According to the workpiece spraying and processing device provided by the invention, because the conveying devices at the spraying area and the drying chamber are arranged independently and separately, and the workpiece transferring device for transferring pieces is arranged between the spraying area and the drying chamber, each part of the conveying devices can be prevented from being polluted, and the transferring not only cannot increase labor cost, but also cannot lower the production efficiency, and additionally, the product quality is not affected, thereby saving energy, reducing consumption, improving the product quality, and improving the production efficiency and economical benefit of enterprises.

Owner:SHENZHEN LIUSH MACHINERY EQUIP

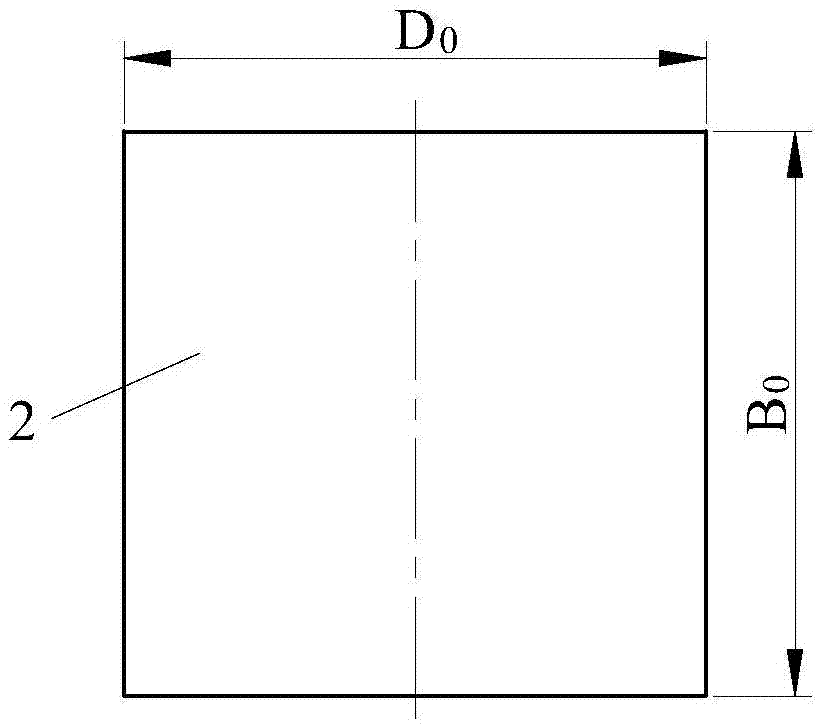

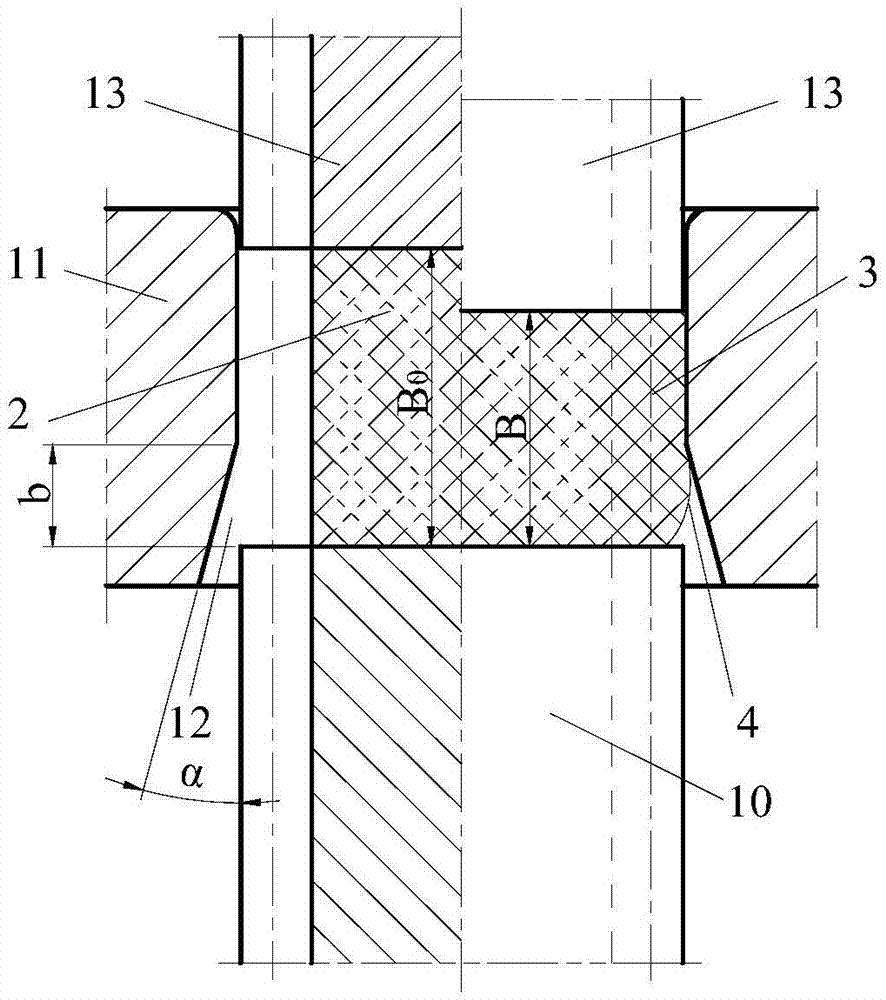

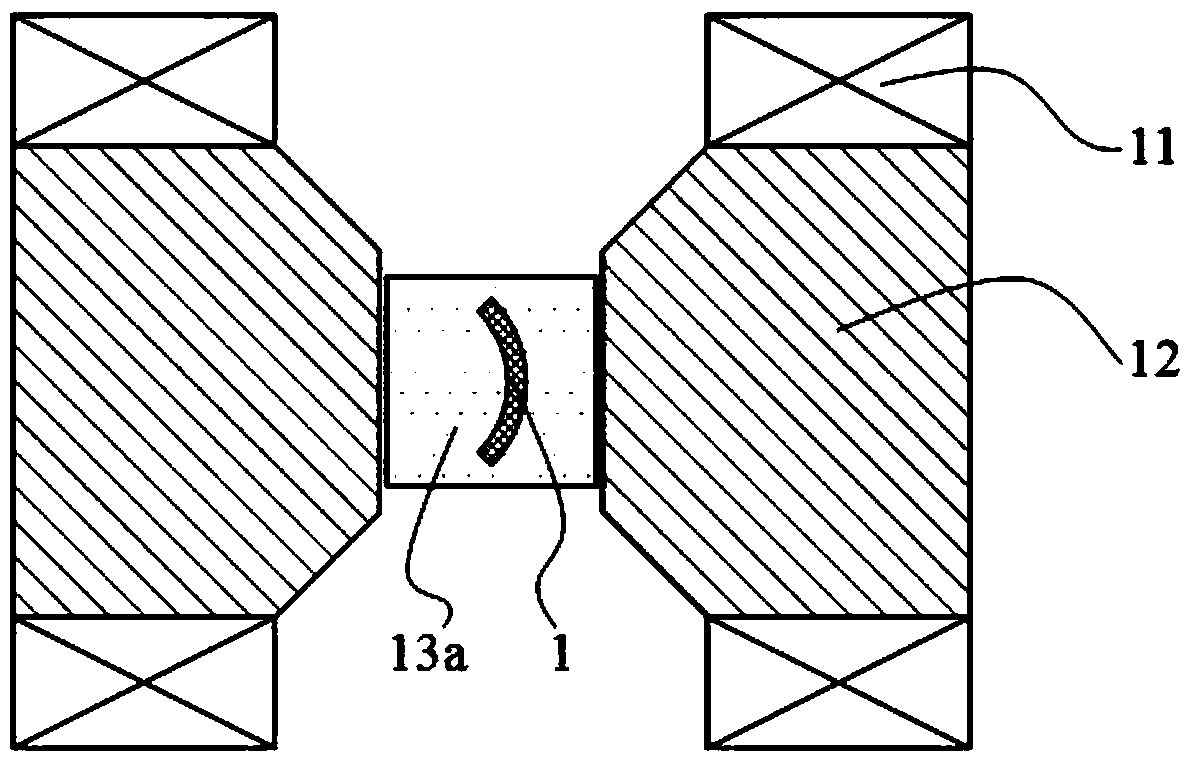

Precision forming method for straight/helical tooth cylinder gear with corners easy to fill and die

InactiveCN105436390AReduce complexityHigh strengthForging/hammering/pressing machinesWheelsGear wheelEngineering

The invention discloses a precision forming method for a straight / helical tooth cylinder gear with corners easy to fill and a die. During a closed die forging upsetting stage, a cylindrical blank is manufactured into an intermediate process part with lower corners not tidy enough in an upsetting mode; a volume protruding relative to a tooth outline is reserved near each lower corner of the intermediate process part; during an ejection-out stage, a lower convex die moves upwards, due to the function of a lateral wall conical surface of a concave die, the lower corners, not tidy enough, of the intermediate process part are deformed again, the protruding volumes transfer towards the lower corners, and forming of the lower corners is completed. According to the structure of the concave die, the conical surface with the bottom surface outline larger than the gear tooth top outline is used for expanding a concave die cavity near each lower corner, a cylindrical die cavity of the corresponding portion becomes a big-end-down prism-frustum-shaped die cavity, and the tooth root and the parts far away from the lower corners still keep the cylinder die cavity. By means of the precision forming method for the straight / helical tooth cylinder gear with the corners easy to fill and the die, the problems that according to traditional cylindrical gear precision forming, the gear tooth corners are not full enough, forming force is large, the structure of the die is complex, the service conditions are bad, the service life of the die is short, and the requirements for motions of equipment are complex are solved.

Owner:NANCHANG UNIV

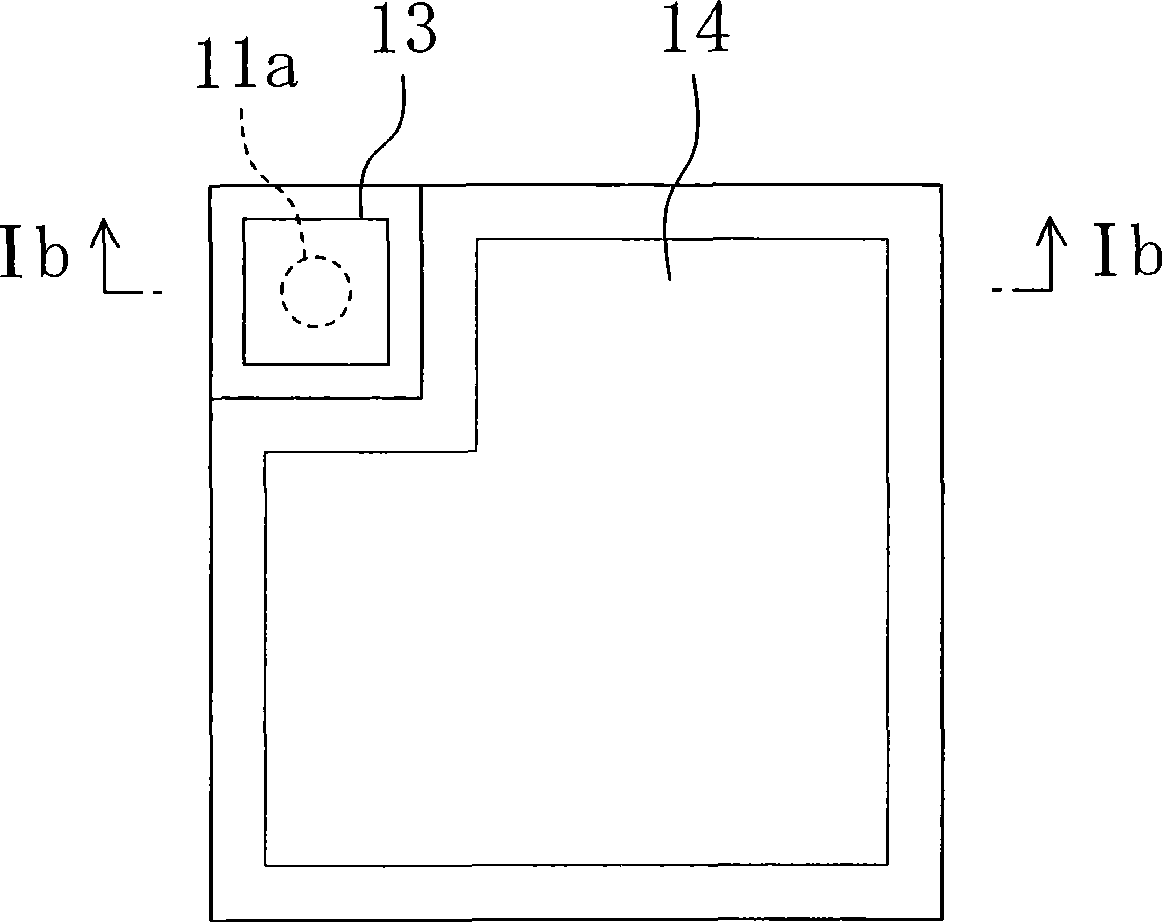

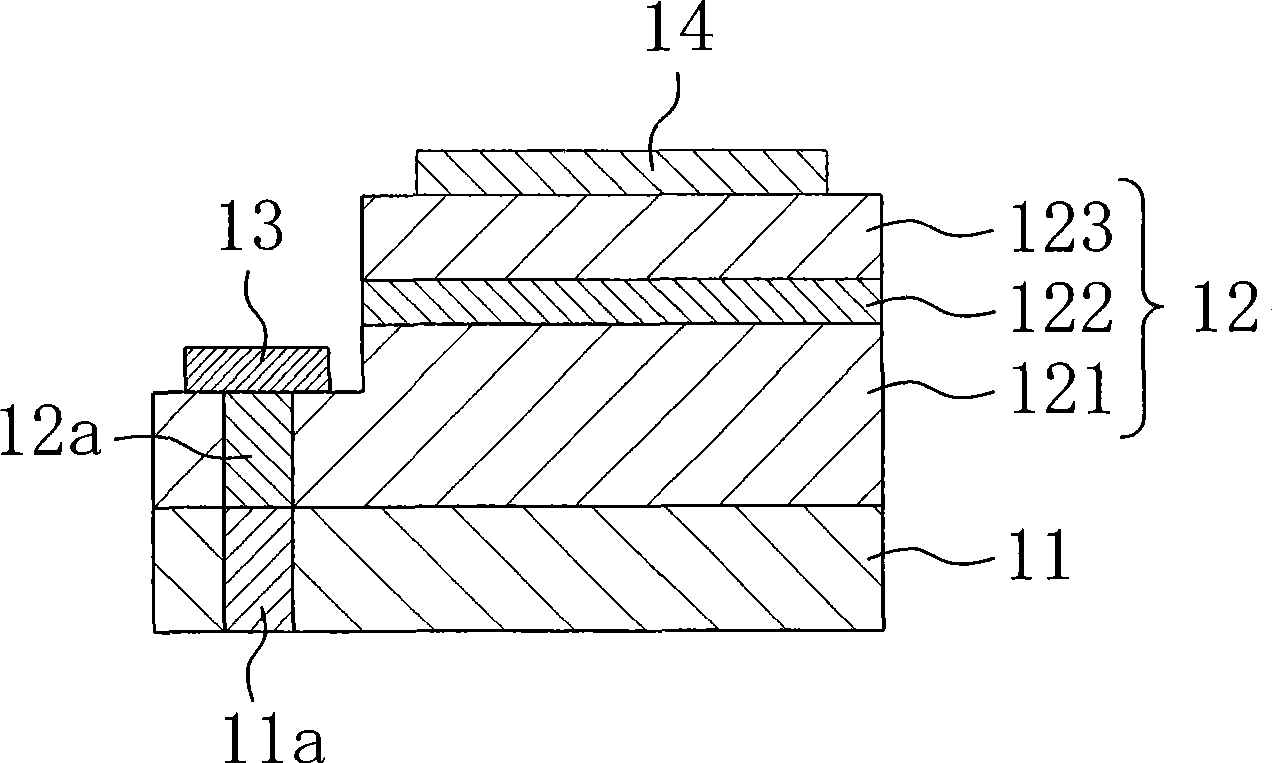

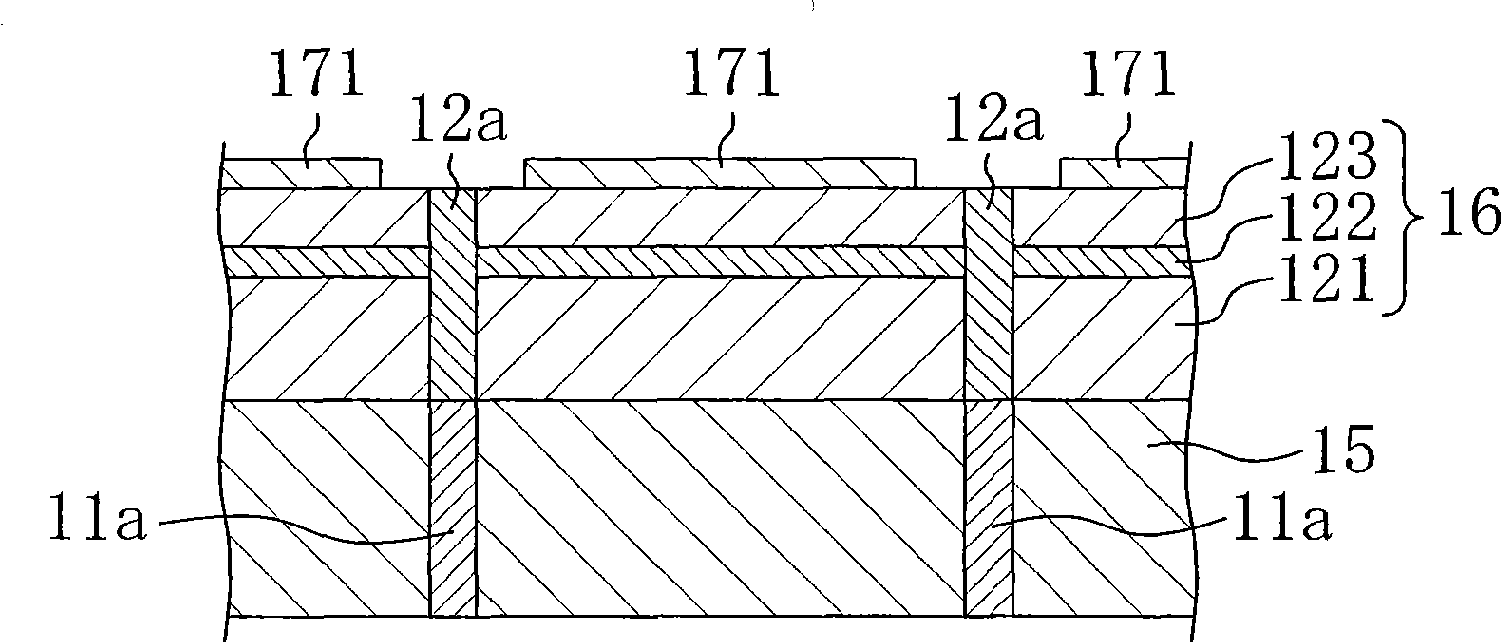

Semiconductor light emitting element and method for fabricating the same

InactiveCN101473457ANo reduction in production efficiencyLaser detailsSemiconductor lasersSemiconductorCrystallization

A semiconductor light emitting element includes a substrate 11 having a defect concentrated region 11a which has a crystal defect density higher than in the other region. On the substrate 11, a semiconductor layer 12 is formed. On the defect concentrated region 11a, a first electrode 13 is formed. On the semiconductor layer 12, a second electrode 14 is formed.

Owner:PANASONIC CORP

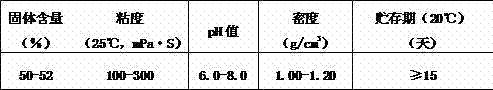

Formaldehyde elimination agent and preparation method thereof

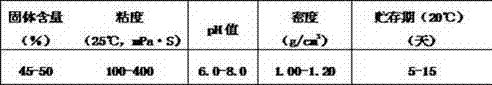

InactiveCN101037576AImprove elimination effectReduce production efficiencyNon-macromolecular adhesive additivesDispersed particle separationStable stateFiber

The invention discloses a formaldehyde eliminating agent and preparing method thereof. Weight proportioning of raw material for the formaldehyde eliminating agent is: 100-300 quotient of formaldehyde, 150-700 quotient of urea, 50-500 quotient of water, 10-80 quotient of accelerant, 0.1-5 quotient of stabilizer, and 1-20 quotient of catalyst. The preparing method includes steps: adding each component into reaction kettle in turn, stirring the mixture at temperature of 20-50 DEG C until equally mixed and whole dissolved, adjusting pH between 7.5-9.0, and stirring until stable. Advantages of the formaldehyde eliminating agent are: preparing cost is low, formaldehyde eliminating effect is evident and permanent when the formaldehyde eliminating agent is used with urea-formaldehyde resin glue or melamine modified urea-formaldehyde resin glue for synthetic plate of incompetent formaldehyde releasing amount and E2 level synthetic plate, making formaldehyde releasing amount of incompetent and E2 level middle / high density fiber board reach to E2 and E1 level separately and observably reducing preparing cost of the middle / high density fiber board without reducing mechanics capability of the synthetic plate.

Owner:EVERFIRST WISEFUND TECH BEIJING

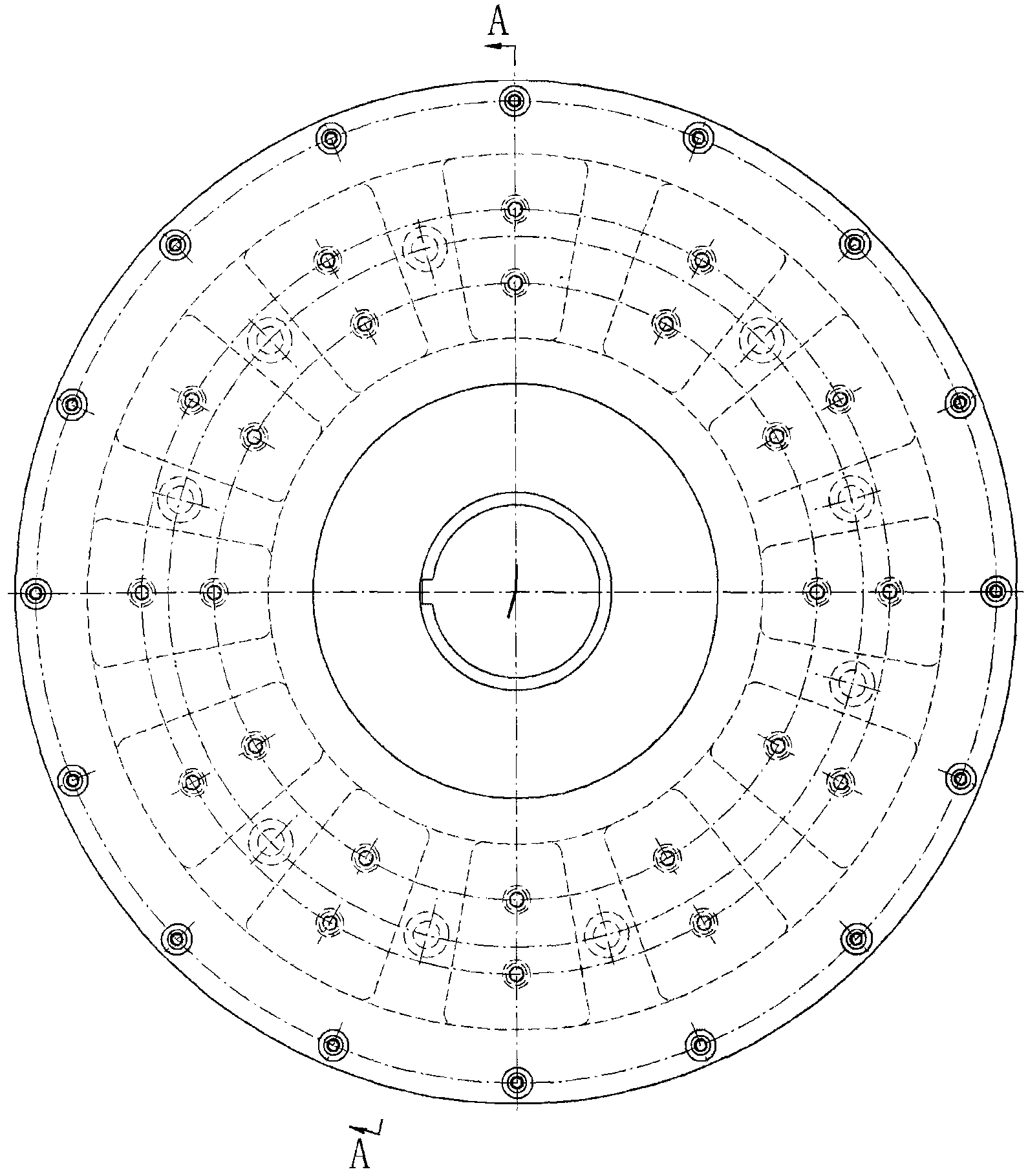

Multi-pole magnetic ring of anisotropic bonded NdFeB and manufacturing method thereof

ActiveCN108063037AHigh strengthImprove versatilityTransportation and packagingMetal-working apparatusUltimate tensile strengthField intensity

The invention provides a multi-pole magnetic ring of anisotropic bonded NdFeB and a manufacturing method thereof. The multi-pole magnetic ring is an anisotropic bonded NdFeB 2n-pole magnetic ring, wherein n is a natural number larger than or equal to 2. 2n splicing lines are seen indistinctly or clearly on magnetic shoe splicing positions on the magnetic ring. The magnetic ring is obtained by a secondary forming method after 2n bonded anisotropic tile type workblanks which are performed by orientation pressing are spliced on an annular die, the central angle of the bonded anisotropic tile typeworkblank is [pi] / n. The manufacturing method is characterized by high magnetic ring orientation degree, high oriented magnetic field intensity, easy obtaining, good universality, adjustable demagnetized field intensity, short production process, high production efficiency, and low cost.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

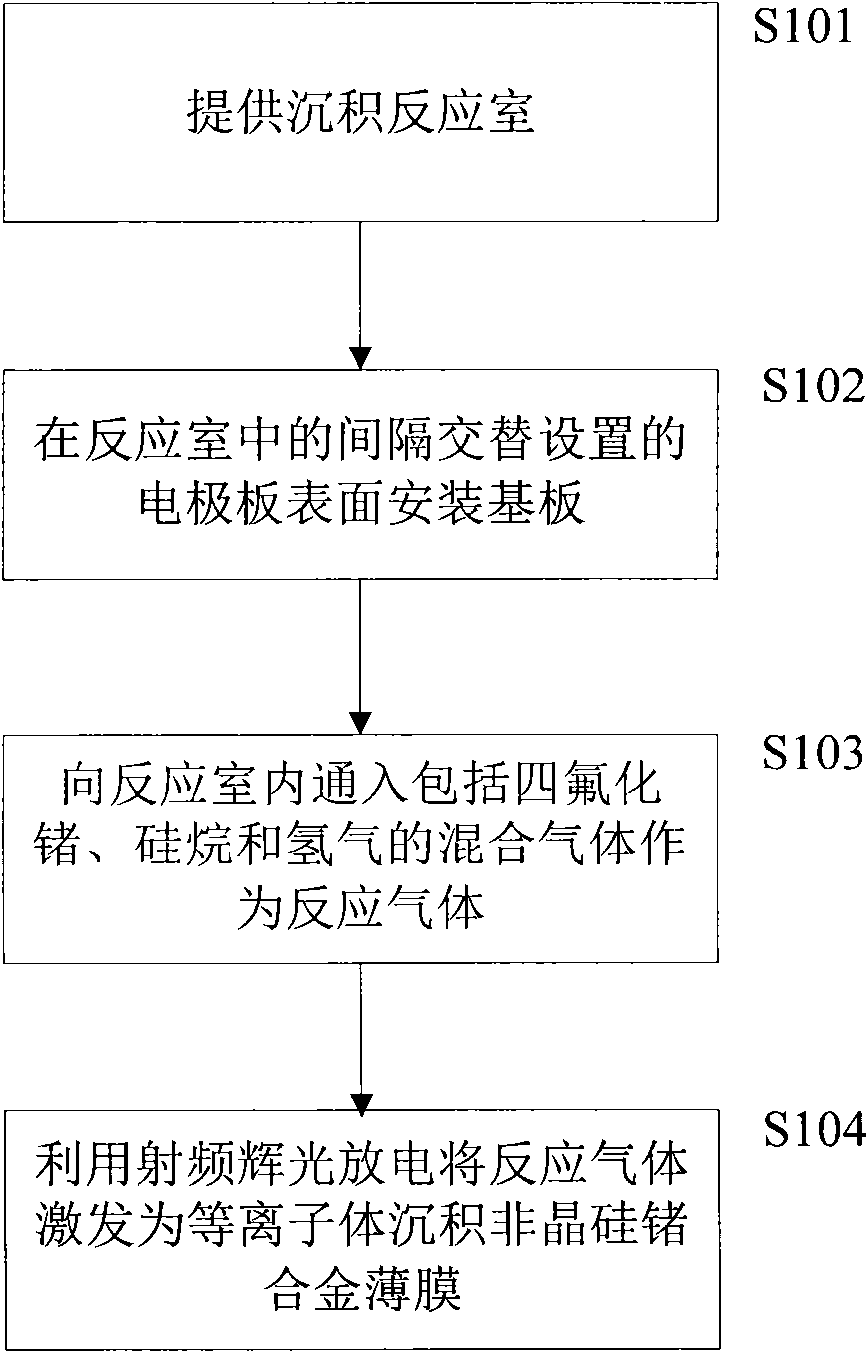

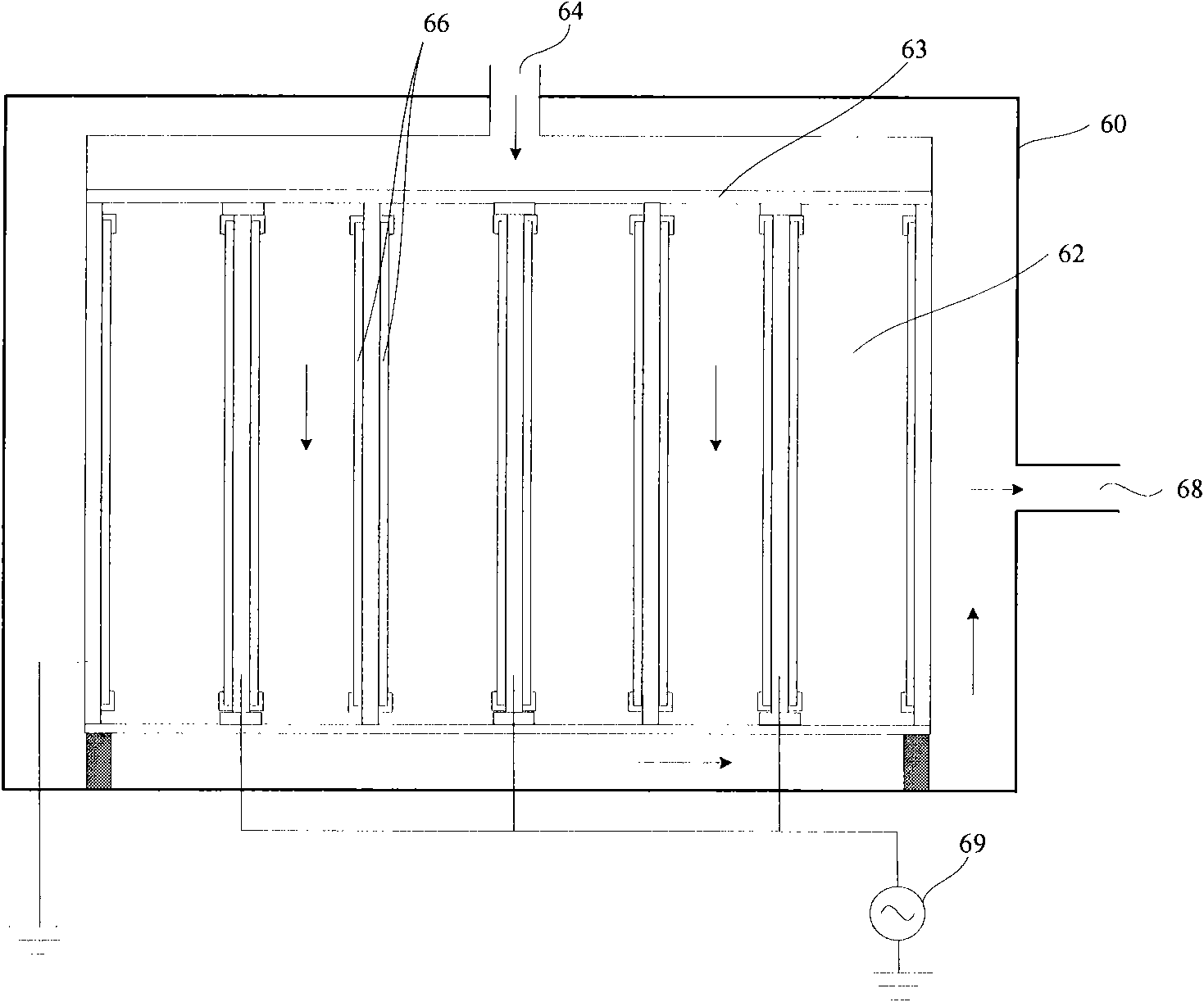

Method for manufacturing film solar cell

InactiveCN101626049AImprove stabilityImprove featuresFinal product manufactureChemical vapor deposition coatingPlasma depositionRadio frequency

The invention discloses a method for manufacturing a film solar cell, which comprises the following steps: providing a deposition reaction chamber; putting a substrate on the surface of an electrode plate in the reaction chamber; introducing reaction gases comprising germanium tetrafluoride, silicane and hydrogen into the reaction chamber; and using radio-frequency glow discharge to excite the reaction gases into plasma to deposite a amorphous silicon-germanium film. The method for manufacturing the film solar cell can remarkably improve evenness of band gap and thickness of amorphous silicon-germanium films deposited on the large-area substrate in batch in a large-sized PECVD deposition device.

Owner:GS SOLAR FU JIAN COMPANY +1

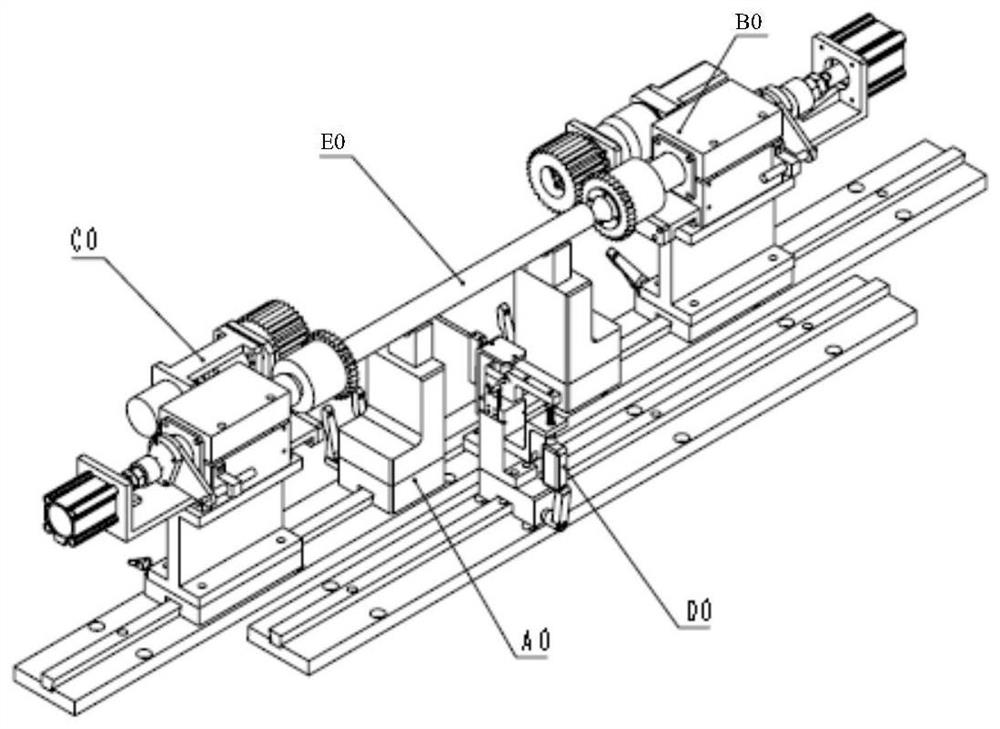

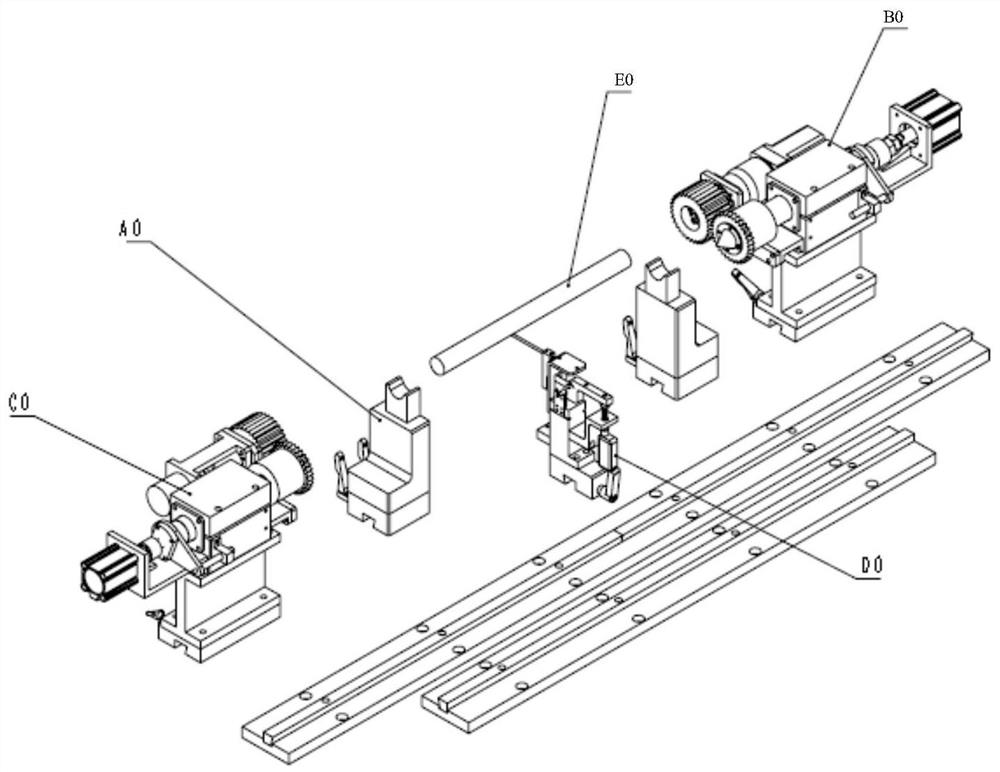

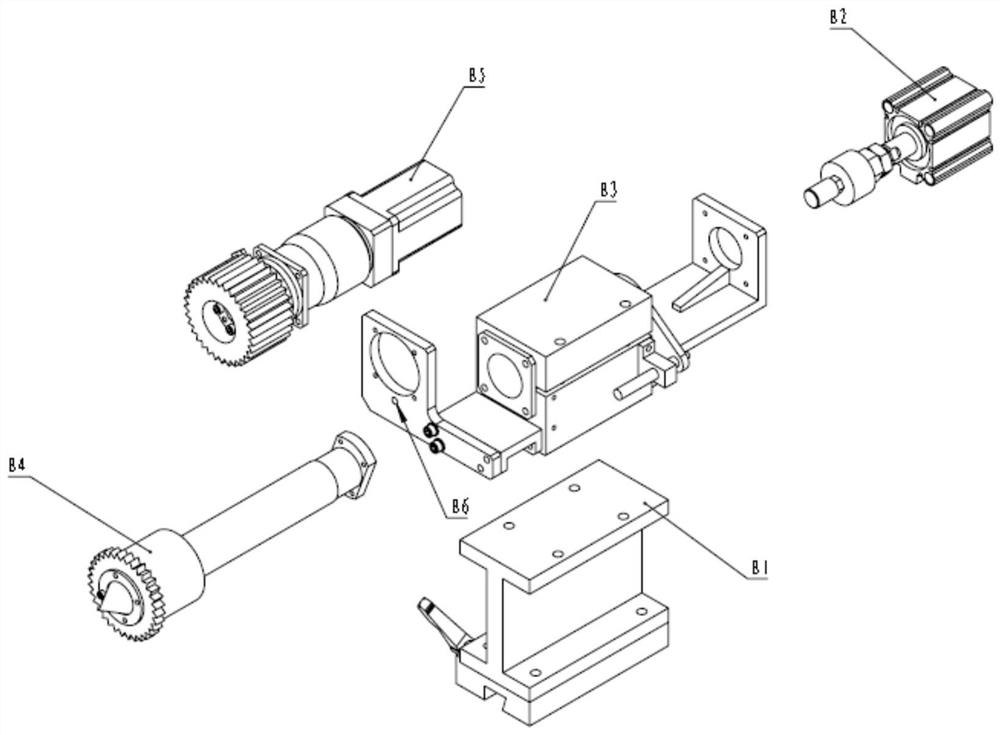

Shaft part bounce detection mechanism and detection method capable of automatically eliminating spindle errors

PendingCN111811449AImproving the detection accuracy of rotary runoutLower requirementMeasurement devicesControl engineeringMachine

The invention discloses a shaft part bounce detection mechanism and a detection method capable of automatically eliminating spindle errors. Two supporting mechanisms are fixed to a machine base through screws, and a workpiece is placed on the two supporting mechanisms. Driving and driven side clamping driving components are located on the left side and the right side of the workpiece correspondingly and fixed to the machine base; the driving and driven side clamping driving components are pushed out and clamped at the two ends of the workpiece through live centers, so that the workpiece is clamped and driven to rotate around the axis of the workpiece to do rotary motion; through pushing out of clamping air cylinders, the live centers clamp the workpiece, and the servo motor drives the centers to enable the workpiece to do rotary motion around the axis of the workpiece; and the bounce detection mechanism is installed beside the workpiece and detects surface bounce of the workpiece in the rotating process. According to the invention, the rotation run-out detection precision of shaft parts is improved; and on the premise that the production efficiency of equipment is not reduced and the detection precision is not sacrificed, the requirements of an equipment tool clamp and the production and use cost are reduced.

Owner:杭州集智机电股份有限公司 +2

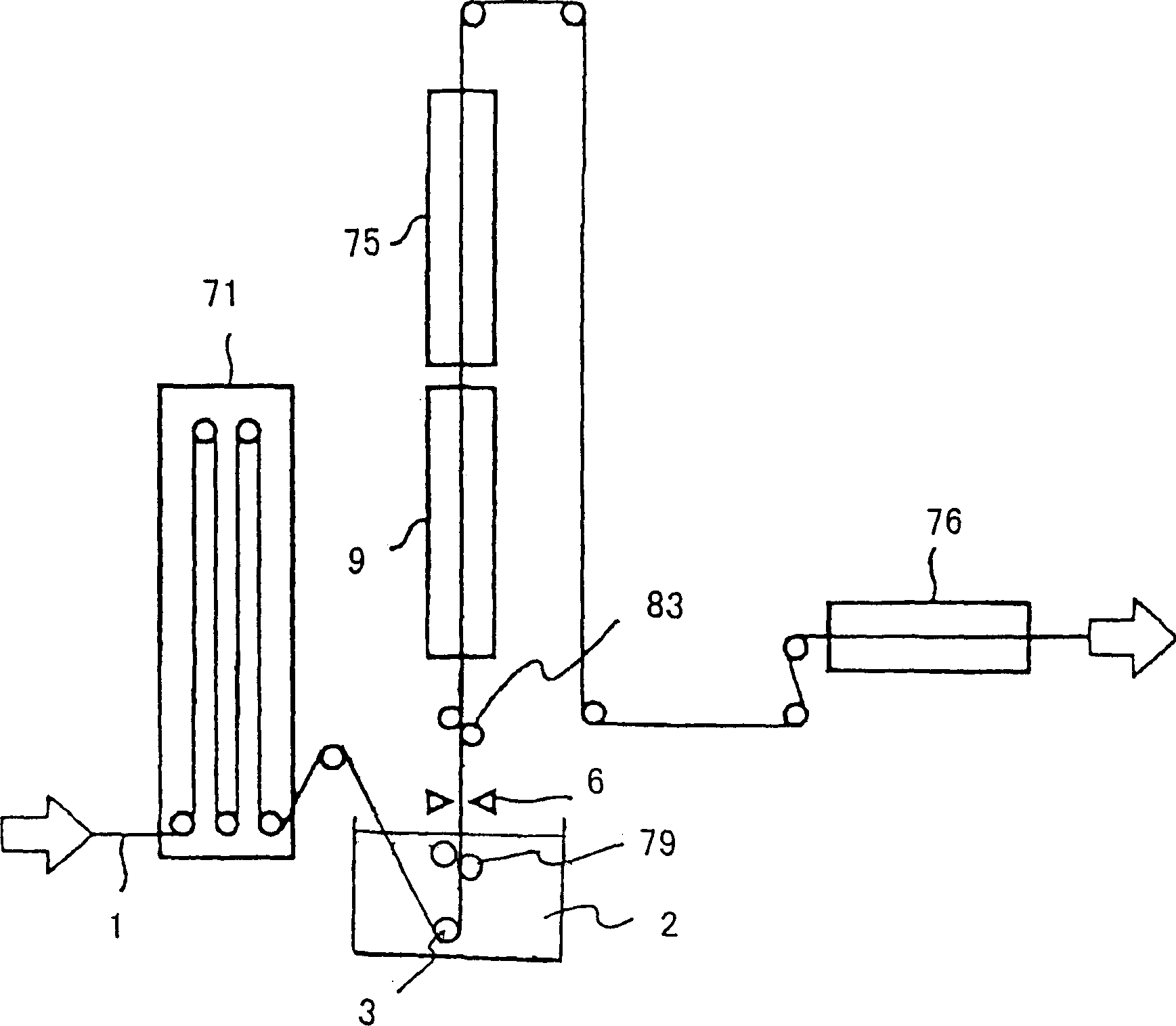

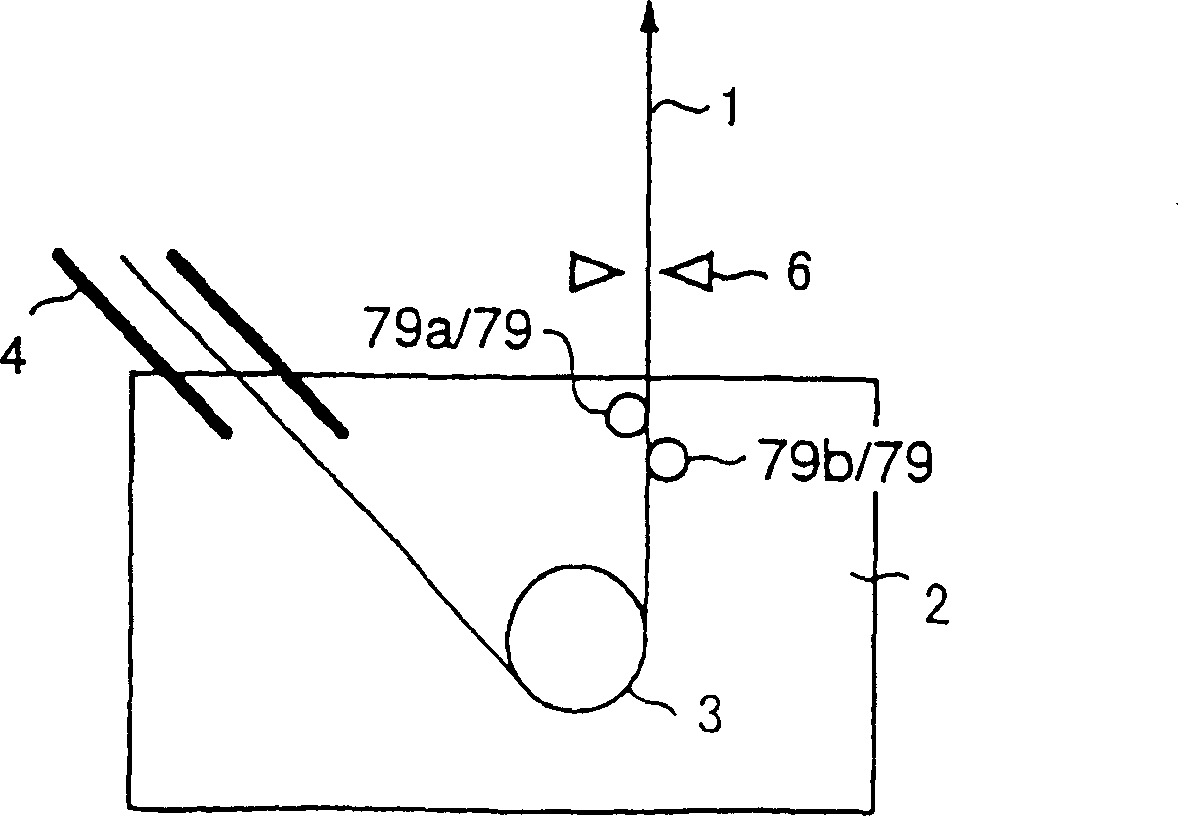

Production method of hot-dip metal strip and device therefor

InactiveCN1501985APrevent adhesionImprove qualityHot-dipping/immersion processesPretreated surfacesMetal stripsDross

The invention relates to a method for manufacturing a hot-dip plated metal strip comprising the steps of: introducing a metal strip into a molten metal bath of plating metal to adhere the molten metal onto the surface of the metal strip; taking out the metal strip, after turning the running direction of the metal strip, from the molten metal bath without applying external force from outside the surface of the metal strip; adjusting the plating weight of the molten metal adhered onto the metal strip; and controlling the shape of the metal strip using magnetic force in non-contact state directly before or after the step of adjusting the coating weight. The invention prevents adhesion of dross to the metal strip without degrading the productivity, and thus manufactures a high quality hot-dip plated metal strip.

Owner:JFE STEEL CORP

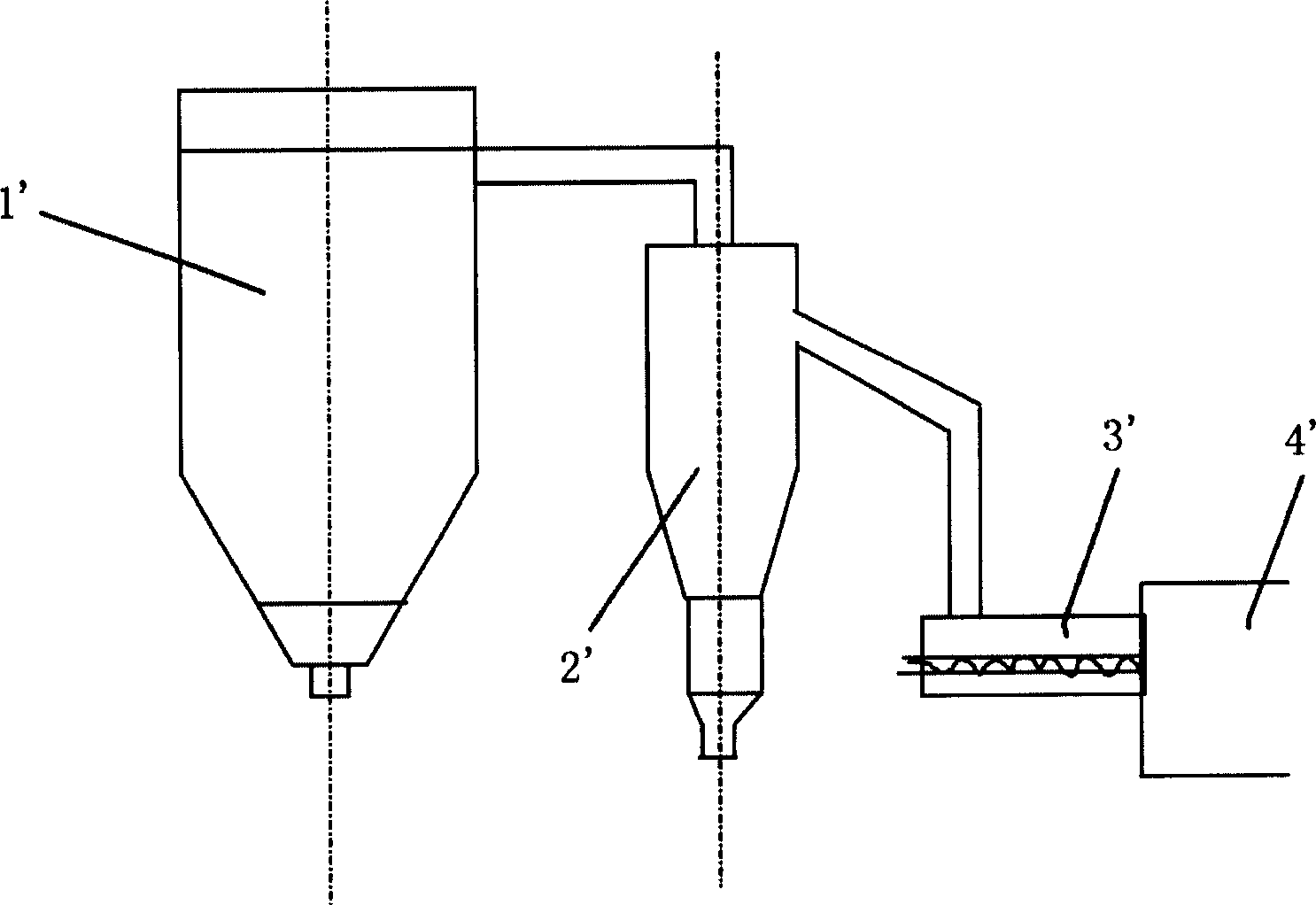

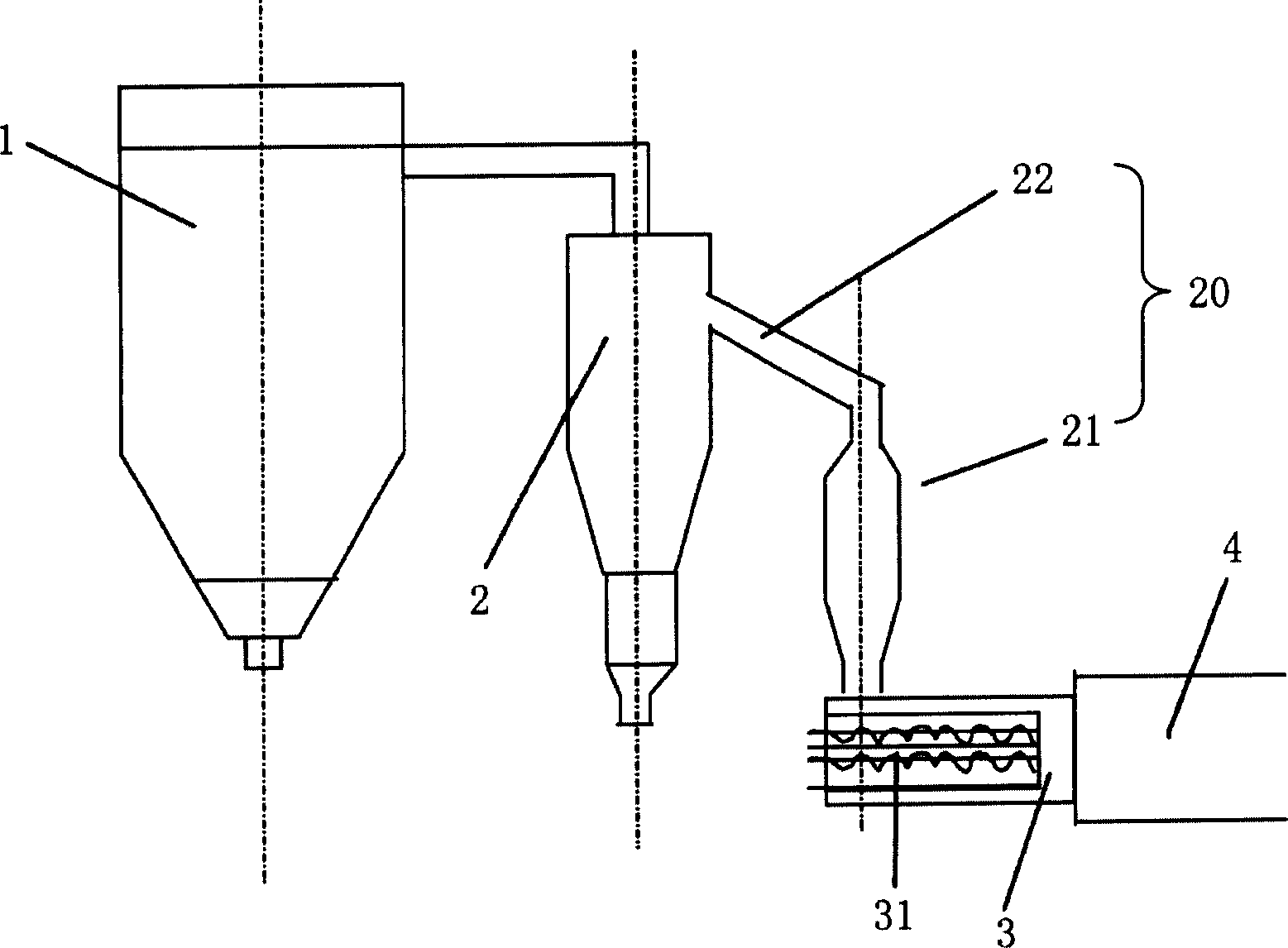

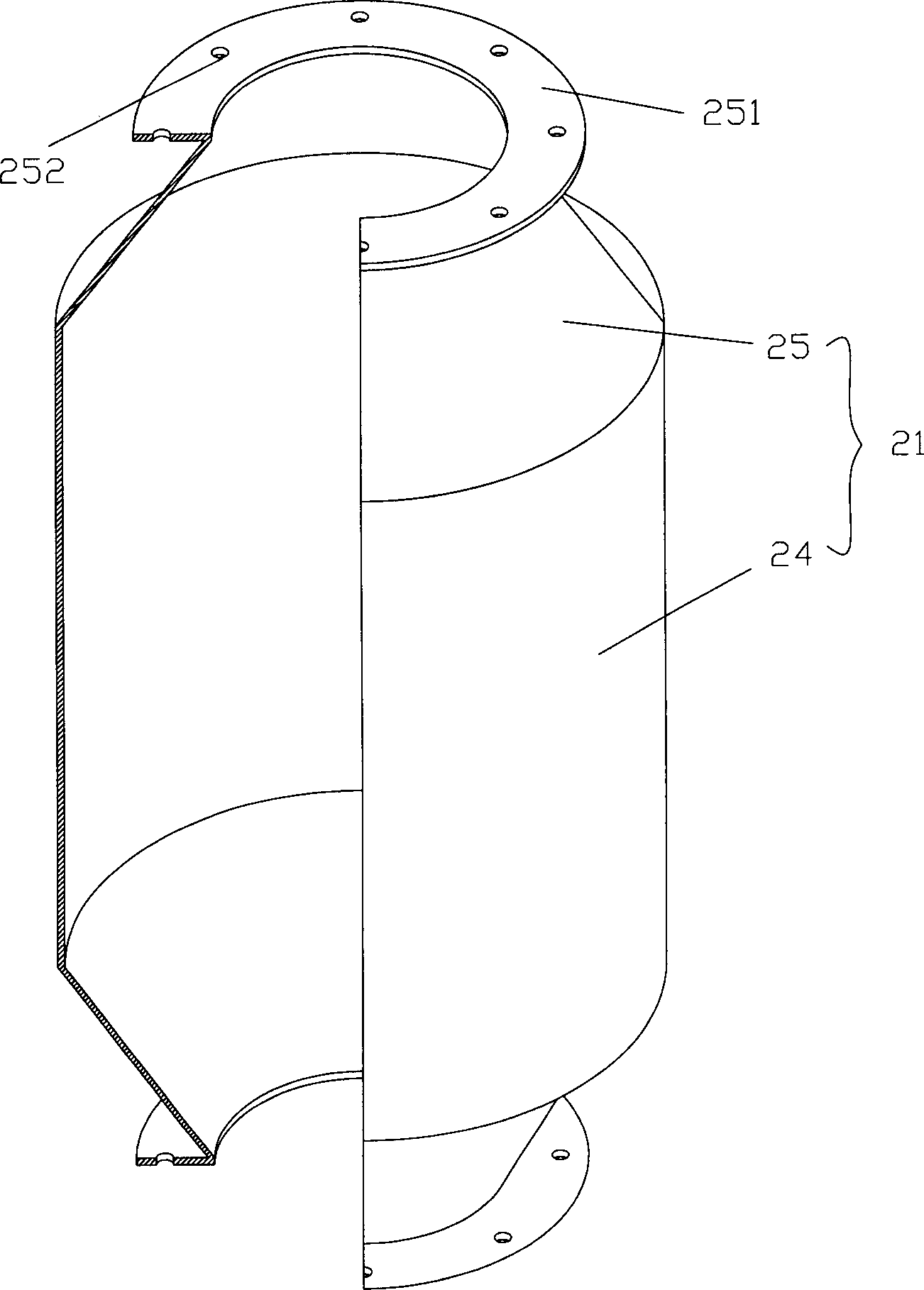

Lead powder machine

A lead powder machine is composed of powder collector, cyclone separator, hollow axle, the pipeline connected between cyclone separator and hollow axle and with a thickened segment, and drum. In said hollow axle there are three powder returning screws for returning the big particles back into drum to grind again.

Owner:赵恒祥

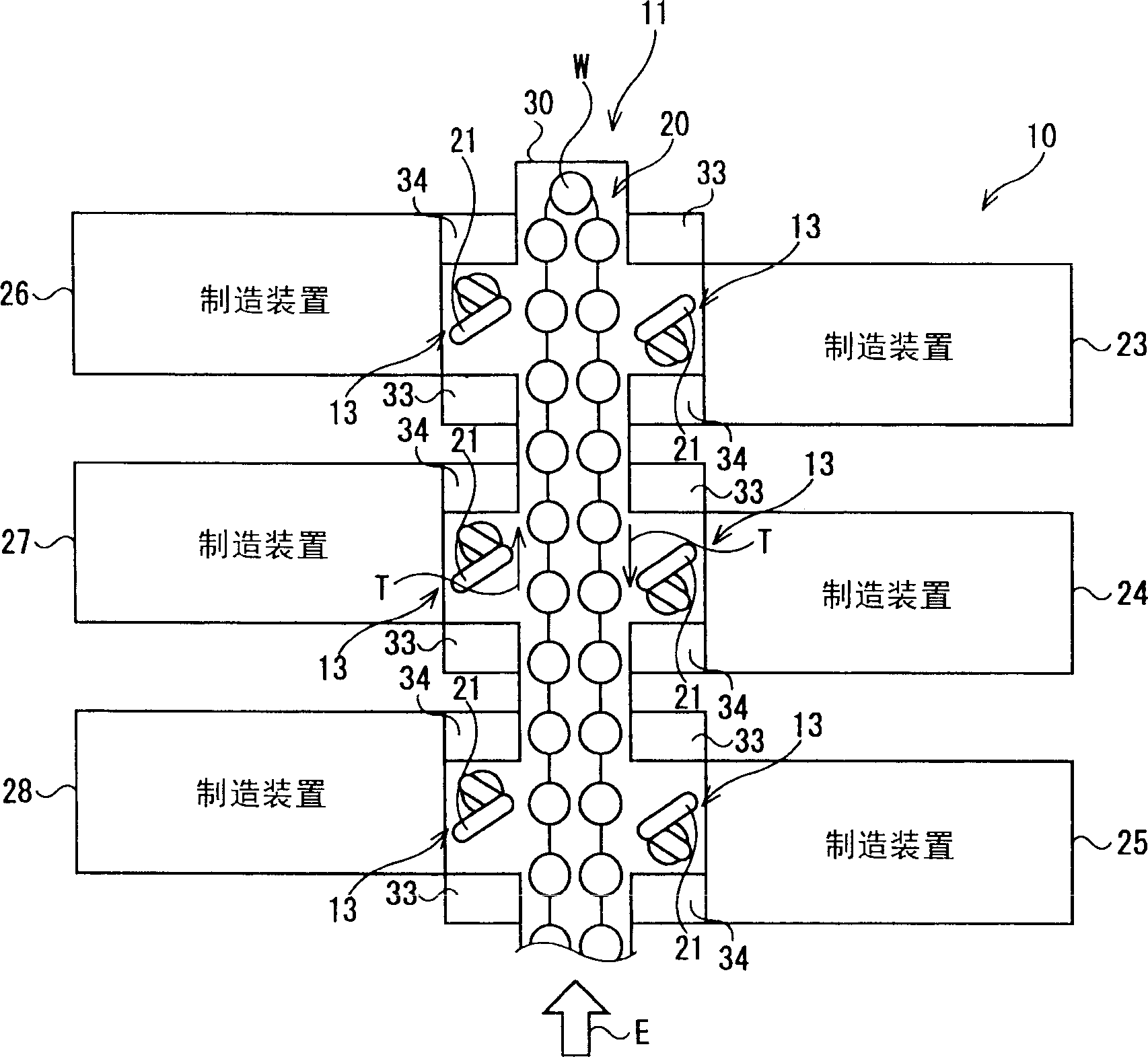

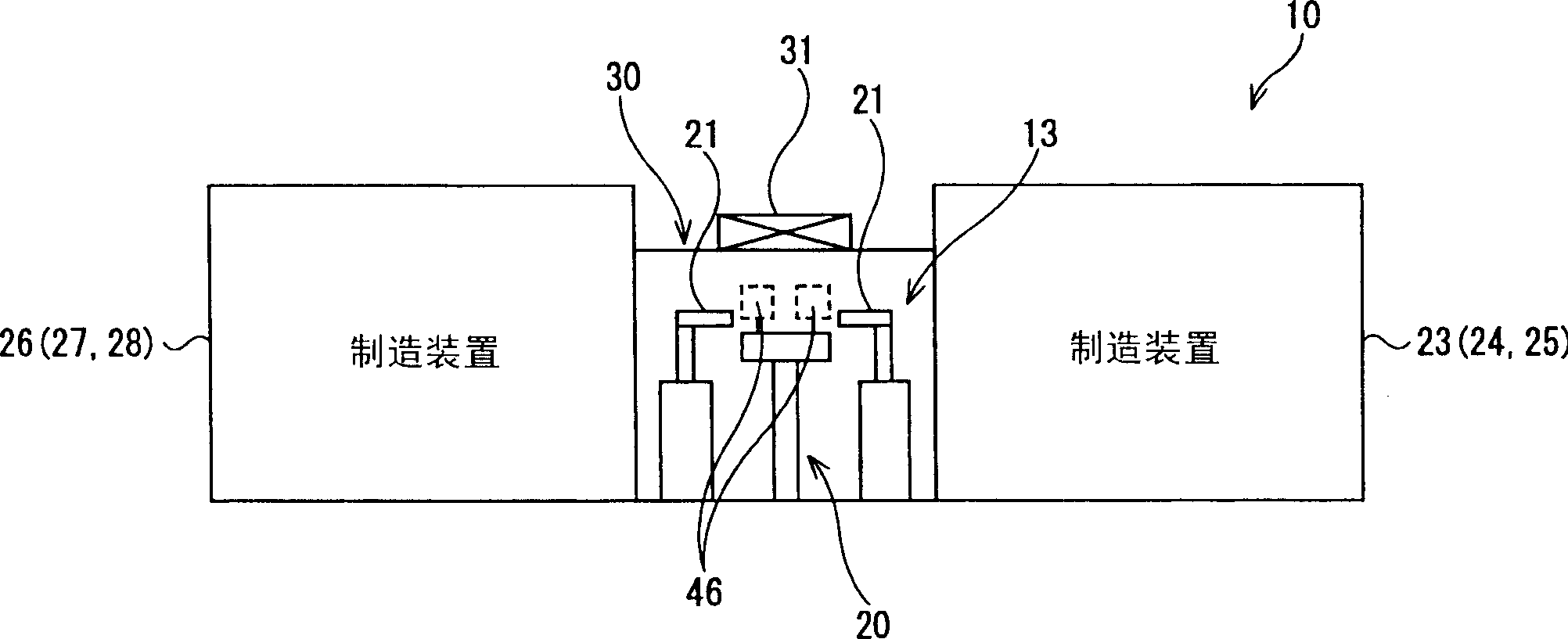

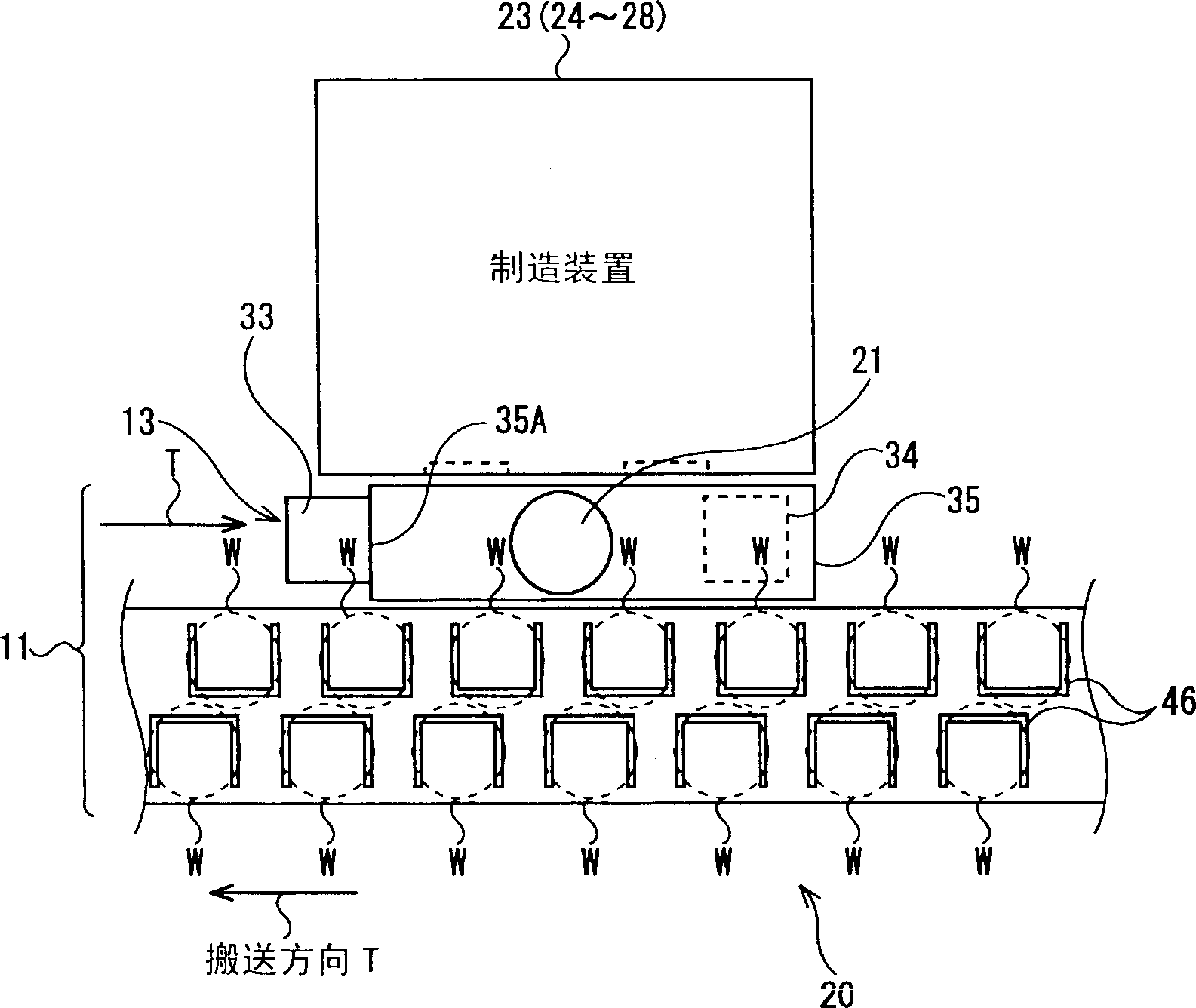

Producing object connecting device and carrying system therewith

InactiveCN1531048AFast transferHandover is reliableSemiconductor/solid-state device manufacturingCharge manipulationDelivery systemRobot

Provided is a system for delivering a production object, e.g. a wafer, quickly and surely between a line for carrying a sheet production object and a production system of the production object, and to provide a carrying system having the delivery system of the production object. The system 13 for delivering a production object W between a line 20 for carrying a sheet production object W and a production system of the production object W comprises a robot 21 for transferring the production object W between the sheet object carrying line 20 and the production system, and a buffer 34 for temporarily storing the production object W transferred from the single object carrying line 20 by means of the transfer robot 21 or the production object W processed by the production system.

Owner:SEIKO EPSON CORP

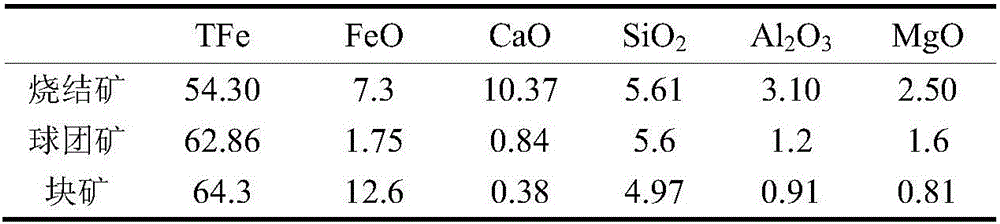

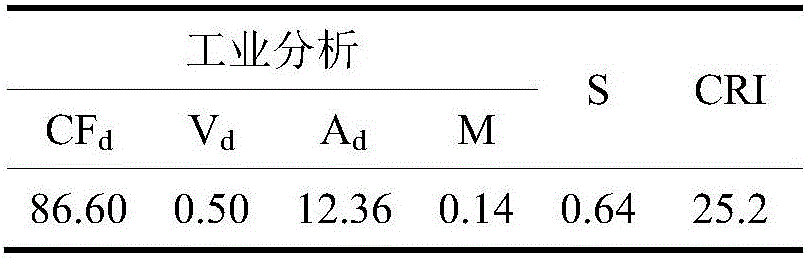

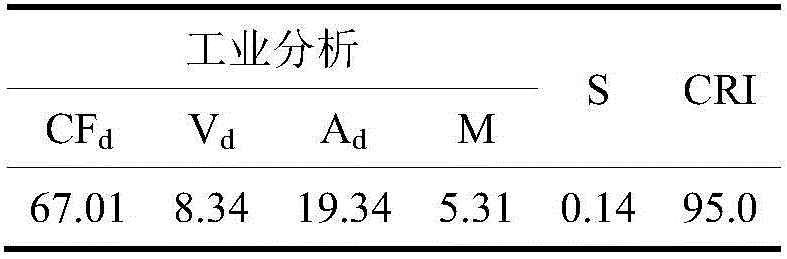

Method for improving blast furnace smelting efficiency of high-aluminum iron ore with high-reactivity coke

ActiveCN106399608AReduce manufacturing costImprove efficiencyBlast furnace detailsSocial benefitsBlast furnace smelting

The invention discloses a method for improving the blast furnace smelting efficiency of high-aluminum iron ore with high-reactivity coke, and belongs to the field of ironmaking of ferrous metallurgy. The method is characterized in that based on the fact that an ore-coke mixed charging technology is universally adopted in present ironmaking production, and aiming at the problems of low breathability, wide soft melting interval and difficulty in slag and iron separation in blast furnace smelting of the high-aluminum iron ore, the high-reactivity coke is adopted to replace the conventional metallurgical coke to be made into coke nut which is fed in a blast furnace, and owning to the high reactivity of the coke nut, the temperature of a heat reserve area can be lowered, the pre-reduction degree of ferrous furnace charge is increased, the FeO content of primary slag containing Al2O3 is reduced, the melting point of the slag containing Al2O3 is increased, the melting interval is narrowed, a soft melting belt moves down, and the breathability of a material layer is further improved on the base of ore-coke mixed charging, so that the purpose of improving the blast furnace smelting efficiency of the high-aluminum iron ore is achieved. The method provided by the invention is conducive to utilization of inferior iron ore and inferior coke resources, reduces the ironmaking production cost of a steel-iron enterprise, guarantees the production efficiency of ironmaking, and has high economic and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

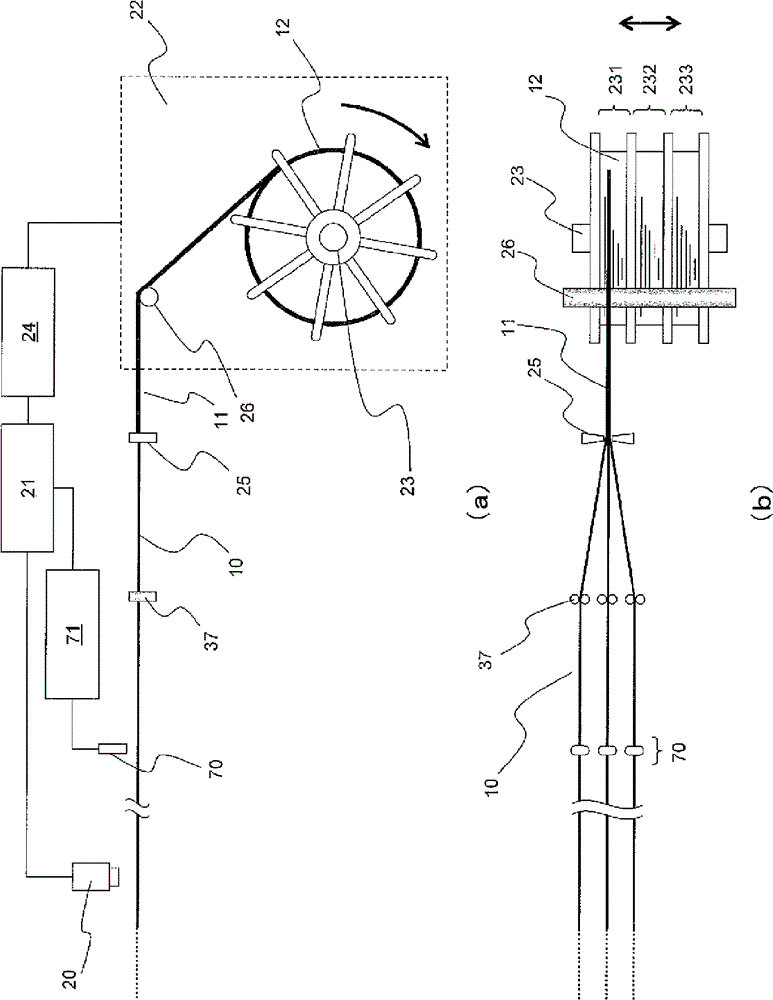

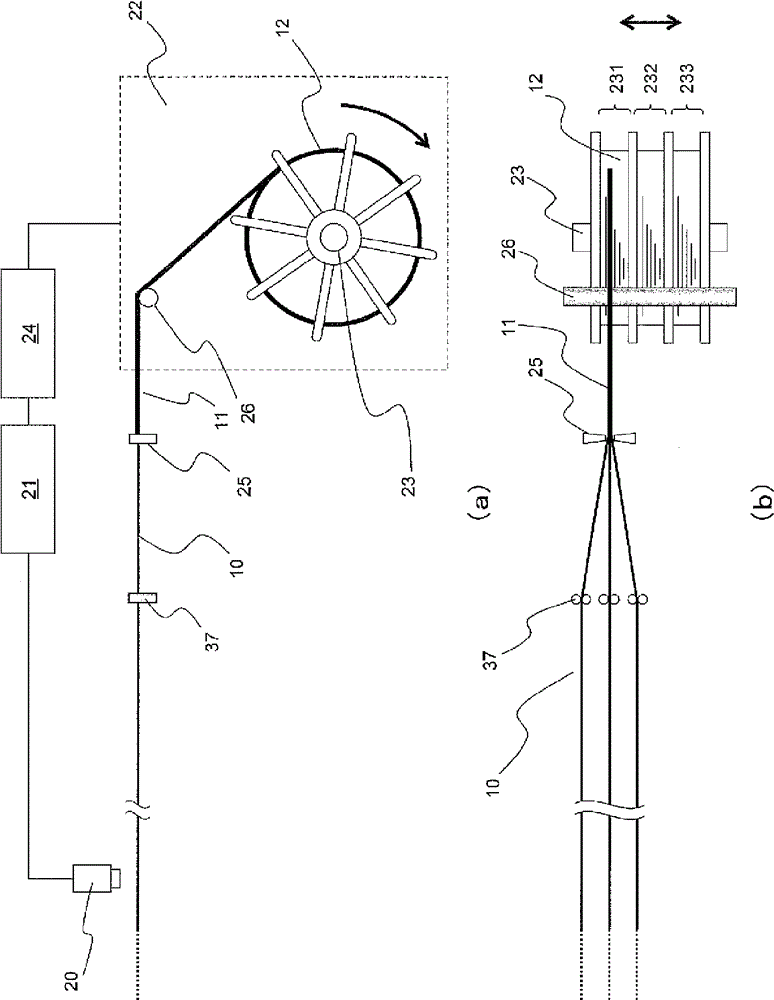

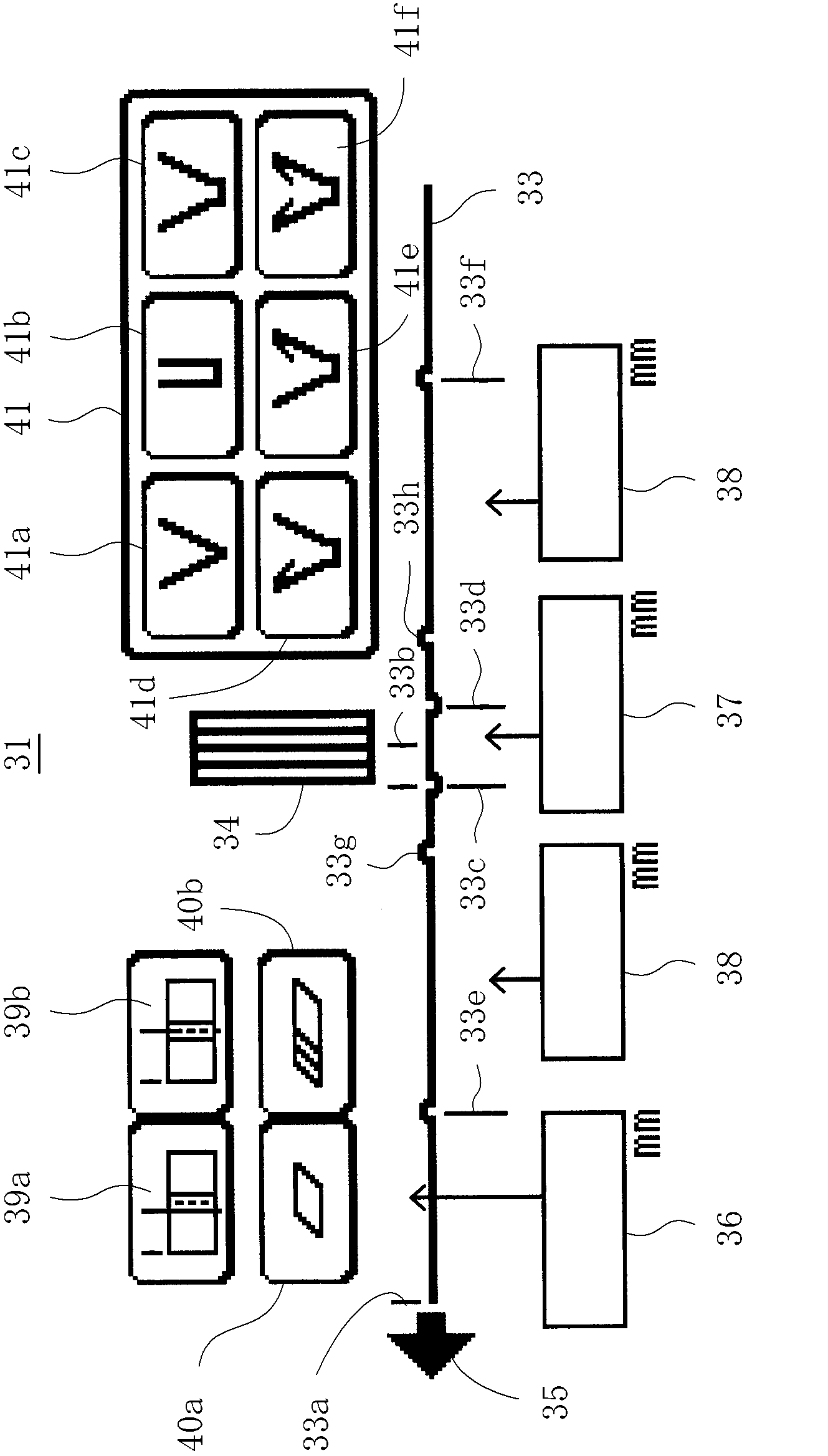

Manufacturing method and manufacturing device for bundle product

ActiveCN104136351AGuaranteed qualityControl the amount of windingMembranesSemi-permeable membranesImage InspectionEngineering

A manufacturing method for a bundle product (13) comprises: a step for inspecting a plurality of traveling threads (10) by a measurement / inspection head (20) such as a digital camera; a step for winding the threads (10) around a reel (23); and a step for cutting the wound threads (12) by a cutter (40) to obtain the bundle product (13). A measurement / inspection control mechanism (21) such as an image inspection system finds the total surface area of the traveling threads (10) on the basis of the result of the inspection by the measurement / inspection head (20). A winding and collection control mechanism (24) continues winding until the total surface area of the threads (12) wound around the reel (23) exceeds a standard value. The thread (10) is a hollow fiber. A hollow fiber membrane bundle (13) having a total surface area exceeding the standard value can be obtained by this method. The hollow fiber membrane bundle (13) is incorporated in a module for filtering water. This module has sufficient filterability.

Owner:TORAY IND INC

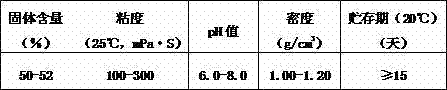

Formaldehyde eliminating agent and preparation method thereof

InactiveCN102399514AReduce releaseImprove elimination effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyProcess engineering

The invention discloses a formaldehyde eliminating agent and a preparation method thereof. The formaldehyde eliminating agent consists of the following raw materials in part by weight: 100 to 300 parts of water borne epoxy resin (solid), 200 to 1,000 parts of melamine, 100 to 1,000 parts of water, and 0.1 to 10 parts of stabilizing agent. The preparation method for the formaldehyde eliminating agent comprises the following steps of: 1) sequentially adding the raw materials into a reaction kettle according to the raw material proportion of claim 1 or 2 with stirring, controlling the heating temperature at 40 to 60 DEG C, fully stirring the raw materials uniformly, and regulating the pH to be between 5.0 and 5.5 by using acid; and 2) heating the raw materials to the temperature of between 75 and 80 DEG C, reacting for 30 minutes, regulating the pH value to be between 6.0 and 8.0 by using alkali, cooling the reaction product to the temperature of 30 DEG C, and discharging.

Owner:BEIJING FORESTRY UNIVERSITY +1

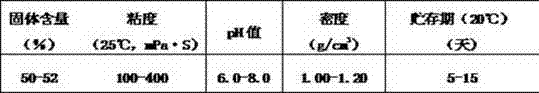

R-T-B based permanent magnet

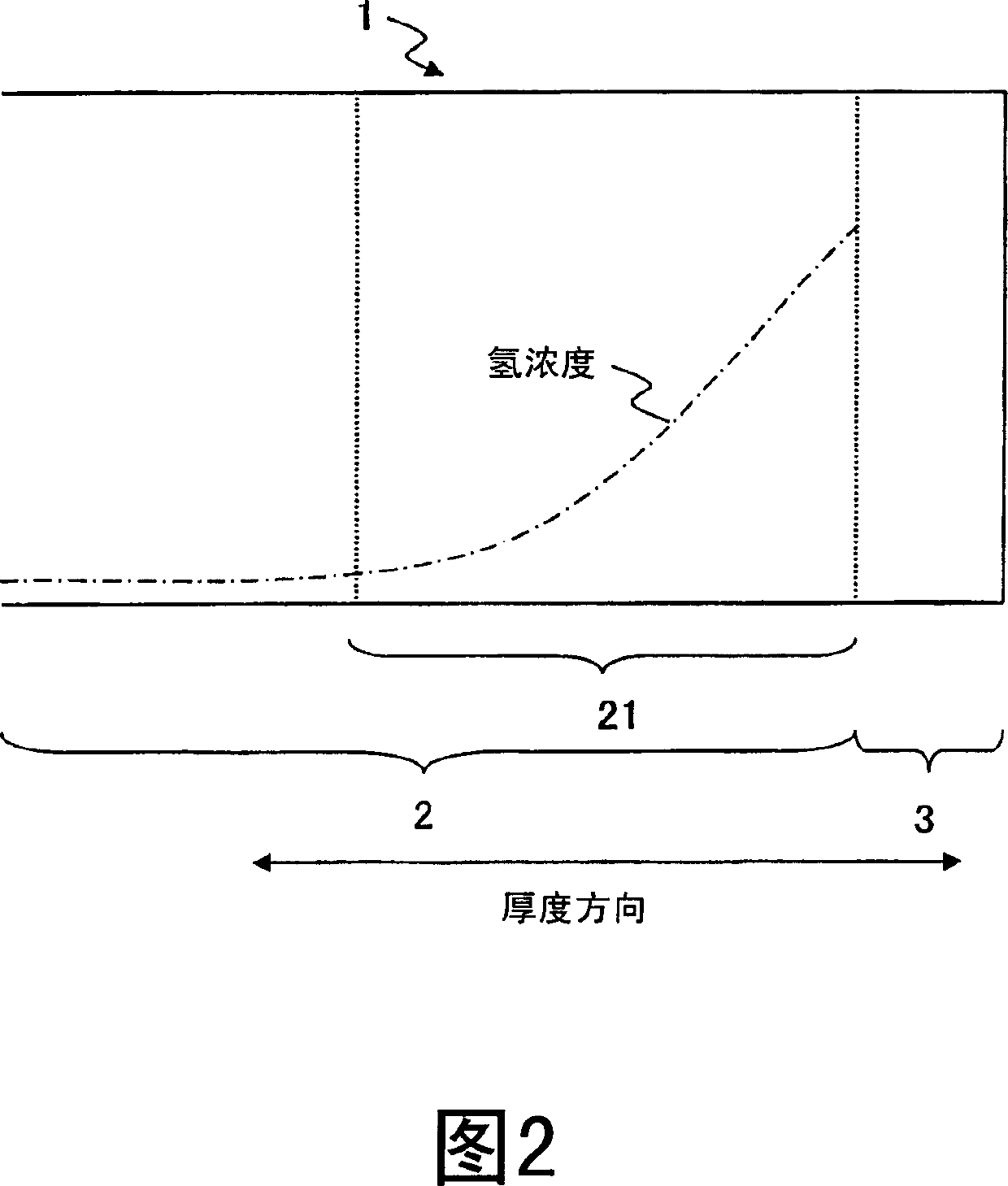

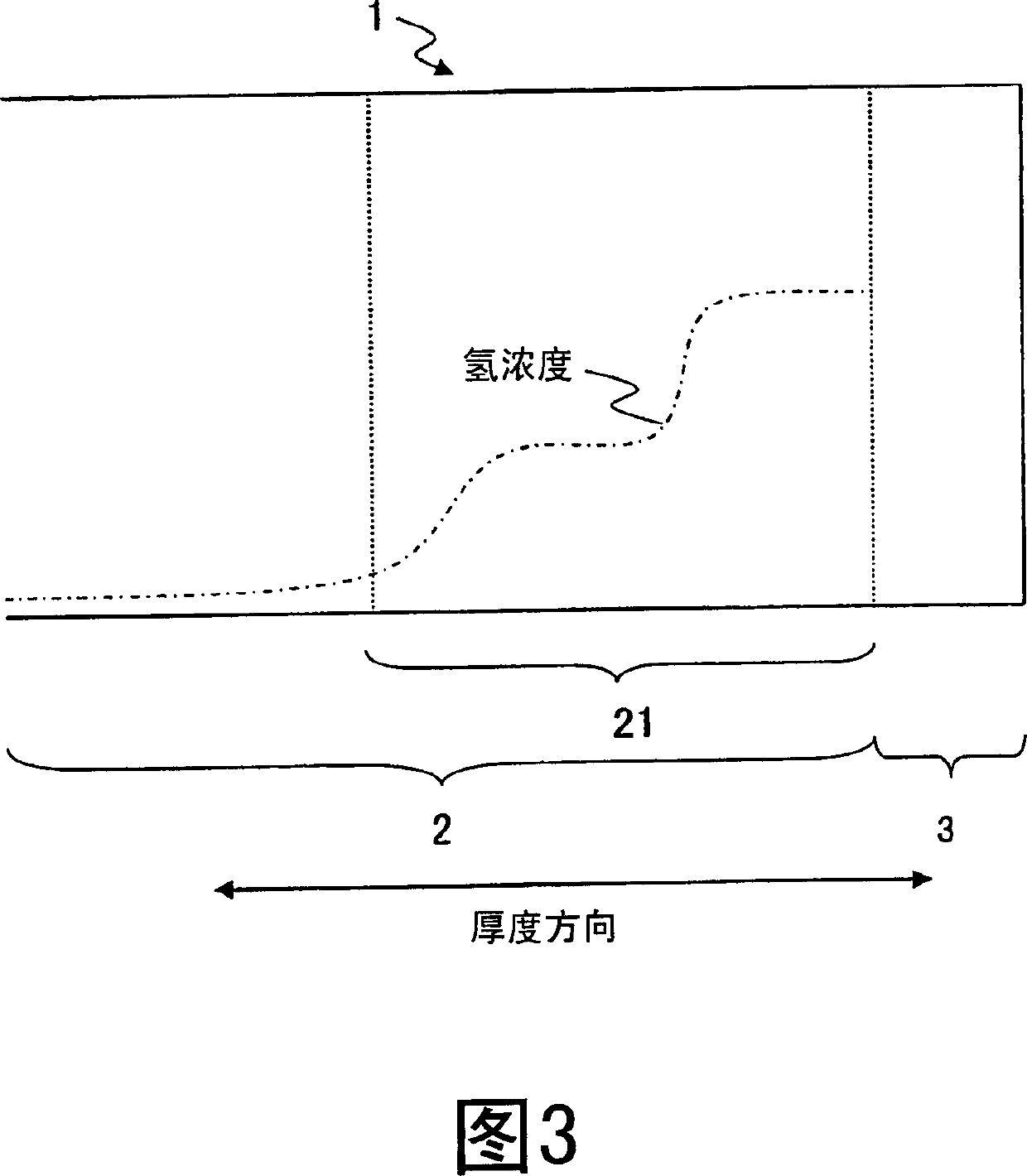

ActiveCN1799111AImprove corrosion resistanceGuaranteed corrosion resistanceInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementHydrogen concentration

An R-T-B based permanent magnet (1) which comprises a magnet body (2) comprising a sintered product comprising a main phase comprising R2T14B crystal grains (wherein R represents one or more of rare earth elements, and T represents one or more transition metals comprising Fe or Fe and Co) and a grain boundary phase containing R in an amount more than that in the main phase and, formed in the surface layer portion thereof, a hydrogen-rich layer (21) having a hydrogen concentration of 300 ppm or more and having a thickness of 300 mum or less (exclusive of zero), and a protective coating film (3) covering the surface of the magnet body (2). The R-T-B based permanent magnet (1) exhibits the corrosion resistance being improved by the protective coating film (3) without the deterioration of magnetic characteristics, and the protective coating film (3) may be formed by electrolytic plating. The R-T-B based permanent magnet (1) can secure the satisfactory corrosion resistance, which is the object of the formation of the protective coating film (3), with little reduction of the efficiency in the production, and also is reduced in the partial disintegration (falling of grains) in the surface thereof and thus exhibits high dimensional precision.

Owner:TDK CORPARATION

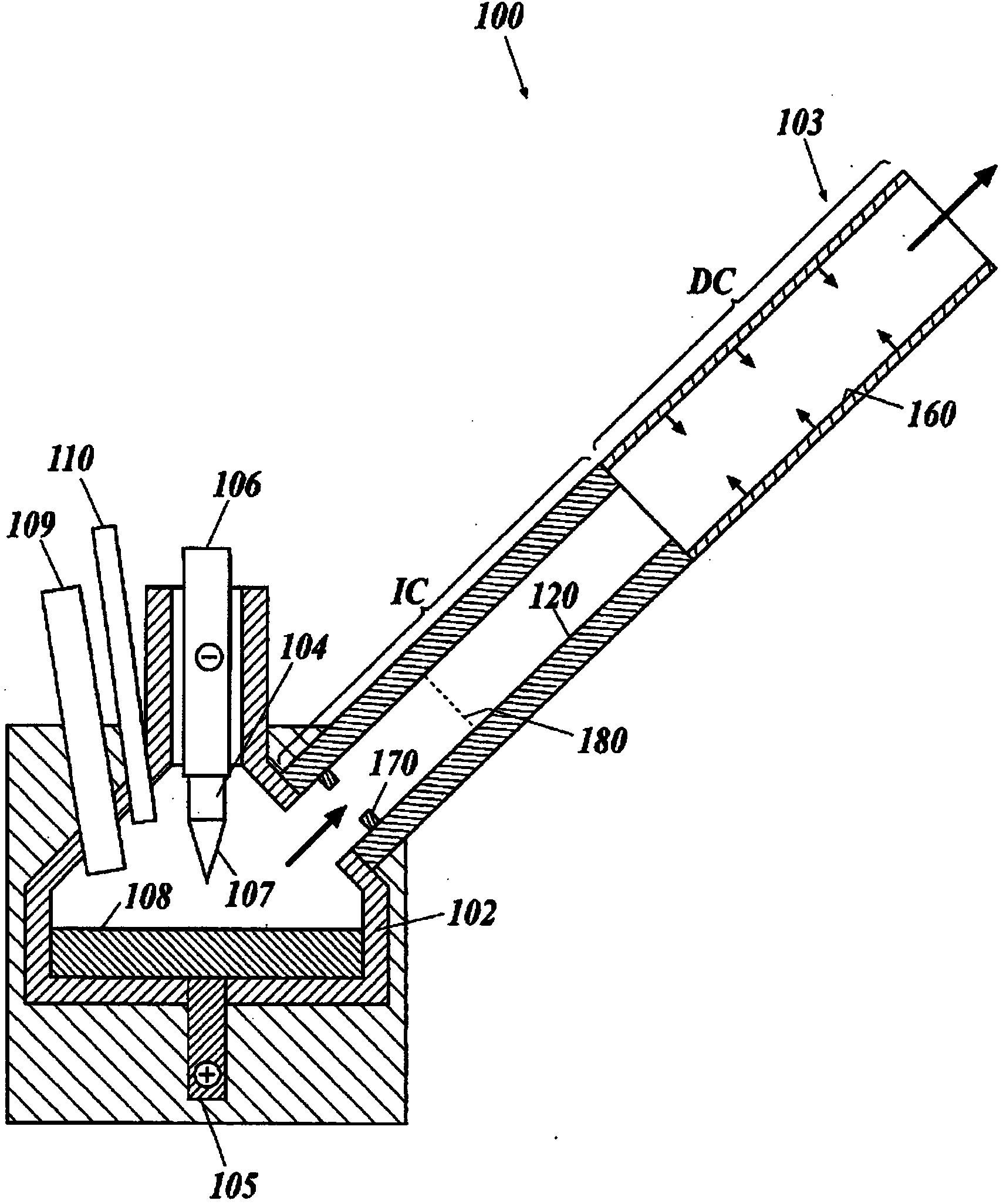

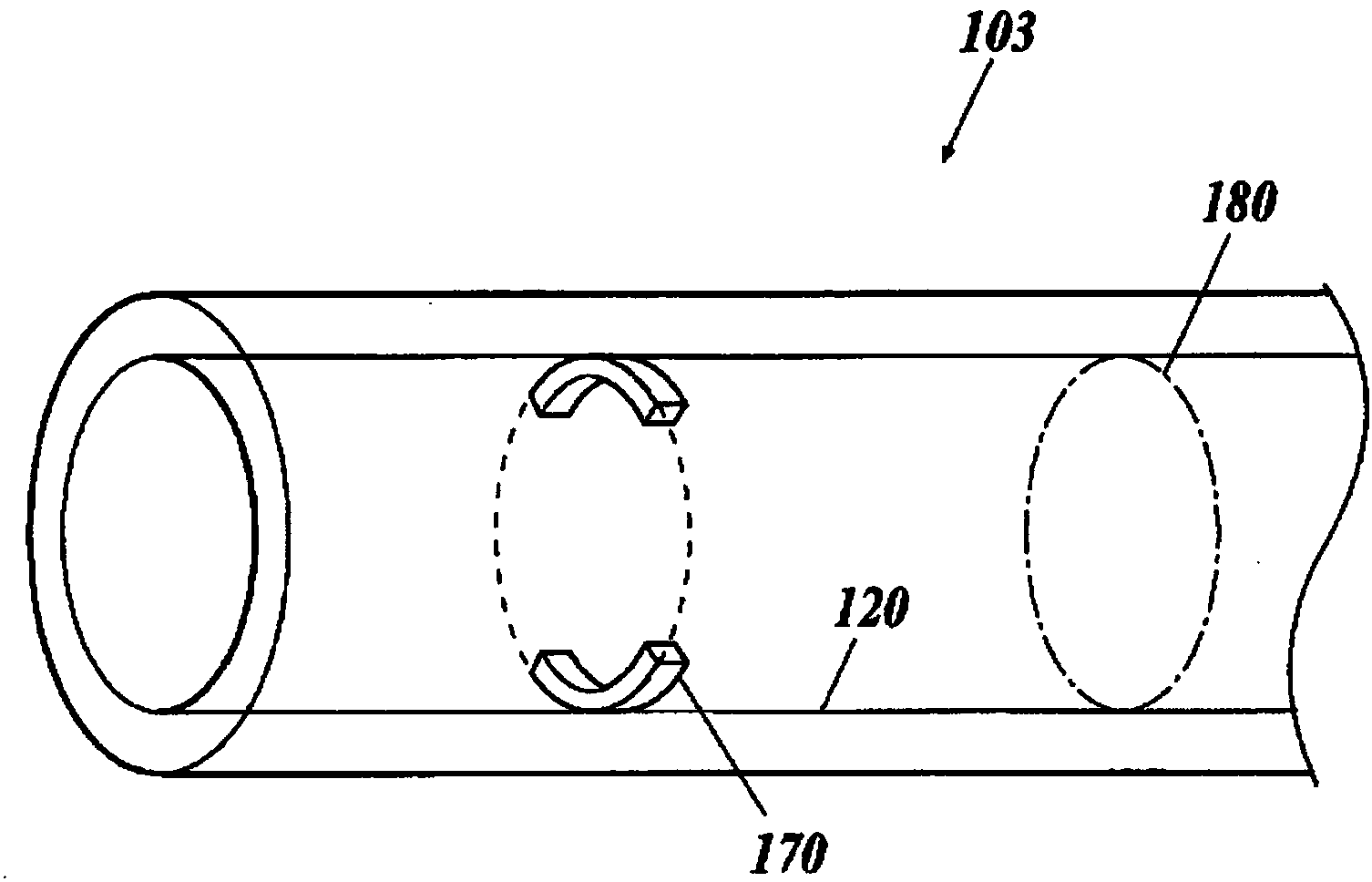

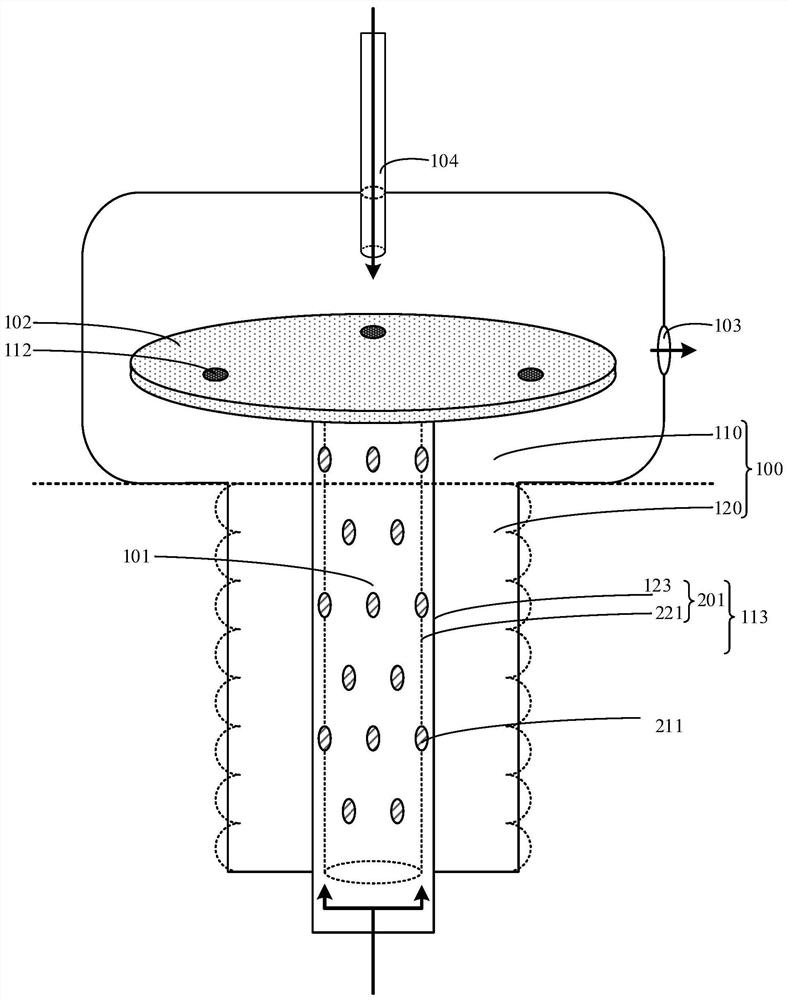

Plasma device for production of metal powder

ActiveCN104066537ANarrow particle size distributionUniform flow rateElectric discharge heatingEnergy based chemical/physical/physico-chemical processesMetal powderGas supply

A plasma device which is provided with: a reaction container to which a metal starting material is supplied; a plasma torch which generates plasma between itself and the metal starting material within the reaction container, thereby evaporating the metal starting material and producing a metal vapor; a carrier gas supply unit which supplies, into the reaction container, a carrier gas for conveying the metal vapor; and a cooling tube which cools the metal vapor that is conveyed from the reaction container by the carrier gas, thereby producing a metal powder. The cooling tube is provided with: an indirect cooling section for indirectly cooling the metal vapor that is conveyed from the reaction container by the carrier gas and / or the metal powder; and a direct cooling section for directly cooling the metal vapor and / or the metal powder, said direct cooling section being continued to the indirect cooling section. At least a part of the inner wall of the indirect cooling section is provided with projections and / or recesses.

Owner:SHOEI CHEM IND CO LTD

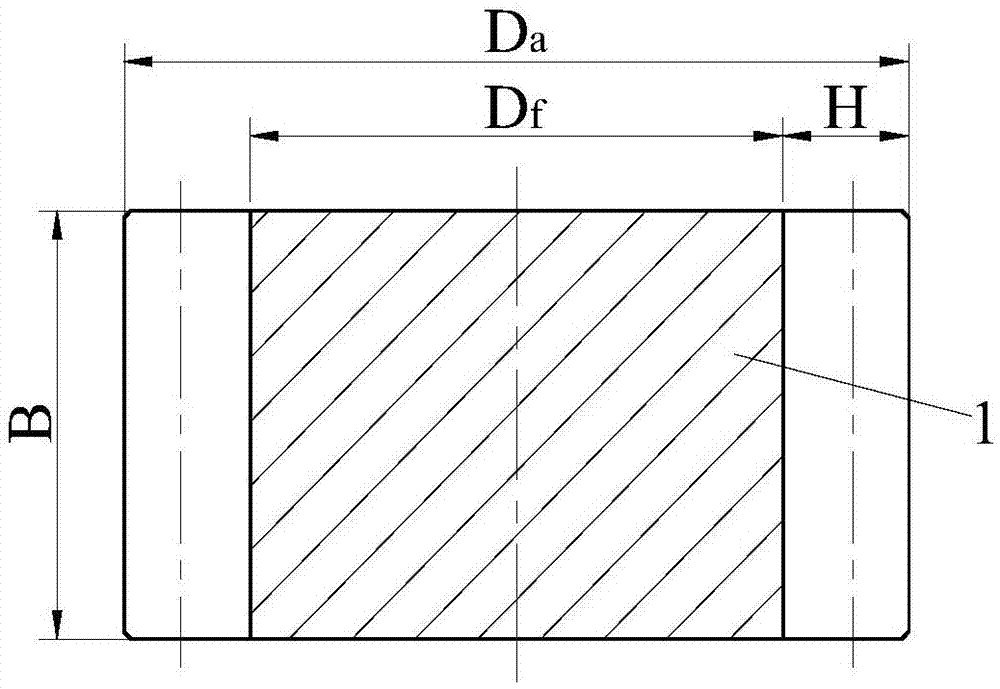

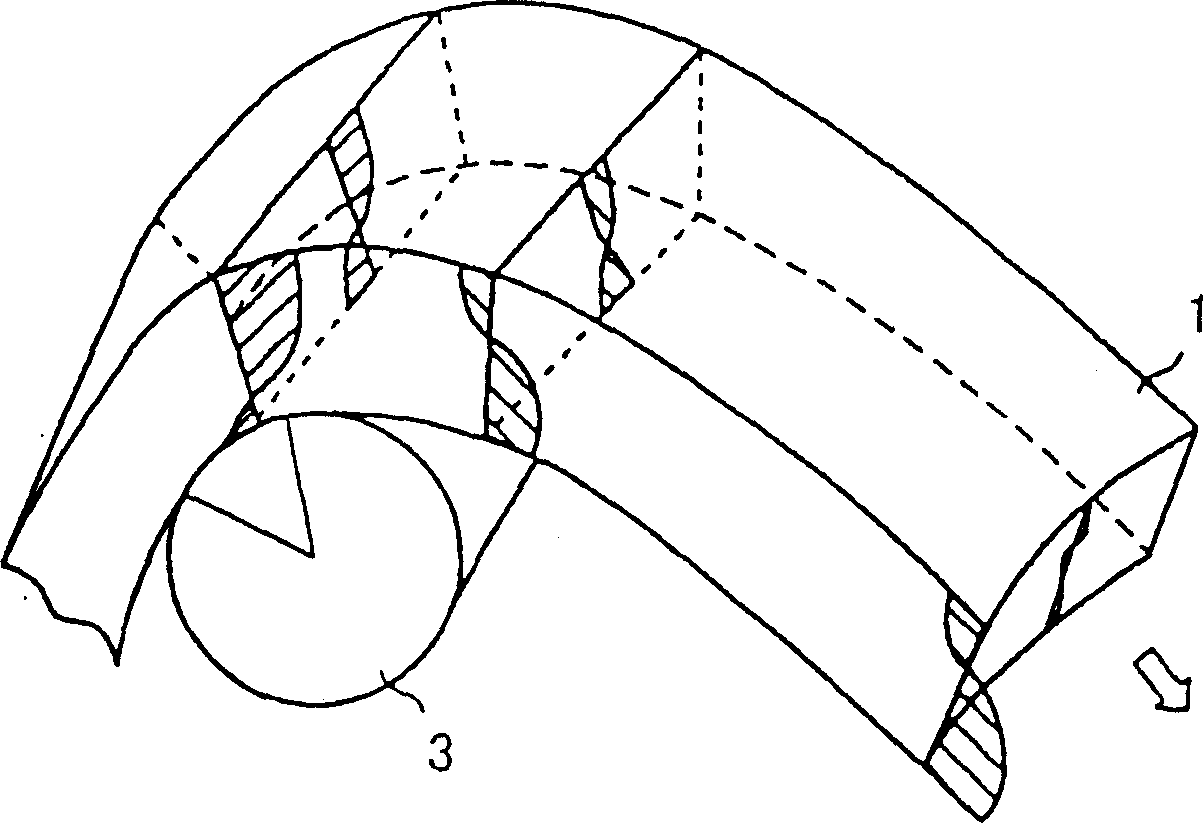

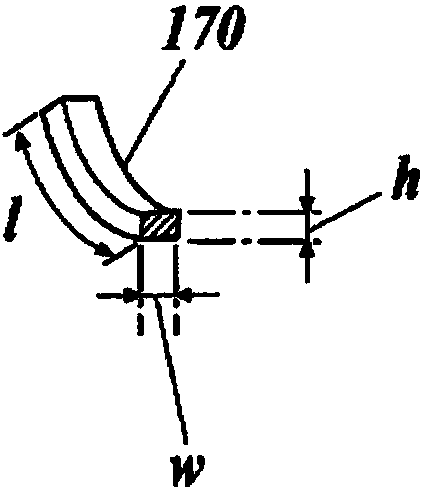

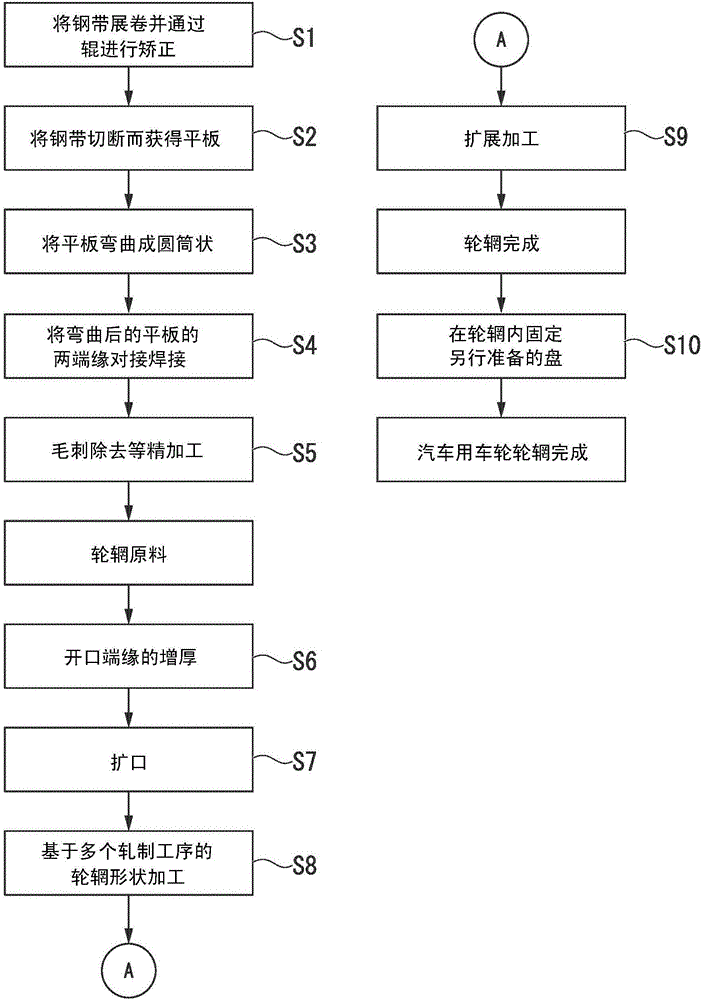

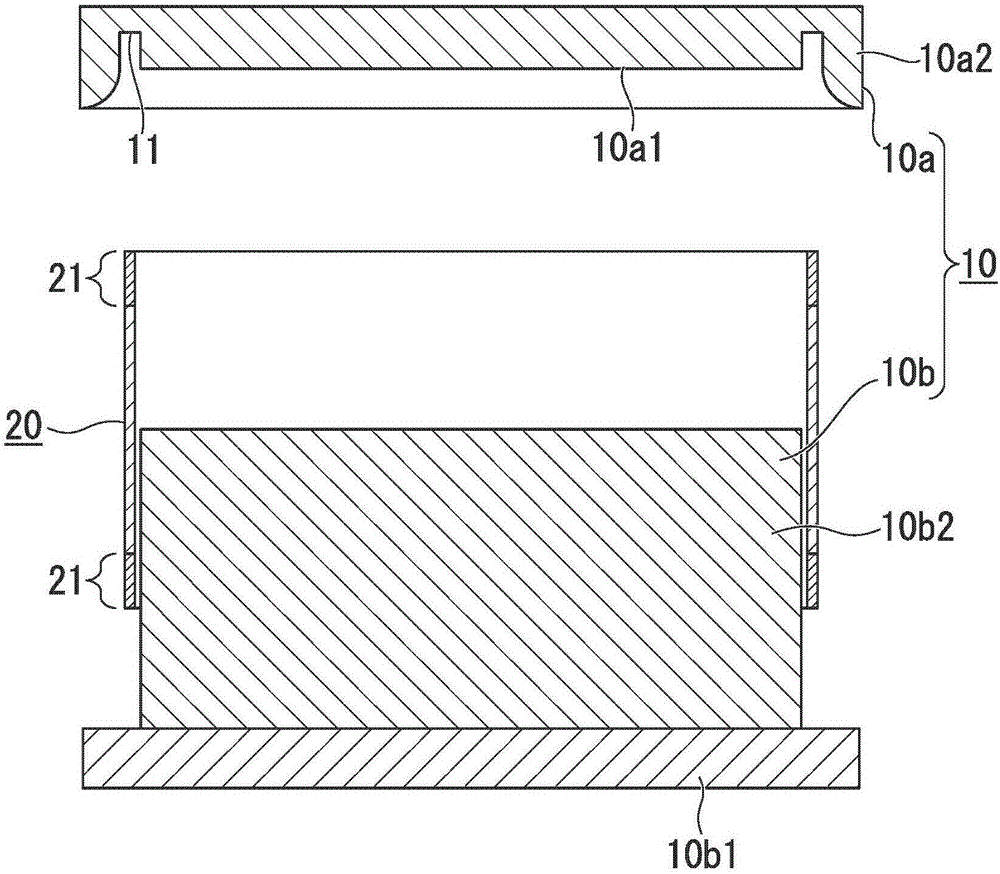

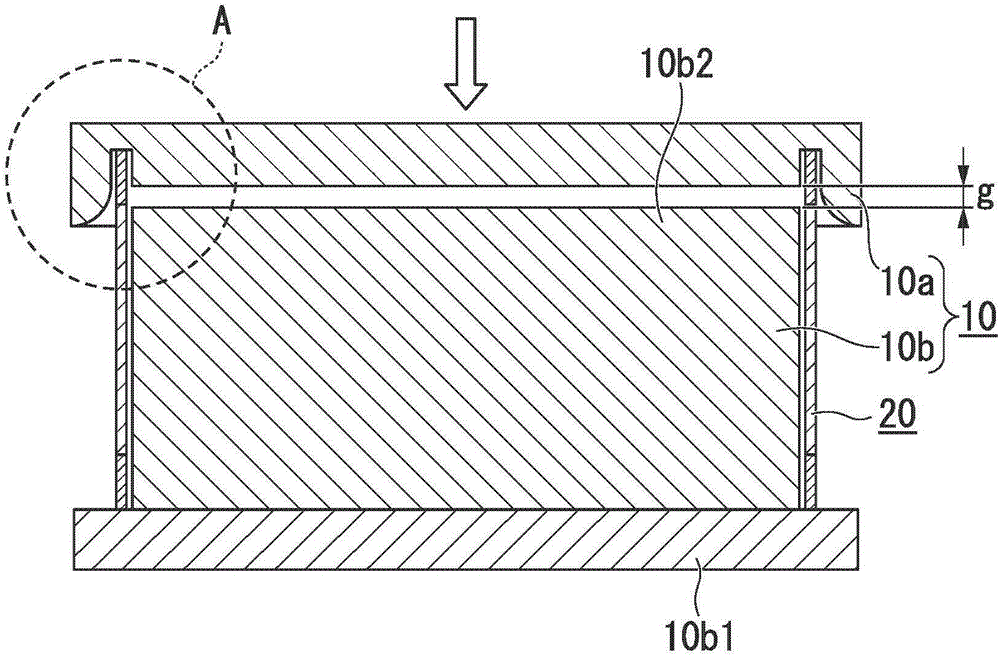

Wheel rim manufacturing method and automobile wheel rim manufacturing method

ActiveCN106102953AGood dimensional accuracyNo reduction in production efficiencyRimsForging press detailsCompression loadMechanical engineering

This wheel rim manufacturing method comprises a molding step for molding a cylindrical rim material into a rim shape, and a thickening step for increasing the plate thickness of at least one opening edge of the rim material before and / or after the molding step. In the thickening step, a thick part is formed by applying a compression load in an axial direction of the rim material onto the opening edge in a state in which the opening edge has been inserted into an annular groove of a metallic mold, the annular groove being wider than the plate thickness of the opening edge.

Owner:NIPPON STEEL CORP

High strength Fe-Ni-Co series alloy for shadow mask

InactiveCN1550564AImprove drop strengthLow costCathode ray tubes/electron beam tubesNanotechnologyHigh intensityAlloy

The invention improves falling strength of a Fe-Ni-Co alloy without addition of elements for high strengthening. In a Fe-Ni-Co alloy that contains 30 to 35 mass% of Ni, 2 to 8 mass% of Co, 0.50 mass% or less of Mn, and the balance of Fe and inevitable impurities or accompanying elements including 0.10 mass% or less of C, 0.10 mass% or less of Si, 0.05 mass% or less of Al, 0.005 mass% or less of S and 0.005 mass% or less of P and is constructed in a rolling work structure, the high strength Fe-Ni-Co alloy for shadow mask is peculiar to that a recrystallization structure consisting of a grain size number of 9.5 or more is revealed when the Fe-Ni-Co alloy is annealed at 750 deg.C for 15 minutes, and a recrystallization structure consisting of a grain size number of 8.5 or more is revealed when the Fe-Ni-Co alloy is annealed at 850 deg.C for 15 minutes.

Owner:JX NIPPON MINING & METALS CO LTD

COB production process capable of detecting LED temperature

ActiveCN109887856AExtended service lifeLong-term monitoring of working temperatureSemiconductor/solid-state device testing/measurementSemiconductor devicesWorking temperatureEngineering

The invention relates to the technical field of circuit board production, in particular to a COB production process capable of detecting LED temperature, which comprises the steps of cutting a substrate, etching, solder resisting, surface treatment, pre-gluing, windowing, pressing and installing a temperature measuring probe, wherein the windowing step comprises the step of arranging a mirror surface window and a temperature measuring point window on the substrate, The production process of the invention arranges a temperature measuring point window on the substrate and a temperature measuringprobe in the temperature measuring point window, and the temperature measuring probe is aligned with the LED, so that the working temperature of the LED can be accurately detected, and accurate datais further provided to calculate whether the COB area is matched with the LED power or not, so that the requirement that the LED does not generate light attenuation is met, and the technical problem that the actual temperature of the LED cannot be tested in the current industry is solved. The temperature measuring probe can also be used for detecting the temperature of the mirror aluminum, and then the temperature when using the LED can be detected, and the effect of the temperature measuring probe lies in prolonging the service life of the temperature measuring probe, which is convenient forlong-term monitoring of LED working temperature.

Owner:珠海市协宇电子有限公司

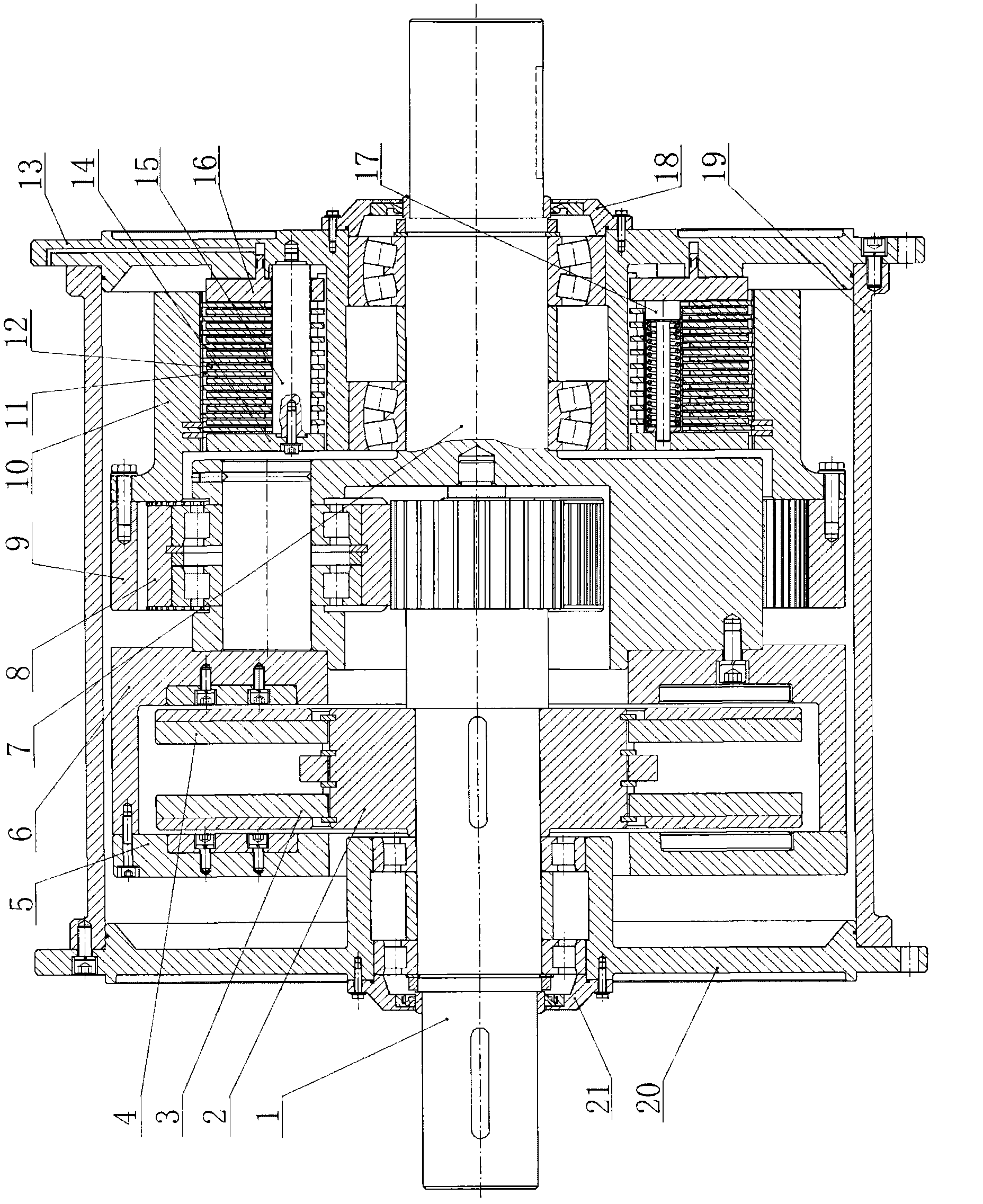

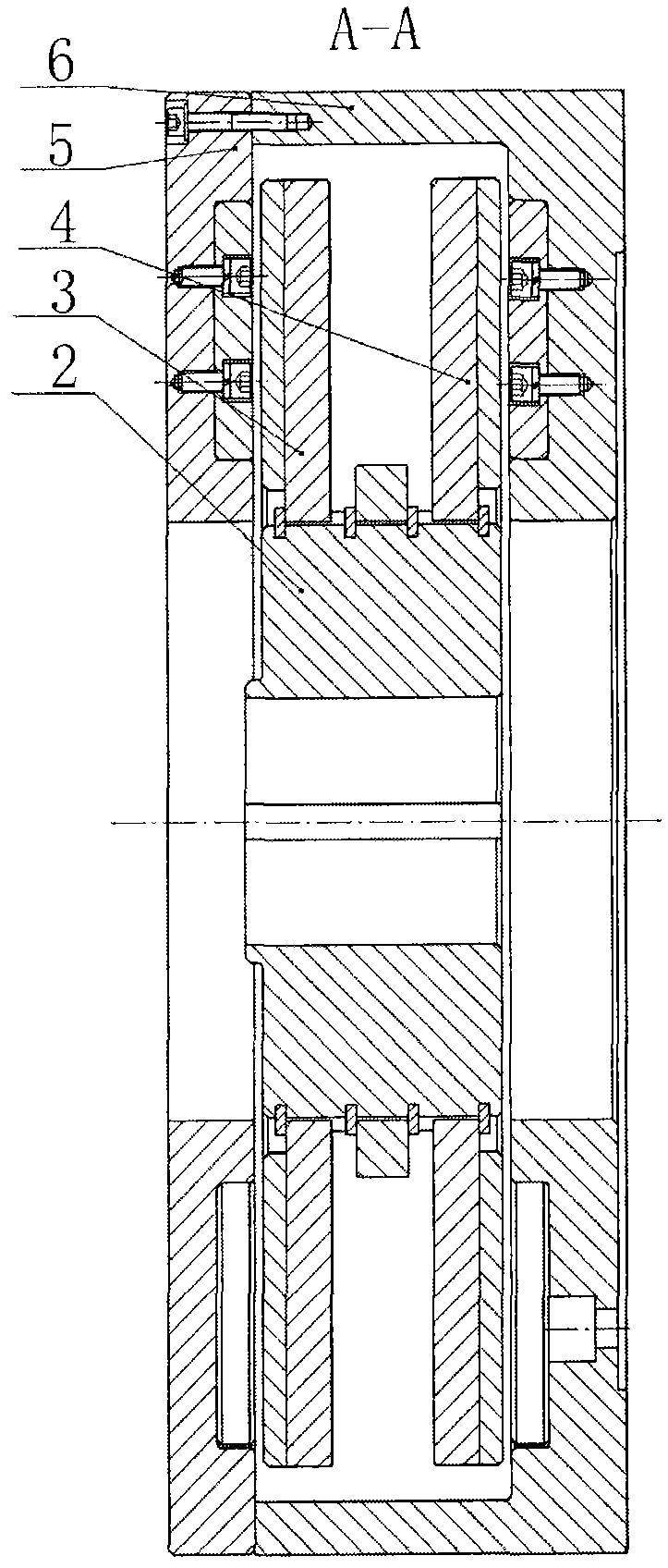

Clutch type high-power efficient mechanical torque converter

ActiveCN102537270ASolve the overload pressure carSolve the problem of not startingFluid gearingsSpelunkingControl theory

The invention relates to the technical field of overload starting of a conveyor for a working face of an underground coal mine, in particular to a clutch type high-power efficient mechanical torque converter. Due to caving or top failure of the working face of the underground coal mine with poor conditions, the conveyor for the working face frequently has the problem of delay unloading or incapability of starting, coal can only be manually cleaned, and production efficiency is seriously affected. The clutch type high-power efficient mechanical torque converter comprises a permanent magnet coupling transmission system, a planetary transmission system and a hydraulic control friction clutch system, wherein the permanent magnet coupling transmission system is used for transmitting normal torque and disconnecting overload torque, and the hydraulic control friction clutch system is used for inputting the output torque of an amplification driving system of the planetary transmission system, limiting the maximum output torque of the driving system and slowing down load fluctuation. The clutch type high-power efficient mechanical torque converter solves the problem of delay unloading or incapability of starting of the conveyor for the working face in overload.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

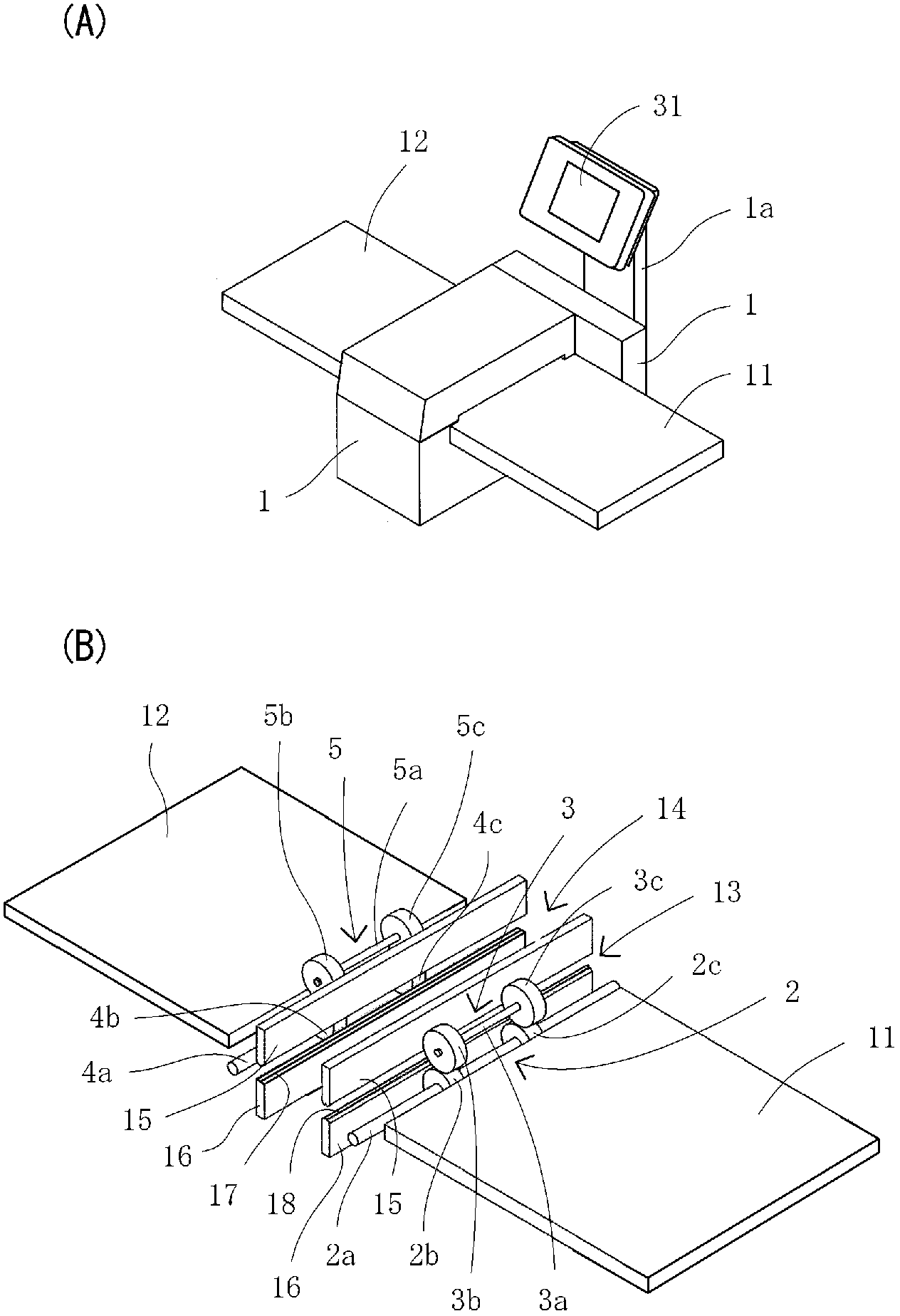

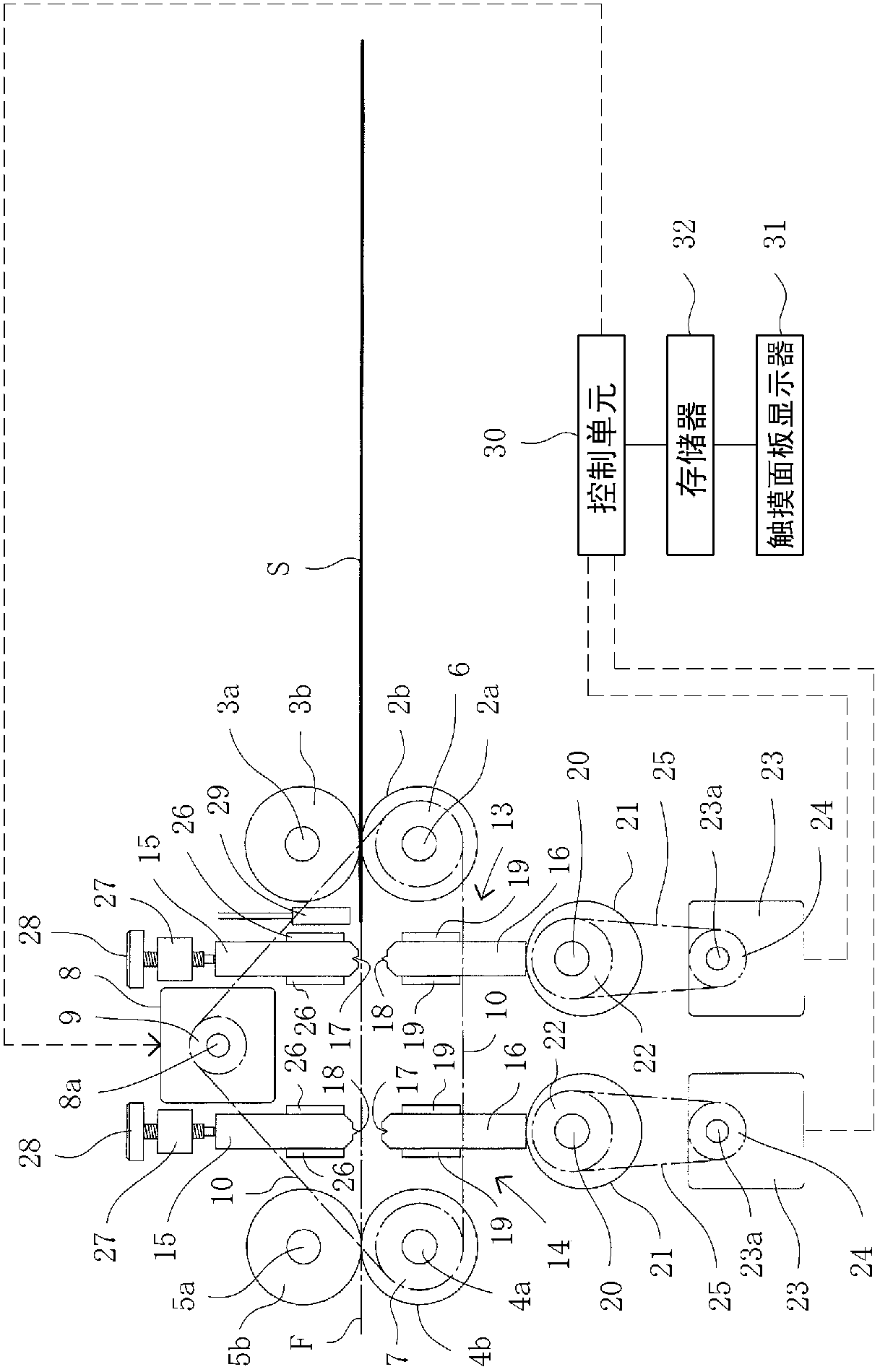

Device for applying line for folding process on front cover before attachment to main body

InactiveCN102741058ANo reduction in production efficiencyQuick and easy to deal withMechanical working/deformationBookbinding casesEngineeringFront cover

A front cover (S) is transferred between first and second feed roller pairs (2, 3; 4, 5), which synchronously rotate in the same direction; first and second line forming units (13, 14) each consisting of a stationary die (15) and a movable die (16) are arranged between the first and second feed roller pairs; and the stationary die and the movable die are opposed with a transfer path (F) of the front cover therebetween. Further, a sensor (29) for detecting a front end edge of the front cover is arranged between the first feed roller pair (2, 3) and the first line forming unit (13), so that, while rotational amounts of the first and second feed roller pairs are controlled, each time that the front cover is transferred a predetermined length from the sensor, the rotation of the first and second feed roller pairs is stopped and the line forming units are operated to form a line on the front cover by pressing the movable die onto the stationary die.

Owner:HORIZON INTERNATIONAL INC

A cylindrical object surface information on-line acquisition method and system

PendingCN109886055ANo reduction in production efficiencyCharacter and pattern recognitionSensing by electromagnetic radiationAssembly lineComputer science

The invention relates to a cylindrical object surface information on-line acquisition method and a cylindrical object surface information on-line acquisition system. Original assembly line hardware equipment and production flow are not changed; the production efficiency is not reduced; a plurality of pattern information areas are repeatedly printed, and a plurality of image capturing devices are additionally arranged; the cylindrical objects on the assembly line are positioned at any position and angle; meanwhile, an optimal matching scheme of multiple pattern information areas and the image capturing device is provided, and an enterprise can select a matching scheme most suitable for the assembly line to erect according to the actual situation of the assembly line.

Owner:南京新智客信息科技有限公司

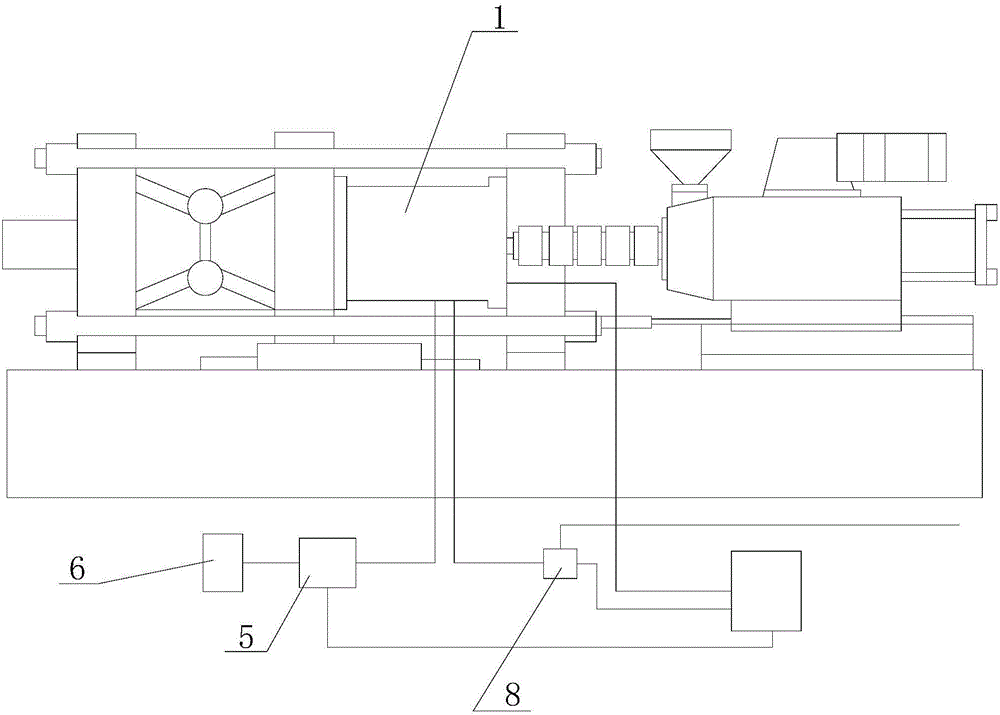

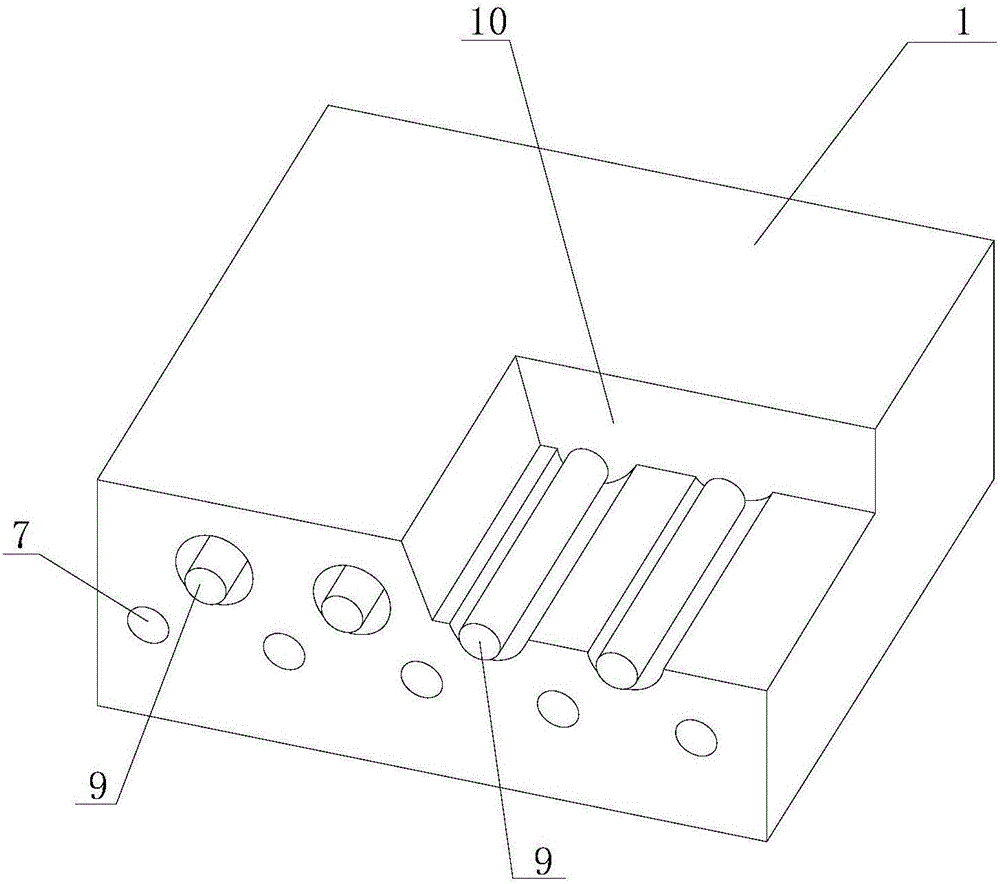

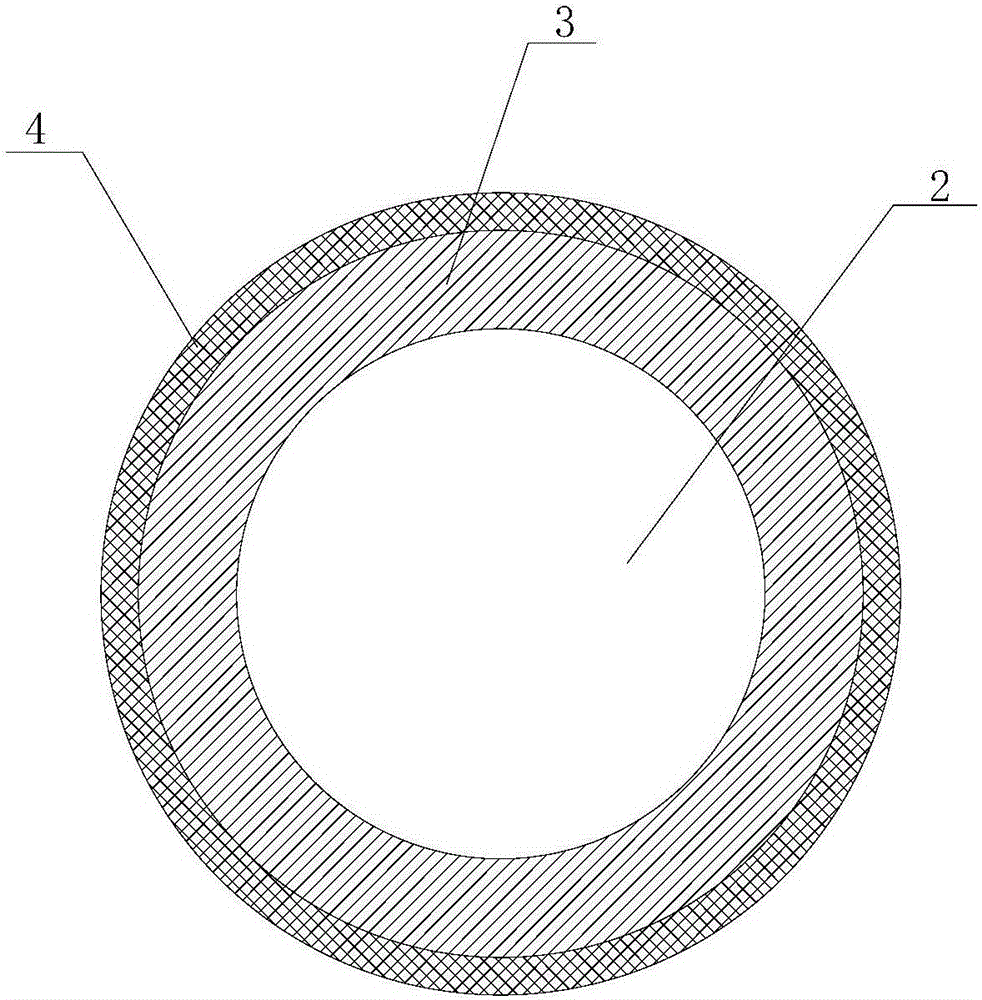

Mold temperature control device

InactiveCN106182660AOvercome inherent flawsAchieve high mold temperature injectionTemperature controlInjection moulding

The invention discloses a mold temperature control device which comprises a mold, a cooling system and heating devices. A shell of the mold is provided with cooling pipelines. A cooling water outlet of the cooling system communicates with water inlets of the cooling pipelines through pipelines. Each heating device comprises a ceramic core bar, a coil and an insulating layer, wherein the coil is wound around the ceramic core bar, the coil is wrapped by the insulating layer, the heating device is inserted in a cavity of the mold. By the adoption of a variable-mold-temperature injection molding method, a dynamic mold temperature control strategy is adopted, in other words, the mold is rapidly heated before glue injection, high-mold-temperature injection is achieved, then the forming period is shortened through fast cooling, and therefore inherent defects of a traditional injection molding technology are overcome while the production efficiency is not reduced.

Owner:苏州路熙光电科技有限公司

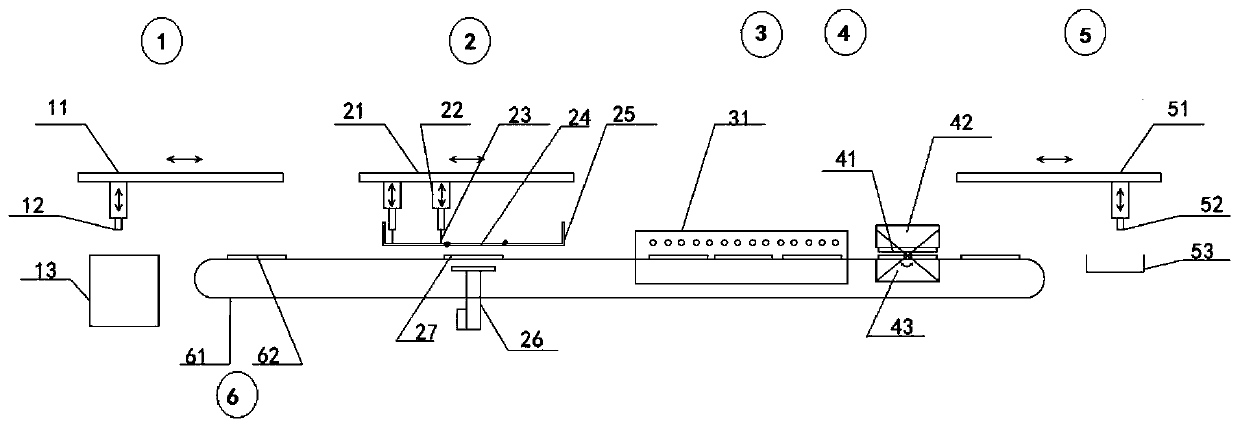

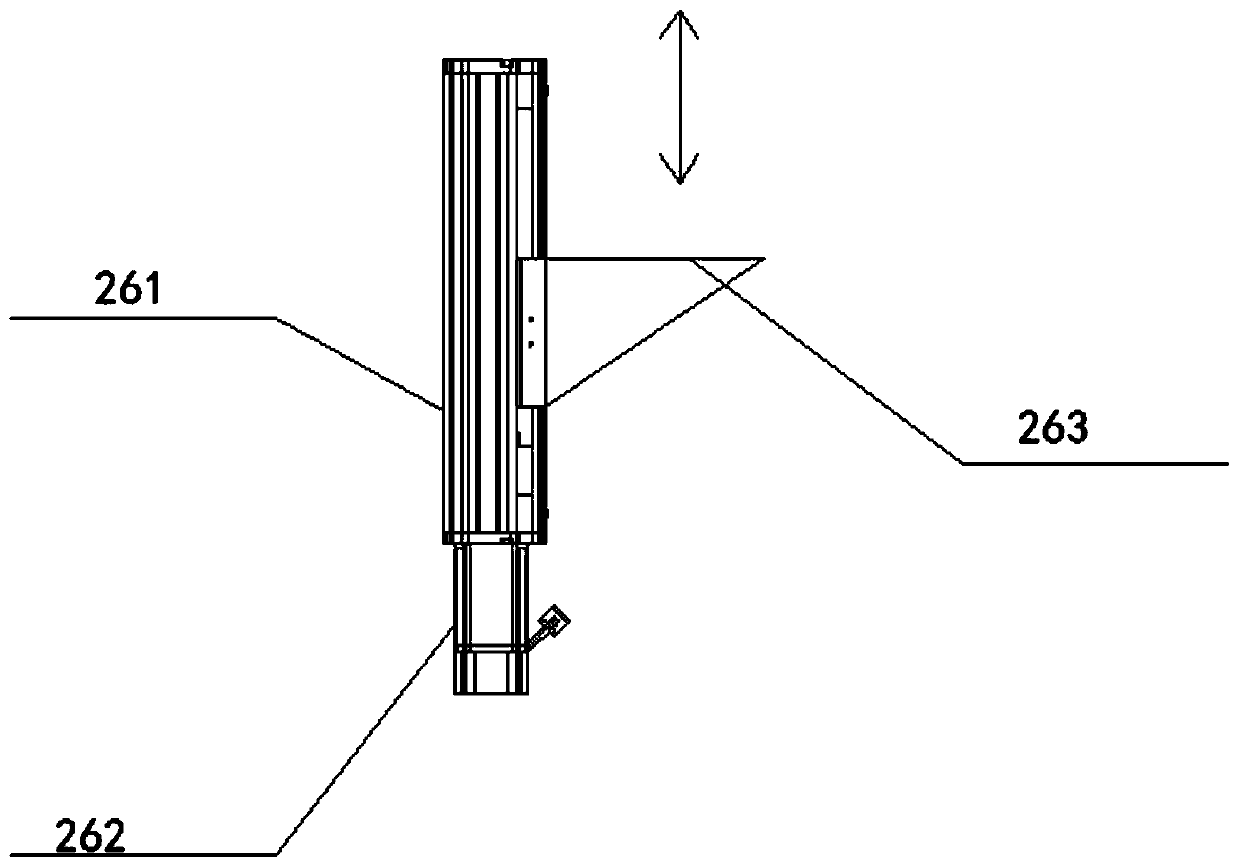

Automatic scrape coating equipment for neodymium iron boron products

ActiveCN110882877AAvoid wastingThickness is easy to controlLiquid surface applicatorsCoatingsEngineeringStructural engineering

The invention discloses an automatic scrape coating equipment for neodymium iron boron products. The automatic scrape coating equipment comprises a conveying platform, a tray, material upper and lowermechanisms, a baking mechanism, a turn-over mechanism and a scrape coating mechanism, the scrape coating mechanism comprises a jacking device and a scrape coating device, the jacking device is located under the conveying platform, the scrape coating device is located above the conveying platform, the scrape coating device comprises a scrape coating groove, a transverse-moving air cylinder, lifting air cylinders and a scrape coating plate, the bottom of the scrape coating groove, with a certain thickness, is provided with an opening which is matched with the size of a material, the lifting aircylinders are perpendicular to the movement direction of the material and located above the scrape coating groove, the scrape coating plate is installed on the front and rear lifting air cylinders, the lifting air cylinders are connected with the transverse-moving air cylinder; and when the scrape coating plate is lowered to the bottom of the scrape coating groove, the scrape coating plate is closely fitted with the bottom and side edge of the scrape coating groove. According to the automatic scrape coating equipment for the neodymium iron boron products, the problem of paint splashing does not exist, and more than 30% of the paint cost is saved.

Owner:天津京磁电子元件制造有限公司

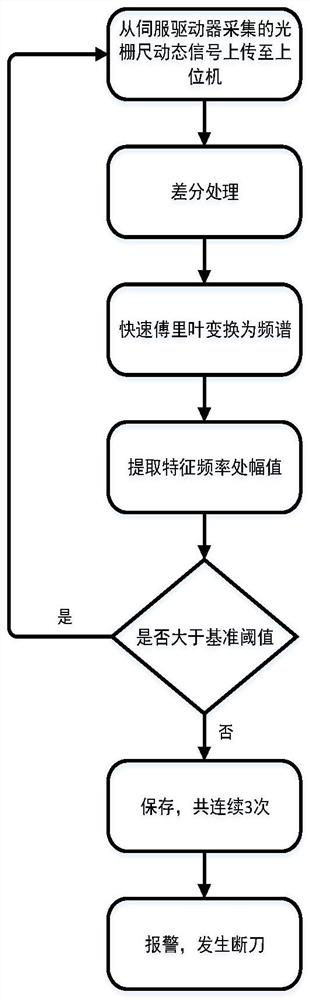

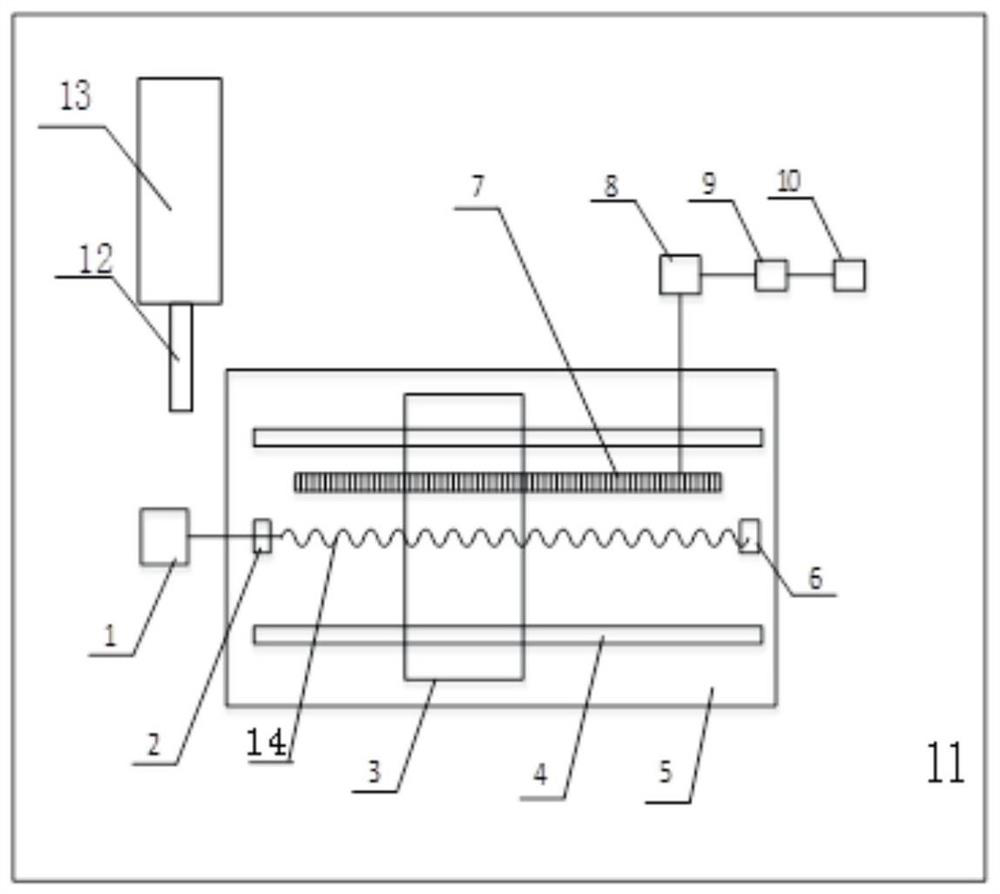

Real-time monitoring system, device and method for tool breakage in machining process of numerical control machine tool

ActiveCN112255967AReal-time monitoring of knife breakingReal-time monitoring of health statusProgramme controlComputer controlPulse numberMachining process

The invention discloses a real-time monitoring system, device and method for tool breakage in the machining process of a numerical control machine tool. The method comprises the following steps: carrying out differential processing on an accumulated pulse number collected by a collection grating ruler to obtain time domain data, carrying out Fourier transform on the time domain data, converting the time domain data into frequency domain data, extracting the amplitude of a feature frequency from the frequency domain data, comparing the amplitude with the reference threshold value to judge whether the cutter is short or not in order to monitor the cutter breaking condition of the cutter in real time with high sensitivity in the machining process. The current health state of the cutter can bemonitored in real time, the machining process does not need to be interrupted, and the production efficiency is not reduced. The judgment method is simple, reliable and high in judgment accuracy; andno additional sensor is needed, hardware cost is reduced, and integration with a machine tool is facilitated.

Owner:西安精雕精密机械工程有限公司

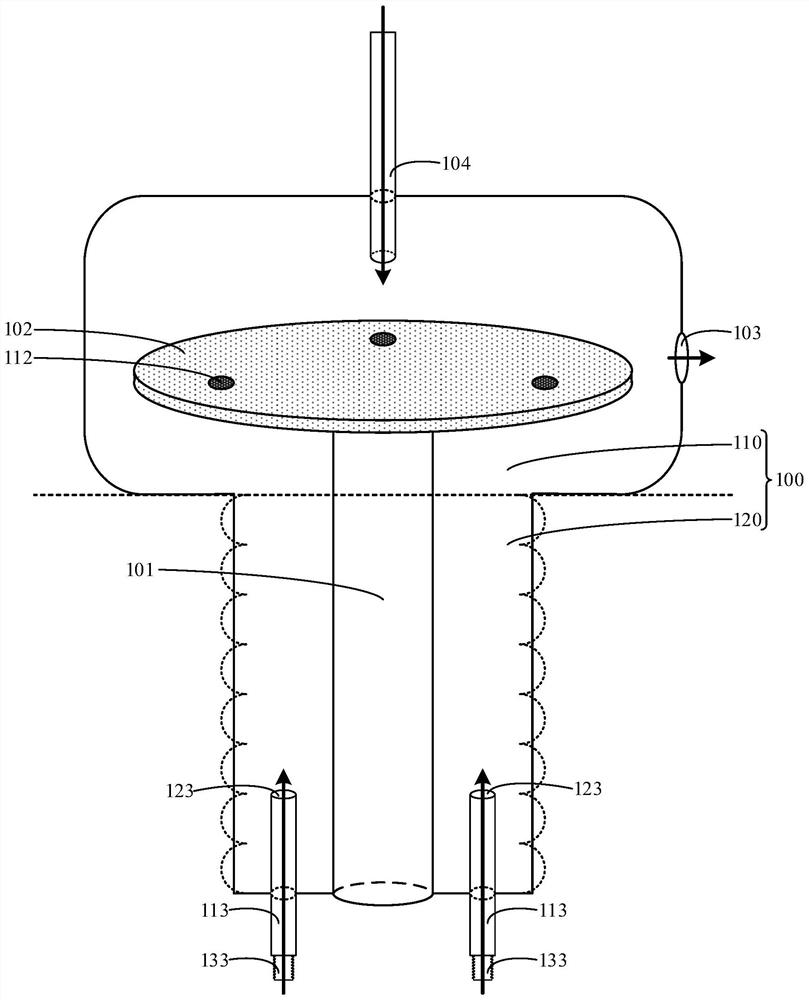

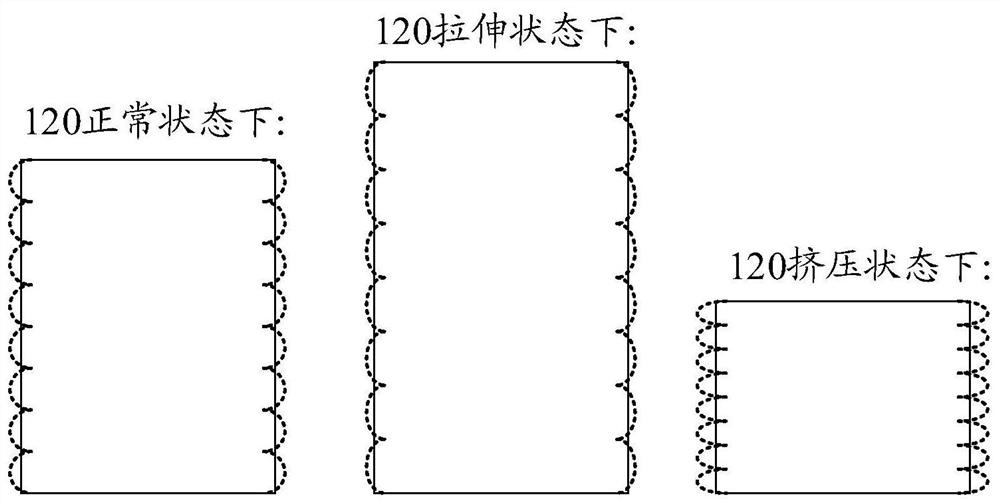

Semiconductor device and cleaning system

PendingCN114790542ANo reduction in production efficiencyChemical vapor deposition coatingDevice materialEngineering

The embodiment of the invention provides semiconductor equipment and a cleaning system.The semiconductor equipment comprises an equipment cavity, a supporting column and a bearing table, the supporting column and the bearing table are located in the equipment cavity, and the supporting column is used for supporting the bearing table; the gas outlet, the first gas inlet assembly and the second gas inlet assembly are arranged on the equipment cavity, the first gas inlet assembly and the second gas inlet assembly are used for introducing clean gas into the equipment cavity, and the gas outlet is used for discharging gas in the equipment cavity; the first air inlet assembly and the second air inlet assembly are arranged on the equipment cavities on the upper side and the lower side of the bearing face of the bearing table correspondingly, one of the first air inlet assembly and the second air inlet assembly is used for cleaning the equipment cavity, away from the supporting column, of the bearing face, and the other one is used for cleaning a gap between the supporting column and the equipment cavity. According to the embodiment of the invention, the bottom gap of the machine table can be cleaned under the condition that the machine table is not shut down, so that the cleaning operation of the machine table is completed on the premise that the production efficiency of products is not reduced.

Owner:CHANGXIN MEMORY TECH INC

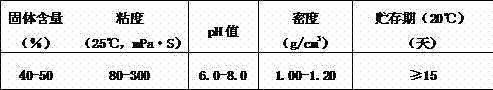

Urea resin additive and preparation method and application thereof

InactiveCN102391796AReduce releaseImprove elimination effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses a urea resin and a preparation method thereof. The urea resin additive comprises the following raw materials in parts by weight: 100-300 parts of waterborne epoxy resin (solid), 100-1000 parts of urea, 50-1000 parts of water and 0.1-10 parts of stabilizing agent. The preparation method comprises the following steps: 1) adding the raw materials to a reaction kettle in sequence according to the proportion in claim 1 or 2, beginning stirring when the raw materials are added, raising the temperature and controlling the temperature at 40-60 DEG C, fully stirring the raw materials until the raw materials are uniform and regulating the pH value of the reaction liquid to be 5.0-5.5 with acid; and 2) raising the temperature to 70-72 DEG C and reacting for 30 minutes, regulating the pH value of the reaction liquid to be 6.0-8.0 with alkali, lowering the temperature to 30 DEG C and discharging the material.

Owner:BEIJING FORESTRY UNIVERSITY +1

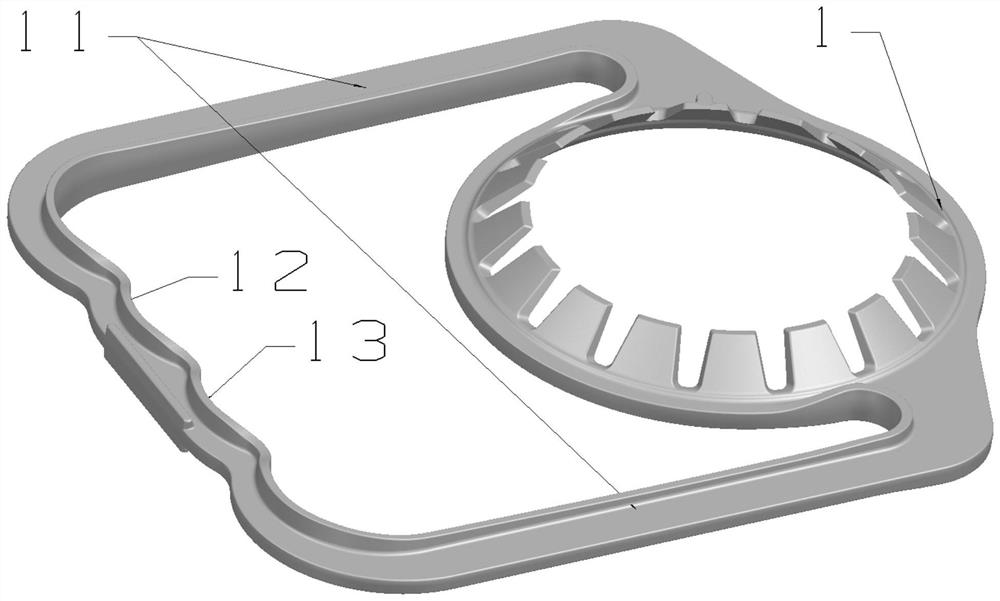

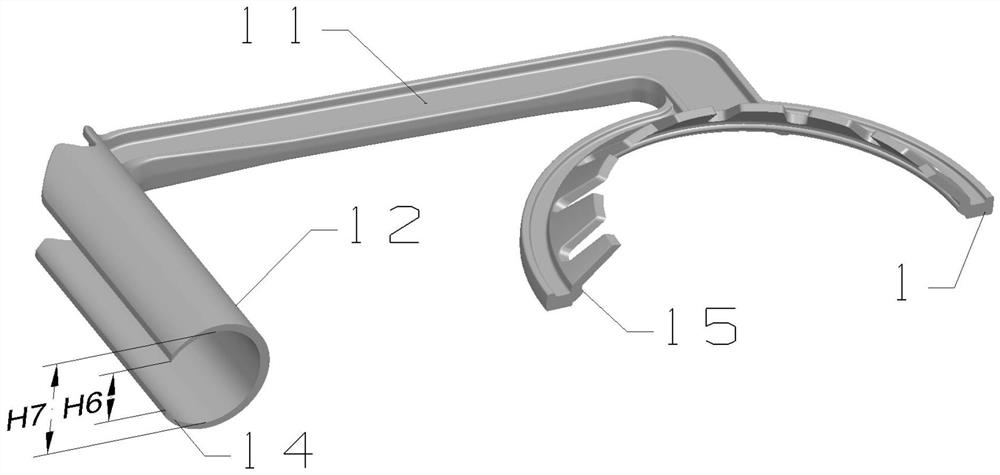

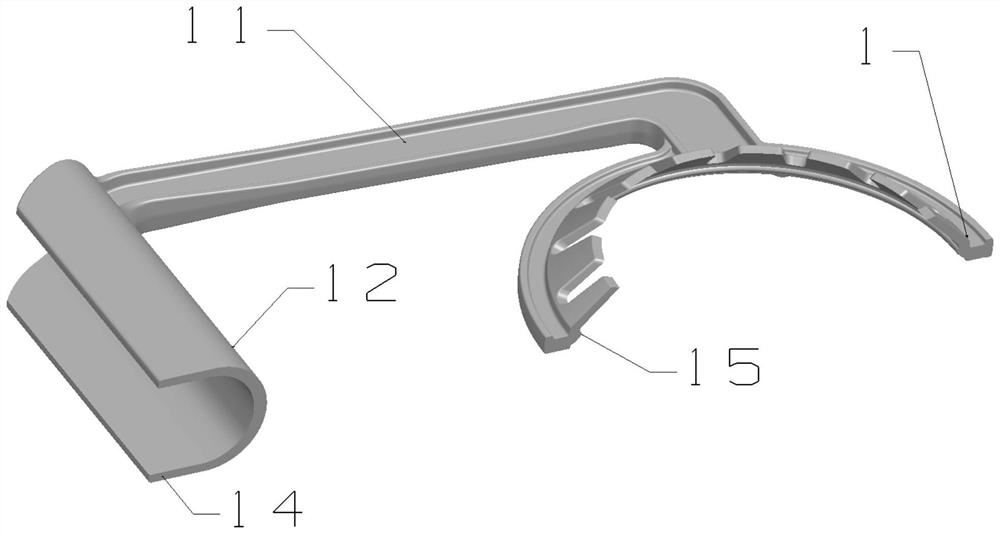

Opening type comfortable handle mold structure

PendingCN112140478ASolve the demoulding problemNo reduction in production efficiencyDomestic articlesStructural engineeringLantern

The invention discloses an opening type comfortable handle mold structure, a lifting handle is divided into a lantern ring part, a lifting handle part and a connecting belt between the lantern ring part and the lifting handle part, wherein the section of the lifting handle part is of an annular opening structure, and a core rod is arranged in an annular opening. The core point of the invention isthat a core rod subjected to mold opening drives the annular opening to form a certain distance H with a mold cavity plate through various mechanical driving structures, the distance can accommodate peripheral expansion generated when the annular opening is separated from the core rod, due to the distance, the annular opening does not interfere with the mold cavity plate when being separated fromthe core rod or does not interfere with the mold cavity plate when being separated from the annular opening as well, and in addition, the various mechanical structures are used for changing the direction when the annular opening is separated from the core rod, so that the direction is closer to the positive demolding direction or the mold opening direction in order to prevent the annular opening from interfering with the cavity plate when the annular opening is separated from the core rod, in addition, a lantern ring inner core is arranged to clamp the lantern ring part in order to enable theannular opening to be pulled by the lantern ring part through a connecting belt when the annular opening is separated from the core rod.

Owner:徐勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com